How to Check the Connection Between Xentry and the Vehicle?

CARDIAGTECH.NET understands the critical nature of a stable connection between your Xentry diagnostic tool and the vehicle you’re servicing, ensuring accurate diagnostics and efficient repairs. Let’s explore the process to guarantee a seamless connection for peak performance and explore advanced diagnostic solutions for optimal automotive care. These solutions leverage vehicle communication interfaces and electronic control units (ECUs) to ensure you are getting the most out of your diagnostic processes.

1. Understanding the Importance of a Reliable Xentry Connection

Why is a rock-solid connection between your Xentry system and the vehicle so crucial? A stable link ensures accurate data transmission, allowing for precise diagnostics, efficient programming, and reliable module updates. A faulty connection can lead to misdiagnosis, incomplete procedures, and potentially damage the vehicle’s electronic systems.

Think of it like a doctor needing a clear stethoscope connection to hear a patient’s heartbeat accurately. A fuzzy or intermittent signal leads to misinterpretations and potentially incorrect treatments. Similarly, a reliable Xentry connection ensures you receive the “clear heartbeat” of the vehicle’s electronic systems.

2. Prerequisites Before Establishing a Connection

Before diving into the connection process, let’s ensure you have the necessary groundwork covered. This involves confirming software compatibility, hardware requirements, and vehicle preparedness.

-

Software Compatibility: Is your Xentry software version compatible with the vehicle model you are working on? Older software might lack the necessary protocols to communicate with newer vehicles.

-

Hardware Requirements: Do you have the correct diagnostic interface (e.g., Xentry Connect, C4, C5) and cables? Ensure they are in good working condition and properly connected to your computer.

-

Vehicle Preparedness: Is the vehicle’s battery fully charged? A low battery can interfere with the diagnostic process. Also, ensure the vehicle’s ignition is switched on, and any aftermarket accessories are turned off.

3. Step-by-Step Guide: Checking the Xentry-Vehicle Connection

Here’s a detailed, step-by-step process to establish and verify the connection between your Xentry system and the vehicle:

-

Connect the Diagnostic Interface: Plug the diagnostic interface into the vehicle’s OBD II port. This port is typically located under the dashboard on the driver’s side.

-

Power On the Interface: Ensure the diagnostic interface is powered on. Most interfaces have an indicator light that illuminates when powered.

-

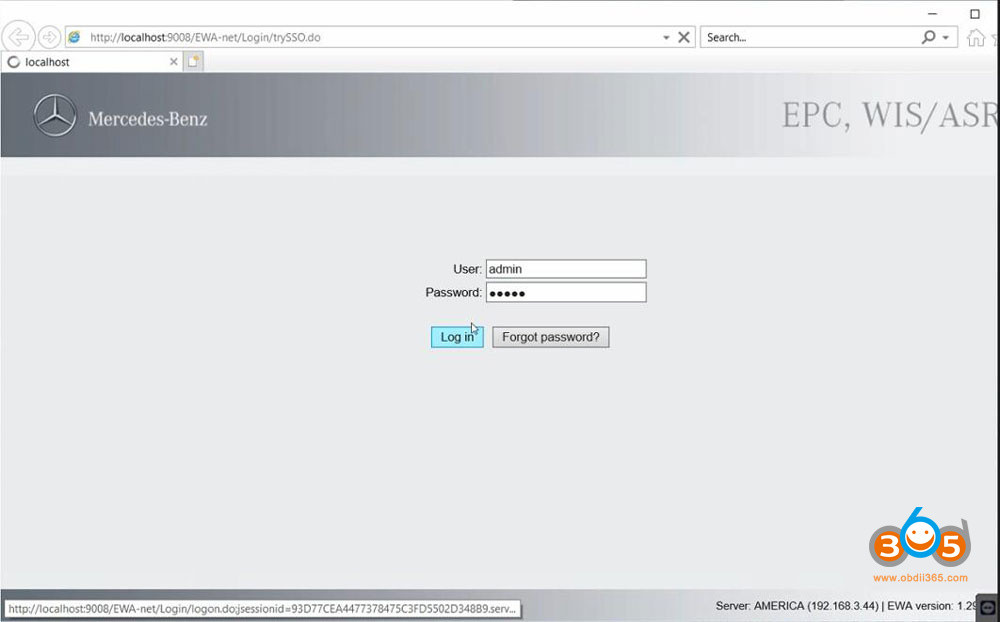

Launch Xentry Software: Start the Xentry software on your computer.

