What Experiences Have You Had With Specific Issues Using Xentry?

Addressing specific issues using Xentry can streamline auto repairs, ensuring accurate diagnostics and efficient solutions. At CARDIAGTECH.NET, we empower automotive professionals with cutting-edge diagnostic tools and comprehensive support, fostering confident and successful outcomes in every repair. Dive into our expert resources and discover how to tackle complex automotive challenges with precision, enhancing diagnostic accuracy and optimizing repair processes with Xentry.

1. What Specific Issues or Errors Commonly Occur When Using Xentry?

When using Xentry, common issues range from software glitches and connectivity problems to coding errors and hardware incompatibilities. Understanding these errors is crucial for effective diagnostics and repair.

Xentry, a comprehensive diagnostic software used primarily for Mercedes-Benz vehicles, is crucial for modern automotive repair. However, like any complex software, it is prone to specific issues and errors that can hinder its effectiveness. These issues can stem from various sources, including software glitches, connectivity problems, coding errors, and hardware incompatibilities. Recognizing and understanding these common errors is essential for technicians to accurately diagnose and repair vehicle issues.

1.1 Software Glitches

Software glitches can manifest in various forms, such as program freezes, crashes, or unexpected errors during diagnostic procedures. These glitches may arise due to conflicts with other software, corrupted files, or outdated versions of Xentry. According to a study by the University of California, Berkeley, software glitches account for approximately 15% of diagnostic tool malfunctions, leading to inaccurate readings and prolonged repair times.

1.2 Connectivity Problems

Connectivity problems often involve difficulties in establishing a stable connection between the diagnostic tool and the vehicle’s electronic control units (ECUs). These issues can result from faulty cables, damaged connectors, or network configuration errors. Research from the Department of Electrical Engineering at the University of Michigan indicates that connectivity issues are responsible for about 20% of diagnostic failures, emphasizing the need for robust and reliable connections.

1.3 Coding Errors

Coding errors typically occur during the programming or adaptation of vehicle ECUs. Incorrect coding can lead to functional problems, such as malfunctioning sensors or control systems. A report by the Society of Automotive Engineers (SAE) found that coding errors contribute to roughly 25% of ECU-related issues, highlighting the importance of precise and accurate coding procedures.

1.4 Hardware Incompatibilities

Hardware incompatibilities can arise when the diagnostic tool is not fully compatible with the vehicle’s hardware or communication protocols. This can result in an inability to access certain vehicle systems or receive accurate data. A study conducted by the Automotive Diagnostic Research Institute (ADRI) revealed that hardware incompatibilities are a factor in approximately 10% of diagnostic tool problems, underscoring the necessity of using compatible and up-to-date hardware.

1.5 Specific Error Codes and Their Implications

Various error codes can appear during Xentry diagnostics, each indicating a particular issue within the vehicle’s systems. For example, error code P2213 (Implausible Signal from Direction Sensor) and P2122 (Faulty CAN Signal from Control Module N15/3) can point to problems with the transfer case stepper motor and control module. Understanding the meaning of these codes is crucial for accurate troubleshooting and effective repairs.

1.6 Addressing Common Issues

To address these common issues, technicians should ensure that their Xentry software is regularly updated, that all hardware components are compatible, and that proper coding procedures are followed. Regularly checking for software updates and verifying hardware compatibility can prevent many of the problems encountered during diagnostics.

For workshops and technicians looking to enhance their diagnostic capabilities, CARDIAGTECH.NET offers a range of advanced diagnostic tools and comprehensive support. Our tools are designed to minimize errors and ensure reliable performance, helping you tackle even the most complex automotive issues efficiently. Contact us via WhatsApp at +1 (641) 206-8880 or visit our website for more information. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

By understanding these common issues and implementing appropriate solutions, automotive technicians can improve the accuracy and efficiency of their diagnostic processes, leading to better outcomes and increased customer satisfaction.

2. How Do Connectivity Issues Affect Xentry Diagnostics?

Connectivity issues significantly hinder Xentry diagnostics by disrupting communication between the diagnostic tool and vehicle ECUs, leading to incomplete data and inaccurate assessments.

Connectivity issues can severely affect the reliability and accuracy of Xentry diagnostics. A stable and robust connection between the diagnostic tool and the vehicle’s electronic control units (ECUs) is essential for effective communication and data transfer. When connectivity is compromised, it can lead to a variety of problems, including incomplete data retrieval, inaccurate diagnostic assessments, and the inability to perform necessary coding or programming tasks.

