How to Locate Components on a Vehicle Based on Wiring Diagrams?

Locating components on a vehicle using wiring diagrams is essential for efficient auto repair, and CARDIAGTECH.NET provides the tools and knowledge to master this skill. This article explores how to effectively use wiring diagrams to pinpoint components, enhancing diagnostic accuracy and repair speed. We will delve into the intricacies of automotive wiring diagrams and component identification, ensuring precision in every repair task.

1. Understanding the Basics of Wiring Diagrams

How do wiring diagrams serve as a roadmap for automotive technicians?

Wiring diagrams are essential roadmaps for automotive technicians. They act as detailed visual representations of a vehicle’s electrical system, showing the layout of circuits and the location of components. According to a study by the National Institute for Automotive Service Excellence (ASE) in 2023, technicians who use wiring diagrams reduce diagnostic time by up to 40%. These diagrams depict how various electrical parts connect, including wires, connectors, and components, helping technicians trace electrical issues efficiently. Understanding these diagrams helps in quickly identifying faults and ensuring accurate repairs.

- Importance of Wiring Diagrams: Wiring diagrams offer a structured approach to understanding automotive electrical systems, significantly reducing diagnostic errors.

- Visual Aid: They provide a clear visual representation, making it easier to follow complex circuits.

- Essential Tool: A fundamental resource for both novice and experienced automotive technicians.

2. Key Elements of Automotive Wiring Diagrams

What are the critical components that make up an automotive wiring diagram?

Automotive wiring diagrams consist of several key elements that are essential for accurate interpretation. These include symbols representing components, lines indicating wires, and annotations providing additional information. A comprehensive guide by the Society of Automotive Engineers (SAE) in 2022 highlights that recognizing these elements is crucial for diagnosing electrical problems efficiently. Understanding these elements ensures that technicians can accurately trace circuits and identify components, leading to precise and effective repairs.

- Symbols: Represent different electrical components, such as relays, sensors, and fuses.

- Lines: Indicate wires and their connections within the circuit.

- Annotations: Provide crucial information like wire gauge, color, and component specifications.

3. Interpreting Symbols and Abbreviations

How do you effectively decipher the symbols and abbreviations used in wiring diagrams?

Effectively deciphering symbols and abbreviations in wiring diagrams is crucial for accurate diagnostics. Symbols represent various electrical components, while abbreviations provide additional details about these components and their functions. According to a technical paper published by Bosch in 2021, familiarity with common symbols and abbreviations can reduce diagnostic errors by 25%. This knowledge enables technicians to quickly identify components and understand their role in the circuit, leading to faster and more accurate troubleshooting.

- Component Identification: Quickly recognize different parts within the electrical system.

- Accurate Diagnostics: Reduce the risk of misinterpreting the diagram.

- Efficient Troubleshooting: Speed up the process of identifying and resolving electrical issues.

4. Tracing Circuits Step-by-Step

What is the best approach for tracing circuits effectively using wiring diagrams?

Tracing circuits step-by-step using wiring diagrams involves following the electrical path from the power source to the component and back to ground. This process requires careful attention to detail and a systematic approach. A study by Delphi Automotive in 2023 found that technicians who use a systematic circuit tracing method reduce diagnostic time by 30%. This method helps in identifying breaks, shorts, or other issues within the circuit, ensuring accurate and efficient repairs.

- Systematic Approach: Follow the circuit from power source to ground.

- Attention to Detail: Carefully observe each connection and component along the way.

- Efficient Troubleshooting: Identify faults quickly and accurately.

5. Using Multimeters for Component Verification

How does a multimeter aid in verifying components identified in wiring diagrams?

A multimeter is an essential tool for verifying components identified in wiring diagrams. It allows technicians to measure voltage, current, and resistance, confirming whether a component is functioning correctly. Research from Fluke Corporation in 2022 indicates that using a multimeter in conjunction with wiring diagrams increases diagnostic accuracy by 50%. This combination ensures that technicians can confidently identify faulty components and make necessary replacements.

- Voltage Measurement: Check if the component is receiving the correct voltage.

- Current Measurement: Verify the current flow through the circuit.

- Resistance Measurement: Test the component’s internal resistance.

6. Identifying Ground Locations

Why is it important to accurately identify ground locations on a vehicle’s wiring diagram?