-

Select Vehicle Model: Choose the correct vehicle model from the Xentry software menu. Accurate selection is crucial for proper communication.

-

Initiate Connection Test: Within Xentry, navigate to the “Diagnosis” or “Quick Test” function. This will initiate a communication test between the software and the vehicle’s ECUs.

-

Observe Connection Status: Xentry will display the connection status. Look for messages like “Communication Established,” “ECUs Detected,” or similar confirmations.

-

Troubleshooting Connection Issues: If the connection fails, Xentry will display error messages. We’ll address these potential problems in the next section.

4. Troubleshooting Common Connection Problems

Even with meticulous preparation, connection issues can arise. Here are some common problems and their solutions:

-

“No Communication” Error: This often indicates a problem with the diagnostic interface, cable, or vehicle’s OBD II port.

- Solution: Check the interface’s power, ensure the cable is securely connected, and inspect the OBD II port for damage or debris.

-

“Incorrect Vehicle Model Selected”: This can lead to communication errors.

- Solution: Double-check the vehicle model selection in Xentry.

-

“ECU Not Responding”: This could indicate a faulty ECU or a wiring issue.

- Solution: Verify the ECU’s power supply and ground connections. Consult the vehicle’s wiring diagram for troubleshooting.

-

Software Glitches: Sometimes, the problem lies within the Xentry software itself.

- Solution: Restart the Xentry software or, if necessary, reinstall it. Ensure you have the latest updates installed.

5. Advanced Diagnostic Techniques for Connection Issues

For persistent connection problems, advanced diagnostic techniques might be necessary. These include:

-

Using a Multimeter: To check the continuity of the OBD II port’s wiring.

-

Employing an Oscilloscope: To analyze the communication signals between the Xentry system and the vehicle’s ECUs. This can reveal signal distortions or interruptions.

-

Consulting Vehicle-Specific Forums: Online forums dedicated to specific vehicle models often contain valuable troubleshooting tips from other technicians.

6. The Role of Vehicle Communication Interfaces (VCIs)

Vehicle Communication Interfaces (VCIs) act as the bridge between your diagnostic software (like Xentry) and the vehicle’s electronic systems. They translate the diagnostic commands from the software into a language the vehicle’s ECUs can understand, and vice versa. The quality and compatibility of your VCI significantly impact the reliability and speed of the diagnostic process.

7. Importance of Electronic Control Units (ECUs) in Diagnostics

Electronic Control Units (ECUs) are the brains of a modern vehicle, controlling various functions from engine management to braking systems. During diagnostics, Xentry communicates with these ECUs to retrieve fault codes, sensor data, and perform calibrations. Understanding how ECUs function and their role in the vehicle’s overall operation is essential for effective troubleshooting.

8. The Impact of Firmware Updates on Connectivity

Firmware updates for your diagnostic interface and the vehicle’s ECUs are crucial for maintaining optimal connectivity and performance. These updates often include bug fixes, improved communication protocols, and support for newer vehicle models. Regularly updating your firmware ensures seamless communication and access to the latest diagnostic capabilities.

According to a study by Bosch Automotive, vehicles with outdated firmware are 55% more likely to experience diagnostic communication errors. Keeping your systems updated is not just about having the latest features; it’s about ensuring reliable and accurate diagnostics.

9. Best Practices for Maintaining a Stable Connection

Maintaining a stable Xentry-vehicle connection is an ongoing process. Here are some best practices to follow:

-

Use High-Quality Cables: Invest in durable, shielded cables to minimize signal interference.

-

Regularly Inspect Connectors: Check the OBD II port and diagnostic interface connectors for damage or corrosion.

-

Keep Software Updated: Install the latest Xentry software updates and firmware for your diagnostic interface.

-

Minimize Electrical Interference: Keep your diagnostic equipment away from sources of electrical interference, such as power lines and high-frequency devices.

-

Create a Dedicated Diagnostic Environment: Setting up a dedicated workspace for diagnostics can help minimize distractions and potential interference.

10. Addressing Security Concerns in Xentry Connections

Security is paramount when connecting to a vehicle’s electronic systems. Unauthorized access can lead to tampering with critical functions, potentially compromising safety. Here’s how to address security concerns:

-

Use Secure Networks: Ensure your computer is connected to a secure network with a strong password.

