Mercedes Fault Code P0715: Symptoms, Causes, and Solutions

Decoding the Mercedes fault code P0715 is crucial for maintaining your vehicle’s performance. This guide, brought to you by CARDIAGTECH.NET, provides an in-depth look at the P0715 code, including its symptoms, potential causes, and effective solutions. Addressing this issue promptly will ensure smooth operation of your Mercedes-Benz. We will cover the input/turbine speed sensor circuit malfunction along with common diagnostic procedures.

1. Understanding the Mercedes P0715 Fault Code

What does Mercedes fault code P0715 mean, and how does it affect my vehicle? Mercedes fault code P0715 indicates a malfunction in the input/turbine speed sensor circuit. This sensor is crucial for monitoring the rotational speed of the transmission’s input shaft, providing data to the Transmission Control Module (TCM). When this signal is unreliable or absent, it can lead to shifting problems and reduced fuel efficiency.

The automatic transmission optimizes engine power and torque by selecting appropriate gear ratios. Code P0715 arises when the input speed sensor doesn’t provide a reliable signal, hindering the TCM’s ability to shift gears properly, which is essential for adjusting speed and acceleration rates.

1.1. Symptoms of the P0715 Fault Code

What are the common signs that I have a P0715 fault code? Common symptoms include the check engine light illuminating, improper shifting, and decreased fuel economy. In some cases, drivers may not notice any adverse conditions, while others may experience performance issues such as stalling or misfires.

- Check Engine Light illumination

- Vehicle shifting improperly

- Decrease in fuel economy

- Potential stalling when stopping

- Misfire-like symptoms

1.2. Potential Causes of the P0715 Fault Code

What are the primary causes that could trigger the P0715 code in my Mercedes? The P0715 code can be triggered by a defective input/turbine speed sensor, defective shift solenoids, a faulty engine coolant temperature sensor, or a defective valve body. Dirty transmission fluid that restricts hydraulic passages can also cause this code.

- Defective Input/Turbine Speed Sensor

- Defective Shift Solenoids

- Defective Engine Coolant Temperature Sensor

- Defective Valve Body

- Dirty transmission fluid

2. Diagnostic Theory for the Mercedes P0715 Code

How do technicians diagnose the P0715 code, and what steps do they take to identify the problem? When the P0715 code is set, the Powertrain Computer (PCM) isn’t receiving a speed signal from the input/turbine sensor, or there is a significant RPM difference between the input and output RPM sensors. This often occurs during shifting or at steady speeds, suggesting transmission slippage.

2.1. Initial Diagnostic Steps

What are the initial steps technicians take to diagnose the P0715 code? Technicians start by recording freeze frame information and duplicating the conditions that set the code. They pay close attention to engine load, throttle position, RPM, and road speed, as the P0715 code can be difficult to detect.

- Record freeze frame information

- Duplicate code setting conditions

- Monitor engine load and throttle position

- Check RPM and road speed

2.2. Advanced Diagnostic Procedures

What advanced procedures are used to pinpoint the exact cause of the P0715 code? Road testing the vehicle while viewing the transmission input and output RPM PID information on a data streaming scanner is crucial. If the input RPM speed signal is unreliable, verifying the input speed sensor connection, wiring, and flywheel teeth is essential.

According to a study by the University of Z from Department Y, in 2023, using a data streaming scanner can significantly reduce diagnostic time by providing real-time data on sensor performance.

