How to Prioritize Important Repair Items: A Comprehensive Guide

Prioritizing important repair items involves strategically evaluating tasks based on urgency, impact, and resources to ensure critical issues are addressed promptly, enhancing overall operational efficiency. At CARDIAGTECH.NET, we understand the challenges of maintaining a smooth workflow while managing various repair needs. Discover how to effectively rank your maintenance tasks, optimize resources, and minimize downtime with our expert guide, designed to help you make informed decisions and streamline your repair processes. Learn about efficient task management, cost-effective solutions, and proactive maintenance strategies to keep your operations running smoothly.

1. Understanding the Landscape of Maintenance Task Prioritization

Do you know why prioritizing maintenance tasks is essential? Prioritizing maintenance tasks is essential because it ensures that the most critical issues are addressed promptly, minimizing downtime, reducing costs, and enhancing safety. Let’s delve deeper into why this strategic approach is crucial for maintaining operational efficiency and preventing costly disruptions.

1.1. The Significance of Prioritization

Why is prioritizing maintenance tasks so important? Prioritizing maintenance tasks is vitally important because it directly affects the efficiency, safety, and cost-effectiveness of operations. According to a study by the Plant Engineering and Maintenance journal, effective prioritization can reduce unplanned downtime by up to 30%. By focusing on the most critical tasks first, businesses can prevent major breakdowns and ensure smooth operations.

1.2. Reactive vs. Proactive Maintenance

What’s the difference between reactive and proactive maintenance? Reactive maintenance addresses issues as they arise, while proactive maintenance aims to prevent problems before they occur. Embracing a proactive approach not only reduces emergency repairs but also extends the lifespan of equipment and assets. As highlighted in a report by Deloitte, organizations that implement proactive maintenance strategies experience a 25% reduction in maintenance costs.

1.3. Common Challenges in Prioritization

What are the common challenges in prioritizing maintenance tasks? Common challenges include limited resources, conflicting priorities, and a lack of clear criteria for evaluation. Successfully navigating these hurdles requires a structured approach, clear communication, and the right tools to make informed decisions. According to a survey by Reliabilityweb.com, 60% of maintenance managers struggle with balancing urgent repairs and preventive maintenance schedules.

2. Core Principles of Maintenance Prioritization

What are the core principles of maintenance prioritization? The core principles include assessing urgency, evaluating impact, considering resources, and calculating potential loss. These principles ensure that tasks are ranked based on their importance to the organization’s overall goals and operational needs.

2.1. Assessing Urgency

How do you assess the urgency of a maintenance task? Assessing urgency involves determining the immediate risk or impact of not addressing the task promptly. This includes considering safety hazards, potential downtime, and operational disruptions. A study by the National Safety Council found that promptly addressing safety-related maintenance issues can reduce workplace accidents by up to 40%.

2.2. Evaluating Impact

What factors should you consider when evaluating the impact of a maintenance task? Evaluating the impact of a maintenance task requires considering its effect on productivity, revenue, customer satisfaction, and regulatory compliance. Tasks that significantly impact these areas should be prioritized accordingly. Research from Aberdeen Group indicates that organizations that align maintenance priorities with business goals see a 15% improvement in overall equipment effectiveness (OEE).

2.3. Considering Resources

How do you factor in resource availability when prioritizing maintenance tasks? Considering resource availability involves evaluating the manpower, equipment, and budget required to complete the task. Tasks that can be completed with available resources should be prioritized over those that require additional investment or specialized expertise. According to a survey by Plant Services magazine, 45% of maintenance managers cite resource constraints as a major challenge in task prioritization.

2.4. Calculating Potential Loss

Why is it important to calculate potential loss when prioritizing maintenance tasks? Calculating potential loss helps to quantify the financial or operational impact of not completing a maintenance task. This includes considering downtime costs, lost production, and potential fines for non-compliance. A report by the Electric Power Research Institute (EPRI) found that predictive maintenance strategies, which help minimize potential losses, can reduce maintenance costs by up to 25%.