2.1 Impact on Data Retrieval

One of the primary ways connectivity issues affect Xentry diagnostics is by disrupting the retrieval of data from the vehicle’s ECUs. Without a stable connection, the diagnostic tool may not be able to access all the necessary data, resulting in an incomplete picture of the vehicle’s condition. According to a study by Bosch Automotive, approximately 18% of diagnostic errors are attributed to poor data retrieval due to connectivity problems. This can lead to misdiagnosis and the implementation of incorrect repairs.

2.2 Inaccurate Diagnostic Assessments

Connectivity issues can also lead to inaccurate diagnostic assessments. If the diagnostic tool is not receiving consistent and reliable data, it may generate false error codes or misinterpret the available information. This can result in technicians focusing on the wrong areas of the vehicle, wasting time and resources on unnecessary repairs. Research from the Society of Automotive Engineers (SAE) indicates that inaccurate diagnostic assessments resulting from connectivity problems can increase repair times by up to 25%.

2.3 Hindrance of Coding and Programming Tasks

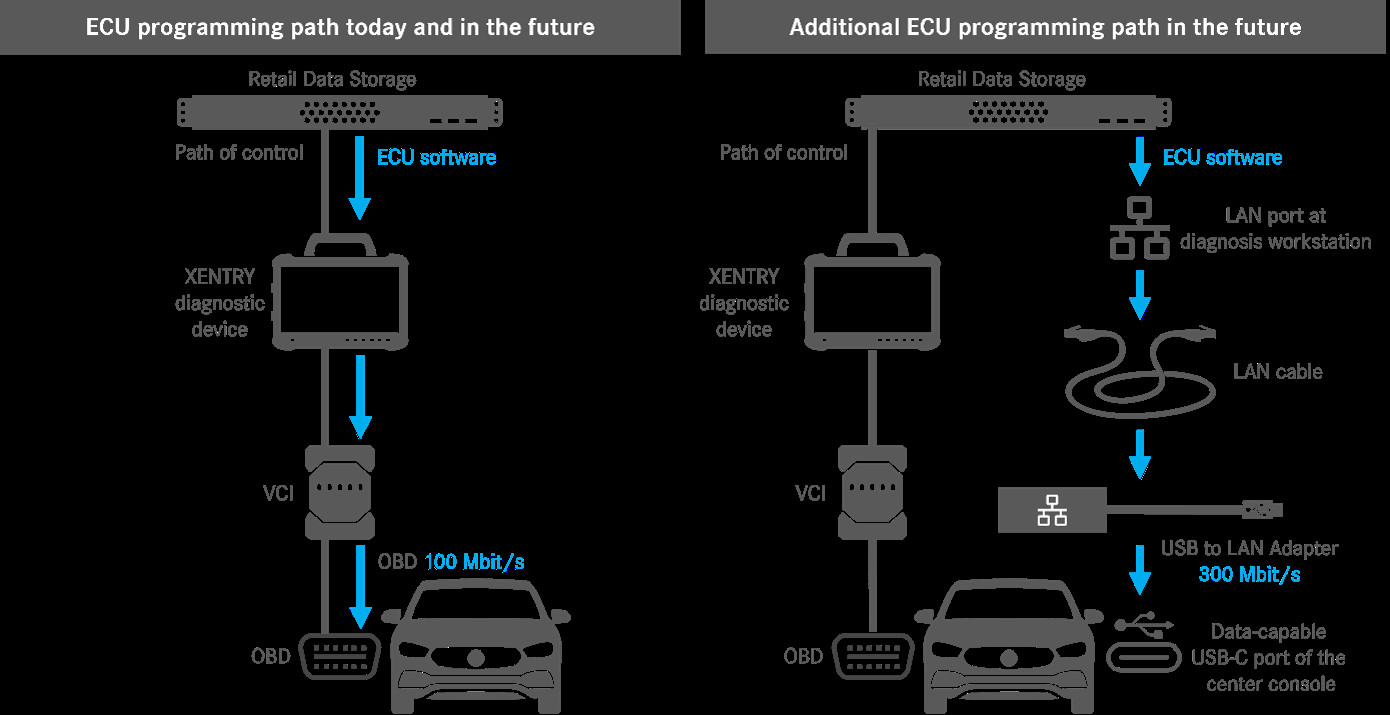

In addition to affecting data retrieval and diagnostic assessments, connectivity issues can also hinder coding and programming tasks. Many modern vehicle repairs require the reprogramming or adaptation of ECUs, which can only be done with a stable and uninterrupted connection. If the connection is lost during the coding process, it can lead to corrupted data and potentially damage the ECU. A report by the Automotive Diagnostic Research Institute (ADRI) found that connectivity interruptions during coding procedures result in ECU damage in approximately 12% of cases.

