**How to Check the Knock Sensor: A Comprehensive Guide**

The knock sensor is an essential component for monitoring engine health, and knowing how to check the knock sensor is crucial for diagnosing engine issues. CARDIAGTECH.NET is here to help you understand the process of knock sensor testing, helping you maintain optimal engine performance and prevent costly damage. Regular inspection and prompt action can ensure the longevity and efficiency of your vehicle.

1. What is a Knock Sensor and Why is it Important?

A knock sensor is a vital device installed on the engine block or intake manifold, designed to detect engine knocking or pinging. According to a 2018 study by the University of Michigan’s Automotive Research Center, knock sensors play a critical role in preventing engine damage by detecting abnormal combustion. Also called a knock suppression sensor, the knock sensor detects vibrations and sounds in the combustion chamber and sends this data to the engine control unit (ECU). This feedback loop allows the ECU to adjust ignition timing, ensuring smooth combustion, optimal engine performance, and preventing damage or reduced efficiency.

1.1 What does a knock sensor do?

The primary job of a knock sensor is to listen for unusual engine noises or vibrations. When it detects an issue, it sends a signal to the car’s computer, the ECU. The ECU then takes steps to fix the problem, like changing when the engine sparks. According to the Society of Automotive Engineers (SAE), “Knock sensors are integral to modern engine management systems, ensuring engines operate within safe parameters.” This helps the engine run well and avoids damage from abnormal combustion.

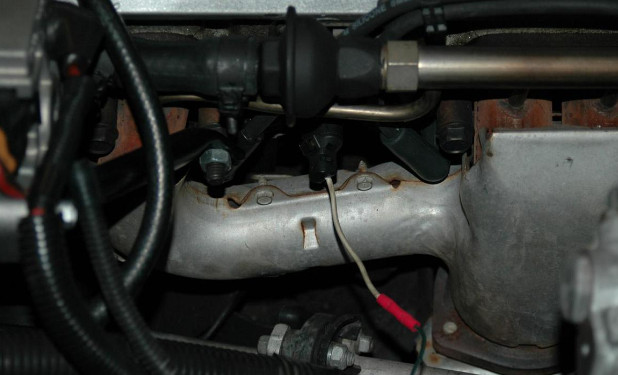

1.2 Where is a knock sensor located?

Knock sensors are typically located on the engine block or intake manifold. The specific location can vary depending on the vehicle’s make and model. According to data from RepairPal, most vehicles have the knock sensor either screwed into the engine block, cylinder head, or under the intake manifold.

Knock Sensor Location

Knock Sensor Location

1.3 Types of Knock Sensors

Based on their construction, knock sensors can be categorized as piezoelectric non-resonant, piezoelectric resonant, and piezoelectric spark plug seat metal gasket-type. However, they are generally classified into two main types: piezoelectric and inductive.

- Piezoelectric Knock Sensors: These sensors use a piezoelectric crystal that generates an electrical charge when subjected to mechanical stress (vibration). The voltage produced is proportional to the intensity of the knock.

- Inductive Knock Sensors: These sensors use a coil and a magnet to generate a signal when vibration occurs. The movement of the magnet relative to the coil induces a voltage, which is then sent to the ECU.

The choice between these types often depends on the specific engine design and the manufacturer’s preferences.

2. Understanding the Working Principles of a Knock Sensor

The fundamental principle of a knock sensor involves the piezoelectric effect. When the engine knocks or vibrates, the piezoelectric ceramic inside the sensor generates a voltage peak. According to research from the Bosch Automotive Handbook, the amplitude of this voltage is directly proportional to the intensity of the knock. The ECU then processes this signal, and if knocking is detected, the ECU retards the ignition timing to prevent further knocking. When the ECU doesn’t receive signals from the knock sensor, it advances the ignition timing to ensure optimal engine performance.

2.1 How do piezoelectric knock sensors work?

Piezoelectric sensors are the most common type of knock sensor. They use a crystal material that generates an electrical charge when subjected to mechanical stress, such as the vibrations caused by engine knocking. The intensity of the voltage produced is proportional to the severity of the knock.