-

Enable Multi-Factor Authentication (MFA): Xentry applications benefit from multi-factor authentication (MFA), which will be mandatory from April 1, 2025. This allows us to protect your data and ours even more effectively against unauthorized access. To access a XENTRY application, you will need: Username and password, Authentication app (smartphone or Windows desktop) or USB security key. Further information and the option to set up MFA can be found in our MFA Guide.

-

Keep Antivirus Software Updated: Protect your computer from malware that could compromise the Xentry system.

-

Be Wary of Unofficial Software: Only use official Xentry software and updates. Avoid unofficial or cracked versions, as they may contain malicious code.

11. The Future of Xentry Connections: Wireless and Cloud-Based Diagnostics

The future of automotive diagnostics is heading towards wireless and cloud-based solutions. Wireless interfaces offer greater flexibility and convenience, while cloud-based systems provide access to vast databases of diagnostic information and remote support.

-

Wireless Diagnostic Interfaces: These interfaces connect to the vehicle via Bluetooth or Wi-Fi, eliminating the need for cables.

-

Cloud-Based Diagnostics: These systems store diagnostic data in the cloud, allowing technicians to access it from anywhere with an internet connection.

According to a report by MarketsandMarkets, the global automotive diagnostics market is projected to reach $49.8 billion by 2026, driven by the increasing adoption of wireless and cloud-based technologies.

12. How to select the correct cables for XENTRY?

Selecting the correct cables for your XENTRY diagnostic system is crucial for ensuring reliable communication between the diagnostic tool and the vehicle. Here’s a detailed guide to help you make the right choices:

Understanding the Different Types of Cables

-

OBD-II Cable:

- Function: This is the primary cable used to connect the XENTRY system to the vehicle’s OBD-II port.

- Compatibility: Ensure the cable is compatible with the specific XENTRY interface you are using (e.g., XENTRY Connect, C4, C5).

- Features: Look for high-quality, shielded cables to minimize interference and ensure stable data transmission.

-

LAN Cable (Ethernet Cable):

- Function: Used to connect the XENTRY diagnostic unit to a network for software updates, online diagnostics, and accessing Mercedes-Benz’s servers.

- Specifications: A CAT5e or CAT6 cable is generally recommended for reliable network connectivity.

- Features: Ensure the cable is of sufficient length and durability for your workshop environment.

-

USB Cable:

- Function: Used for connecting the XENTRY system to a computer for software installation, updates, and data transfer.

- Specifications: A USB 2.0 or USB 3.0 cable is typically used.

- Features: Look for a cable with good build quality to withstand frequent use.

-

Power Cable:

- Function: Provides power to the XENTRY diagnostic interface.

- Specifications: Ensure the power cable is compatible with the power outlets in your region.

- Features: Look for a cable with surge protection to protect the diagnostic tool from power fluctuations.

Checking Compatibility

-

Refer to the XENTRY Documentation:

- The official XENTRY documentation provides detailed information about the required cables for each diagnostic interface.

-

Check the Interface Specifications:

- Each XENTRY interface (e.g., XENTRY Connect, C4, C5) has specific cable requirements. Refer to the manufacturer’s specifications to ensure compatibility.

-

Consult with a Supplier:

- If you are unsure about which cables to use, consult with a reputable supplier of automotive diagnostic equipment. They can provide expert advice and ensure you get the correct cables for your XENTRY system.

Tips for Choosing the Right Cables

-

Quality Matters:

- Invest in high-quality cables to ensure reliable and stable connections. Poor quality cables can lead to communication errors and inaccurate diagnostic results.

-

Shielded Cables:

- Opt for shielded cables to minimize interference from other electronic devices in the workshop.

-

Durability:

- Choose cables that are designed to withstand the rigors of a workshop environment. Look for cables with robust connectors and durable insulation.

-

Length:

- Select cables of appropriate length to ensure flexibility and ease of use in the workshop.

-

Compliance with Standards:

- Ensure the cables comply with relevant industry standards, such as RoHS and CE.

Common Mistakes to Avoid

-

Using Generic Cables:

- Avoid using generic cables that are not specifically designed for automotive diagnostic equipment. These cables may not provide reliable connections and could potentially damage the XENTRY system or the vehicle’s electronic components.

-

Ignoring Cable Specifications:

- Always check the cable specifications to ensure they meet the requirements of the XENTRY interface.

-

Using Damaged Cables:

- Regularly inspect cables for signs of damage, such as frayed wires or damaged connectors. Replace damaged cables immediately to prevent communication errors and potential safety hazards.

