How to Check the Output Current of the Alternator: A Comprehensive Guide

Checking the output current of the alternator is crucial for diagnosing electrical issues and ensuring your vehicle runs smoothly. CARDIAGTECH.NET provides the tools and knowledge you need to accurately assess alternator performance and maintain your car’s electrical system. Dive in to discover how you can master alternator current testing and keep your vehicle in top condition with the right equipment from CARDIAGTECH.NET. We will also cover alternator diagnostics, automotive electrical systems, and voltage regulator functions.

1. What is Alternator Output Current and Why is it Important?

Alternator output current is the amount of electrical energy, measured in amperes (amps), that the alternator produces to power a vehicle’s electrical system and recharge the battery. According to a study by the University of Michigan Transportation Research Institute in 2022, proper alternator function is essential for maintaining consistent voltage levels, which prevents damage to sensitive electronic components.

1.1. Key Reasons Why Checking Alternator Output Current Matters

- Battery Health: The alternator keeps your battery charged. Insufficient output can lead to a dead battery and starting problems.

- Electrical System Performance: A faulty alternator can cause dimming headlights, malfunctioning accessories, and other electrical issues.

- Component Lifespan: Consistent voltage and current from a healthy alternator protect other electrical components from damage.

- Vehicle Reliability: Regular checks help identify potential problems early, preventing breakdowns and costly repairs.

- Diagnostic Accuracy: Measuring output current helps pinpoint alternator issues versus other electrical problems.

1.2. Understanding the Alternator’s Role

The alternator converts mechanical energy from the engine into electrical energy. This energy powers the vehicle’s electrical systems while the engine is running and recharges the battery. According to a 2021 report by the Automotive Aftermarket Suppliers Association (AASA), a properly functioning alternator ensures that all electrical components receive the necessary power without draining the battery.

1.3. Symptoms of a Failing Alternator

Recognizing the symptoms of a failing alternator can save you from unexpected breakdowns. Here are some common signs:

- Dim or Flickering Headlights: Insufficient power can cause headlights to dim or flicker, especially at low engine speeds.

- Warning Lights: The battery or alternator warning light on the dashboard may illuminate.

- Difficulty Starting: A weak or dead battery, due to insufficient charging, can make starting difficult.

- Slow or Malfunctioning Accessories: Power windows, radio, and other accessories may operate slowly or not at all.

- Unusual Noises: Grinding or whining noises from the alternator may indicate worn bearings or other internal issues.

1.4 Alternator Basics: How It Powers Your Car

The alternator’s primary job is to supply electrical power to your car’s systems while the engine is running. It also recharges the battery, ensuring you have enough juice to start your engine the next time you turn the key. Understanding how the alternator works can help you troubleshoot issues more effectively.

The alternator uses a rotating magnetic field to generate electricity. Key components include:

- Rotor: The rotating part of the alternator, driven by the engine via a belt.

- Stator: The stationary part where electricity is generated as the rotor spins.

- Rectifier: Converts AC voltage produced by the stator to DC voltage, which your car’s electrical system uses.

- Voltage Regulator: Controls the alternator’s output to maintain a stable voltage, preventing overcharging and damage.

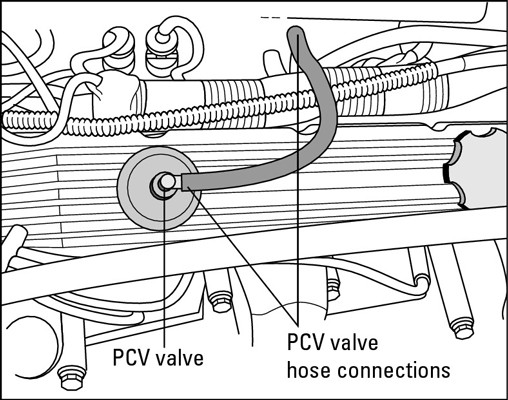

Wiring diagram for a standard automotive alternator, detailing connections between the alternator, battery, and voltage regulator.

2. Essential Tools for Checking Alternator Output Current

Having the right tools is crucial for accurately checking alternator output current. Here’s a list of essential tools and how they contribute to the testing process. CARDIAGTECH.NET offers a range of high-quality tools to ensure you get reliable results every time.

2.1. Digital Multimeter

A digital multimeter (DMM) is the most essential tool for electrical testing. It measures voltage, current (amps), and resistance (ohms). Look for a DMM with a DC amp range of at least 20 amps for alternator testing.

- Voltage Measurement: Check the battery voltage and alternator output voltage.