2.2 How do inductive knock sensors work?

Inductive knock sensors operate using electromagnetic induction. They consist of a coil and a magnet. When the engine vibrates, the magnet moves relative to the coil, generating a voltage signal. This signal is then sent to the ECU for processing.

2.3 The role of the ECU in knock detection

The Engine Control Unit (ECU) plays a crucial role in knock detection. It receives the signal from the knock sensor and analyzes it to determine if engine knocking is occurring. If knocking is detected, the ECU adjusts the ignition timing to prevent engine damage. According to a study by the Oak Ridge National Laboratory, “Effective ECU calibration is essential for optimizing engine performance and preventing knock.”

3. Common Symptoms of Knock Sensor Malfunction

A malfunctioning knock sensor can significantly impact engine performance and operation. Here are some common symptoms:

- Unusual Engine Noise

- Decreased Acceleration

- Poor Fuel Economy

- Check Engine Light Illumination

- Piston Damage

3.1 Unusual Engine Noise

Engine knocking is a telltale sign. It’s an audible knocking or pinging noise. Describing the noise can be challenging if you’ve never heard it before, but it becomes evident when it occurs. It’s most recognizable during engine load or non-idling conditions. To diagnose if the vehicle experiences engine knocking due to a faulty sensor, open the vehicle’s hood and gently rev the engine in neutral to make the diagnosis easier. Typically, the higher the engine RPM, the more pronounced the noise becomes.

3.2 Decreased Acceleration

Engines and all their moving parts are designed to work harmoniously and with precise timing. Any disruption in this balance can lead to poor engine performance. When the knock sensor is faulty, it fails to provide information about knocking occurrences, and the ignition timing remains unchanged.

Engine Knocking Sound

Engine Knocking Sound

3.3 Poor Fuel Economy

Poor fuel economy can result from incorrect combustion timing or additional combustion occurring within the engine. While rarely the sole indicator of a faulty knock sensor, as it can be associated with various issues in different vehicle systems, it’s more of a supplementary symptom of engine knocking rather than a primary one.

3.4 Check Engine Light Illuminates

The simplest way to identify a malfunctioning knock sensor is to check for the illumination of the check engine light. The vehicle’s ECU easily communicates a fault signal when the information received from the sensor begins to slow down or doesn’t reach the computer. Besides physically hearing the knocking, an OBD scanner is the most straightforward way to diagnose sensor issues, as it displays fault codes specifically related to this problem.

3.5 Piston Damage

Piston damage typically occurs when vehicle owners fail to address existing issues. Before severe engine damage takes place, several other methods can determine whether the knock sensor has failed. It’s crucial to investigate these issues promptly when they arise to mitigate more severe damage to major components in the future.

4. Common Causes of Knock Sensor Failure

Engine knocking typically occurs when the air-fuel mixture in the combustion chamber ignites prematurely before the flame front has fully developed. Unburned fuel and air situated in remote areas of the chamber auto-ignite due to elevated temperatures and pressures. The flames resulting from this auto-ignition intersect with those from the regular combustion process, generating substantial pressure and giving rise to abnormal knocking within the engine. The primary causes of engine knocking are:

- Excessive Ignition Advance

- Carbon Deposits on Pistons

- Engine Overheating

- Low-Octane Fuel

- Abnormal Air-Fuel Ratios

4.1 Excessive Ignition Advance

Ignition timing usually takes place prior to the piston reaching top dead center during the compression stroke. If ignition occurs too early, a significant portion of the gasoline combusts during the compression stroke, while the remaining unburned fuel experiences pressure, leading to spontaneous knocking.

4.2 Carbon Deposits on Pistons

Over prolonged use, a thick layer of carbon deposits can accumulate on the piston crown. This reduces the available space within the combustion chamber, resulting in higher compression ratios and contributing to knocking.

4.3 Engine Overheating

Prolonged engine operation can lead to the buildup of excessive heat, especially when the cooling system is inefficient. This can result in engine overheating and subsequent knocking.

4.4 Low-Octane Fuel

High-compression engines require high-octane gasoline, while lower-compression engines can use lower-octane options. Using gasoline with an octane rating that is too low for the engine can be a factor in engine knocking.