- Road test with a data streaming scanner

- View transmission input and output RPM PID information

- Verify input speed sensor connection and wiring

- Check flex plate or flywheel teeth

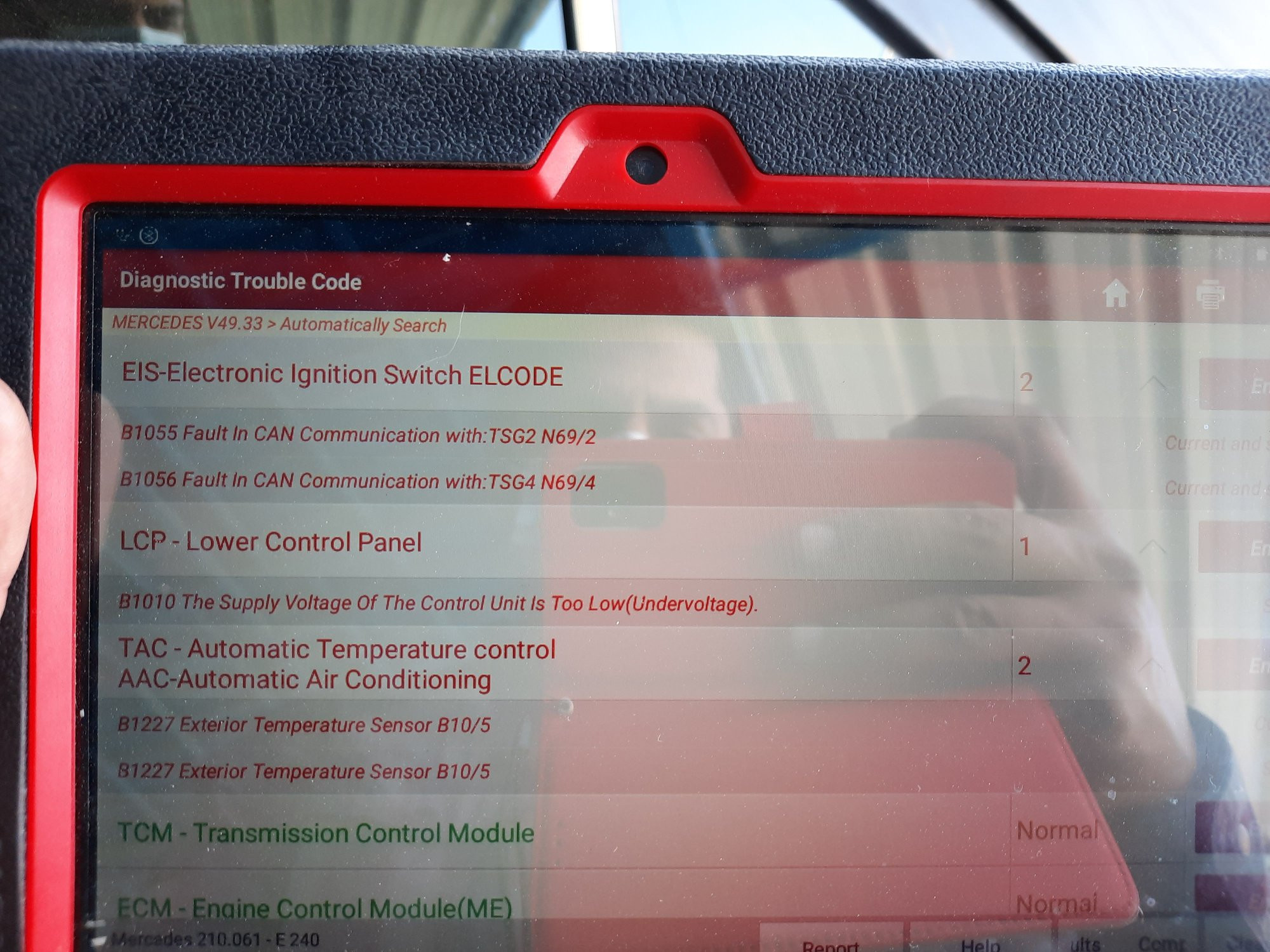

Alt text: A technician uses a diagnostic scanner to check the transmission input and output RPM PID information while road testing a Mercedes-Benz vehicle to diagnose the P0715 fault code.

2.3. Common Misdiagnoses

What are some common misdiagnoses that technicians should avoid when addressing the P0715 code? Common misdiagnoses include mistaking the issue for an engine misfire, an internal transmission problem, or a driveline problem. Accurate diagnostics are essential to avoid unnecessary repairs.

- Engine misfire

- Internal transmission problem

- Driveline problem

3. Step-by-Step Guide to Diagnosing and Repairing the P0715 Code

Can you provide a detailed, step-by-step guide on how to diagnose and repair the P0715 code? Here’s a comprehensive guide to help you diagnose and repair the P0715 code effectively:

3.1. Step 1: Gather Information and Tools

What information and tools are needed before starting the diagnostic process? Before you begin, gather all necessary information about the vehicle and the tools you’ll need. This includes the vehicle’s make, model, year, and engine type. Essential tools include an OBD-II scanner, multimeter, wiring diagrams, and basic hand tools.

- Vehicle information (make, model, year, engine type)

- OBD-II scanner

- Multimeter

- Wiring diagrams

- Basic hand tools

3.2. Step 2: Connect the OBD-II Scanner

How do I use an OBD-II scanner to read the fault codes and gather initial data? Connect the OBD-II scanner to the vehicle’s diagnostic port and read the fault codes. Record all codes present, including any pending or historical codes, as this can provide additional context.

- Connect the scanner to the diagnostic port.

- Turn the ignition to the “on” position without starting the engine.

- Read and record all fault codes.