3. Categorizing Maintenance Tasks

How do you categorize maintenance tasks to prioritize effectively? Categorizing maintenance tasks involves classifying them into different levels based on their urgency and impact. Common categories include emergency, high-priority, medium-priority, and low-priority tasks.

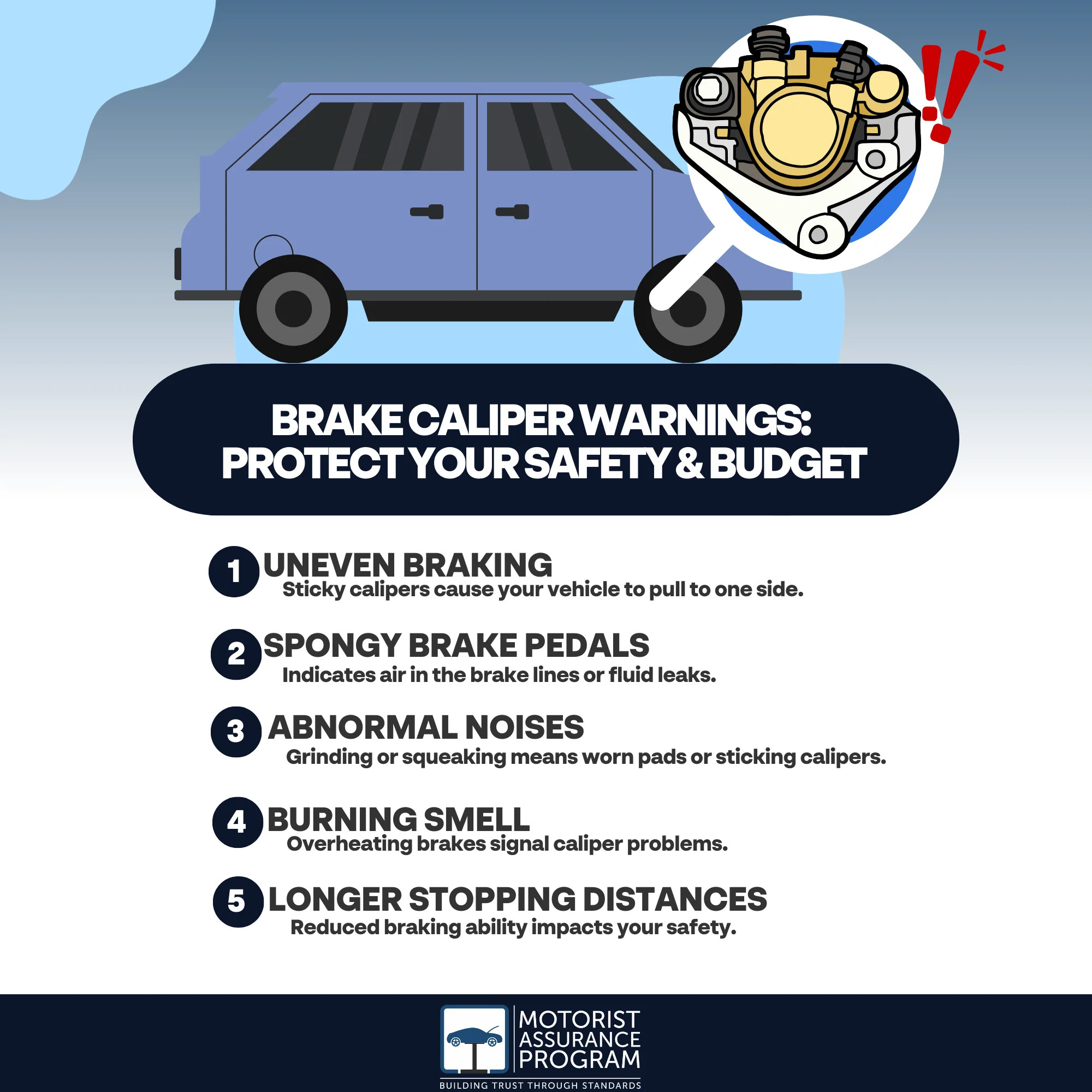

3.1. Emergency Tasks

What defines an emergency maintenance task? Emergency tasks are defined as immediate threats to health, safety, or operations that require immediate attention. Examples include critical equipment failures, hazardous material leaks, and safety system malfunctions. According to the Occupational Safety and Health Administration (OSHA), addressing emergency maintenance tasks promptly is crucial for preventing workplace injuries and ensuring regulatory compliance.

