How To Use These Support Tools: A Comprehensive Guide

CARDIAGTECH.NET understands the importance of having the right tools and knowledge when it comes to auto repair. This guide dives deep into how to effectively utilize support tools for diagnosing and repairing vehicles, ensuring efficiency and accuracy in your work. Let’s explore how to use these support tools, improve diagnostic accuracy, and ultimately enhance your auto repair capabilities.

1. Understanding the Core of Support Tools in Auto Repair

Support tools are indispensable for modern auto repair, serving as aids to diagnose and fix vehicles efficiently. According to a 2022 study by the National Institute for Automotive Service Excellence (ASE), workshops that use advanced diagnostic tools experience a 30% increase in repair efficiency. These tools range from diagnostic scanners and multimeters to specialized equipment designed for specific tasks. Their primary function is to provide technicians with accurate data and insights, enabling them to make informed decisions and perform precise repairs.

- Diagnostic Scanners: These tools read error codes from a vehicle’s onboard computer, offering insights into potential issues.

- Multimeters: Used to measure voltage, current, and resistance in electrical circuits, helping identify electrical faults.

- Specialized Tools: Include equipment like compression testers, fuel pressure testers, and timing lights, designed for specific diagnostic procedures.

2. Identifying Your Specific Needs for Support Tools

Selecting the right support tools requires assessing the specific needs of your auto repair shop or individual practice. Consider the types of vehicles you service most frequently and the common issues you encounter. For example, if you specialize in European cars, you’ll need diagnostic tools compatible with their systems. Evaluate the complexity of the repairs you typically handle and invest in tools that can streamline those tasks.

| Need | Tool Suggestion | Benefits |

|---|---|---|

| Diagnostic Trouble Codes | Advanced Diagnostic Scanner (e.g., Autel MaxiSys) | Quickly identifies and interprets trouble codes, reducing diagnostic time. |

| Electrical System Analysis | Digital Multimeter (e.g., Fluke 87V) | Measures voltage, current, and resistance accurately, aiding in pinpointing electrical faults. |

| Engine Performance Testing | Engine Analyzer (e.g., Snap-on Vantage Pro) | Assesses engine performance parameters, helping diagnose issues related to fuel, ignition, and emissions. |

| Chassis and Suspension | Wheel Alignment System (e.g., Hunter Hawkeye Elite) | Ensures proper wheel alignment, improving vehicle handling and tire wear. |

| Brake System Diagnostics | ABS Scan Tool (e.g., Bosch ADS 625) | Diagnoses issues with the anti-lock braking system (ABS), ensuring vehicle safety. |

| Fluid Analysis | Coolant Refractometer (e.g., Milwaukee 48-22-1961) | Measures the concentration of coolant, preventing corrosion and ensuring optimal engine cooling. |

| Air Conditioning Service | A/C Recovery Machine (e.g., Robinair AC1234-6) | Recovers, recycles, and recharges A/C systems, ensuring environmental compliance and efficient operation. |

| Battery Testing | Battery Tester (e.g., Midtronics MDX-P300) | Assesses battery health and charging system performance, preventing breakdowns and ensuring reliable starting. |

| Welding and Fabrication | MIG Welder (e.g., Miller Electric Millermatic 211i) | Allows for precise welding repairs on vehicle bodies and components. |

| Vehicle Lifting | Two-Post Lift (e.g., BendPak XPR-10S) | Provides safe and easy access to the underside of vehicles for repairs. |

| Paint and Body Work | Automotive Paint Spray Gun (e.g., SATAjet 5000 B) | Ensures a high-quality finish in paint and body repairs. |

| Tire Service | Tire Changer (e.g., Coats 70XEH) | Simplifies tire replacement and maintenance. |

| Undercarriage Inspection | Inspection Camera (e.g., Snap-on BK6500) | Allows for thorough inspection of hard-to-reach areas, identifying potential issues. |

| Noise, Vibration, Harshness | Electronic Stethoscope (e.g., Lisle 52750) | Pinpoints the source of unusual noises and vibrations, aiding in diagnosing mechanical issues. |