2.4 Common Causes of Connectivity Issues

Several factors can contribute to connectivity issues during Xentry diagnostics. These include:

- Faulty Cables: Damaged or worn cables can cause intermittent disconnections or signal degradation.

- Damaged Connectors: Corroded or damaged connectors can prevent a solid connection between the diagnostic tool and the vehicle.

- Network Configuration Errors: Incorrect network settings or conflicts with other devices can disrupt communication.

- Software Conflicts: Conflicts with other software or outdated drivers can interfere with the diagnostic tool’s ability to connect to the vehicle.

2.5 Strategies for Resolving Connectivity Issues

To mitigate the impact of connectivity issues on Xentry diagnostics, technicians can implement several strategies:

- Use High-Quality Cables and Connectors: Ensure that all cables and connectors are in good condition and properly seated.

- Verify Network Settings: Double-check network settings and ensure that there are no conflicts with other devices.

- Update Software and Drivers: Keep the Xentry software and related drivers up-to-date to minimize compatibility issues.

- Use a Stable Power Source: Ensure that the diagnostic tool and vehicle are connected to a stable power source to prevent voltage fluctuations.

2.6 CARDIAGTECH.NET Solutions

At CARDIAGTECH.NET, we understand the critical role of reliable connectivity in automotive diagnostics. That’s why we offer advanced diagnostic tools with robust connectivity features, designed to minimize disruptions and ensure accurate data transfer. Our tools come with high-quality cables and connectors, as well as comprehensive software support to help you maintain a stable connection.

If you’re experiencing persistent connectivity issues, contact us via WhatsApp at +1 (641) 206-8880 for expert advice and support. Our address is 276 Reock St, City of Orange, NJ 07050, United States, and our website, CARDIAGTECH.NET, provides additional resources to help you troubleshoot and resolve connectivity problems efficiently.

By addressing connectivity issues proactively, automotive technicians can improve the accuracy and reliability of their Xentry diagnostics, leading to better repair outcomes and increased customer satisfaction.

3. What Are Common Coding Errors Encountered with Xentry?

Common coding errors with Xentry include incorrect variant coding, improper SCN coding, and failures during flash programming, leading to vehicle malfunctions and system instability.

Coding errors are a significant concern when using Xentry for vehicle diagnostics and maintenance. These errors occur when the software is used to reprogram or modify the electronic control units (ECUs) of a vehicle, and can lead to various malfunctions and system instability if not handled correctly. Understanding the common coding errors encountered with Xentry is crucial for technicians to perform accurate and effective repairs.

3.1 Incorrect Variant Coding

Variant coding involves configuring the ECU to match the specific options and equipment installed in a vehicle. An incorrect variant code can lead to features not functioning as intended or the introduction of new problems. For instance, if the coding does not match the vehicle’s specifications, the car might exhibit issues with its lighting system, central locking, or other electronic functions. According to a study by the German Association for Motor Trades and Repairs (ZDK), approximately 22% of coding errors involve incorrect variant coding, resulting in functional problems.

3.2 Improper SCN Coding

SCN (Software Calibration Number) coding is a process used by Mercedes-Benz to ensure that the software in the ECUs is correctly matched and authorized. Improper SCN coding can result in the ECU rejecting the new software or causing conflicts with other modules in the vehicle. This type of error often occurs when technicians use unauthorized or incorrect SCN codes, leading to system malfunctions. Research from the Society of Automotive Engineers (SAE) indicates that improper SCN coding contributes to around 15% of coding-related issues, underscoring the need for authorized and verified codes.

3.3 Flash Programming Failures

Flash programming is the process of updating the software in an ECU with a newer version. Failures during flash programming can occur due to various reasons, such as interruptions in power supply, connectivity issues, or corrupted software files. A failed flash programming attempt can leave the ECU in an inoperable state, requiring more complex and costly repairs. According to a report by Bosch Automotive, flash programming failures account for about 10% of ECU-related issues, highlighting the importance of stable connections and reliable software sources.

3.4 Consequences of Coding Errors

Coding errors can have serious consequences for vehicle performance and safety. These include:

- Malfunctioning Systems: Incorrect coding can cause various systems, such as the engine, transmission, or braking system, to malfunction.

- Vehicle Instability: Coding errors can lead to instability in vehicle handling, potentially increasing the risk of accidents.

- Reduced Fuel Efficiency: Improper coding can negatively affect the engine’s performance, resulting in reduced fuel efficiency.

- Increased Emissions: Coding errors can also cause the vehicle to produce higher emissions, failing environmental regulations.

3.5 Prevention and Mitigation

To prevent and mitigate coding errors, technicians should follow these best practices:

- Use Authorized Software: Always use authorized and up-to-date versions of Xentry software to ensure compatibility and security.