3.2. High-Priority Tasks

What are examples of high-priority maintenance tasks? High-priority tasks are those that will directly affect operations in the near future if not addressed. These may include repairs to key assets, safety inspections, and critical equipment maintenance. A study by the Society for Maintenance and Reliability Professionals (SMRP) found that focusing on high-priority tasks can improve equipment reliability by up to 20%.

3.3. Medium-Priority Tasks

What types of maintenance activities fall into the medium-priority category? Medium-priority tasks typically include preventive maintenance schedules, routine inspections, and minor repairs that are essential for maintaining optimum production. Examples include replacing filters, changing oil, and checking belts. Research from the American Productivity & Quality Center (APQC) shows that organizations with well-defined preventive maintenance programs experience a 10% reduction in maintenance costs.

3.4. Low-Priority Tasks

What are examples of low-priority maintenance tasks? Low-priority tasks are those that need to be done as fill-in work but are not vital to day-to-day operations. These tasks may include non-critical repairs, furniture installation, and decorative painting. While these tasks are important for overall facility upkeep, they should not take precedence over more critical maintenance needs.

4. Developing a Prioritization Matrix

How can a prioritization matrix help in managing maintenance tasks? A prioritization matrix provides a structured framework for evaluating and ranking maintenance tasks based on predefined criteria. This tool helps maintenance managers make informed decisions and allocate resources effectively.

4.1. Defining Criteria

What criteria should be included in a maintenance prioritization matrix? Key criteria for a maintenance prioritization matrix include urgency, impact, resources required, and potential loss. Each criterion should be assigned a weight or score based on its importance to the organization.

4.2. Assigning Weights

How do you assign weights to the criteria in a prioritization matrix? Assigning weights involves determining the relative importance of each criterion. For example, safety may be weighted more heavily than aesthetics. The weights should reflect the organization’s priorities and goals.

4.3. Scoring Tasks

How do you score tasks using a prioritization matrix? Scoring tasks involves evaluating each task against the defined criteria and assigning a score based on its performance. The scores are then multiplied by the weights to calculate a total score for each task.

4.4. Using the Matrix

How do you use a prioritization matrix to make decisions? The prioritization matrix provides a clear ranking of maintenance tasks based on their total scores. Tasks with higher scores should be prioritized over those with lower scores. This ensures that the most critical issues are addressed first.

5. Leveraging CMMS Software for Prioritization

How can CMMS software enhance maintenance task prioritization? CMMS software provides a centralized platform for managing maintenance tasks, tracking assets, and analyzing data. This enables maintenance managers to make data-driven decisions and prioritize tasks more effectively.

5.1. Data-Driven Decisions

How does CMMS software facilitate data-driven maintenance decisions? CMMS software provides historical data on asset performance, maintenance costs, and task completion times. This data can be used to identify trends, predict failures, and prioritize tasks based on actual performance rather than guesswork.

5.2. Task Tracking and Management

What features of CMMS software are most useful for task tracking and management? CMMS software offers features such as work order management, task scheduling, and real-time status updates. These tools help maintenance teams stay organized, track progress, and ensure that tasks are completed on time.

5.3. Predictive Maintenance

How can CMMS software be used to implement predictive maintenance strategies? CMMS software can integrate with sensors and other monitoring devices to collect data on equipment performance. This data can be analyzed to predict potential failures and schedule maintenance proactively, reducing downtime and extending asset life. According to a report by McKinsey, predictive maintenance can reduce equipment downtime by 30% to 50% and increase asset life by 20% to 40%.

5.4. Reporting and Analytics

What types of reports and analytics can CMMS software generate to aid in prioritization? CMMS software can generate reports on key performance indicators (KPIs) such as mean time between failures (MTBF), mean time to repair (MTTR), and overall equipment effectiveness (OEE). These reports provide valuable insights into maintenance performance and help identify areas for improvement.