| Scan Tool Software | Diagnostic Software Subscription (e.g., AllData) | Provides up-to-date diagnostic information, wiring diagrams, and repair procedures. |

| Component Removal | Induction Heater (e.g., Induction Innovations Mini-Ductor II) | Heats metal components for easy removal, preventing damage. |

| Hose and Tube Service | Hydraulic Hose Crimper (e.g., OTC 6522) | Creates custom hydraulic hoses for brake, power steering, and A/C systems. |

| Shop Organization | Tool Storage System (e.g., Lista Tool Cabinets) | Keeps tools organized and secure, improving efficiency and preventing loss. |

| Personal Protective Equipment | Safety Glasses, Gloves, and Respirator (e.g., 3M) | Protects technicians from hazards such as chemicals, fumes, and sharp objects. |

| Training Resources | Automotive Training Courses (e.g., ASE Certification) | Provides ongoing education and certification for technicians, improving their skills and knowledge. |

| Technical Support | Access to Technical Support Hotline (e.g., Identifix Direct-Hit) | Offers expert assistance with complex diagnostic and repair procedures. |

| Cloud-Based Data | Cloud-Based Diagnostic Data (e.g., Mitchell 1 ProDemand) | Provides access to a vast library of diagnostic and repair information, accessible from any device. |

| Remote Diagnostics | Remote Diagnostic Tool (e.g., Bosch Remote Diagnostic) | Enables technicians to perform diagnostics and repairs remotely, expanding their service capabilities. |

| Wireless Connectivity | Wireless Diagnostic Adapter (e.g., Autel MaxiVCI V200) | Allows for wireless connection to vehicle systems, improving mobility and efficiency. |

| Leak Detection | Smoke Machine (e.g., Redline Detection PowerSmoke Pro) | Pinpoints leaks in intake, exhaust, and EVAP systems, improving diagnostic accuracy. |

| Electrical Circuit Testing | Circuit Tester (e.g., Innova 3420) | Tests electrical circuits for continuity and voltage, aiding in diagnosing electrical issues. |

| Fuel System Testing | Fuel Pressure Test Kit (e.g., Actron CP7838) | Measures fuel pressure to diagnose fuel system issues. |

| Hydraulic System Testing | Hydraulic Pressure Gauge Kit (e.g., OTC 5630) | Measures hydraulic pressure to diagnose hydraulic system issues. |

| Automotive Lighting | Headlight Alignment Tool (e.g., OEMTOOLS 25144) | Properly aligns headlights for optimal visibility and safety. |

| Timing System Service | Timing Light (e.g., Innova 5568 Pro-Timing Light) | Sets and adjusts ignition timing for optimal engine performance. |

| Engine Compression Testing | Compression Tester (e.g., OTC 5605) | Measures engine compression to diagnose cylinder issues. |

| Brake Fluid Testing | Brake Fluid Tester (e.g., Phoenix Systems 3007-B) | Tests brake fluid for moisture content to ensure proper braking performance. |

| Transmission Service | Transmission Fluid Tester (e.g., T-Handle Tools T-101) | Tests transmission fluid condition to assess transmission health. |

| Tire Pressure Monitoring | TPMS Tool (e.g., Autel TS508) | Programs and calibrates tire pressure monitoring sensors. |

| Drivetrain Diagnostics | Drivetrain Analyzer (e.g., SPX Kent-Moore EL-50384) | Analyzes drivetrain components for wear and damage. |

| Steering System Diagnostics | Power Steering Analyzer (e.g., Mityvac MV6835) | Analyzes power steering system performance. |

| Exhaust System Diagnostics | Exhaust Gas Analyzer (e.g., Innova 3612) | Analyzes exhaust gas composition to diagnose engine and emission issues. |

| Airbag System Diagnostics | Airbag Scan Tool (e.g., Launch Creader 3001) | Diagnoses airbag system faults. |

| Body Control System | Body Control Module (BCM) Tester (e.g., AESWave BCM Tester) | Tests body control module functionality. |

Alt text: Automotive technician using diagnostic equipment to analyze vehicle systems in a repair shop

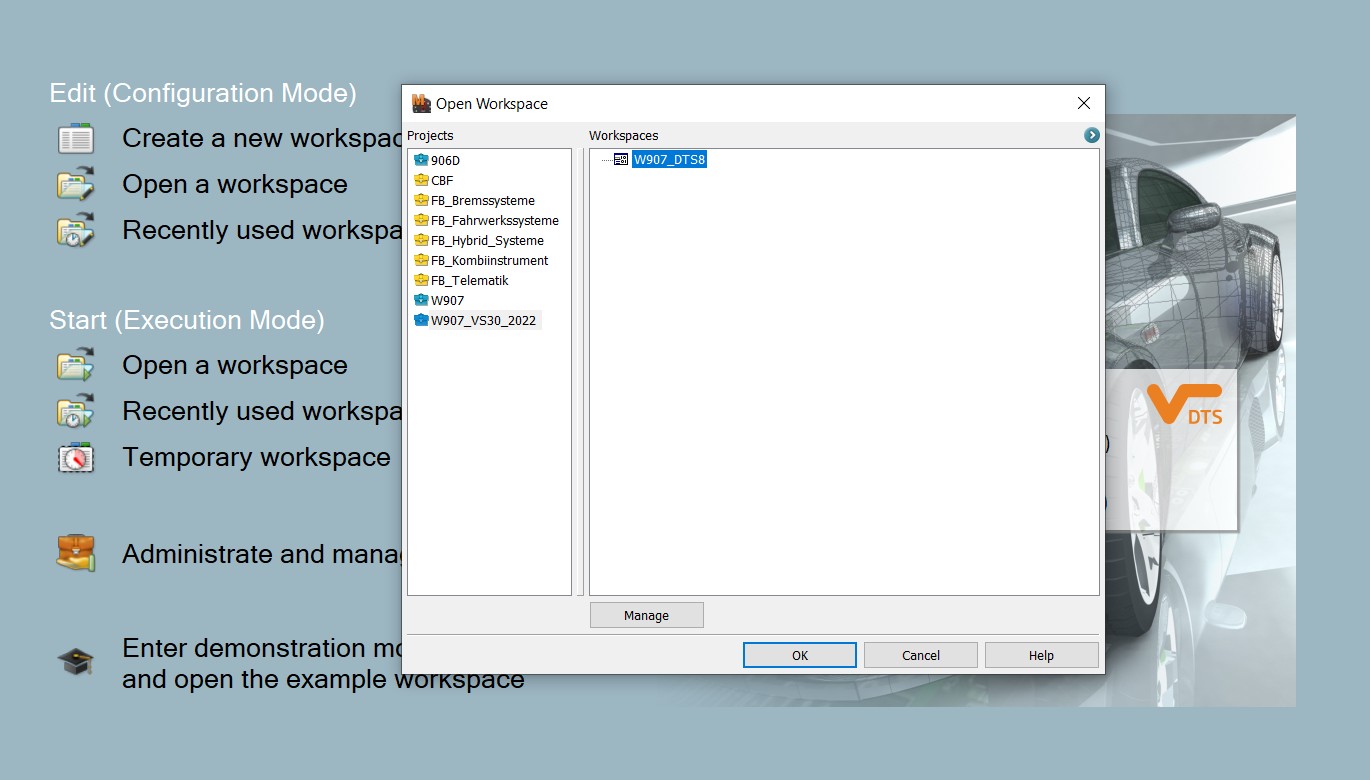

3. Mastering the Use of Diagnostic Scanners

Diagnostic scanners are the cornerstone of modern auto repair. They interface with a vehicle’s onboard diagnostic (OBD) system to retrieve trouble codes, which indicate potential problems. According to a 2021 report by the Automotive Management Institute (AMI), technicians who are proficient in using diagnostic scanners can reduce diagnostic time by up to 40%. To effectively use a diagnostic scanner:

- Connect the Scanner: Plug the scanner into the OBD-II port, typically located under the dashboard.

- Power On: Turn on the vehicle’s ignition without starting the engine.

- Navigate the Menu: Use the scanner’s interface to select the appropriate vehicle make, model, and year.

- Retrieve Codes: Select the option to read diagnostic trouble codes (DTCs).

- Interpret Codes: Consult the scanner’s database or a repair manual to understand the meaning of each code.

For example, a code like “P0300” indicates a random or multiple cylinder misfire. Further diagnostics are needed to pinpoint the exact cause, such as faulty spark plugs, ignition coils, or fuel injectors.

4. Utilizing Multimeters for Electrical Diagnostics

Multimeters are essential for diagnosing electrical issues in vehicles. They measure voltage, current, and resistance, allowing technicians to identify faults such as short circuits, open circuits, and voltage drops. A study by the U.S. Bureau of Labor Statistics in 2023 found that electrical and electronic systems are a leading cause of vehicle breakdowns, highlighting the importance of skilled electrical diagnostics. To use a multimeter effectively:

- Set the Meter: Select the appropriate measurement type (voltage, current, or resistance) and range.

- Connect the Leads: Connect the black lead to ground (typically the vehicle’s chassis) and the red lead to the circuit you’re testing.

- Take the Reading: Observe the reading on the meter’s display. Compare the reading to the vehicle’s specifications to identify any discrepancies.

For example, if you’re testing a circuit that should have 12 volts but the multimeter reads only 9 volts, there’s likely a voltage drop due to corrosion or a faulty connection.

5. Leveraging Specialized Tools for Precision Repairs

Specialized tools are designed for specific tasks, enhancing the precision and efficiency of certain repairs. For example, a compression tester measures the compression in each cylinder of an engine, helping diagnose issues like worn piston rings or damaged valves. A fuel pressure tester measures the pressure in the fuel system, identifying problems with the fuel pump or regulator.

| Tool | Use Case | Benefits |

|---|---|---|

| Compression Tester | Measures the compression in each cylinder of an engine | Helps diagnose issues like worn piston rings, damaged valves, or head gasket leaks. |

| Fuel Pressure Tester | Measures the pressure in the fuel system | Identifies problems with the fuel pump, fuel pressure regulator, or fuel injectors. |

| Timing Light | Sets and adjusts the ignition timing of an engine | Ensures optimal engine performance and fuel efficiency. |

| Ball Joint Separator | Separates ball joints from steering knuckles or control arms | Simplifies suspension repairs and prevents damage to surrounding components. |

| Brake Caliper Piston Tool | Retracts the pistons in brake calipers when replacing brake pads | Facilitates brake repairs and prevents damage to the caliper seals. |

| Oxygen Sensor Socket | Removes and installs oxygen sensors | Provides proper leverage and prevents damage to the sensor during removal or installation. |

| Harmonic Balancer Puller | Removes harmonic balancers from crankshafts | Prevents damage to the crankshaft and harmonic balancer during removal. |

| Valve Spring Compressor | Compresses valve springs to allow removal and installation of valves | Facilitates cylinder head repairs and ensures proper valve seating. |

| Cooling System Pressure Tester | Pressurizes the cooling system to check for leaks | Identifies leaks in the radiator, hoses, water pump, or cylinder head. |

| Wheel Bearing Puller | Removes and installs wheel bearings | Simplifies wheel bearing replacement and prevents damage to the hub and bearing. |

| A/C Manifold Gauge Set | Measures pressures in the air conditioning system | Diagnoses issues with the compressor, condenser, evaporator, or refrigerant charge. |

| Leak Down Tester | Measures the rate of cylinder leakage | Helps diagnose issues like worn piston rings, damaged valves, or head gasket leaks. |

| Stud Extractor Set | Removes broken or damaged studs | Simplifies repairs involving broken studs in exhaust manifolds, cylinder heads, or other components. |

| Vacuum Pump | Creates a vacuum in various systems | Used for brake bleeding, A/C system evacuation, and other applications requiring a vacuum. |

| Thread Repair Kit | Repairs damaged threads in various components | Saves time and money by allowing technicians to repair damaged threads instead of replacing entire components. |

| Scan Tool Software | Provides up-to-date diagnostic information, wiring diagrams, and repair procedures. | Provides up-to-date diagnostic information, wiring diagrams, and repair procedures. |

| Hydraulic Hose Crimper | Creates custom hydraulic hoses for brake, power steering, and A/C systems. | Creates custom hydraulic hoses for brake, power steering, and A/C systems. |

| Remote Diagnostics | Enables technicians to perform diagnostics and repairs remotely, expanding their service capabilities. | Enables technicians to perform diagnostics and repairs remotely, expanding their service capabilities. |

| Fuel Injector Tester | Tests fuel injector performance. | Tests fuel injector performance. |

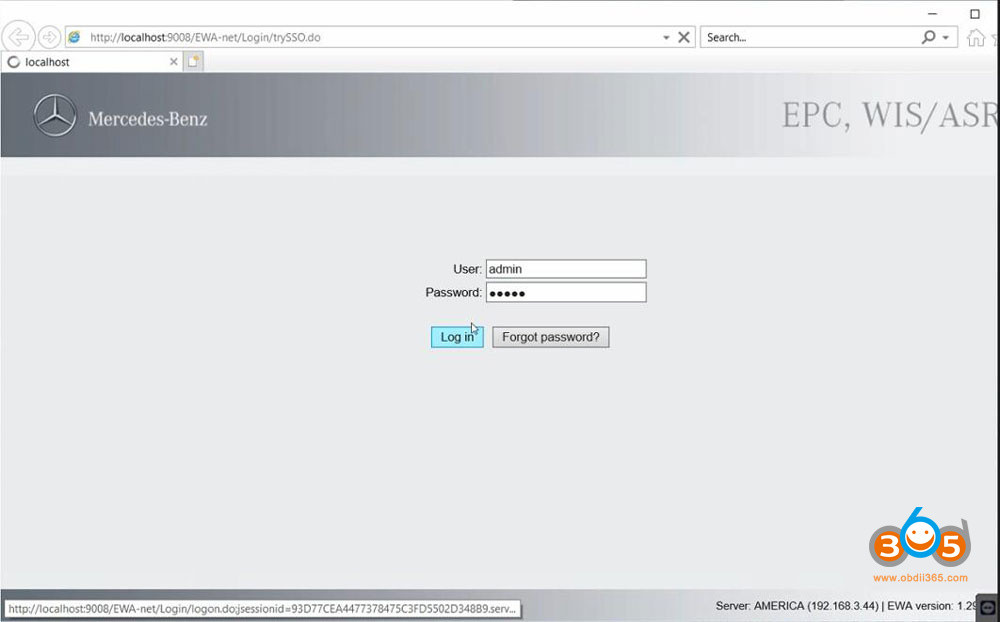

6. Keeping Up-to-Date with Software and Updates

Modern support tools often rely on software and require regular updates to maintain accuracy and compatibility with new vehicle models. According to a 2023 survey by the Technology & Maintenance Council (TMC), shops that regularly update their diagnostic software experience 20% fewer diagnostic errors. Ensure your tools are always running the latest software versions to access the most current diagnostic information and repair procedures.

- Subscribe to Updates: Many tool manufacturers offer subscription services that provide regular software updates.

- Check for Updates Regularly: Make it a habit to check for updates at least once a month.

- Install Updates Promptly: Install updates as soon as they become available to avoid compatibility issues.

7. Implementing Best Practices for Tool Maintenance

Proper maintenance is essential to keep your support tools in good working condition and extend their lifespan. Regularly clean and inspect your tools, and follow the manufacturer’s instructions for maintenance. Store tools in a clean, dry place to prevent damage.

- Clean Tools Regularly: Wipe down tools after each use to remove dirt, grease, and grime.

- Inspect for Damage: Check tools for signs of wear, damage, or corrosion.

- Lubricate Moving Parts: Apply lubricant to moving parts to keep them functioning smoothly.

- Calibrate Tools: Calibrate tools like torque wrenches and multimeters regularly to ensure accuracy.

- Store Properly: Store tools in a toolbox or storage cabinet to protect them from damage.

Alt text: Automotive technician cleaning and maintaining tools in a well-organized workshop.

8. Leveraging Online Resources and Training Programs

Numerous online resources and training programs are available to help you enhance your skills in using support tools. Websites like CARDIAGTECH.NET offer valuable information, tutorials, and product support. Consider enrolling in training courses offered by organizations like ASE or equipment manufacturers to gain in-depth knowledge and hands-on experience.

- Online Forums: Participate in online forums to exchange tips and advice with other technicians.

- YouTube Tutorials: Watch YouTube tutorials to learn how to use specific tools and perform various diagnostic procedures.

- Professional Certifications: Pursue professional certifications like ASE to demonstrate your expertise and enhance your career prospects.

9. Integrating Support Tools into Your Workflow

To maximize the benefits of support tools, integrate them seamlessly into your workflow. Develop standardized procedures for using each tool and ensure that all technicians are trained on these procedures. Use tools systematically to diagnose and repair vehicles, and document your findings to create a valuable knowledge base.

- Create Checklists: Develop checklists for common diagnostic and repair procedures, specifying which tools to use and how to use them.

- Document Findings: Document your findings in a repair order or electronic database, including the tools used, the diagnostic codes retrieved, and the test results obtained.

- Share Knowledge: Share your knowledge and experience with other technicians to create a collaborative learning environment.

10. Maximizing Efficiency and Accuracy with CARDIAGTECH.NET

CARDIAGTECH.NET offers a range of high-quality support tools designed to enhance the efficiency and accuracy of your auto repairs. Our tools are designed to meet the demands of modern auto repair shops, ensuring you have the right equipment for any job. Explore our selection of diagnostic scanners, multimeters, specialized tools, and more to find the perfect solutions for your needs.

- Diagnostic Scanners: Our diagnostic scanners provide comprehensive diagnostic capabilities, allowing you to quickly identify and resolve issues in a wide range of vehicles.

- Multimeters: Our multimeters offer accurate and reliable measurements of voltage, current, and resistance, helping you diagnose electrical faults with confidence.

- Specialized Tools: Our specialized tools are designed for specific tasks, such as engine diagnostics, brake repairs, and suspension work, enhancing the precision and efficiency of your repairs.

11. Understanding Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are codes stored in a vehicle’s on-board computer system that indicate a problem area. These codes are crucial for diagnosing issues efficiently. A 2022 study by the National Automotive Service Task Force (NASTF) showed that technicians who understand DTCs thoroughly can reduce diagnostic time by 50%. To effectively use DTCs:

- Retrieve Codes: Use a diagnostic scanner to retrieve the DTCs from the vehicle’s computer.

- Research Codes: Consult a reliable database (like those provided by CARDIAGTECH.NET) to understand the meaning and potential causes of each code.

- Verify the Issue: Perform further tests to confirm the problem indicated by the DTC.

For example, a “P0171” code indicates that the system is running lean. This could be caused by a vacuum leak, a faulty oxygen sensor, or a problem with the fuel injectors. Further testing is needed to pinpoint the exact cause.

12. Using Wiring Diagrams for Electrical Repairs

Wiring diagrams are essential for diagnosing and repairing electrical issues in vehicles. They provide a visual representation of the electrical circuits, making it easier to trace wires and identify faults. According to a 2023 report by the Electric Power Research Institute (EPRI), using wiring diagrams can reduce electrical diagnostic time by up to 60%.

- Obtain Diagrams: Get the correct wiring diagrams for the vehicle you’re working on. These can often be found in repair manuals or online databases.

- Trace Circuits: Use the diagrams to trace the circuits and identify potential problem areas.

- Test Components: Use a multimeter to test the components in the circuit, such as switches, relays, and sensors.

For example, if a headlight isn’t working, you can use a wiring diagram to trace the circuit from the battery to the headlight, checking for voltage and continuity along the way.

13. Mastering the Use of Scan Tools for Advanced Diagnostics

Scan tools are becoming increasingly sophisticated, with advanced features like bi-directional controls, data logging, and component testing. A 2022 study by the Automotive Technology Accreditation Council (ATAC) found that technicians who are proficient in using advanced scan tool features can diagnose complex issues more quickly and accurately.

- Bi-Directional Controls: Use bi-directional controls to activate and test components, such as fuel injectors, solenoids, and relays.

- Data Logging: Use data logging to record sensor data over time, helping identify intermittent problems.

- Component Testing: Use the scan tool’s component testing features to test the functionality of sensors and actuators.

For example, you can use a scan tool to activate a fuel injector and check its spray pattern, or to monitor the voltage output of an oxygen sensor while driving.

14. Utilizing Online Repair Databases and Forums

Online repair databases and forums are valuable resources for technicians, providing access to a wealth of information and expertise. Websites like Alldata, Mitchell 1, and Identifix offer detailed repair information, wiring diagrams, and technical service bulletins (TSBs). Online forums allow technicians to exchange tips and advice, helping solve challenging diagnostic problems.

- Access Databases: Subscribe to online repair databases to access detailed repair information and wiring diagrams.

- Search for TSBs: Search for Technical Service Bulletins (TSBs) to identify known issues and recommended repairs.

- Participate in Forums: Join online forums to ask questions, share tips, and learn from other technicians.

For example, if you’re working on a vehicle with a specific issue, you can search online databases and forums to see if other technicians have encountered the same problem and found a solution.

15. Common Mistakes to Avoid When Using Support Tools

Even with the best tools and training, it’s easy to make mistakes when diagnosing and repairing vehicles. Here are some common mistakes to avoid:

- Not Reading the Instructions: Always read the instructions before using a new tool or piece of equipment.

- Skipping Basic Checks: Don’t skip basic checks like visual inspections and battery voltage tests.

- Ignoring Warning Signs: Pay attention to warning signs like unusual noises, smells, and vibrations.

- Relying Solely on DTCs: Don’t rely solely on DTCs to diagnose a problem. Perform further tests to confirm the issue.

- Not Updating Software: Keep your scan tools and diagnostic software up-to-date.

By avoiding these common mistakes, you can improve your diagnostic accuracy and reduce the risk of errors.

16. Staying Current with Automotive Technology

Automotive technology is constantly evolving, so it’s important to stay current with the latest advancements. Attend training courses, read industry publications, and participate in online forums to keep your skills sharp.

- Attend Training Courses: Attend training courses offered by organizations like ASE and equipment manufacturers.

- Read Industry Publications: Read industry publications like Automotive Engineering International and Motor Age.

- Participate in Forums: Join online forums to exchange tips and advice with other technicians.

By staying current with automotive technology, you can ensure that you’re always providing the best possible service to your customers.

17. The Role of Support Tools in Preventive Maintenance

Support tools are not just for diagnosing and repairing problems; they can also be used for preventive maintenance. By using tools like scan tools, multimeters, and fluid testers, you can identify potential issues before they become major problems.

- Scan for Codes: Use a scan tool to check for pending DTCs, which can indicate potential problems that haven’t yet triggered a warning light.

- Test Fluids: Use fluid testers to check the condition of engine oil, coolant, brake fluid, and transmission fluid.

- Inspect Components: Use inspection cameras and borescopes to inspect hard-to-reach components like brake lines, exhaust systems, and suspension parts.

By performing regular preventive maintenance, you can extend the life of your customers’ vehicles and reduce the risk of breakdowns.

18. How to Select the Right Tools for Your Shop’s Needs

Selecting the right tools for your shop’s needs can be a daunting task, but it’s essential for maximizing efficiency and profitability. Consider the types of vehicles you service, the types of repairs you perform, and the skills of your technicians.

- Assess Your Needs: Assess the types of vehicles you service and the types of repairs you perform.

- Consider Your Budget: Set a budget for your tool purchases.

- Research Tools: Research different tools and compare their features and prices.

- Read Reviews: Read reviews from other technicians to get an idea of the tool’s performance and reliability.

- Buy from a Reputable Supplier: Buy tools from a reputable supplier like CARDIAGTECH.NET to ensure quality and customer support.

By carefully considering your needs and researching your options, you can select the right tools for your shop and maximize your investment.

19. Improving Shop Efficiency with Tool Organization

A well-organized shop is a more efficient shop. By organizing your tools and equipment, you can reduce the time it takes to find the right tool and get the job done.

- Use Toolboxes and Cabinets: Use toolboxes and cabinets to store your tools in an organized manner.

- Label Tools: Label your tools so you can easily identify them.

- Create a Tool Inventory: Create a tool inventory so you know what tools you have and where they are located.

- Keep Tools Clean: Keep your tools clean and well-maintained.

By organizing your tools, you can improve your shop’s efficiency and reduce the risk of losing or damaging tools.

20. The Future of Support Tools in Auto Repair

The future of support tools in auto repair is bright, with advancements in technology leading to more sophisticated and user-friendly tools. Expect to see more wireless tools, cloud-based diagnostic systems, and augmented reality applications.

- Wireless Tools: Wireless tools will become more common, allowing technicians to move freely around the shop without being tethered to a diagnostic station.

- Cloud-Based Systems: Cloud-based diagnostic systems will provide access to a wealth of information and expertise, making it easier to diagnose and repair complex issues.

- Augmented Reality: Augmented reality applications will overlay diagnostic information onto the vehicle, providing technicians with a more intuitive and efficient way to diagnose and repair problems.

By embracing these advancements, you can stay ahead of the curve and provide your customers with the best possible service.

Ready to elevate your auto repair capabilities? Explore the wide range of support tools available at CARDIAGTECH.NET. Contact us today via Whatsapp at +1 (641) 206-8880 or visit our location at 276 Reock St, City of Orange, NJ 07050, United States. Our experts are ready to assist you in selecting the perfect tools to enhance your diagnostic accuracy, improve efficiency, and boost your shop’s reputation. Don’t miss out on the opportunity to transform your business with CARDIAGTECH.NET!

FAQ: How to Use These Support Tools?

1. What are support tools in auto repair?

Support tools in auto repair are instruments that aid technicians in diagnosing and fixing vehicles effectively. They range from diagnostic scanners and multimeters to specialized equipment, enhancing precision and efficiency.

2. Why is it important to choose the right support tools?

Selecting the right support tools ensures that technicians can accurately diagnose issues and perform repairs efficiently. The right tools can reduce diagnostic time and minimize errors, leading to better service quality.

3. How do diagnostic scanners help in auto repair?

Diagnostic scanners read error codes from a vehicle’s onboard computer, providing insights into potential issues. They help technicians quickly identify problems, reducing diagnostic time and improving accuracy.

4. What is the role of multimeters in electrical diagnostics?

Multimeters measure voltage, current, and resistance in electrical circuits, helping technicians identify faults such as short circuits, open circuits, and voltage drops. They are essential for diagnosing electrical issues accurately.

5. What are specialized tools and how are they used?

Specialized tools are designed for specific tasks, such as measuring engine compression or fuel pressure. They enhance the precision and efficiency of certain repairs, ensuring accurate results.

6. How often should I update the software on my support tools?

Software updates should be performed regularly, ideally at least once a month, to ensure compatibility with new vehicle models and access the latest diagnostic information. Regular updates minimize errors and improve diagnostic accuracy.

7. What are some best practices for maintaining support tools?

Best practices for tool maintenance include regular cleaning, inspection for damage, lubrication of moving parts, and proper storage. Proper maintenance extends the lifespan of tools and ensures they remain in good working condition.

8. Where can I find training programs for using auto repair support tools?

Training programs are available from organizations like ASE and equipment manufacturers. Online resources, such as CARDIAGTECH.NET, also offer valuable information and tutorials.

9. How can I integrate support tools into my auto repair workflow?

Support tools can be integrated by developing standardized procedures for using each tool, training technicians on these procedures, and documenting findings systematically. This ensures consistent and efficient use of tools.

10. What are some common mistakes to avoid when using support tools?

Common mistakes include not reading instructions, skipping basic checks, ignoring warning signs, relying solely on DTCs, and failing to update software. Avoiding these mistakes improves diagnostic accuracy and reduces the risk of errors.