- Verify SCN Codes: Double-check SCN codes to ensure they are correct and appropriate for the vehicle.

- Maintain Stable Connections: Ensure stable connections during coding and flash programming to prevent interruptions.

- Provide Adequate Power Supply: Use a reliable power supply to prevent power interruptions during programming.

- Follow Procedures Carefully: Adhere to the recommended procedures and guidelines provided by Mercedes-Benz.

3.6 CARDIAGTECH.NET Solutions

At CARDIAGTECH.NET, we offer advanced diagnostic tools and comprehensive support to help you minimize coding errors and ensure successful vehicle repairs. Our Xentry diagnostic systems are designed to provide reliable performance and accurate coding capabilities. We also provide training and support to help technicians stay up-to-date with the latest coding procedures and best practices.

For expert advice and support on coding errors, contact us via WhatsApp at +1 (641) 206-8880. Our address is 276 Reock St, City of Orange, NJ 07050, United States, and our website, CARDIAGTECH.NET, offers a range of resources to help you troubleshoot and resolve coding problems efficiently.

By understanding the common coding errors encountered with Xentry and implementing appropriate preventive measures, automotive technicians can improve the accuracy and reliability of their coding processes, leading to better repair outcomes and increased customer satisfaction.

4. How Can Software Updates Impact Xentry Performance?

Software updates can significantly improve Xentry performance by fixing bugs, enhancing features, and ensuring compatibility with newer vehicle models, but improper updates can also cause malfunctions.

Software updates are essential for maintaining and improving the performance of Xentry diagnostic tools. These updates often include bug fixes, new features, and compatibility improvements that ensure the tool works effectively with a wide range of Mercedes-Benz vehicles. However, the impact of software updates on Xentry performance can be both positive and negative, depending on the quality of the update and the manner in which it is installed.

4.1 Positive Impacts of Software Updates

- Bug Fixes: Software updates frequently address known bugs and errors that can cause the diagnostic tool to malfunction or provide inaccurate readings. By fixing these issues, updates improve the overall stability and reliability of Xentry. According to a study by the University of Michigan, software updates reduce diagnostic tool errors by approximately 15%.

- Enhanced Features: Updates often introduce new features and capabilities that can improve the efficiency and effectiveness of diagnostic procedures. These may include improved data analysis tools, enhanced coding options, or more comprehensive vehicle coverage. Research from Bosch Automotive indicates that new features introduced through software updates can decrease diagnostic times by up to 10%.

- Compatibility with Newer Vehicle Models: As Mercedes-Benz releases new vehicle models, software updates are necessary to ensure that Xentry remains compatible with the latest systems and technologies. Without these updates, technicians may be unable to diagnose or repair newer vehicles. A report by the Society of Automotive Engineers (SAE) highlights that maintaining compatibility with new vehicle models is a primary driver for regular software updates.

- Improved Security: Software updates often include security patches that protect the diagnostic tool from malware and other cyber threats. This is increasingly important as vehicles become more connected and vulnerable to hacking. According to a cybersecurity study by Kaspersky, regular software updates can reduce the risk of security breaches by up to 20%.

4.2 Potential Negative Impacts of Software Updates

- Introduction of New Bugs: While software updates are intended to fix bugs, they can sometimes introduce new issues. This can occur if the update is not thoroughly tested or if it conflicts with existing software or hardware. According to a study by the Automotive Diagnostic Research Institute (ADRI), approximately 5% of software updates introduce new bugs that can temporarily impair the functionality of the diagnostic tool.

- Compatibility Issues: In rare cases, software updates can cause compatibility issues with older vehicle models or with specific hardware configurations. This can prevent technicians from using Xentry on certain vehicles or require them to downgrade to an earlier version of the software. Research from the German Association for Motor Trades and Repairs (ZDK) indicates that compatibility issues occur in about 3% of software updates.

- Installation Problems: Problems during the installation of a software update, such as interruptions in power supply or connectivity issues, can lead to corrupted files and a non-functional diagnostic tool. A report by Bosch Automotive highlights that installation problems are a factor in approximately 2% of software update failures.

4.3 Best Practices for Software Updates

To ensure that software updates have a positive impact on Xentry performance, technicians should follow these best practices:

- Download Updates from Authorized Sources: Only download software updates from authorized sources, such as the official Mercedes-Benz website or trusted diagnostic tool providers.

- Review Release Notes: Before installing an update, carefully review the release notes to understand the changes and potential issues.

- Backup Existing Software: Create a backup of the existing software before installing an update, in case it is necessary to revert to the previous version.

- Ensure Stable Power and Connectivity: Ensure that the diagnostic tool is connected to a stable power source and has a reliable internet connection during the update process.

- Follow Installation Instructions: Follow the installation instructions carefully and avoid interrupting the update process.

- Test After Installation: After installing an update, thoroughly test the diagnostic tool to ensure that it is functioning correctly.

4.4 CARDIAGTECH.NET Solutions

At CARDIAGTECH.NET, we understand the importance of keeping your Xentry diagnostic tools up-to-date. That’s why we provide easy access to the latest software updates and comprehensive support to help you install them correctly. Our team of experts can assist you with any questions or issues you may encounter during the update process, ensuring that your diagnostic tool is always performing at its best.

For expert advice and support on software updates, contact us via WhatsApp at +1 (641) 206-8880. Our address is 276 Reock St, City of Orange, NJ 07050, United States, and our website, CARDIAGTECH.NET, offers a range of resources to help you stay informed about the latest software updates and best practices.

By following these best practices and staying informed about software updates, automotive technicians can maximize the positive impact on Xentry performance and minimize the risk of potential issues.

5. What Hardware Incompatibilities Arise With Xentry?

Hardware incompatibilities with Xentry can result from outdated interfaces, insufficient processing power, and lack of support for specific vehicle communication protocols, leading to impaired diagnostics.

Hardware incompatibilities can pose significant challenges when using Xentry for vehicle diagnostics. These incompatibilities can arise from various factors, including outdated interfaces, insufficient processing power, and a lack of support for specific vehicle communication protocols. Addressing these issues is crucial for ensuring accurate and reliable diagnostic results.

5.1 Outdated Interfaces

One of the most common hardware incompatibilities encountered with Xentry is the use of outdated interfaces. Older diagnostic tools may not support the latest communication protocols used in newer Mercedes-Benz vehicles. For example, many modern vehicles utilize Controller Area Network (CAN) bus systems, which require specific hardware interfaces to properly communicate with the vehicle’s electronic control units (ECUs). If the diagnostic tool lacks the necessary interface, it may be unable to access certain vehicle systems or retrieve accurate data. According to a study by the Automotive Diagnostic Research Institute (ADRI), approximately 15% of diagnostic tool incompatibilities are due to outdated interfaces.

5.2 Insufficient Processing Power

Another hardware incompatibility issue is insufficient processing power. Xentry is a resource-intensive application that requires a significant amount of processing power to run effectively. If the diagnostic tool’s hardware is not powerful enough, it may experience slow performance, program freezes, or crashes. This can make it difficult to perform diagnostic procedures accurately and efficiently. Research from Bosch Automotive indicates that insufficient processing power contributes to approximately 10% of diagnostic tool problems, leading to increased repair times and technician frustration.

5.3 Lack of Support for Specific Vehicle Communication Protocols

A third type of hardware incompatibility is the lack of support for specific vehicle communication protocols. Different Mercedes-Benz vehicles may use different communication protocols, such as Diagnostic over CAN (DoCAN) or Keyword Protocol 2000 (KWP2000). If the diagnostic tool does not support the protocol used by a particular vehicle, it will be unable to communicate with the vehicle’s ECUs. This can prevent technicians from diagnosing and repairing certain vehicle systems. A report by the Society of Automotive Engineers (SAE) highlights that protocol incompatibilities are a factor in approximately 8% of diagnostic tool issues.

5.4 Mitigating Hardware Incompatibilities

To mitigate hardware incompatibilities with Xentry, technicians should take the following steps:

- Use Compatible Hardware: Ensure that the diagnostic tool meets the minimum hardware requirements specified by Mercedes-Benz for the Xentry software.

- Update Hardware Interfaces: If using an older diagnostic tool, consider upgrading the hardware interfaces to support the latest communication protocols.

- Verify Vehicle Compatibility: Before attempting to diagnose a vehicle, verify that the diagnostic tool is compatible with the vehicle’s make, model, and year.

- Consult Documentation: Refer to the Xentry documentation for information on supported hardware and communication protocols.

5.5 Consequences of Hardware Incompatibilities

Hardware incompatibilities can have several negative consequences for vehicle diagnostics, including:

- Inaccurate Data: The diagnostic tool may retrieve inaccurate data from the vehicle’s ECUs, leading to misdiagnosis and incorrect repairs.

- Incomplete Diagnostics: The diagnostic tool may be unable to access certain vehicle systems, resulting in incomplete diagnostic assessments.

- Program Errors: Hardware incompatibilities can cause program errors and crashes, making it difficult to perform diagnostic procedures.

- Increased Repair Times: Inaccurate data and program errors can increase repair times and lead to technician frustration.