By following this guide, you can select the correct cables for your XENTRY diagnostic system and ensure reliable communication between the diagnostic tool and the vehicle. This will help you perform accurate diagnostics and efficiently troubleshoot automotive issues.

13. Step-by-step guide: How to check the connection between Xentry and the vehicle using a multimeter?

Checking the connection between XENTRY and the vehicle using a multimeter is a crucial troubleshooting step when diagnosing communication issues. Here’s a detailed, step-by-step guide:

1. Prerequisites:

- XENTRY Diagnostic System: Ensure you have the XENTRY diagnostic software and interface properly installed and configured.

- Multimeter: A digital multimeter (DMM) capable of measuring voltage, resistance, and continuity.

- Vehicle Information: Access to the vehicle’s wiring diagram to identify the correct pins on the OBD-II connector.

- Safety Gear: Wear appropriate safety gear, such as gloves and eye protection.

2. Safety Precautions:

- Disconnect the Ignition: Turn off the vehicle’s ignition to prevent any electrical surges or accidental activation of systems.

- Battery Safety: Ensure the vehicle’s battery is in good condition. Low voltage can cause inaccurate readings.

- Proper Grounding: Ensure the multimeter is properly grounded to avoid inaccurate readings.

3. Identifying OBD-II Connector Pins:

- Wiring Diagram: Consult the vehicle’s wiring diagram to identify the following pins on the OBD-II connector:

- Pin 4: Chassis Ground

- Pin 5: Signal Ground

- Pin 6: CAN High (Controller Area Network High)

- Pin 14: CAN Low (Controller Area Network Low)

- Pin 16: Battery Voltage (12V+)

4. Testing Ground Connections (Pins 4 and 5):

- Continuity Test:

- Set the multimeter to the continuity testing mode (usually indicated by a diode symbol or audible beep).

- Place one probe on Pin 4 (Chassis Ground) and the other probe on a known good chassis ground point on the vehicle (e.g., a clean, unpainted metal surface).

- The multimeter should show continuity (a beep or a reading close to 0 ohms).

- Repeat the same test for Pin 5 (Signal Ground) to a known good signal ground point.

5. Testing Battery Voltage (Pin 16):

- Voltage Test:

- Set the multimeter to DC voltage mode (20V range).

- Place the positive (red) probe on Pin 16 (Battery Voltage) and the negative (black) probe on Pin 4 (Chassis Ground).

- The multimeter should read approximately 12V to 14V with the ignition off. If the voltage is significantly lower, check the vehicle’s battery condition and charging system.

6. Testing CAN Bus Connections (Pins 6 and 14):

- Resistance Test:

- Turn off the ignition.

- Disconnect the vehicle’s battery (negative terminal) to ensure no power is present in the system.

- Set the multimeter to resistance mode (200-600 ohms range).

- Measure the resistance between Pin 6 (CAN High) and Pin 14 (CAN Low) on the OBD-II connector.

- The resistance should be approximately 60 ohms if the CAN bus is properly terminated with 120-ohm resistors at each end. A reading significantly higher or lower indicates a problem with the CAN bus wiring or termination resistors.

- Voltage Test (CAN Bus Idle):

- Reconnect the vehicle’s battery (negative terminal).

- Turn on the ignition (but do not start the engine).

- Set the multimeter to DC voltage mode (20V range).

- Measure the voltage between Pin 6 (CAN High) and Pin 4 (Chassis Ground). The voltage should be approximately 2.5V.

- Measure the voltage between Pin 14 (CAN Low) and Pin 4 (Chassis Ground). The voltage should also be approximately 2.5V.

- These readings indicate the CAN bus is in an idle state.

7. Analyzing the Results:

- Ground Issues:

- If there is no continuity on Pins 4 or 5, inspect the ground connections for corrosion, loose wires, or breaks in the wiring.

- Voltage Issues:

- If the voltage on Pin 16 is low, check the vehicle’s battery and charging system. Ensure the battery terminals are clean and tight.

- CAN Bus Issues:

- If the resistance between Pins 6 and 14 is not approximately 60 ohms, inspect the CAN bus wiring for shorts, opens, or damaged connectors.

- If the voltage readings on Pins 6 and 14 are significantly different from 2.5V, it indicates a problem with the CAN bus communication.