4.5 Abnormal Air-Fuel Ratios

When the air-fuel ratio exceeds 14.7, the mixture becomes lean, causing increased combustion temperatures and, consequently, elevated engine temperatures, which can trigger knocking.

5. Step-by-Step Guide on How to Check the Knock Sensor

To effectively diagnose knock sensor issues, follow these steps:

- Visual Inspection

- OBD-II Scanner Check

- Multimeter Testing

- Oscilloscope Testing

- Wiring Harness Inspection

5.1 Visual Inspection

Begin by visually inspecting the knock sensor for any physical damage, such as cracks, corrosion, or loose connections. According to the National Institute for Automotive Service Excellence (ASE), a visual inspection is the first step in diagnosing any sensor-related issue.

5.2 OBD-II Scanner Check

Use an OBD-II scanner to check for any diagnostic trouble codes (DTCs) related to the knock sensor. Common codes include P0325 (Knock Sensor 1 Circuit Malfunction) and P0330 (Knock Sensor 2 Circuit Malfunction).

5.3 Multimeter Testing

A multimeter can be used to check the resistance and voltage of the knock sensor.

- Resistance Test: Disconnect the knock sensor and use a multimeter to measure the resistance between the sensor terminals. The resistance value should fall within the manufacturer’s specified range.

- Voltage Test: With the engine running, use a multimeter to measure the voltage output of the knock sensor. Tap gently on the engine block near the sensor. The voltage should fluctuate as you tap.

Knock Sensor Testing

Knock Sensor Testing

5.4 Oscilloscope Testing

An oscilloscope provides a visual representation of the knock sensor’s signal.

- Connect the oscilloscope to the knock sensor signal wire.

- Start the engine and let it idle.

- Tap gently on the engine block near the sensor.

- Observe the oscilloscope waveform. A functioning knock sensor should produce a varying waveform when the engine block is tapped.

5.5 Wiring Harness Inspection

Check the wiring harness and connectors for any signs of damage or corrosion. Use a multimeter to test the continuity of the wires between the knock sensor and the ECU. Repair or replace any damaged wiring or connectors.

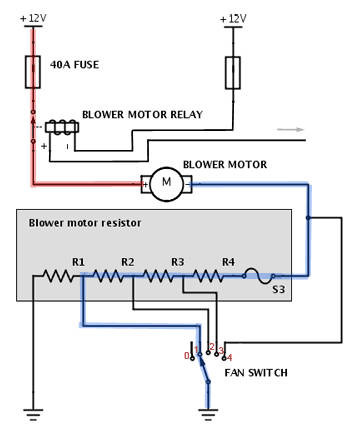

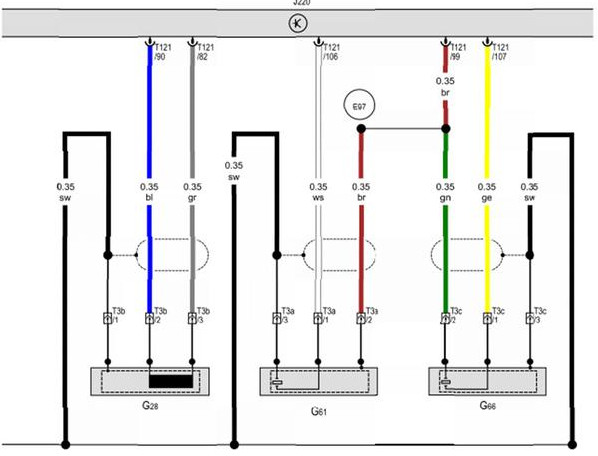

6. Detailed Example: Testing a Knock Sensor on a Volkswagen Passat NMS

For the Volkswagen Passat NMS, the procedure for testing the knock sensor can be broken down as follows:

6.1 Testing the Knock Sensor Circuit

- Begin by stripping the outer insulation of the wiring harness to expose the two shielded wires, usually in black. Using a multimeter set to the 200-ohm range, measure the wire resistance between T3c/3 and ground, as well as between T3a/3 and ground. A normal resistance reading should be approximately 0.1 ohms. Any significant deviation from this value suggests a wiring harness fault.

- Proceed to disconnect the connector linking the knock sensor to the Engine Control Unit (ECU). Measure the wire resistance separately for the following pairs: T3c/1 to T121/107, T3c/2 to T121/99, T3a/1 to T121/106, and T3a/2 to T121/99. In the case of normal functioning, the resistance values should hover around 0.1 ohms. If you obtain notably different readings, it indicates a wiring harness issue.

6.2 Checking the Operational Performance of the Knock Sensor

- To assess the operational performance of the knock sensor G61, connect an oscilloscope tool to it. Start the engine and let it idle, then utilize the oscilloscope to record the signal waveform produced by the knock sensor. If the waveform fails to display a knock signal, it signifies a malfunctioning knock sensor.

- Apply the same approach to measure the performance of the knock sensor G66 for a comprehensive evaluation of its functionality.

7. Tips for Preventing Engine Knocking and Sensor Issues

While the knock sensor can detect engine knock, relay knock signals to the ECU, and help mitigate knocking by adjusting ignition timing, it’s important to recognize its limitations. This adjustment is constrained by the engine’s operational range. Excessively delaying ignition timing not only leads to reduced power and increased fuel consumption but also results in incomplete combustion, potentially raising engine temperatures and causing damage to components like the catalytic converter and cylinder head gasket.

To effectively eliminate knocking, consider the following steps:

- Use the Recommended Octane Fuel

- Avoid High Gears at Low Speeds

- Routinely Clean Carbon Deposits

- Monitor Engine Coolant Temperature

- Regularly Inspect Engine Components

7.1 Use the Recommended Octane Fuel

Use gasoline with the compression ratio recommended for your engine. Opt for 97-octane gasoline and avoid adding 93-octane gasoline under any circumstances.

7.2 Avoid High Gears at Low Speeds

Steer clear of driving in high gears at low speeds, as this can increase engine load and advance ignition timing. Lower RPMs in higher gears can easily induce knocking.

7.3 Routinely Clean Carbon Deposits

Routinely clean carbon deposits on the pistons. Avoid prolonged low-speed and idle operation and occasionally rev up the engine to higher speeds.

7.4 Monitor Engine Coolant Temperature

Stay vigilant about engine coolant temperature to prevent overheating. Regularly inspect the coolant level, monitor oil levels, and stick to a routine oil change schedule.

Preventing Engine Knock

Preventing Engine Knock

7.5 Regularly Inspect Engine Components

Regularly inspect the engine components to ensure everything is in good working order. Addressing issues early can prevent knocking.

8. The Consequences of Ignoring a Faulty Knock Sensor

Ignoring a faulty knock sensor can lead to severe engine damage. The knock sensor’s primary function is to detect engine knocking or pinging, which can cause significant damage to internal engine components such as pistons, valves, and cylinder walls. According to a report by AAA, neglecting engine maintenance can result in repair costs that are significantly higher than the cost of regular maintenance.

8.1 Potential Engine Damage

Engine knocking can cause high-temperature and high-pressure shock waves, leading to damage to internal engine components like pistons, valves, and cylinder walls.

8.2 Reduced Engine Performance

A faulty knock sensor can cause the ECU to retard ignition timing excessively, leading to reduced engine power and fuel efficiency.

8.3 Increased Repair Costs

Ignoring a faulty knock sensor can result in more severe engine damage, leading to increased repair costs. Addressing the issue promptly can prevent more costly repairs in the future.

9. Choosing the Right Replacement Knock Sensor

When replacing a knock sensor, selecting the right one is crucial for ensuring optimal engine performance. Here are some factors to consider:

- OEM vs. Aftermarket

- Sensor Compatibility

- Sensor Quality

9.1 OEM vs. Aftermarket

OEM (Original Equipment Manufacturer) sensors are made by the same manufacturer that produced the original sensor for your vehicle. Aftermarket sensors are produced by third-party manufacturers. OEM sensors are typically more expensive but offer the best compatibility and reliability.

9.2 Sensor Compatibility

Ensure that the replacement knock sensor is compatible with your vehicle’s make, model, and year. Refer to your vehicle’s service manual or consult a professional mechanic to determine the correct part number.

9.3 Sensor Quality

Choose a replacement knock sensor from a reputable manufacturer to ensure quality and reliability. Read online reviews and check for certifications to ensure that the sensor meets industry standards.

10. Why Choose CARDIAGTECH.NET for Your Automotive Diagnostic Needs?

At CARDIAGTECH.NET, we understand the critical role that each component plays in your vehicle’s performance. That’s why we offer a wide range of high-quality diagnostic tools and replacement parts, including knock sensors.

10.1 High-Quality Products

We source our products from reputable manufacturers to ensure that they meet or exceed OEM standards. Our knock sensors are designed to provide accurate and reliable performance, helping you maintain the health and efficiency of your engine.

10.2 Expert Support

Our team of experienced technicians is available to provide expert support and guidance. Whether you need help diagnosing a problem or selecting the right replacement part, we’re here to assist you every step of the way.

10.3 Comprehensive Diagnostic Solutions

In addition to knock sensors, we offer a comprehensive range of diagnostic tools, including OBD-II scanners, multimeters, and oscilloscopes. These tools can help you accurately diagnose a wide range of automotive issues, saving you time and money.

FAQ: Frequently Asked Questions About Knock Sensors

1. What happens if a knock sensor fails?

If a knock sensor fails, the ECU may not be able to detect engine knocking, leading to potential engine damage. The engine may also experience reduced power and fuel efficiency.

2. Can I drive with a bad knock sensor?

Driving with a bad knock sensor is not recommended. While it may be possible to drive short distances, the risk of engine damage is significantly increased.

3. How much does it cost to replace a knock sensor?

The cost to replace a knock sensor can vary depending on the vehicle’s make and model, as well as the cost of labor. Generally, the cost ranges from $150 to $500.

4. How often should I replace my knock sensor?

Knock sensors typically last for the life of the vehicle. However, they should be inspected regularly and replaced if any signs of malfunction are detected.

5. Can a bad knock sensor cause a misfire?

Yes, a bad knock sensor can cause a misfire. When the knock sensor malfunctions, it can send incorrect signals to the ECU, leading to improper ignition timing and causing the engine to misfire.

6. Is it difficult to replace a knock sensor?

The difficulty of replacing a knock sensor can vary depending on its location. Some sensors are easily accessible, while others may require the removal of other components.

7. Can I test a knock sensor with a multimeter?

Yes, you can test a knock sensor with a multimeter. By measuring the resistance and voltage output, you can determine if the sensor is functioning correctly.

8. What is the function of a knock sensor?

The primary function of a knock sensor is to detect engine knocking or pinging, which can cause damage to internal engine components. The knock sensor sends a signal to the ECU, which then adjusts the ignition timing to prevent further knocking.

9. Where is the knock sensor located?

Knock sensors are typically located on the engine block or intake manifold. The specific location can vary depending on the vehicle’s make and model.

10. What tools do I need to test a knock sensor?

To test a knock sensor, you will need the following tools:

- OBD-II scanner

- Multimeter

- Oscilloscope

- Wrench or socket set

Final Words

Engine knocking can often cause serious damage to the engine. Knocking refers to abnormal self-ignition before the spark plug in the combustion process of the mixture in a car engine. It is usually caused by excessive compression ratio, inappropriate ignition timing, poor fuel quality, or poor engine working conditions. Detonation will produce high-temperature and high-pressure shock waves, causing damage to internal engine components and performance, including pistons, valves, cylinder walls, etc. Therefore, it is very important to maintain your car regularly to avoid abnormal combustion and knocking. This helps extend the life of your car, improves fuel economy, and provides better performance.

Don’t let a faulty knock sensor compromise your engine’s health. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit us at 276 Reock St, City of Orange, NJ 07050, United States, to explore our range of diagnostic tools and replacement sensors. Our expert team is ready to help you find the perfect solution to keep your vehicle running smoothly. Plus, with our comprehensive selection of automotive diagnostic tools, maintaining your vehicle has never been easier. Trust CARDIAGTECH.NET to deliver quality and performance every time. Visit our website at CARDIAGTECH.NET for more information.