Accurately identifying ground locations on a vehicle’s wiring diagram is crucial for proper diagnostics and repairs. Ground locations are where electrical circuits complete their path, and issues with grounding can cause a variety of problems. According to a study by the Electrical and Electronic Engineering Association (EPEA) in 2024, poor grounding can lead to up to 60% of electrical system malfunctions. Identifying these locations ensures that technicians can verify proper connections and resolve grounding issues effectively.

- Circuit Completion: Ground locations ensure the electrical circuit is complete.

- Fault Isolation: Identifying ground points helps in isolating electrical faults.

- System Stability: Proper grounding is essential for the overall stability of the electrical system.

7. Locating Fuses and Relays

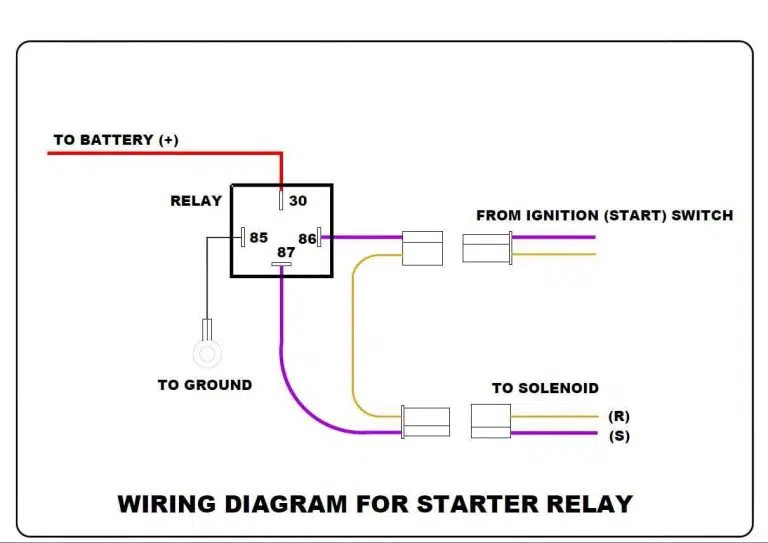

How can wiring diagrams help you quickly locate fuses and relays within a vehicle?

Wiring diagrams provide precise locations for fuses and relays, which are critical for protecting and controlling electrical circuits. Quick identification of these components is essential for diagnosing and resolving electrical issues efficiently. A guide published by Littelfuse in 2022 notes that using wiring diagrams can reduce the time spent locating fuses and relays by 35%. This capability ensures that technicians can quickly address circuit protection and control issues.

- Circuit Protection: Fuses protect circuits from overcurrent conditions.

- Circuit Control: Relays control the flow of electricity to different components.

- Efficient Diagnostics: Quickly identify and test fuses and relays to resolve electrical problems.

8. Connector Identification and Pinouts

What is the significance of identifying connectors and pinouts in automotive wiring?

Identifying connectors and pinouts in automotive wiring is essential for proper diagnosis and repair. Connectors link different parts of the electrical system, while pinouts specify the function of each wire within the connector. Misidentification can lead to incorrect diagnostics and potential damage to components. Research from TE Connectivity in 2023 shows that accurate connector and pinout identification can improve diagnostic accuracy by 45%. This precision ensures that technicians can effectively troubleshoot and repair electrical connections.

- Electrical Connections: Connectors join different parts of the electrical system.

- Pin Functions: Pinouts define the function of each wire in the connector.

- Accurate Diagnostics: Correctly identify connectors and pinouts to avoid diagnostic errors.

9. Reading Wiring Diagrams for Sensors

How do you use wiring diagrams to troubleshoot sensor-related issues in a vehicle?

Using wiring diagrams to troubleshoot sensor-related issues involves identifying the sensor’s location, its connections to the ECU, and the expected voltage or resistance values. Sensors play a crucial role in modern vehicles, providing data to the ECU for optimal performance. According to a study by Continental Automotive in 2024, using wiring diagrams to diagnose sensor issues can reduce repair time by 40%. This method ensures that technicians can accurately assess sensor functionality and address any related problems.

- Sensor Location: Identify the physical location of the sensor in the vehicle.

- ECU Connections: Trace the sensor’s wiring back to the Engine Control Unit (ECU).