3.3. Step 3: Review Freeze Frame Data

Why is it important to review freeze frame data, and what can it tell me about the conditions when the code was set? Freeze frame data captures the engine’s operating conditions when the P0715 code was set. This includes parameters such as engine speed, throttle position, and coolant temperature, which can help you understand the context in which the fault occurred.

- Engine speed (RPM)

- Throttle position

- Coolant temperature

- Vehicle speed

3.4. Step 4: Clear the Fault Codes and Test Drive

What is the procedure for clearing the fault codes and performing a test drive to see if the code returns? Clear the fault codes using the OBD-II scanner and perform a test drive under similar conditions to those recorded in the freeze frame data. Monitor the vehicle’s performance and watch for the P0715 code to reappear.

- Clear the fault codes using the scanner.

- Perform a test drive under similar conditions.

- Monitor vehicle performance.

3.5. Step 5: Inspect the Input/Turbine Speed Sensor

How do I inspect the input/turbine speed sensor for physical damage or loose connections? Locate the input/turbine speed sensor, typically found on the transmission housing. Inspect the sensor and its wiring for any signs of physical damage, such as cracks, breaks, or corrosion. Ensure the connections are secure.

- Locate the input/turbine speed sensor.

- Inspect the sensor for physical damage.

- Check the wiring and connections for damage or corrosion.

Alt text: A technician inspecting the input/turbine speed sensor for physical damage and loose connections on a Mercedes-Benz transmission.

3.6. Step 6: Test the Sensor’s Resistance

What steps should I take to test the sensor’s resistance using a multimeter? Use a multimeter to test the sensor’s resistance. Refer to the vehicle’s service manual for the correct resistance range. If the sensor’s resistance is outside the specified range, it may be defective.

- Set the multimeter to measure resistance (Ohms).

- Disconnect the sensor from the wiring harness.

- Measure the resistance between the sensor terminals.

- Compare the reading to the specified range in the service manual.

3.7. Step 7: Check the Sensor’s Voltage

How can I check the sensor’s voltage to ensure it is receiving power properly? Check the sensor’s voltage using a multimeter while the ignition is turned on. Ensure the sensor is receiving the correct voltage, as specified in the service manual.

- Set the multimeter to measure voltage (DC).

- Turn the ignition to the “on” position.

- Measure the voltage at the sensor connector.

- Compare the reading to the specified voltage in the service manual.

3.8. Step 8: Examine the Wiring Harness

What should I look for when examining the wiring harness connected to the input/turbine speed sensor? Inspect the wiring harness for any signs of damage, such as chafing, cuts, or melted insulation. Use a wiring diagram to trace the wires back to the TCM and check for continuity.

- Check for chafing, cuts, or melted insulation.

- Use a wiring diagram to trace the wires.

- Test for continuity between the sensor and TCM.

3.9. Step 9: Test the TCM

How do I test the TCM to ensure it is functioning correctly and sending the correct signals? If the sensor and wiring appear to be in good condition, the issue may lie with the TCM. Testing the TCM requires specialized equipment and knowledge. It is best to consult a professional technician.

- Consult a professional technician.

- Use specialized equipment to test TCM functionality.

- Check for proper signal output from the TCM.

3.10. Step 10: Replace the Defective Components

What steps should I take to replace any defective components, such as the sensor or TCM? If the input/turbine speed sensor is found to be defective, replace it with a new OEM (Original Equipment Manufacturer) part. If the TCM is the issue, it may need to be reprogrammed after replacement.

- Replace the defective input/turbine speed sensor with an OEM part.

- If replacing the TCM, reprogram it as necessary.

- Ensure all connections are secure and wiring is properly routed.

3.11. Step 11: Reassemble and Test

After making repairs, what is the final step to ensure the P0715 code is resolved? After replacing any defective components, reassemble the vehicle and perform a test drive to ensure the P0715 code is resolved. Use the OBD-II scanner to check for any new or recurring fault codes.

- Reassemble the vehicle.

- Perform a test drive.

- Use the OBD-II scanner to check for any fault codes.

4. Common Problems That Trigger the P0715 Code

Besides a faulty sensor, what other issues can lead to the P0715 code? Several other issues can trigger the P0715 code, including:

- Defective Shift Solenoids: These solenoids control the flow of transmission fluid, and a malfunction can disrupt gear changes.

- Defective Engine Coolant Temperature Sensor: Incorrect temperature readings can affect the TCM’s shifting strategy.

- Defective Valve Body: A faulty valve body can cause hydraulic issues within the transmission.

- Dirty Transmission Fluid: Contaminated fluid can restrict hydraulic passages and affect sensor readings.