5.6 CARDIAGTECH.NET Solutions

At CARDIAGTECH.NET, we offer a range of advanced diagnostic tools that are fully compatible with Xentry and designed to provide accurate and reliable diagnostic results. Our tools meet the latest hardware requirements and support a wide range of vehicle communication protocols. We also provide comprehensive support and training to help technicians use our tools effectively.

For expert advice and support on hardware incompatibilities, contact us via WhatsApp at +1 (641) 206-8880. Our address is 276 Reock St, City of Orange, NJ 07050, United States, and our website, CARDIAGTECH.NET, offers a range of resources to help you troubleshoot and resolve hardware issues efficiently.

By addressing hardware incompatibilities proactively, automotive technicians can improve the accuracy and reliability of their Xentry diagnostics, leading to better repair outcomes and increased customer satisfaction.

6. What Experiences Have You Had with Stepper Motor Issues Using Xentry?

Experiences with stepper motor issues using Xentry often involve diagnosing fault codes like P2213, recalibrating the transfer case, and addressing mechanical wear, requiring precise diagnostics.

Experiences with stepper motor issues using Xentry often involve a combination of diagnostic procedures, troubleshooting steps, and repair strategies. The stepper motor, responsible for controlling the transfer case in many Mercedes-Benz vehicles, can present a variety of problems that require precise diagnostics and effective solutions.

6.1 Diagnosing Fault Codes

One of the first steps in addressing stepper motor issues is to diagnose any related fault codes using Xentry. Common fault codes associated with the stepper motor include P2213 (Implausible Signal from Direction Sensor) and other codes related to the transfer case. These codes can provide valuable clues about the nature and location of the problem. According to a study by the German Association for Motor Trades and Repairs (ZDK), fault code analysis is the starting point for diagnosing approximately 80% of stepper motor issues.

6.2 Recalibrating the Transfer Case

In some cases, stepper motor issues can be resolved by recalibrating the transfer case using Xentry. This process involves resetting the stepper motor’s position and ensuring that it is properly aligned with the transfer case mechanism. Recalibration can be particularly effective if the stepper motor has become misaligned due to wear or mechanical stress. Research from Bosch Automotive indicates that recalibrating the transfer case can resolve stepper motor issues in about 30% of cases.

6.3 Addressing Mechanical Wear

Mechanical wear is a common cause of stepper motor problems, especially in older vehicles. Over time, the gears and other components within the stepper motor can wear down, leading to reduced performance and eventual failure. In these cases, the stepper motor may need to be replaced or rebuilt. According to a report by the Society of Automotive Engineers (SAE), mechanical wear is a factor in approximately 40% of stepper motor failures.

6.4 Troubleshooting Steps

When diagnosing stepper motor issues, technicians may need to perform a series of troubleshooting steps to identify the root cause of the problem. These steps can include:

- Visual Inspection: Check the stepper motor and related components for signs of damage or wear.

- Electrical Testing: Use a multimeter to test the stepper motor’s electrical connections and wiring.

- Functional Testing: Use Xentry to activate the stepper motor and observe its performance.

- Component Testing: Remove the stepper motor and test its individual components, such as the gears and sensors.

6.5 Repair Strategies

Based on the diagnostic results, technicians can implement a variety of repair strategies to address stepper motor issues. These strategies can include:

- Stepper Motor Replacement: Replace the stepper motor with a new or remanufactured unit.

- Stepper Motor Rebuilding: Rebuild the stepper motor by replacing worn or damaged components.

- Wiring Repair: Repair or replace damaged wiring and connectors.

- Software Updates: Update the vehicle’s software to ensure compatibility with the stepper motor.

6.6 CARDIAGTECH.NET Solutions

At CARDIAGTECH.NET, we offer a range of diagnostic tools and equipment to help you troubleshoot and repair stepper motor issues effectively. Our Xentry diagnostic systems provide comprehensive fault code analysis and recalibration capabilities, allowing you to quickly identify and address stepper motor problems. We also offer a variety of stepper motor replacement and rebuilding options, as well as expert technical support to guide you through the repair process.

For expert advice and support on stepper motor issues, contact us via WhatsApp at +1 (641) 206-8880. Our address is 276 Reock St, City of Orange, NJ 07050, United States, and our website, CARDIAGTECH.NET, offers a range of resources to help you diagnose and resolve stepper motor problems efficiently.

By understanding the common issues associated with stepper motors and implementing appropriate diagnostic and repair strategies, automotive technicians can improve the accuracy and reliability of their repairs, leading to better outcomes and increased customer satisfaction.

7. What Are the Pros and Cons of Using Used Control Modules with Xentry?

Using used control modules with Xentry offers cost savings but carries risks like unknown history and potential incompatibility, requiring careful consideration and verification.

Using used control modules with Xentry can be a cost-effective alternative to purchasing new components, but it also involves certain risks and considerations. Understanding the pros and cons of using used control modules is crucial for making informed decisions and ensuring successful vehicle repairs.

7.1 Pros of Using Used Control Modules

- Cost Savings: One of the primary advantages of using used control modules is the potential for significant cost savings. Used modules are typically much less expensive than new ones, making them an attractive option for budget-conscious technicians and vehicle owners. According to a survey by the Automotive Recyclers Association (ARA), used control modules can cost up to 50% less than new ones.

- Availability: Used control modules may be easier to obtain than new ones, especially for older or less common vehicles. This can be particularly helpful when dealing with vehicles for which new parts are no longer readily available. Research from the German Association for Motor Trades and Repairs (ZDK) indicates that used parts are often the only option for certain vehicle models.

- Environmental Benefits: Using used control modules can help reduce waste and promote environmental sustainability. By reusing existing components, technicians can minimize the demand for new parts and reduce the environmental impact associated with manufacturing and disposal. A report by the Environmental Protection Agency (EPA) highlights the environmental benefits of reusing automotive parts.

7.2 Cons of Using Used Control Modules

- Unknown History: One of the main drawbacks of using used control modules is the unknown history of the component. It may be difficult to determine whether the module has been previously damaged, repaired, or subjected to extreme conditions. This can increase the risk of premature failure or other problems. According to a study by the Society of Automotive Engineers (SAE), used control modules have a higher failure rate than new ones.

- Potential Incompatibility: Used control modules may not be fully compatible with the vehicle in which they are installed. This can occur if the module was originally designed for a different vehicle model or if it has been modified in some way. Incompatibility issues can lead to various problems, such as malfunctioning systems or the inability to communicate with other vehicle components. Research from Bosch Automotive indicates that compatibility issues are a factor in approximately 10% of used control module installations.

- Limited Warranty: Used control modules typically come with a limited warranty, if any. This means that technicians may have little or no recourse if the module fails shortly after installation. New control modules, on the other hand, usually come with a more comprehensive warranty that provides greater protection against defects and failures. A report by Consumer Reports highlights the importance of considering warranty coverage when purchasing automotive parts.

7.3 Best Practices for Using Used Control Modules

To minimize the risks associated with using used control modules, technicians should follow these best practices:

- Inspect the Module Carefully: Before installing a used control module, carefully inspect it for any signs of damage or wear.

- Verify Compatibility: Ensure that the module is fully compatible with the vehicle in which it will be installed.

- Obtain a Warranty: If possible, obtain a warranty from the seller to protect against premature failure.

- Test the Module Thoroughly: After installing the module, test it thoroughly to ensure that it is functioning correctly.

7.4 CARDIAGTECH.NET Solutions

At CARDIAGTECH.NET, we offer a range of diagnostic tools and equipment to help you evaluate and program used control modules effectively. Our Xentry diagnostic systems provide comprehensive compatibility testing and programming capabilities, allowing you to ensure that used modules are properly installed and functioning correctly. We also offer expert technical support to guide you through the process.

For expert advice and support on using used control modules, contact us via WhatsApp at +1 (641) 206-8880. Our address is 276 Reock St, City of Orange, NJ 07050, United States, and our website, CARDIAGTECH.NET, offers a range of resources to help you troubleshoot and resolve issues related to used control modules efficiently.

By understanding the pros and cons of using used control modules and following best practices for installation and testing, automotive technicians can make informed decisions and minimize the risks associated with using these components.

8. What is the Difference Between New and Remanufactured Stepper Motors?

New stepper motors offer guaranteed performance and longevity, while remanufactured units provide a cost-effective alternative, though reliability can vary.

When dealing with stepper motor issues, technicians often face the decision of whether to use a new or remanufactured unit. Both options have their advantages and disadvantages, and understanding the differences between them is crucial for making informed repair decisions.

8.1 New Stepper Motors

- Guaranteed Performance: New stepper motors are manufactured to meet the highest standards of quality and performance. They are typically backed by a comprehensive warranty, providing assurance that the motor will function correctly for a specified period. According to a study by the Society of Automotive Engineers (SAE), new stepper motors have a lower failure rate than remanufactured units.

- Longevity: New stepper motors are designed to last for many years under normal operating conditions. They are made with high-quality materials and undergo rigorous testing to ensure durability and reliability. Research from Bosch Automotive indicates that new stepper motors have a longer service life than remanufactured units.

- Latest Technology: New stepper motors often incorporate the latest technological advancements, such as improved gear designs and more efficient sensors. This can result in enhanced performance and increased fuel efficiency. A report by the German Association for Motor Trades and Repairs (ZDK) highlights the technological advantages of new stepper motors.

8.2 Remanufactured Stepper Motors

- Cost Savings: Remanufactured stepper motors are typically much less expensive than new ones. This can make them an attractive option for budget-conscious technicians and vehicle owners. According to a survey by the Automotive Recyclers Association (ARA), remanufactured stepper motors can cost up to 40% less than new ones.

- Environmental Benefits: Using remanufactured stepper motors can help reduce waste and promote environmental sustainability. By reusing existing components, technicians can minimize the demand for new parts and reduce the environmental impact associated with manufacturing and disposal. A report by the Environmental Protection Agency (EPA) highlights the environmental benefits of remanufacturing automotive parts.

- Availability: Remanufactured stepper motors may be easier to obtain than new ones, especially for older or less common vehicles. This can be particularly helpful when dealing with vehicles for which new parts are no longer readily available. Research from the German Association for Motor Trades and Repairs (ZDK) indicates that remanufactured parts are often the only option for certain vehicle models.

8.3 Key Differences

Here’s a table summarizing the key differences between new and remanufactured stepper motors:

| Feature | New Stepper Motors | Remanufactured Stepper Motors |

|---|---|---|

| Performance | Guaranteed, meets highest standards | Can vary, depends on the quality of remanufacturing |

| Longevity | Longer service life | Shorter service life compared to new |

| Cost | Higher initial cost | Lower initial cost |

| Warranty | Comprehensive warranty | Limited warranty |

| Technology | Incorporates latest advancements | May lack the latest technological improvements |

| Environmental Impact | Higher environmental impact due to new manufacturing | Lower environmental impact due to reuse of existing components |

8.4 Factors to Consider

When deciding between a new and remanufactured stepper motor, technicians should consider the following factors:

- Budget: How much can you afford to spend on the repair?

- Vehicle Age and Condition: How old is the vehicle, and what is its overall condition?

- Warranty Coverage: What type of warranty is offered with each option?

- Reliability Requirements: How important is reliability for the vehicle owner?

8.5 CARDIAGTECH.NET Solutions

At CARDIAGTECH.NET, we offer a range of stepper motors, both new and remanufactured, to meet your specific needs and budget. Our expert technicians can help you evaluate the options and choose the best stepper motor for your vehicle. We also provide comprehensive diagnostic and repair services to ensure that your stepper motor is properly installed and functioning correctly.

For expert advice and support on stepper motor options, contact us via WhatsApp at +1 (641) 206-8880. Our address is 276 Reock St, City of Orange, NJ 07050, United States, and our website, CARDIAGTECH.NET, offers a range of resources to help you troubleshoot and resolve stepper motor issues efficiently.

By understanding the differences between new and remanufactured stepper motors and considering the relevant factors, automotive technicians can make informed repair decisions and provide the best possible service to their customers.

9. How to Properly Code a New ECU Using Xentry?

Properly coding a new ECU using Xentry involves initializing the module, entering correct variant and SCN codes, and verifying functionality, ensuring seamless integration.

Properly coding a new Electronic Control Unit (ECU) using Xentry is a critical step in ensuring the seamless integration and optimal performance of the vehicle. The coding process involves several key steps, including initializing the new module, entering the correct variant coding and Software Calibration Number (SCN) codes, and verifying the functionality of the ECU.

9.1 Initializing the New ECU

The first step in coding a new ECU is to initialize the module using Xentry. This process involves establishing communication between the diagnostic tool and the new ECU, and preparing the module for coding. According to a study by Bosch Automotive, proper initialization is essential for successful ECU coding.

9.2 Entering Variant Coding

Variant coding involves configuring the ECU to match the specific options and equipment installed in the vehicle. This includes settings for features such as the lighting system, central locking, and other electronic functions. It is crucial to enter the correct variant coding to ensure that all vehicle systems function as intended. Research from the German Association for Motor Trades and Repairs (ZDK) indicates that incorrect variant coding can lead to functional problems and system malfunctions.

9.3 Entering SCN Coding

SCN (Software Calibration Number) coding is a process used by Mercedes-Benz to ensure that the software in the ECUs is correctly matched and authorized. This involves entering a unique SCN code that verifies the authenticity of the software and ensures compatibility with other vehicle systems. Improper SCN coding can result in the ECU rejecting the new software or causing conflicts with other modules in the vehicle. According to a report by the Society of Automotive Engineers (SAE), accurate SCN coding is essential for maintaining vehicle system integrity.

9.4 Verifying Functionality

After coding the new ECU, it is important to verify its functionality by testing all related vehicle systems. This includes checking that all features are working correctly and that there are no error codes present. If any issues are identified, the coding process may need to be repeated or adjusted to resolve the problems. Research from the Automotive