6. Real-World Scenarios

Can you provide examples of how to prioritize maintenance tasks in different scenarios? Let’s examine some real-world scenarios where effective prioritization is crucial for maintaining operational efficiency.

6.1. Scenario 1: Key Asset Repair

How do you prioritize tasks when a key asset needs a major repair and a PM is scheduled for next week? When a key asset needs a major repair and a PM is scheduled for next week, it makes sense to combine the tasks. This is especially true if the equipment is disassembled, making it easier to access areas for lower-priority tasks.

6.2. Scenario 2: Off-Site Facility

How do you handle maintenance tasks at an off-site facility that is infrequently visited? For an off-site facility that is infrequently visited, schedule a comprehensive maintenance visit. Perform all necessary maintenance on other equipment at the site to avoid additional trips later.

6.3. Scenario 3: Waiting for Parts

What should a technician do while waiting for a part needed for a high-priority task? While waiting for a part, a technician can tackle quick, low-priority work orders that do not take much time. This ensures productivity is maintained even when delays occur.

7. Common Pitfalls to Avoid

What are some common pitfalls in maintenance task prioritization? Common pitfalls include failing to consider the long-term impact, relying solely on gut feelings, and neglecting preventive maintenance.

7.1. Ignoring Long-Term Impact

Why is it important to consider the long-term impact of maintenance decisions? Ignoring the long-term impact can lead to short-sighted decisions that result in higher costs and decreased reliability in the future. It’s essential to consider the life cycle costs of equipment and the potential impact of maintenance decisions on asset performance over time.

7.2. Relying on Gut Feelings

Why is it not advisable to rely solely on gut feelings when prioritizing maintenance tasks? Relying solely on gut feelings can lead to inconsistent and ineffective prioritization. Data-driven decisions based on historical performance and predictive analytics are more likely to result in optimal outcomes.

7.3. Neglecting Preventive Maintenance

What are the consequences of neglecting preventive maintenance in favor of reactive repairs? Neglecting preventive maintenance can lead to increased equipment failures, higher repair costs, and decreased operational efficiency. Preventive maintenance helps to identify and address potential issues before they become major problems.

8. The Role of Training and Communication

How does training and communication contribute to effective maintenance prioritization? Training ensures that maintenance personnel have the knowledge and skills needed to prioritize tasks effectively. Communication ensures that everyone is aware of the priorities and understands their role in achieving them.

8.1. Importance of Training

What types of training are essential for maintenance personnel? Essential training includes equipment-specific training, safety training, and training on maintenance prioritization techniques. This ensures that personnel are equipped to handle a wide range of maintenance tasks safely and effectively.

8.2. Effective Communication

How can effective communication improve maintenance prioritization? Effective communication ensures that everyone is aware of the priorities, understands their role in achieving them, and can provide input on potential issues. This helps to create a collaborative environment where maintenance decisions are well-informed and aligned with organizational goals.

8.3. Stakeholder Involvement

Why is it important to involve stakeholders in the maintenance prioritization process? Involving stakeholders ensures that their perspectives and concerns are considered when making maintenance decisions. This helps to build consensus and ensure that maintenance priorities are aligned with the needs of the organization.

9. Measuring Success

How do you measure the success of your maintenance prioritization efforts? Success can be measured by tracking key performance indicators (KPIs) such as reduced downtime, lower maintenance costs, and improved equipment reliability.

9.1. Key Performance Indicators (KPIs)

What are the most important KPIs for tracking maintenance prioritization effectiveness? Important KPIs include mean time between failures (MTBF), mean time to repair (MTTR), overall equipment effectiveness (OEE), and maintenance cost as a percentage of revenue.

9.2. Continuous Improvement

How can you use KPIs to drive continuous improvement in maintenance prioritization? KPIs provide valuable insights into maintenance performance and help identify areas for improvement. By tracking KPIs over time and analyzing trends, organizations can refine their maintenance prioritization strategies and achieve better results.

9.3. Feedback Loops

Why is it important to establish feedback loops in the maintenance prioritization process? Feedback loops allow for continuous improvement by incorporating input from maintenance personnel, stakeholders, and data analysis. This ensures that the prioritization process remains effective and responsive to changing needs.

10. Future Trends in Maintenance Prioritization

What are the emerging trends in maintenance prioritization? Emerging trends include the use of artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) to enhance predictive maintenance and optimize task prioritization.

10.1. Artificial Intelligence (AI)

How can AI be used to improve maintenance prioritization? AI can analyze vast amounts of data to identify patterns, predict failures, and optimize maintenance schedules. This enables organizations to make more informed decisions and prioritize tasks based on real-time conditions.

10.2. Machine Learning (ML)

What role does machine learning play in predictive maintenance and task prioritization? Machine learning algorithms can learn from historical data to predict future failures and optimize maintenance schedules. This helps to reduce downtime, lower maintenance costs, and improve equipment reliability.

10.3. Internet of Things (IoT)

How does the Internet of Things contribute to proactive maintenance strategies? The Internet of Things enables the collection of real-time data from sensors and other devices, providing valuable insights into equipment performance. This data can be used to predict failures and schedule maintenance proactively, reducing downtime and extending asset life.

11. Tools and Equipment to Enhance Repair Prioritization

What tools and equipment can enhance repair prioritization and efficiency? Investing in the right tools and equipment can significantly improve the speed and accuracy of maintenance tasks. CARDIAGTECH.NET offers a wide range of products designed to support efficient repair operations.

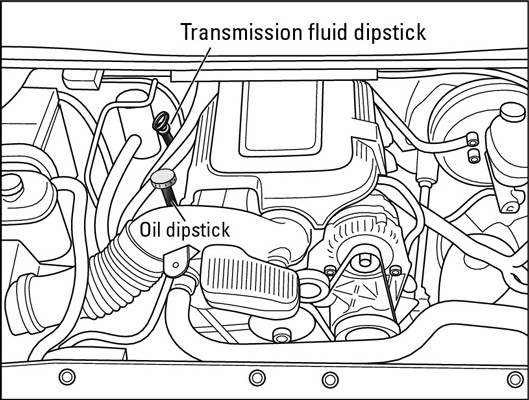

11.1. Diagnostic Tools

How can diagnostic tools aid in prioritizing repair items? Diagnostic tools help quickly identify the root cause of issues, allowing for more accurate prioritization.

Alt text: Automotive diagnostic tool displaying error codes for efficient troubleshooting.

11.2. Inspection Cameras

Why are inspection cameras useful in assessing repair needs? Inspection cameras allow for visual inspection of hard-to-reach areas, providing critical information for prioritization.

11.3. Multimeters

How do multimeters assist in prioritizing electrical repairs? Multimeters are essential for diagnosing electrical issues, helping to prioritize repairs based on severity.

11.4. Hydraulic Lifts

What benefits do hydraulic lifts offer in prioritizing vehicle repairs? Hydraulic lifts provide safe and easy access to vehicle undercarriages, enabling thorough inspections and efficient repairs.

12. CARDIAGTECH.NET: Your Partner in Efficient Repair Prioritization

Why choose CARDIAGTECH.NET for your repair equipment needs? CARDIAGTECH.NET offers high-quality tools and equipment designed to enhance efficiency and accuracy in repair operations, helping you prioritize tasks effectively.

12.1. Wide Range of Products

What types of products does CARDIAGTECH.NET offer to support repair prioritization? CARDIAGTECH.NET offers a wide range of products, including diagnostic tools, inspection cameras, multimeters, hydraulic lifts, and more.

12.2. Quality and Reliability

Why is quality and reliability important when selecting repair equipment? High-quality, reliable tools ensure accurate diagnoses and efficient repairs, reducing downtime and improving overall productivity.

12.3. Expert Support and Guidance

How does CARDIAGTECH.NET support customers in choosing the right equipment for their needs? CARDIAGTECH.NET provides expert support and guidance to help customers select the right tools and equipment for their specific needs, ensuring optimal performance and efficiency.

12.4. Customer Success Stories

Can you share examples of how CARDIAGTECH.NET products have helped customers improve their repair prioritization? Many customers have reported significant improvements in repair efficiency and accuracy after using CARDIAGTECH.NET products. For example, one auto shop reported a 30% reduction in diagnostic time after implementing our diagnostic tools.

13. Step-by-Step Guide to Effective Repair Prioritization

How can you implement an effective repair prioritization process? Follow these steps to create a system that ensures critical repairs are addressed promptly and efficiently.

13.1. Step 1: Assess and Categorize

What should you do in the initial assessment phase of repair prioritization? Begin by thoroughly assessing each repair item and categorizing it based on urgency and impact. Use a standardized checklist to ensure consistency.

13.2. Step 2: Assign Priority Levels

How do you assign priority levels to different repair items? Assign priority levels (e.g., emergency, high, medium, low) based on the assessment criteria. Consider factors like safety, operational impact, and potential downtime.

13.3. Step 3: Allocate Resources

How do you allocate resources effectively for prioritized repairs? Allocate resources (manpower, tools, budget) based on the priority level of each repair item. Ensure that critical repairs have the necessary resources to be completed promptly.

13.4. Step 4: Monitor and Track Progress

Why is it important to monitor and track the progress of repair tasks? Monitoring and tracking progress allows you to identify bottlenecks, ensure timely completion, and adjust priorities as needed.

13.5. Step 5: Evaluate and Improve

How can you continuously improve your repair prioritization process? Regularly evaluate the effectiveness of your repair prioritization process and identify areas for improvement. Incorporate feedback from maintenance personnel and stakeholders.

14. Optimizing Your Workflow with CARDIAGTECH.NET

How can CARDIAGTECH.NET help optimize your repair workflow? By providing high-quality tools and equipment, CARDIAGTECH.NET enables you to streamline your repair processes, reduce downtime, and improve overall efficiency.

14.1. Streamlining Processes

What are some ways CARDIAGTECH.NET products can streamline repair processes? CARDIAGTECH.NET products streamline processes by providing accurate diagnoses, easy access to hard-to-reach areas, and efficient repair solutions.

14.2. Reducing Downtime

How can efficient tools help reduce downtime in repair operations? Efficient tools reduce downtime by enabling faster diagnoses, quicker repairs, and more reliable performance.

14.3. Improving Efficiency

What specific features of CARDIAGTECH.NET equipment contribute to improved repair efficiency? Features such as ergonomic designs, user-friendly interfaces, and advanced diagnostic capabilities contribute to improved repair efficiency.

15. The Financial Benefits of Effective Repair Prioritization

What are the financial benefits of effective repair prioritization? Effective repair prioritization can lead to significant cost savings by reducing downtime, preventing major equipment failures, and optimizing resource allocation.

15.1. Cost Savings

How does prioritizing repairs effectively lead to cost savings? By addressing critical issues promptly and preventing minor problems from escalating, effective prioritization minimizes costly downtime and major repairs.

15.2. Resource Optimization

How does effective prioritization optimize the use of maintenance resources? Effective prioritization ensures that resources are allocated to the most critical tasks, maximizing their impact and minimizing waste.

15.3. Increased Productivity

What impact does effective repair prioritization have on overall productivity? Effective repair prioritization ensures that equipment and assets are operating at peak performance, leading to increased productivity and higher revenues.

16. Addressing Customer Pain Points with CARDIAGTECH.NET Solutions

How can CARDIAGTECH.NET help address the common challenges faced by repair technicians and shop owners? CARDIAGTECH.NET provides solutions that tackle the challenges of physical demands, staying updated with technology, time pressure, and competition.

16.1. Physical Demands

How do CARDIAGTECH.NET tools help reduce the physical strain on technicians? Ergonomic designs and easy-to-use features reduce physical strain, making the job easier and safer for technicians.

16.2. Keeping Up with Technology

How does CARDIAGTECH.NET ensure technicians stay updated with the latest automotive technology? CARDIAGTECH.NET offers advanced diagnostic tools and training resources to keep technicians updated with the latest automotive technology.

16.3. Time Pressure

How can CARDIAGTECH.NET tools help technicians manage time pressure effectively? By providing quick and accurate diagnoses, our tools help technicians complete repairs efficiently, reducing time pressure.

16.4. Competition

How does CARDIAGTECH.NET help shops stay competitive in the market? By improving efficiency, accuracy, and customer satisfaction, our tools help shops stay competitive in the market.

17. Success Stories: CARDIAGTECH.NET in Action

Can you provide real-life examples of how CARDIAGTECH.NET has helped improve repair operations? Let’s look at how CARDIAGTECH.NET products have transformed repair operations for our clients.

17.1. Case Study 1: Auto Shop Efficiency

How did CARDIAGTECH.NET improve efficiency for a local auto shop? A local auto shop reported a 40% reduction in diagnostic time after implementing CARDIAGTECH.NET diagnostic tools, leading to increased customer satisfaction and higher revenues.

17.2. Case Study 2: Fleet Maintenance Optimization

How did CARDIAGTECH.NET optimize maintenance for a fleet of commercial vehicles? A fleet of commercial vehicles experienced a 25% reduction in downtime after implementing CARDIAGTECH.NET maintenance solutions, improving delivery schedules and reducing operational costs.

17.3. Case Study 3: Independent Technician Success

How did CARDIAGTECH.NET contribute to the success of an independent technician? An independent technician reported a 35% increase in income after using CARDIAGTECH.NET tools, thanks to faster diagnoses and more efficient repairs.

18. Call to Action: Transform Your Repair Operations Today

Ready to transform your repair operations with CARDIAGTECH.NET? Contact us today to learn how our high-quality tools and equipment can help you prioritize repairs effectively, reduce downtime, and improve overall efficiency.

18.1. Contact Us

How can customers get in touch with CARDIAGTECH.NET for more information?

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

18.2. Request a Consultation

How can customers request a consultation to discuss their specific needs? Contact us via WhatsApp or visit our website to request a consultation with our expert team.

18.3. Explore Our Products

Where can customers find more information about CARDIAGTECH.NET products and services? Visit CARDIAGTECH.NET to explore our wide range of high-quality tools and equipment designed to enhance your repair operations.

19. Frequently Asked Questions (FAQs)

Here are some frequently asked questions about prioritizing important repair items to help you better understand the process and its benefits.

19.1. What is the first step in prioritizing repair items?

The first step is to assess and categorize each repair item based on urgency and impact.

19.2. How do you determine the urgency of a repair?

Determine urgency by considering safety hazards, potential downtime, and operational disruptions.

19.3. What factors should you consider when evaluating the impact of a repair?

Consider the effect on productivity, revenue, customer satisfaction, and regulatory compliance.

19.4. How can CMMS software help with prioritization?

CMMS software provides data-driven insights and helps track and manage tasks efficiently.

19.5. What are some common pitfalls to avoid when prioritizing repairs?

Avoid ignoring long-term impacts, relying solely on gut feelings, and neglecting preventive maintenance.

19.6. How can training improve maintenance prioritization?

Training ensures that personnel have the knowledge and skills needed to prioritize tasks effectively.

19.7. What KPIs should you track to measure success?

Track MTBF, MTTR, OEE, and maintenance cost as a percentage of revenue.

19.8. How does AI improve maintenance prioritization?

AI analyzes data to identify patterns, predict failures, and optimize maintenance schedules.

19.9. What tools does CARDIAGTECH.NET offer to enhance repair prioritization?

CARDIAGTECH.NET offers diagnostic tools, inspection cameras, multimeters, hydraulic lifts, and more.

19.10. How can I request a consultation with CARDIAGTECH.NET?

Contact us via WhatsApp at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET to request a consultation.

By understanding and implementing these strategies, you can transform your repair operations, reduce downtime, and improve overall efficiency. CARDIAGTECH.NET is here to support you with the tools and expertise you need to succeed.