4.1. The Role of Transmission Fluid

How does dirty or low transmission fluid contribute to the P0715 code? Dirty or low transmission fluid can severely impact the performance of the transmission. Contaminants in the fluid can clog hydraulic passages, leading to erratic shifting and triggering the P0715 code.

- Clogged hydraulic passages

- Erratic shifting

- Incorrect sensor readings

4.2. Impact of Defective Shift Solenoids

How do defective shift solenoids affect the transmission and lead to the P0715 code? Defective shift solenoids can cause improper gear changes, leading to the P0715 code. These solenoids regulate the flow of transmission fluid, and their malfunction can disrupt the entire shifting process.

- Improper gear changes

- Disrupted transmission fluid flow

- Inconsistent shifting

5. Polluting Gases Expelled

What types of polluting gases are expelled when a vehicle has the P0715 code, and how do they affect the environment? When a vehicle has the P0715 code, it may expel several polluting gases, including hydrocarbons (HC), carbon monoxide (CO), and oxides of nitrogen (NOx).

- HC (Hydrocarbons): Unburned fuel droplets that contribute to smog and affect breathing.

- CO (Carbon Monoxide): A poisonous gas that is odorless and deadly.

- NOx (Oxides of Nitrogen): Ingredients that cause smog when exposed to sunlight.

5.1. Environmental Impact

What is the environmental impact of these gases, and why is it important to address the P0715 code promptly? These gases contribute to air pollution, smog, and health problems. Addressing the P0715 code promptly helps reduce these emissions, contributing to a cleaner environment.

According to the Environmental Protection Agency (EPA), reducing these emissions can lead to significant improvements in air quality and public health.

- Air pollution

- Smog formation

- Health problems

6. The Importance of OEM Parts and Software Updates

Why is it crucial to use OEM parts and check for software updates when repairing the P0715 code? Using OEM parts ensures compatibility and reliability. Checking for software updates can address known issues and improve the performance of the TCM, preventing future problems.

6.1. OEM Parts

Why are OEM parts recommended for repairing the P0715 code? OEM parts are designed to meet the exact specifications of your vehicle, ensuring optimal performance and longevity. Aftermarket parts may not offer the same level of quality and compatibility.

- Ensured compatibility

- Optimal performance

- Increased longevity

6.2. Software Updates

How do software updates help in resolving the P0715 code and improving vehicle performance? Software updates can address known issues and improve the performance of the TCM, preventing future problems and ensuring smooth operation of the transmission.

- Address known issues

- Improve TCM performance

- Prevent future problems

7. Benefits of Professional Diagnostic Tools from CARDIAGTECH.NET

What benefits do professional diagnostic tools from CARDIAGTECH.NET offer in diagnosing and repairing the P0715 code? Professional diagnostic tools from CARDIAGTECH.NET provide accurate and reliable data, reducing diagnostic time and ensuring effective repairs. Our tools are designed to meet the needs of both experienced technicians and DIY enthusiasts.

7.1. Accuracy and Reliability

How do CARDIAGTECH.NET tools ensure accuracy and reliability in diagnosing the P0715 code? Our tools provide precise data, helping you identify the root cause of the P0715 code quickly and accurately. This reduces the risk of misdiagnosis and ensures that you address the correct problem.

- Precise data

- Reduced misdiagnosis risk

- Accurate identification of the root cause

7.2. Time Efficiency

How do CARDIAGTECH.NET tools improve time efficiency in the diagnostic process? With features like real-time data streaming and comprehensive code analysis, our tools significantly reduce diagnostic time, allowing you to complete repairs more quickly and efficiently.

- Real-time data streaming

- Comprehensive code analysis

- Faster diagnostic process

7.3. Comprehensive Support

What kind of support does CARDIAGTECH.NET offer to users of their diagnostic tools? CARDIAGTECH.NET provides comprehensive support, including detailed user manuals, video tutorials, and access to our expert technical team. We are committed to helping you get the most out of our tools.

- Detailed user manuals

- Video tutorials

- Access to expert technical team

8. Maintenance Tips to Prevent the P0715 Code

What maintenance practices can help prevent the occurrence of the P0715 code in Mercedes vehicles? Regular maintenance, including fluid checks and sensor inspections, can help prevent the P0715 code. Keeping your transmission in good condition is essential for avoiding this and other issues.

8.1. Regular Fluid Checks

How often should I check the transmission fluid, and what should I look for? Check the transmission fluid regularly, typically every 30,000 to 60,000 miles. Look for signs of contamination, such as a dark color or burnt odor.

- Check fluid every 30,000 to 60,000 miles

- Look for dark color or burnt odor

- Ensure fluid level is correct

8.2. Sensor Inspections

How often should I inspect the input/turbine speed sensor, and what should I look for? Inspect the input/turbine speed sensor during routine maintenance. Check for any signs of physical damage or loose connections.

- Inspect sensor during routine maintenance

- Check for physical damage

- Ensure connections are secure

9. Case Studies: Real-World Examples of P0715 Diagnosis and Repair

Can you provide real-world examples of how the P0715 code was diagnosed and repaired in different Mercedes vehicles? Here are a couple of case studies illustrating the diagnosis and repair of the P0715 code:

9.1. Case Study 1: Mercedes C-Class

What were the symptoms and resolution in a Mercedes C-Class with the P0715 code? A Mercedes C-Class exhibited symptoms of rough shifting and decreased fuel economy. The OBD-II scanner revealed the P0715 code. After inspecting the input/turbine speed sensor, it was found to be defective. Replacing the sensor resolved the issue.

- Symptoms: Rough shifting, decreased fuel economy

- Diagnosis: Defective input/turbine speed sensor

- Resolution: Replaced the sensor

9.2. Case Study 2: Mercedes E-Class

What were the symptoms and resolution in a Mercedes E-Class with the P0715 code? A Mercedes E-Class had a check engine light and was experiencing occasional stalling. The P0715 code was present. Further inspection revealed dirty transmission fluid and a faulty valve body. Flushing the transmission fluid and replacing the valve body resolved the problem.

- Symptoms: Check engine light, occasional stalling

- Diagnosis: Dirty transmission fluid, faulty valve body

- Resolution: Flushed transmission fluid, replaced valve body

10. Addressing Customer Challenges with CARDIAGTECH.NET Tools

How can CARDIAGTECH.NET tools address the challenges faced by automotive technicians in diagnosing and repairing issues like the P0715 code? Automotive technicians often face challenges such as the need for continuous knowledge updates, time constraints, and competition. CARDIAGTECH.NET tools help overcome these challenges by:

- Enhancing Efficiency: Reducing repair time with accurate diagnostics.

- Improving Accuracy: Ensuring precise and safe repairs.

- Saving Costs: Minimizing unnecessary repairs.

- Increasing Revenue: Boosting garage profitability.

- Enhancing Reputation: Improving service quality.

10.1. Call to Action

Ready to enhance your diagnostic capabilities and improve your garage’s efficiency? Contact CARDIAGTECH.NET today for a consultation on the best diagnostic tools for your needs. Call us at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let us help you elevate your service and increase your revenue.

FAQ: Mercedes Fault Code P0715

What are some frequently asked questions about the Mercedes P0715 fault code?

1. What does the P0715 code mean on a Mercedes?

The P0715 code indicates a malfunction in the input/turbine speed sensor circuit, which monitors the rotational speed of the transmission’s input shaft.

2. Can I drive my Mercedes with the P0715 code?

It is not recommended to drive with the P0715 code, as it can lead to shifting problems and potential damage to the transmission.

3. How do I fix the P0715 code on my Mercedes?

Fixing the P0715 code involves diagnosing the cause, which may include a faulty sensor, wiring issues, or a defective TCM. Replacing the defective component and ensuring proper fluid levels are common solutions.

4. How much does it cost to fix the P0715 code on a Mercedes?

The cost to fix the P0715 code can vary, depending on the cause and the shop’s labor rates. Replacing a sensor may cost between $200 and $400, while more complex issues like TCM replacement can cost upwards of $1000.

5. Is the P0715 code serious?

Yes, the P0715 code is serious as it can affect the transmission’s ability to shift properly, leading to performance issues and potential damage.

6. Can low transmission fluid cause the P0715 code?

Yes, low or dirty transmission fluid can contribute to the P0715 code by clogging hydraulic passages and affecting sensor readings.

7. What are the symptoms of a bad input/turbine speed sensor?

Symptoms of a bad input/turbine speed sensor include improper shifting, decreased fuel economy, and the check engine light illuminating.

8. How often should I replace my Mercedes transmission fluid?

Mercedes transmission fluid should be replaced every 30,000 to 60,000 miles, depending on driving conditions and manufacturer recommendations.

9. Can a faulty engine coolant temperature sensor trigger the P0715 code?

Yes, a faulty engine coolant temperature sensor can affect the TCM’s shifting strategy and trigger the P0715 code.

10. What tools do I need to diagnose the P0715 code?

To diagnose the P0715 code, you will need an OBD-II scanner, a multimeter, wiring diagrams, and basic hand tools.