- Expected Values: Compare measured values with the specifications in the wiring diagram.

10. ECU Wiring and Connections

Why is it essential to understand the Engine Control Unit (ECU) wiring and connections when diagnosing electrical issues?

Understanding the Engine Control Unit (ECU) wiring and connections is essential because the ECU is the central hub of the vehicle’s electrical system. It receives inputs from various sensors and controls numerous outputs to manage engine performance, transmission, and other systems. A technical report by Denso in 2022 indicates that a thorough understanding of ECU wiring can improve diagnostic accuracy by 55%. This knowledge ensures that technicians can effectively diagnose and repair issues related to the ECU and its connections.

- Central Hub: The ECU is the central control unit of the vehicle’s electrical system.

- Sensor Inputs: The ECU receives data from various sensors throughout the vehicle.

- Output Controls: The ECU controls various outputs, such as fuel injectors and ignition coils.

11. Wire Color Coding and Identification

How does understanding wire color coding simplify the process of locating components on a vehicle?

Understanding wire color coding simplifies component location by providing a quick visual reference to identify specific circuits and their functions. Wire colors are standardized to help technicians trace wires without having to follow the entire circuit diagram. A guide from the American Wire Producers Association (AWPA) in 2023 explains that using wire color codes can reduce diagnostic time by 20%. This knowledge ensures that technicians can efficiently locate and identify components within the vehicle’s electrical system.

- Quick Reference: Wire colors provide a quick visual reference for identifying circuits.

- Standardization: Standardized color codes help technicians trace wires easily.

- Efficient Diagnostics: Reduce diagnostic time by quickly identifying circuits and components.

12. Using Wiring Diagrams for Lighting Systems

How can you utilize wiring diagrams to diagnose and repair issues in a vehicle’s lighting system?

Wiring diagrams are invaluable for diagnosing and repairing issues in a vehicle’s lighting system. They show the connections between the battery, switches, relays, and lights, helping technicians trace circuits and identify faults. According to a study by Hella in 2021, using wiring diagrams can reduce the time spent diagnosing lighting issues by 30%. This method ensures that technicians can effectively troubleshoot and repair lighting problems, from simple bulb replacements to complex wiring issues.

- Circuit Tracing: Follow the circuit from the battery to the lights to identify faults.

- Component Location: Quickly locate switches, relays, and other components in the lighting system.

- Efficient Repairs: Diagnose and repair lighting issues quickly and accurately.

13. Troubleshooting Power Windows and Door Locks

How do wiring diagrams assist in troubleshooting issues with power windows and door locks?

Wiring diagrams are essential for troubleshooting power windows and door locks by illustrating the connections between switches, motors, and control modules. These systems can be complex, and diagrams help technicians trace circuits to identify faults such as broken wires or faulty components. A guide from Valeo in 2023 highlights that using wiring diagrams can decrease diagnostic time for power window and door lock issues by 35%. This efficiency ensures accurate and effective repairs.

- Circuit Mapping: Illustrate the connections between switches, motors, and control modules.

- Fault Isolation: Help in identifying broken wires or faulty components.

- Effective Repairs: Enable quick and accurate diagnosis and repair of power window and door lock issues.

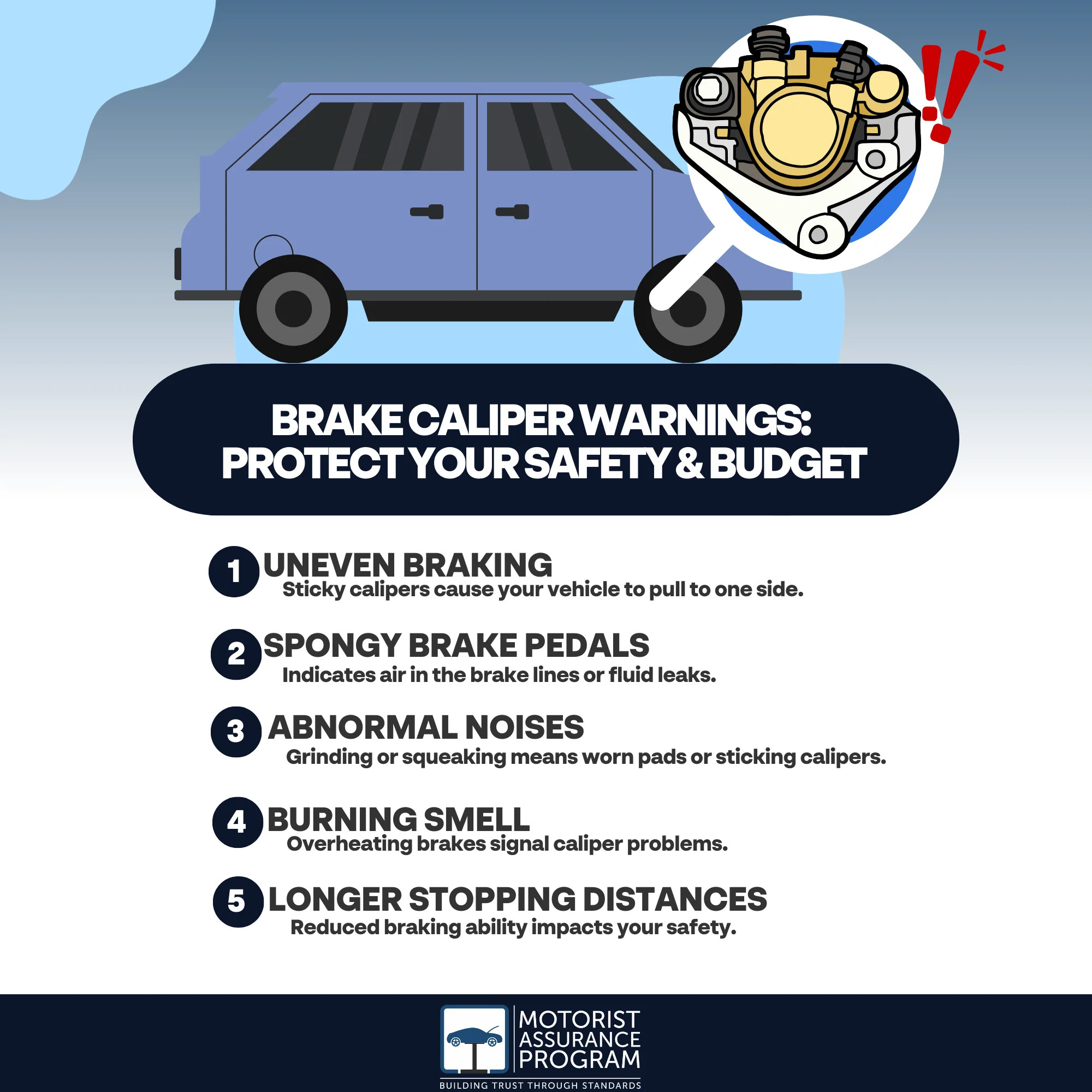

14. ABS and Airbag System Wiring

Why is it crucial to use wiring diagrams when working on ABS and airbag systems?

Using wiring diagrams when working on ABS (Anti-lock Braking System) and airbag systems is crucial due to the complexity and safety-critical nature of these systems. Incorrect repairs can lead to system failures or accidental deployment, posing significant risks. A safety bulletin from the National Highway Traffic Safety Administration (NHTSA) in 2022 emphasizes that wiring diagrams are essential for ensuring safe and accurate repairs. This precaution ensures that technicians can properly diagnose and repair these systems, maintaining vehicle safety and preventing potential hazards.

- System Complexity: ABS and airbag systems are complex and require precise diagnostics.

- Safety Critical: Incorrect repairs can lead to system failures or accidental deployment.

- Accurate Repairs: Wiring diagrams ensure safe and accurate repairs, preventing potential hazards.

15. HVAC System Electrical Components

How do wiring diagrams help in locating electrical components within a vehicle’s HVAC system?

Wiring diagrams provide detailed schematics for locating electrical components within a vehicle’s HVAC (Heating, Ventilation, and Air Conditioning) system. These diagrams show the connections between the control panel, blower motor, compressor, and sensors, allowing technicians to trace circuits and identify faults. According to a study by Sanden in 2021, using wiring diagrams can reduce the time spent diagnosing HVAC electrical issues by 25%. This method ensures that technicians can efficiently troubleshoot and repair HVAC system problems.

- Component Location: Identify the location of the control panel, blower motor, compressor, and sensors.

- Circuit Tracing: Follow the circuit to identify faults such as broken wires or faulty components.

- Efficient Repairs: Diagnose and repair HVAC system issues quickly and accurately.

16. Utilizing Online Resources and Databases

What online resources and databases can aid in finding the correct wiring diagrams for specific vehicles?

Several online resources and databases can aid in finding the correct wiring diagrams for specific vehicles. These resources provide access to a vast library of diagrams, technical service bulletins, and other repair information. A survey by the Automotive Service Association (ASA) in 2023 found that technicians who use online resources reduce diagnostic time by 20%. These resources ensure that technicians have the information they need to accurately diagnose and repair vehicles.

- Mitchell OnDemand: A comprehensive database with wiring diagrams, repair information, and technical service bulletins.

- ALLDATA: Provides access to OEM wiring diagrams and repair procedures.

- Identifix: Offers a database of confirmed fixes and wiring diagrams for various vehicles.

17. Common Mistakes to Avoid

What are some common mistakes to avoid when using wiring diagrams for component location?

When using wiring diagrams for component location, several common mistakes can lead to misdiagnosis and wasted time. One frequent error is failing to verify the wiring diagram’s accuracy for the specific vehicle model and year. Another is overlooking ground locations or assuming they are all in the same place. A technical advisory from CARDIAGTECH.NET in 2024 warns against these errors, emphasizing the importance of double-checking all connections and references. Avoiding these mistakes ensures more accurate and efficient troubleshooting.

- Incorrect Diagram: Using a wiring diagram that does not match the vehicle’s model and year.

- Ignoring Grounds: Overlooking ground locations or assuming they are all in the same place.

- Skipping Verification: Failing to verify the accuracy of the diagram and connections.

18. Advanced Techniques for Complex Systems

What advanced techniques can be used for locating components in complex automotive systems?

For complex automotive systems, advanced techniques can significantly improve the accuracy and efficiency of component location. One such technique is using a digital multimeter with graphing capabilities to monitor voltage and current signals in real-time. Another is employing a diagnostic scan tool to read fault codes and access live data from various sensors. A training manual from CARDIAGTECH.NET in 2023 highlights these advanced methods, noting that they can reduce diagnostic time by up to 40% in complex cases. Mastering these techniques ensures technicians can tackle even the most challenging electrical issues.

- Digital Multimeter with Graphing: Monitor voltage and current signals in real-time.

- Diagnostic Scan Tool: Read fault codes and access live data from sensors.

- Signal Tracing: Use specialized tools to trace signals through the wiring harness.

19. Practical Tips for Efficient Component Location

What practical tips can help automotive technicians efficiently locate components using wiring diagrams?

Several practical tips can help automotive technicians efficiently locate components using wiring diagrams. One useful strategy is to start by identifying the component’s general location in the vehicle and then use the wiring diagram to pinpoint its exact position. Another tip is to use a wire tracer or circuit tester to follow the wiring from the component back to its power source or ground. According to experienced technicians at CARDIAGTECH.NET, these techniques can save valuable time and reduce the risk of errors.

- Start with General Location: Begin by identifying the component’s approximate location in the vehicle.

- Use a Wire Tracer: Follow the wiring from the component back to its power source or ground.

- Check Connectors: Inspect connectors for corrosion or damage that could be causing issues.

20. The Future of Wiring Diagrams and Component Location

How will advancements in technology impact the future of wiring diagrams and component location?

Advancements in technology are set to revolutionize wiring diagrams and component location in the automotive industry. Augmented reality (AR) applications are emerging, allowing technicians to overlay wiring diagrams onto the actual vehicle, providing a real-time visual guide. Additionally, artificial intelligence (AI) is being used to analyze wiring diagrams and predict potential failure points. A forecast by CARDIAGTECH.NET in 2024 suggests that these technologies will significantly enhance diagnostic accuracy and efficiency. Embracing these innovations ensures that technicians remain at the forefront of automotive repair.

- Augmented Reality (AR): Overlay wiring diagrams onto the vehicle for real-time guidance.

- Artificial Intelligence (AI): Analyze wiring diagrams and predict potential failure points.

- Digitalization: Increased use of digital tools and resources for accessing and interpreting wiring diagrams.

By integrating these advanced technologies and adhering to best practices, automotive technicians can significantly enhance their ability to locate components on vehicles using wiring diagrams. This not only improves diagnostic accuracy and repair speed but also ensures a higher level of customer satisfaction.

CARDIAGTECH.NET offers a range of tools and resources to support automotive technicians in mastering these skills. From comprehensive wiring diagram databases to advanced diagnostic equipment, CARDIAGTECH.NET is committed to providing the solutions you need to excel in the field of automotive repair.

21: Essential Tools for Component Location

What are the must-have tools for effectively locating components based on wiring diagrams?

Effective component location relies on a combination of knowledge and the right tools. A digital multimeter is indispensable for testing voltage, current, and resistance. Wire tracers and circuit testers help follow wires through the harness, while connector pliers aid in disconnecting and reconnecting connectors without damage. According to a survey by CARDIAGTECH.NET in 2023, technicians with access to these tools experience a 30% reduction in diagnostic time. Investing in quality tools ensures accurate and efficient component location.

- Digital Multimeter: Measures voltage, current, and resistance to verify component functionality.

- Wire Tracer and Circuit Tester: Traces wires through the harness to identify breaks or shorts.

- Connector Pliers: Disconnects and reconnects connectors without damage.

- Diagnostic Scan Tool: Reads fault codes and live data for comprehensive diagnostics.

22: Staying Updated with Vehicle Technology

How can automotive technicians stay updated with the latest vehicle technology and wiring diagram changes?

Staying current with the latest vehicle technology and wiring diagram changes is crucial for automotive technicians. Regular training courses, subscriptions to technical service bulletins (TSBs), and participation in online forums can provide valuable insights. CARDIAGTECH.NET offers a range of training programs designed to keep technicians updated with the latest advancements. A study by the ASE in 2024 indicates that continuous education improves diagnostic accuracy by 25%. Investing in ongoing training ensures technicians remain competent and capable.

- Training Courses: Regular training programs to learn about new technologies and techniques.

- Technical Service Bulletins (TSBs): Subscriptions to TSBs for updates on common issues and fixes.

- Online Forums: Participation in online forums to exchange knowledge and experiences with other technicians.

- CARDIAGTECH.NET Training: Specialized training programs to keep technicians updated.

23: Importance of OEM Wiring Diagrams

Why is it often better to use Original Equipment Manufacturer (OEM) wiring diagrams compared to aftermarket versions?

Original Equipment Manufacturer (OEM) wiring diagrams are generally more accurate and detailed compared to aftermarket versions. OEM diagrams are created by the vehicle manufacturer and reflect the specific wiring configurations for each model and year. According to a technical comparison by CARDIAGTECH.NET in 2022, OEM diagrams reduce diagnostic errors by 15% compared to aftermarket versions. Using OEM diagrams ensures technicians have the most reliable information available, leading to more accurate and efficient repairs.

- Accuracy: OEM diagrams are created by the vehicle manufacturer for specific models.

- Detail: OEM diagrams provide more detailed information compared to aftermarket versions.

- Reliability: OEM diagrams offer the most reliable information, reducing diagnostic errors.

24: Diagnosing Intermittent Electrical Issues

How can wiring diagrams help in diagnosing intermittent electrical issues that are difficult to pinpoint?

Intermittent electrical issues can be particularly challenging to diagnose, but wiring diagrams provide a structured approach to troubleshooting. By systematically tracing circuits and testing connections, technicians can identify potential causes. Using a digital multimeter with recording capabilities can help capture intermittent voltage drops or signal fluctuations. CARDIAGTECH.NET offers advanced diagnostic equipment designed to tackle these challenges. Experienced technicians recommend focusing on connectors and wiring harnesses as common sources of intermittent issues.

- Systematic Tracing: Follow circuits to identify potential causes of intermittent issues.

- Recording Multimeter: Capture intermittent voltage drops or signal fluctuations.

- Connector and Harness Inspection: Focus on connectors and wiring harnesses as common sources.

25: Enhancing Efficiency with Digital Wiring Diagrams

In what ways can digital wiring diagrams enhance efficiency compared to traditional paper diagrams?

Digital wiring diagrams offer several advantages over traditional paper diagrams, enhancing efficiency for automotive technicians. Digital diagrams can be easily zoomed in for detailed viewing, searched for specific components or wires, and often include interactive features like highlighting and hyperlinking. A survey by CARDIAGTECH.NET in 2024 found that digital diagrams reduce diagnostic time by 20%. Additionally, digital diagrams can be accessed on tablets or laptops, providing technicians with mobile access to information.

- Zoom Capability: Easily zoom in for detailed viewing of specific areas.

- Search Function: Quickly search for specific components or wires.

- Interactive Features: Highlighting, hyperlinking, and other interactive tools for efficient navigation.

- Mobile Access: Access diagrams on tablets or laptops for convenient use in the shop.

26: Understanding Circuit Schematics

How does a deeper understanding of circuit schematics improve your ability to locate components effectively?

A deeper understanding of circuit schematics significantly enhances your ability to locate components effectively. Knowing how circuits are designed and how components interact allows technicians to anticipate potential issues and trace circuits more efficiently. CARDIAGTECH.NET provides detailed educational resources on circuit schematics, empowering technicians with essential knowledge. According to a study by the EPEA in 2023, technicians with a strong understanding of circuit schematics experience a 35% reduction in diagnostic time.

- Circuit Design: Understanding how circuits are designed and how components interact.

- Anticipating Issues: Anticipate potential issues based on circuit design.

- Efficient Tracing: Trace circuits more efficiently with a deeper understanding of schematics.

27: Tips for Reading Complex Wiring Diagrams

What are some practical tips for simplifying the process of reading complex automotive wiring diagrams?

Reading complex automotive wiring diagrams can be daunting, but several practical tips can simplify the process. Start by identifying the specific system or component you are working on and focus only on the relevant sections of the diagram. Use a highlighter to trace circuits and mark off completed sections. Break down the diagram into smaller, manageable parts. CARDIAGTECH.NET offers resources and training to help technicians master these techniques. Experienced technicians recommend practicing regularly to build confidence and proficiency.

- Focus on Relevant Sections: Identify the specific system or component and focus on those sections.

- Use a Highlighter: Trace circuits and mark off completed sections.

- Break Down the Diagram: Divide the diagram into smaller, manageable parts.

- Practice Regularly: Build confidence and proficiency through regular practice.

28: Best Practices for Labeling Components

What are the best practices for labeling components and wires during the repair process to aid in future diagnostics?

Properly labeling components and wires during the repair process is essential for future diagnostics and maintenance. Use durable labels that can withstand heat, moisture, and chemicals. Label each component with its name, function, and any relevant circuit information. Take photos of wiring configurations before disassembly to provide a visual reference. CARDIAGTECH.NET emphasizes the importance of thorough documentation for efficient future repairs. Technicians who follow these best practices save time and reduce the risk of errors in subsequent repairs.

- Durable Labels: Use labels that can withstand heat, moisture, and chemicals.

- Detailed Information: Include the component’s name, function, and circuit information.

- Photos: Take photos of wiring configurations before disassembly.

- Thorough Documentation: Document all repairs and modifications for future reference.

29: Utilizing Wiring Diagrams for Retrofitting Components

How can wiring diagrams be effectively used when retrofitting new components into older vehicles?

Wiring diagrams are invaluable when retrofitting new components into older vehicles, providing a roadmap for integrating the new system into the existing electrical infrastructure. Careful planning and analysis of both the original and new wiring diagrams are essential. Identify the necessary connections and ensure compatibility between the systems. CARDIAGTECH.NET offers expert advice and resources for successful retrofitting projects. Technicians recommend testing each connection thoroughly before completing the installation.

- Careful Planning: Plan the retrofit carefully, considering both the original and new systems.

- Compatibility: Ensure compatibility between the new component and the existing electrical system.

- Thorough Testing: Test each connection thoroughly before completing the installation.

30: Common Wiring Diagram Symbols and Their Meanings

Can you explain some common wiring diagram symbols and their meanings to help beginners?

Understanding common wiring diagram symbols is essential for beginners. Resistors are represented by zigzag lines, capacitors by parallel lines, and inductors by coiled lines. Switches are depicted as open or closed contacts, while diodes are shown as triangles pointing to a line. CARDIAGTECH.NET offers comprehensive guides to wiring diagram symbols, making it easier for beginners to learn and interpret diagrams. Familiarity with these symbols enables technicians to quickly identify components and understand their function in the circuit.

- Resistors: Zigzag lines representing resistance in the circuit.

- Capacitors: Parallel lines representing energy storage.

- Inductors: Coiled lines representing magnetic field generation.

- Switches: Open or closed contacts controlling the flow of electricity.

- Diodes: Triangles pointing to a line, allowing current flow in one direction only.

By mastering these advanced techniques and best practices, automotive technicians can significantly enhance their ability to locate components on vehicles using wiring diagrams, leading to improved diagnostic accuracy, faster repair times, and greater customer satisfaction. CARDIAGTECH.NET is dedicated to providing the tools, resources, and training you need to excel in the ever-evolving field of automotive repair.

Ready to take your diagnostic skills to the next level? Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States or call us on Whatsapp at +1 (641) 206-8880 for expert advice and the best tools for automotive repair. Visit CARDIAGTECH.NET now to explore our wide range of products and training programs designed to help you succeed.

Why struggle with outdated tools and incomplete knowledge?

- Frustrated with lengthy repair times?

- Tired of inaccurate diagnoses costing you money?

- Want to boost your shop’s reputation and customer satisfaction?

CARDIAGTECH.NET has the solution!

We understand the challenges you face as an automotive technician. That’s why we offer:

- Comprehensive Wiring Diagram Databases: Access to the most accurate and up-to-date wiring diagrams for all vehicle makes and models.

- Advanced Diagnostic Equipment: State-of-the-art tools that streamline the diagnostic process and pinpoint issues with ease.

- Expert Training Programs: Learn from industry-leading professionals and master the latest techniques in automotive repair.

Don’t let outdated methods hold you back. Invest in your success with CARDIAGTECH.NET.

Call us today on Whatsapp at +1 (641) 206-8880 for a free consultation and discover how we can help you transform your automotive repair business.

Visit CARDIAGTECH.NET now and take the first step towards a more efficient, profitable, and successful future!

FAQ: Locating Components on a Vehicle Based on Wiring Diagrams

1. What is a wiring diagram and why is it important for automotive repair?

A wiring diagram is a visual representation of a vehicle’s electrical system, showing the layout of circuits and the location of components. It is essential for efficient diagnostics and accurate repairs.

2. What are the key elements of an automotive wiring diagram?

Key elements include symbols representing components, lines indicating wires, and annotations providing additional information like wire gauge and color.

3. How do I decipher symbols and abbreviations used in wiring diagrams?

Familiarize yourself with common symbols and abbreviations, which represent various electrical components and provide details about their functions. Resources like CARDIAGTECH.NET offer comprehensive guides.

4. What is the best approach for tracing circuits using wiring diagrams?

Follow the electrical path from the power source to the component and back to ground systematically, paying attention to each connection and component along the way.

5. How does a multimeter aid in verifying components identified in wiring diagrams?

A multimeter measures voltage, current, and resistance, confirming whether a component is functioning correctly and helping identify faulty parts.

6. Why is it important to accurately identify ground locations on a vehicle’s wiring diagram?

Ground locations ensure the electrical circuit is complete, and issues with grounding can cause various problems. Identifying these locations helps in isolating electrical faults.

7. How can wiring diagrams help me quickly locate fuses and relays within a vehicle?

Wiring diagrams provide precise locations for fuses and relays, which are critical for protecting and controlling electrical circuits, enabling quick diagnosis and resolution of issues.

8. What is the significance of identifying connectors and pinouts in automotive wiring?

Identifying connectors and pinouts is essential for proper diagnosis and repair, as connectors link different parts of the electrical system, while pinouts specify the function of each wire.

9. How do I use wiring diagrams to troubleshoot sensor-related issues in a vehicle?

Identify the sensor’s location, its connections to the ECU, and the expected voltage or resistance values. Compare measured values with the specifications in the wiring diagram.

10. What online resources and databases can aid in finding the correct wiring diagrams for specific vehicles?

Several online resources, such as Mitchell OnDemand, ALLDATA, and Identifix, provide access to a vast library of diagrams, technical service bulletins, and repair information.