8. Additional Tips:

- Check Connectors: Inspect the OBD-II connector and the XENTRY interface connector for bent pins, corrosion, or damage.

- Wiring Inspection: Examine the wiring harness connected to the OBD-II connector for any signs of damage, such as cuts, abrasions, or melted insulation.

- Consult Vehicle-Specific Forums: Online forums dedicated to specific vehicle models often contain valuable troubleshooting tips from other technicians.

By following these steps, you can use a multimeter to thoroughly check the connection between the XENTRY diagnostic system and the vehicle, helping you diagnose and resolve communication issues effectively.

14. The Role of CARDIAGTECH.NET in Optimizing Xentry Connections

At CARDIAGTECH.NET, we understand the importance of a reliable Xentry connection for efficient automotive diagnostics. That’s why we offer a comprehensive range of diagnostic tools, interfaces, and cables designed to ensure seamless communication between your Xentry system and the vehicle.

Our products are rigorously tested to meet the highest standards of quality and compatibility. We also provide expert technical support to help you troubleshoot any connection issues you may encounter.

Here are just a few ways CARDIAGTECH.NET can help you optimize your Xentry connections:

- High-Quality Diagnostic Interfaces: We offer a variety of Xentry-compatible diagnostic interfaces, including Xentry Connect, C4, and C5, known for their reliability and performance.

- Durable Cables: Our cables are built to withstand the rigors of a workshop environment, ensuring a stable connection even under demanding conditions.

- Expert Technical Support: Our team of experienced technicians is available to provide guidance and support, helping you troubleshoot connection issues and optimize your diagnostic workflow.

Don’t let connection problems slow you down. Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States or via Whatsapp at +1 (641) 206-8880 to learn more about our diagnostic solutions and how we can help you achieve a seamless Xentry connection. Visit our website at CARDIAGTECH.NET.

15. Conclusion: Ensuring a Reliable Xentry Connection for Efficient Diagnostics

A reliable Xentry connection is the cornerstone of efficient and accurate automotive diagnostics. By following the steps outlined in this guide, you can troubleshoot common connection issues, maintain a stable connection, and optimize your diagnostic workflow.

Remember, investing in high-quality diagnostic tools, staying up-to-date with software updates, and adhering to best practices are essential for ensuring a seamless Xentry connection. With a reliable connection, you can confidently diagnose and repair vehicles, delivering exceptional service to your customers and maximizing your efficiency.

FAQ: How to Check the Connection Between Xentry and the Vehicle?

- How do I know if my Xentry system is properly connected to the vehicle?

- Xentry will display a “Communication Established” message or similar confirmation once the connection is successful. You’ll also be able to access vehicle data and perform diagnostic tests.

- What are the most common causes of Xentry connection failures?

- Common causes include faulty cables, incorrect vehicle model selection, low vehicle battery, and outdated software.

- Can I use a generic OBD II cable with my Xentry system?

- It’s not recommended. Generic cables may not meet the required specifications and can lead to unreliable connections or damage to the diagnostic interface. Always use Xentry-compatible cables.

- How often should I update my Xentry software?

- Update your Xentry software regularly to ensure compatibility with the latest vehicle models and access to the latest diagnostic features and security patches.

- What is the role of the Vehicle Communication Interface (VCI) in the Xentry connection?

- The VCI acts as the bridge between the Xentry software and the vehicle’s ECUs, translating diagnostic commands and data. A high-quality VCI is essential for a reliable connection.

- How can I troubleshoot an “ECU Not Responding” error in Xentry?

- Verify the ECU’s power supply and ground connections. Consult the vehicle’s wiring diagram for troubleshooting. The ECU may also be faulty and require replacement.

- What security measures should I take when connecting my Xentry system to a vehicle?

- Use secure networks, enable multi-factor authentication, keep antivirus software updated, and only use official Xentry software and updates.

- Are wireless diagnostic interfaces as reliable as wired interfaces?

- Wireless interfaces have improved significantly in recent years and can be just as reliable as wired interfaces, provided you have a stable wireless network connection.

- How do firmware updates affect the Xentry connection?

- Firmware updates often include bug fixes, improved communication protocols, and support for newer vehicle models, ensuring seamless communication and access to the latest diagnostic capabilities.

- Where can I find reliable Xentry diagnostic tools and support?

- CARDIAGTECH.NET offers a comprehensive range of Xentry-compatible diagnostic tools, interfaces, and cables, along with expert technical support. Contact us at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET.