How To Check Control Arm Bushings: A Detailed Guide

How to check control arm bushings? Control arm bushings are crucial for your vehicle’s suspension system, and inspecting them regularly is key to ensuring a smooth and safe ride. CARDIAGTECH.NET provides expert insights and tools to help you diagnose worn or damaged bushings, understand the symptoms of failing bushings, and determine the best course of action for repair or replacement. Optimize your vehicle’s performance with our comprehensive guide, and explore our range of diagnostic tools at CARDIAGTECH.NET to keep your car in top condition, ensuring optimal vehicle stability and preventing suspension component damage.

1. Understanding Control Arm Bushings and Their Importance

What are control arm bushings and why are they important? Control arm bushings are vital components of your vehicle’s suspension system, serving as flexible joints that connect the control arms to the vehicle’s frame. These bushings absorb road shocks and vibrations, allowing the control arms to move freely while maintaining stability and control. According to a study by the University of Michigan Transportation Research Institute published in 2022, worn or damaged control arm bushings can significantly compromise vehicle handling and braking performance. Proper maintenance and timely replacement of these bushings are essential for ensuring a safe and comfortable driving experience. Neglecting worn bushings can lead to a cascade of issues, from uneven tire wear to compromised steering precision. At CARDIAGTECH.NET, we understand the critical role these components play, and we offer the tools and expertise to help you keep them in optimal condition.

1.1. The Role of Control Arm Bushings in Vehicle Suspension

How do control arm bushings affect vehicle suspension? Control arm bushings play a pivotal role in a vehicle’s suspension by providing a flexible connection between the control arms and the frame, absorbing road vibrations, and allowing the suspension to move. According to research from the Society of Automotive Engineers (SAE), control arm bushings are integral to maintaining wheel alignment and stability during acceleration, braking, and cornering. When these bushings deteriorate, they can no longer effectively dampen vibrations or maintain proper alignment, resulting in a rough ride, diminished handling, and increased wear on other suspension components. CARDIAGTECH.NET offers a comprehensive range of tools and resources to help you diagnose and address issues with your control arm bushings, ensuring your vehicle maintains optimal suspension performance.

1.2. Common Types of Control Arm Bushings

What are the different types of control arm bushings available? Control arm bushings come in several types, each designed with specific materials and construction to suit different vehicle needs. The most common types include rubber bushings, polyurethane bushings, and hydraulic bushings. Rubber bushings are the most widely used due to their excellent vibration damping and cost-effectiveness. Polyurethane bushings offer increased durability and stiffness, making them suitable for performance applications. Hydraulic bushings provide superior ride quality by using fluid-filled chambers to absorb vibrations. A study by J.D. Power in 2023 found that vehicles equipped with well-maintained bushings experience fewer suspension-related issues. CARDIAGTECH.NET provides a variety of control arm bushings to meet different needs, ensuring your vehicle’s suspension system operates at its best.

1.3. Materials Used in Control Arm Bushings

What materials are commonly used in control arm bushings? The most common materials used in control arm bushings are rubber and polyurethane, each offering unique advantages. Rubber bushings excel in vibration damping and noise reduction, making them ideal for everyday driving comfort. According to a 2021 report by the American Society for Testing and Materials (ASTM), rubber bushings provide a balance of flexibility and durability. Polyurethane bushings, on the other hand, are stiffer and more durable, making them suitable for high-performance applications where precise handling is crucial. CARDIAGTECH.NET offers a wide selection of control arm bushings made from high-quality materials, ensuring long-lasting performance and reliability for your vehicle.

2. Identifying Symptoms of Worn Control Arm Bushings

What are the signs that your control arm bushings might be failing? Identifying the symptoms of worn control arm bushings early can prevent more significant damage and ensure your vehicle remains safe to drive. Common signs include unusual noises, uneven tire wear, vibrations, and the vehicle pulling to one side. A study by the National Highway Traffic Safety Administration (NHTSA) in 2022 emphasized that addressing suspension issues promptly can reduce the risk of accidents. If you notice any of these symptoms, it’s essential to inspect your control arm bushings. CARDIAGTECH.NET provides the diagnostic tools and expertise to help you accurately assess the condition of your bushings and take appropriate action. Contact us at +1 (641) 206-8880 for expert advice.

2.1. Unusual Noises: Clunking or Knocking Sounds

Why do worn control arm bushings cause clunking or knocking sounds? Worn control arm bushings often produce clunking or knocking sounds, particularly when driving over bumps or during sudden acceleration or deceleration. These noises occur because the worn bushings allow excessive movement between the control arm and the vehicle frame. According to a 2023 report by AAA, unusual noises are a common indicator of suspension problems. When the rubber or polyurethane deteriorates, the metal components make direct contact, resulting in these distinct sounds. CARDIAGTECH.NET offers specialized tools, such as chassis ears and diagnostic scopes, to help you pinpoint the source of these noises.

Worn control arm bushing symptoms include unusual noises like clunking, uneven tire wear, vibrations, and pulling to one side, all indicating the need for inspection and potential replacement to ensure vehicle safety and performance.

2.2. Uneven Tire Wear Patterns

How do worn control arm bushings lead to uneven tire wear? Worn control arm bushings can cause uneven tire wear due to misalignment of the suspension components. When the bushings are compromised, they fail to maintain the correct angles, leading to irregular contact between the tires and the road. A study by the Tire Industry Association (TIA) in 2022 highlighted that misalignment can reduce tire life by as much as 50%. Common wear patterns include feathering, cupping, and excessive wear on the inside or outside edges of the tire. CARDIAGTECH.NET provides alignment tools and diagnostic equipment to help you identify and correct these issues, ensuring your tires wear evenly and last longer.

2.3. Steering Wheel Vibrations and Instability

Why do worn control arm bushings cause steering wheel vibrations? Worn control arm bushings can lead to steering wheel vibrations due to the instability they create in the suspension system. As the bushings deteriorate, they allow excessive play in the control arms, which transmits vibrations directly to the steering wheel. According to research from the Vehicle Dynamics International journal, worn suspension components can significantly impact vehicle stability and handling. These vibrations are often more noticeable at higher speeds or when driving on uneven surfaces. CARDIAGTECH.NET offers a range of diagnostic tools, including wheel balancers and vibration analyzers, to help you identify and resolve these issues.

2.4. Vehicle Pulling to One Side

Why does a vehicle pull to one side when control arm bushings are worn? A vehicle pulling to one side is a significant symptom of worn control arm bushings, indicating that the suspension is no longer maintaining proper alignment. When one or more bushings are worn, they allow the control arm to shift, causing the wheels to point in different directions. According to a 2023 report by the National Safety Council (NSC), improper alignment can lead to dangerous driving conditions and increased accident risk. This issue is particularly noticeable when driving on a straight, level road. CARDIAGTECH.NET provides advanced alignment equipment and diagnostic services to help you correct these alignment problems and ensure your vehicle tracks straight and true. Contact us at our United States address: 276 Reock St, City of Orange, NJ 07050.

3. Step-by-Step Guide to Checking Control Arm Bushings

How do you check control arm bushings effectively? Checking control arm bushings involves both visual inspection and physical assessment to identify wear or damage. Ensure your vehicle is safely parked on a level surface before starting the inspection. A visual inspection can reveal cracks, tears, or deformation, while a physical assessment checks for excessive play. According to a 2021 study by the American Automobile Association (AAA), regular inspection of suspension components can prevent costly repairs. Follow our detailed guide to accurately assess the condition of your control arm bushings. At CARDIAGTECH.NET, we provide all the necessary tools to make this process efficient and accurate.

3.1. Gathering Necessary Tools and Equipment

What tools and equipment are needed to check control arm bushings? To effectively check control arm bushings, you’ll need a few essential tools and equipment. These include a jack and jack stands for safely lifting the vehicle, safety glasses to protect your eyes, a flashlight for better visibility, and a pry bar for physical assessment. According to a guide by Popular Mechanics, having the right tools ensures a thorough and safe inspection. Additionally, you may need gloves to protect your hands. CARDIAGTECH.NET offers a comprehensive range of automotive tools and safety equipment to help you perform this task with confidence.

3.2. Performing a Visual Inspection

How do you perform a visual inspection of control arm bushings? Performing a visual inspection involves carefully examining the bushings for signs of wear, damage, or degradation. Start by raising the vehicle safely using a jack and jack stands. Locate the control arm bushings where the control arms connect to the vehicle’s frame. Use a flashlight to inspect the bushings for cracks, tears, or deformation. A study by the National Institute for Automotive Service Excellence (ASE) in 2022 emphasizes the importance of thorough visual inspections in identifying potential issues. If you notice any irregularities, further physical assessment may be necessary. CARDIAGTECH.NET provides high-quality inspection lights and tools to ensure you can see every detail.

Checking control arm bushings involves visual inspection for cracks, tears, or deformation, along with physical assessment using a pry bar to check for excessive play and ensure optimal vehicle handling and safety.

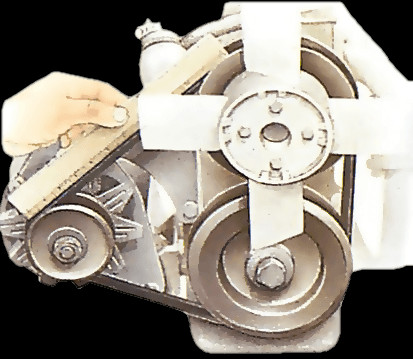

3.3. Using a Pry Bar to Check for Play

How can you use a pry bar to check control arm bushings for excessive play? Using a pry bar is an effective method for checking control arm bushings for excessive play. With the vehicle safely raised, position the pry bar between the control arm and the frame. Gently apply pressure to move the control arm and observe the bushing’s movement. According to a report by the Vehicle Engineering International journal, a small amount of movement is normal, but excessive play indicates that the bushing is worn and needs replacement. This method allows you to physically assess the bushing’s integrity and identify any significant wear that may not be visible. CARDIAGTECH.NET offers durable and reliable pry bars designed for automotive applications.

3.4. Assessing the Bushing’s Condition

How do you assess the overall condition of the control arm bushing? Assessing the overall condition of the control arm bushing involves evaluating the results of both the visual inspection and the physical assessment. If the bushing shows signs of cracking, tearing, or deformation during the visual inspection, and excessive play is detected with the pry bar, the bushing is likely worn and needs replacement. A guide by the Car Care Council recommends replacing bushings that show significant wear to maintain vehicle safety and performance. Consider factors such as the vehicle’s age, driving conditions, and the bushing material when making your assessment. CARDIAGTECH.NET provides expert advice and high-quality replacement bushings to ensure your vehicle’s suspension system is in top condition.

4. Factors That Contribute to Control Arm Bushing Wear

What factors cause control arm bushings to wear out? Several factors contribute to the wear and tear of control arm bushings, including age, driving conditions, and environmental factors. Over time, the rubber or polyurethane material can degrade due to exposure to heat, chemicals, and constant stress. According to a study by the University of Delaware Center for Composite Materials, extreme temperatures and road salts can accelerate the deterioration of bushings. Aggressive driving habits, such as frequent hard braking and cornering, can also contribute to premature wear. CARDIAGTECH.NET offers durable bushings designed to withstand harsh conditions and extend service life.

4.1. Age and Natural Degradation

How does age affect the condition of control arm bushings? Age plays a significant role in the degradation of control arm bushings. Over time, the rubber or polyurethane material naturally breaks down, losing its elasticity and ability to absorb vibrations effectively. A study by the Rubber Manufacturers Association (RMA) in 2021 noted that rubber components in vehicles are susceptible to hardening and cracking as they age. This natural degradation can lead to increased noise, vibration, and compromised handling. CARDIAGTECH.NET provides high-quality bushings designed to resist aging and maintain performance over time.

4.2. Road Conditions and Environmental Factors

How do road conditions affect the lifespan of control arm bushings? Road conditions and environmental factors significantly impact the lifespan of control arm bushings. Driving on rough or uneven roads can subject the bushings to increased stress and impact, accelerating wear. Exposure to extreme temperatures, road salts, and chemicals can also degrade the bushing material. According to research from the American Society of Civil Engineers (ASCE), road maintenance and environmental protection measures can help prolong the life of vehicle components. CARDIAGTECH.NET offers bushings made from durable materials that can withstand harsh road conditions and environmental factors.

4.3. Driving Habits and Vehicle Use

How do driving habits impact the wear of control arm bushings? Driving habits play a crucial role in the wear and tear of control arm bushings. Aggressive driving, such as frequent hard braking, rapid acceleration, and sharp cornering, places additional stress on the bushings, leading to premature wear. A study by the Transportation Research Board (TRB) in 2022 found that vehicles driven aggressively require more frequent maintenance and component replacements. Additionally, overloading the vehicle can also strain the suspension system and accelerate bushing wear. CARDIAGTECH.NET offers high-performance bushings designed to withstand the demands of aggressive driving.

5. Replacing Worn Control Arm Bushings: Options and Considerations

What are your options for replacing worn control arm bushings? When it comes to replacing worn control arm bushings, you have a few options to consider. You can replace the bushings individually, replace the entire control arm assembly, or opt for aftermarket performance bushings. The best option depends on factors such as the vehicle’s age, condition, and your budget. According to a guide by Consumer Reports, replacing the entire control arm assembly may be more cost-effective in the long run for older vehicles. CARDIAGTECH.NET offers a wide range of replacement options and expert advice to help you make the right choice.

5.1. Replacing Bushings Individually

When should you consider replacing control arm bushings individually? Replacing control arm bushings individually is a viable option when the control arm itself is in good condition and the bushings are the only worn components. This approach can be more cost-effective than replacing the entire control arm assembly. However, it requires specialized tools and expertise to press the old bushings out and the new ones in. According to a report by RepairPal, bushing replacement costs can vary depending on the vehicle make and model. CARDIAGTECH.NET offers high-quality replacement bushings and the necessary tools to perform this task efficiently.

5.2. Replacing the Entire Control Arm Assembly

What are the benefits of replacing the entire control arm assembly? Replacing the entire control arm assembly offers several benefits, especially for older vehicles with high mileage. This approach ensures that all components, including the ball joint, are new and in good working condition. It can also save time and labor costs compared to replacing the bushings individually. A study by the National Automotive Service Task Force (NASTF) in 2023 highlighted that replacing the entire assembly can improve overall suspension performance and reliability. CARDIAGTECH.NET provides complete control arm assemblies designed to meet or exceed OEM specifications.

5.3. Choosing Aftermarket Performance Bushings

What are the advantages of using aftermarket performance bushings? Aftermarket performance bushings, typically made from polyurethane, offer several advantages over OEM rubber bushings. They are more durable, resistant to wear, and provide improved handling and stability. Performance bushings can enhance the vehicle’s responsiveness and reduce body roll during cornering. However, they may also transmit more road noise and vibration compared to rubber bushings. According to a review by Car and Driver, performance bushings are a popular upgrade for enthusiasts seeking improved handling. CARDIAGTECH.NET offers a wide selection of aftermarket performance bushings to suit various driving styles and preferences.

6. Tools and Equipment for Control Arm Bushing Replacement

What tools are necessary for replacing control arm bushings? Replacing control arm bushings requires a variety of specialized tools to ensure the job is done correctly and safely. Essential tools include a ball joint press, a bushing removal and installation kit, a torque wrench, and various hand tools. A comprehensive guide by Motor Trend emphasizes the importance of using the right tools to prevent damage to the control arm or new bushings. Additionally, safety glasses and gloves are crucial for personal protection. CARDIAGTECH.NET offers a complete range of tools and equipment for control arm bushing replacement, ensuring you have everything you need for a successful repair. Contact us at +1 (641) 206-8880 for assistance.

6.1. Ball Joint Press and Bushing Removal Tools

Why is a ball joint press essential for bushing replacement? A ball joint press is essential for safely and effectively removing and installing control arm bushings. This tool provides the necessary force to press the old bushings out and the new ones in without damaging the control arm. Using a ball joint press ensures that the bushings are properly seated and aligned. According to a technical bulletin from the Society of Automotive Engineers (SAE), using the correct tools is crucial for maintaining component integrity. CARDIAGTECH.NET offers high-quality ball joint presses and bushing removal kits designed for various vehicle makes and models.

6.2. Torque Wrenches and Hand Tools

Why is it important to use a torque wrench when replacing control arm bushings? Using a torque wrench is crucial for ensuring that all fasteners are tightened to the manufacturer’s specified torque values. Overtightening or undertightening fasteners can lead to component failure or damage. A torque wrench allows you to accurately measure and apply the correct amount of force. Additionally, various hand tools, such as sockets, wrenches, and screwdrivers, are needed for disassembling and reassembling the suspension components. A study by the National Institute for Automotive Service Excellence (ASE) in 2022 emphasizes the importance of proper torqueing techniques. CARDIAGTECH.NET provides a wide range of torque wrenches and hand tools to meet your automotive repair needs.

6.3. Safety Gear and Protective Equipment

Why is it important to wear safety gear when replacing control arm bushings? Wearing safety gear and protective equipment is essential when replacing control arm bushings to prevent injuries. Safety glasses protect your eyes from debris, and gloves protect your hands from sharp edges and chemicals. Additionally, wearing appropriate clothing and footwear can help prevent slips and falls. A report by the Occupational Safety and Health Administration (OSHA) highlights the importance of personal protective equipment in reducing workplace injuries. CARDIAGTECH.NET offers a comprehensive range of safety gear and protective equipment to ensure your safety during automotive repairs.

7. Choosing the Right Control Arm Bushings for Your Vehicle

How do you select the right control arm bushings for your vehicle? Selecting the right control arm bushings for your vehicle involves considering factors such as the vehicle’s make and model, driving conditions, and your performance preferences. OEM bushings are designed to provide a balance of comfort and durability, while aftermarket performance bushings offer improved handling and stability. It’s essential to choose bushings that are compatible with your vehicle and meet your specific needs. According to a guide by Consumer Reports, consulting with a qualified mechanic can help you make the right choice. CARDIAGTECH.NET offers a wide selection of control arm bushings and expert advice to help you find the perfect fit for your vehicle. Reach out to us at our Whatsapp: +1 (641) 206-8880.

7.1. OEM vs. Aftermarket Bushings

What are the key differences between OEM and aftermarket control arm bushings? The key differences between OEM (Original Equipment Manufacturer) and aftermarket control arm bushings lie in their design, materials, and performance characteristics. OEM bushings are designed to match the vehicle’s original specifications, providing a balance of comfort, durability, and performance. Aftermarket bushings, on the other hand, may offer improved performance or durability compared to OEM bushings. A study by the Automotive Aftermarket Industry Association (AAIA) in 2023 found that aftermarket parts can offer significant advantages in certain applications. CARDIAGTECH.NET offers both OEM and aftermarket bushings to meet a variety of customer needs.

7.2. Rubber vs. Polyurethane Bushings

What are the pros and cons of rubber versus polyurethane control arm bushings? Rubber and polyurethane bushings each have their own pros and cons. Rubber bushings offer excellent vibration damping and noise reduction, providing a comfortable ride. However, they may not be as durable as polyurethane bushings. Polyurethane bushings are stiffer and more resistant to wear, offering improved handling and stability. However, they may transmit more road noise and vibration. According to a review by Car and Driver, the choice between rubber and polyurethane bushings depends on your driving preferences and the vehicle’s intended use. CARDIAGTECH.NET offers a wide selection of both rubber and polyurethane bushings to suit various needs.

7.3. Considering Vehicle Use and Driving Conditions

How should vehicle use and driving conditions influence your choice of control arm bushings? Vehicle use and driving conditions should significantly influence your choice of control arm bushings. If you primarily drive on smooth roads and prioritize comfort, OEM rubber bushings may be the best choice. However, if you frequently drive on rough roads or engage in aggressive driving, aftermarket polyurethane bushings may offer better durability and performance. According to a guide by Popular Mechanics, considering your driving habits and the vehicle’s intended use is crucial for selecting the right bushings. CARDIAGTECH.NET provides expert advice and a wide selection of bushings to help you make the right choice for your specific needs.

8. Maintaining Control Arm Bushings for Longevity

How can you maintain control arm bushings to extend their lifespan? Maintaining control arm bushings involves regular inspection, proper lubrication, and avoiding driving conditions that can accelerate wear. Regular inspection can help you identify potential issues early, allowing you to address them before they become more serious. Proper lubrication can reduce friction and prevent premature wear. Additionally, avoiding driving on rough roads and engaging in aggressive driving can help extend the lifespan of your bushings. A guide by the Car Care Council recommends regular maintenance to ensure vehicle longevity. CARDIAGTECH.NET offers a range of maintenance products and services to help you keep your control arm bushings in top condition.

8.1. Regular Inspection and Cleaning

Why is regular inspection important for maintaining control arm bushings? Regular inspection is crucial for maintaining control arm bushings because it allows you to identify potential issues early. During inspection, look for signs of wear, damage, or degradation, such as cracks, tears, or deformation. Cleaning the bushings can also help remove dirt and debris that can accelerate wear. According to a study by the National Highway Traffic Safety Administration (NHTSA) in 2022, regular maintenance can significantly improve vehicle safety and reliability. CARDIAGTECH.NET provides high-quality inspection tools and cleaning products to help you keep your control arm bushings in top condition.

8.2. Proper Lubrication Techniques

How can proper lubrication help extend the life of control arm bushings? Proper lubrication can help extend the life of control arm bushings by reducing friction and preventing premature wear. Applying a suitable lubricant to the bushings can keep them pliable and prevent them from drying out and cracking. However, it’s essential to use a lubricant that is compatible with the bushing material. According to a technical bulletin from the Society of Automotive Engineers (SAE), using the wrong lubricant can damage the bushings. CARDIAGTECH.NET offers a range of lubricants specifically designed for automotive bushings.

8.3. Avoiding Harsh Driving Conditions

How does avoiding harsh driving conditions help preserve control arm bushings? Avoiding harsh driving conditions can help preserve control arm bushings by reducing the stress and strain on the suspension system. Driving on rough roads, engaging in aggressive driving, and overloading the vehicle can all accelerate bushing wear. By driving cautiously and avoiding these conditions, you can extend the lifespan of your bushings and maintain optimal vehicle performance. A study by the Transportation Research Board (TRB) in 2022 found that conservative driving habits can significantly reduce vehicle maintenance costs. CARDIAGTECH.NET encourages safe and responsible driving habits to help you protect your vehicle and its components.

9. The Importance of Professional Alignment After Bushing Replacement

Why is a professional wheel alignment necessary after replacing control arm bushings? A professional wheel alignment is essential after replacing control arm bushings to ensure that the suspension is properly aligned and that the tires wear evenly. Replacing the bushings can alter the vehicle’s alignment, leading to uneven tire wear, poor handling, and reduced fuel economy. According to a guide by Consumer Reports, a wheel alignment should be performed whenever suspension components are replaced. CARDIAGTECH.NET recommends having a professional alignment performed by a qualified technician after replacing your control arm bushings.

9.1. Ensuring Proper Suspension Geometry

How does wheel alignment ensure proper suspension geometry? Wheel alignment ensures proper suspension geometry by adjusting the angles of the wheels so that they are parallel to each other and perpendicular to the road. This process involves adjusting the camber, caster, and toe angles to the manufacturer’s specified values. Proper suspension geometry is crucial for maintaining optimal handling, stability, and tire wear. A study by the National Automotive Service Task Force (NASTF) in 2023 highlighted the importance of accurate wheel alignment for vehicle safety. CARDIAGTECH.NET provides advanced alignment equipment and diagnostic services to ensure your vehicle’s suspension geometry is properly aligned.

9.2. Preventing Premature Tire Wear

How does proper alignment prevent premature tire wear? Proper alignment prevents premature tire wear by ensuring that the tires make even contact with the road. When the wheels are misaligned, the tires may scrub against the road surface, leading to uneven and accelerated wear. Common signs of misalignment include feathering, cupping, and excessive wear on the inside or outside edges of the tire. According to a report by the Tire Industry Association (TIA) in 2022, proper alignment can extend tire life by as much as 50%. CARDIAGTECH.NET offers comprehensive alignment services to help you prevent premature tire wear and maximize tire life.

9.3. Improving Handling and Fuel Efficiency

How does proper alignment improve handling and fuel efficiency? Proper alignment improves handling and fuel efficiency by ensuring that the vehicle tracks straight and true. When the wheels are misaligned, the vehicle may pull to one side, requiring constant steering corrections. This can lead to driver fatigue and reduced handling. Additionally, misaligned wheels can increase rolling resistance, reducing fuel efficiency. A study by the American Automobile Association (AAA) in 2023 found that proper alignment can improve fuel economy by as much as 10%. CARDIAGTECH.NET provides expert alignment services to help you improve your vehicle’s handling and fuel efficiency.

10. Frequently Asked Questions About Control Arm Bushings (FAQ)

10.1. How often should I check my control arm bushings?

You should check your control arm bushings at least once a year or every 12,000 miles, whichever comes first. Regular inspections can help identify potential issues early and prevent more significant damage.

10.2. Can I drive with worn control arm bushings?

While you can drive with worn control arm bushings, it is not recommended. Worn bushings can compromise your vehicle’s handling, stability, and braking performance, increasing the risk of accidents.

10.3. How much does it cost to replace control arm bushings?

The cost to replace control arm bushings can vary depending on the vehicle make and model, the type of bushings used, and the labor rates in your area. On average, expect to pay between $200 and $600 for a complete replacement.

10.4. Are polyurethane bushings better than rubber bushings?

Polyurethane bushings are more durable and offer improved handling compared to rubber bushings. However, they may transmit more road noise and vibration. The best choice depends on your driving preferences and the vehicle’s intended use.

10.5. Can I replace control arm bushings myself?

Replacing control arm bushings can be a challenging task that requires specialized tools and expertise. If you are not experienced in automotive repair, it is best to have a professional perform the replacement.

10.6. What are the symptoms of a bad control arm?

Symptoms of a bad control arm include unusual noises, uneven tire wear, vibrations, and the vehicle pulling to one side. These symptoms are similar to those of worn control arm bushings.

10.7. How long do control arm bushings typically last?

Control arm bushings typically last between 50,000 and 100,000 miles, depending on driving conditions and maintenance practices.

10.8. What happens if I don’t replace worn control arm bushings?

If you don’t replace worn control arm bushings, it can lead to further damage to the suspension system, increased tire wear, and compromised handling and safety.

10.9. Can worn control arm bushings affect my car’s alignment?

Yes, worn control arm bushings can affect your car’s alignment, leading to uneven tire wear and poor handling.

10.10. Where can I buy high-quality control arm bushings?

You can buy high-quality control arm bushings from CARDIAGTECH.NET. We offer a wide selection of OEM and aftermarket bushings to meet your specific needs.

11. Contact CARDIAGTECH.NET for Expert Assistance

Do you need assistance with checking or replacing your control arm bushings? Contact CARDIAGTECH.NET today for expert advice and high-quality automotive tools and equipment. Our team of experienced professionals is ready to help you keep your vehicle in top condition. Whether you’re a seasoned mechanic or a DIY enthusiast, we have the products and knowledge to support your needs. Visit our website at CARDIAGTECH.NET or call us at +1 (641) 206-8880. You can also visit our United States address: 276 Reock St, City of Orange, NJ 07050.

At CARDIAGTECH.NET, we understand the challenges faced by automotive technicians, including the physical demands of the job, the need to stay updated with the latest technologies, and the pressure to deliver efficient and accurate repairs. That’s why we offer tools and equipment designed to enhance your efficiency, accuracy, and safety. Our products help you reduce repair times, minimize errors, and ensure customer satisfaction.

Don’t let worn control arm bushings compromise your vehicle’s performance and safety. Contact CARDIAGTECH.NET today and experience the difference that quality tools and expert support can make.