- Current Measurement: Measure the alternator’s output current to determine its charging capacity.

- Continuity Testing: Verify the integrity of wiring and connections.

2.2. Clamp Meter

A clamp meter measures current without needing to break the circuit. It’s ideal for measuring high currents, such as alternator output. Look for a clamp meter with a DC amp range suitable for automotive applications.

- Non-Invasive Measurement: Measure current without disconnecting wires.

- High Current Capacity: Accurately measure the high output current of the alternator.

- Safety: Reduces the risk of electrical shock by avoiding direct contact with live wires.

2.3. Battery Load Tester

A battery load tester assesses the battery’s ability to deliver current under load. This helps determine if the battery is contributing to electrical issues.

- Battery Health Assessment: Determines the battery’s overall condition and capacity.

- Load Simulation: Simulates the load of starting the engine to identify weak batteries.

- Comprehensive Testing: Provides a complete picture of the battery’s performance.

2.4. Jumper Cables or Battery Charger

Sometimes, a battery may be too discharged to start the vehicle for testing. Jumper cables or a battery charger can provide the necessary boost.

- Jump Starting: Quickly start the vehicle if the battery is dead.

- Battery Charging: Recharge the battery to a sufficient level for testing.

- Versatility: Useful for various automotive maintenance tasks.

2.5. Safety Gear

Safety should always be a priority when working with electrical systems. Essential safety gear includes:

- Safety Glasses: Protect your eyes from debris and battery acid.

- Gloves: Insulated gloves protect against electrical shock.

- Proper Clothing: Avoid loose clothing that can get caught in moving parts.

2.6. Optional but Helpful Tools

- Circuit Tester: Quickly check for voltage in circuits.

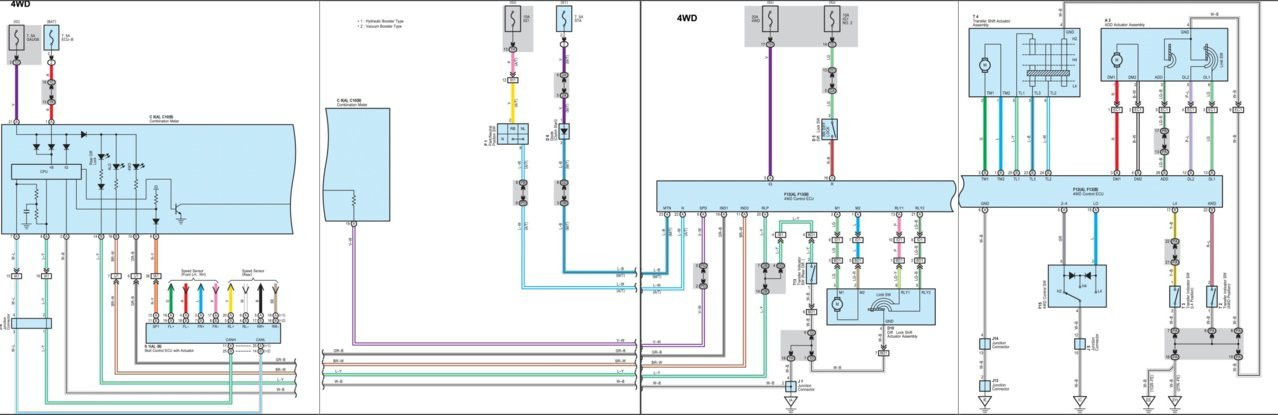

- Wiring Diagrams: Essential for understanding the vehicle’s electrical system.

- Scan Tool: Reads diagnostic trouble codes (DTCs) from the vehicle’s computer.

Using these tools effectively will help you accurately diagnose alternator issues and ensure your vehicle’s electrical system is functioning correctly. CARDIAGTECH.NET provides high-quality tools that meet the demands of both professional technicians and DIY enthusiasts.

3. Step-by-Step Guide: How to Check Alternator Output Current with a Multimeter

Using a multimeter to check alternator output current is a straightforward process that can help you diagnose electrical issues. Here’s a detailed, step-by-step guide:

3.1. Safety First

Before starting, ensure the vehicle is parked on a level surface, the parking brake is engaged, and the engine is turned off. Wear safety glasses and gloves to protect yourself from potential hazards.

3.2. Prepare the Multimeter

Set your multimeter to the DC amps (A) setting. Ensure the meter is capable of reading at least 20 amps. Connect the red lead to the amp terminal and the black lead to the common (COM) terminal on the multimeter.

3.3. Locate the Alternator

The alternator is typically located at the front of the engine and is driven by a belt connected to the crankshaft pulley. Refer to your vehicle’s repair manual for the exact location.

3.4. Disconnect the Battery

Disconnect the negative (-) battery cable from the battery terminal. This prevents electrical shorts during the testing process.

3.5. Access the Alternator Output Wire

Locate the main output wire on the back of the alternator. This wire is usually connected to the battery’s positive (+) terminal.

3.6. Connect the Multimeter in Series

- Disconnect the alternator output wire from the alternator.

- Connect the red lead of the multimeter to the alternator output terminal.

- Connect the black lead of the multimeter to the disconnected alternator output wire. This creates a series circuit where all the current from the alternator will flow through the multimeter.

3.7. Reconnect the Battery (Temporarily)

Temporarily reconnect the negative (-) battery cable to the battery terminal.

3.8. Start the Engine

Start the engine and let it idle.

3.9. Read the Alternator Output Current

Observe the multimeter reading. This is the alternator’s output current at idle.

3.10. Increase Engine Speed

Increase the engine speed to around 1500-2000 RPM. This simulates driving conditions and allows the alternator to produce more current.

3.11. Observe the Output Current Again

Check the multimeter reading again. The output current should increase but should not exceed the alternator’s rated output. Refer to your vehicle’s repair manual for the alternator’s specifications.

3.12. Turn on Accessories

Turn on accessories such as headlights, the radio, and the air conditioner to increase the electrical load.

3.13. Check the Output Current Under Load

Observe the multimeter reading with the accessories turned on. The output current should increase further to meet the increased demand.

3.14. Analyze the Results

- Low Output Current: If the output current is significantly lower than the alternator’s rated output, the alternator may be failing.

- Excessive Output Current: If the output current exceeds the alternator’s rated output, there may be a short circuit or other electrical issue.

- Fluctuating Output Current: Fluctuating readings may indicate a faulty voltage regulator.

3.15. Turn Off the Engine and Disconnect the Multimeter

Turn off the engine and disconnect the negative (-) battery cable again.

3.16. Reconnect the Alternator Output Wire

Reconnect the alternator output wire to the alternator.

3.17. Secure Connections

Ensure all connections are secure and properly tightened.

3.18. Reconnect the Battery

Reconnect the negative (-) battery cable to the battery terminal.

3.19. Verify Operation

Start the engine and verify that the vehicle’s electrical system is functioning correctly. Check that the battery warning light is off and that all accessories are working properly.

By following these steps, you can effectively check the alternator output current with a multimeter and diagnose potential issues. CARDIAGTECH.NET provides the tools and resources you need to perform this test accurately and safely.

4. Using a Clamp Meter to Check Alternator Output Current

A clamp meter offers a non-invasive way to measure alternator output current, making it a safer and more convenient option. Here’s how to use a clamp meter effectively:

4.1. Safety First

Ensure the vehicle is parked on a level surface, the parking brake is engaged, and the engine is turned off. Wear safety glasses and gloves.

4.2. Prepare the Clamp Meter

Set the clamp meter to the DC amps (A) setting. Ensure the meter is capable of reading the expected range of alternator output current.

4.3. Locate the Alternator Output Wire

Identify the main output wire on the back of the alternator. This wire is usually connected to the battery’s positive (+) terminal.

4.4. Clamp the Meter Around the Wire

Open the clamp on the meter and place it around the alternator output wire. Ensure the clamp is fully closed and that only one wire is inside the clamp.

4.5. Start the Engine

Start the engine and let it idle.

4.6. Read the Alternator Output Current

Observe the clamp meter reading. This is the alternator’s output current at idle.

4.7. Increase Engine Speed

Increase the engine speed to around 1500-2000 RPM.

4.8. Observe the Output Current Again

Check the clamp meter reading again. The output current should increase as the engine speed increases.

4.9. Turn on Accessories

Turn on accessories such as headlights, the radio, and the air conditioner to increase the electrical load.

4.10. Check the Output Current Under Load

Observe the clamp meter reading with the accessories turned on. The output current should increase further to meet the increased demand.

4.11. Analyze the Results

- Low Output Current: If the output current is significantly lower than the alternator’s rated output, the alternator may be failing.

- Excessive Output Current: If the output current exceeds the alternator’s rated output, there may be a short circuit or other electrical issue.

- Fluctuating Output Current: Fluctuating readings may indicate a faulty voltage regulator.

4.12. Turn Off the Engine

Turn off the engine.

4.13. Remove the Clamp Meter

Remove the clamp meter from the alternator output wire.

4.14. Verify Operation

Start the engine and verify that the vehicle’s electrical system is functioning correctly. Check that the battery warning light is off and that all accessories are working properly.

Using a clamp meter provides a safe and efficient way to measure alternator output current. CARDIAGTECH.NET offers a variety of clamp meters to suit your needs, ensuring accurate and reliable results.

5. Interpreting Alternator Output Current Readings

Understanding what the alternator output current readings mean is crucial for accurate diagnosis. Here’s how to interpret the readings you obtain during testing:

5.1. Normal Output Current

A healthy alternator should produce an output current that meets or exceeds the vehicle’s electrical demands. At idle, the output current should be sufficient to maintain battery voltage and power essential systems. At higher engine speeds and under load, the output current should increase to meet the additional demand from accessories.

- Idle Speed: Typically, an alternator should produce around 10-30 amps at idle, depending on the vehicle and its electrical load.

- Higher Engine Speeds (1500-2000 RPM): The output current should increase to 40-70 amps or more, depending on the alternator’s rated output and the electrical load.

- Under Load: With accessories turned on, the output current should increase further to meet the demand. A healthy alternator should be able to maintain a stable voltage while supplying the necessary current.

5.2. Low Output Current

Low output current indicates that the alternator is not producing enough power to meet the vehicle’s electrical demands. This can lead to a discharged battery, dim headlights, and other electrical issues.

Possible Causes of Low Output Current:

- Worn Brushes: Worn brushes can reduce the alternator’s ability to generate current.

- Faulty Voltage Regulator: A faulty voltage regulator may not allow the alternator to produce sufficient output.

- Slipping Belt: A loose or worn belt can cause the alternator to spin too slowly, reducing its output.

- Damaged Stator or Rotor: Internal damage to the stator or rotor can significantly reduce the alternator’s output.

- Poor Connections: Corroded or loose connections can restrict current flow.

5.3. Excessive Output Current

Excessive output current indicates that the alternator is producing more power than necessary, which can damage the battery and other electrical components.

Possible Causes of Excessive Output Current:

- Faulty Voltage Regulator: A faulty voltage regulator may cause the alternator to overcharge the battery.

- Short Circuit: A short circuit in the vehicle’s electrical system can draw excessive current from the alternator.

- Battery Issues: A failing battery may draw excessive current as it tries to charge.

5.4. Fluctuating Output Current

Fluctuating output current indicates that the alternator’s output is unstable, which can cause erratic electrical behavior.

Possible Causes of Fluctuating Output Current:

- Faulty Voltage Regulator: A faulty voltage regulator may cause the alternator to produce an unstable output.

- Loose Connections: Loose or corroded connections can cause intermittent current flow.

- Worn Slip Rings: Worn slip rings can cause the alternator’s output to fluctuate.

5.5. Using Diagnostic Trouble Codes (DTCs)

Many modern vehicles have diagnostic systems that can detect alternator issues and store diagnostic trouble codes (DTCs). Use a scan tool to retrieve any DTCs related to the alternator.

Common Alternator-Related DTCs:

- P0620: Alternator Control Circuit Malfunction

- P0621: Generator Lamp Control Circuit Malfunction

- P0622: Generator Field Control Circuit Malfunction

- P0562: System Voltage Low

- P0563: System Voltage High

By understanding these readings and potential causes, you can accurately diagnose alternator issues and take appropriate action. CARDIAGTECH.NET offers a range of diagnostic tools and equipment to help you keep your vehicle’s electrical system in top condition.

6. Common Issues Affecting Alternator Output Current

Several factors can affect alternator output current. Identifying these issues is crucial for effective troubleshooting and repair. Here are some common problems:

6.1. Worn Brushes

The brushes in the alternator make contact with the slip rings on the rotor to transfer electrical current. Over time, these brushes wear down, reducing their ability to conduct current.

Symptoms of Worn Brushes:

- Low Output Current: Reduced current output, especially at low engine speeds.

- Intermittent Charging: The battery may not charge consistently.

- Battery Warning Light: The battery warning light may illuminate intermittently.

Solution:

- Replace the worn brushes. This typically requires disassembling the alternator.

6.2. Faulty Voltage Regulator

The voltage regulator controls the alternator’s output voltage to prevent overcharging and maintain a stable voltage. A faulty voltage regulator can cause various issues.

Symptoms of a Faulty Voltage Regulator:

- Overcharging: The battery voltage may be too high, leading to battery damage.

- Undercharging: The battery voltage may be too low, resulting in a discharged battery.

- Fluctuating Voltage: The voltage may fluctuate erratically.

- Battery Warning Light: The battery warning light may illuminate.

Solution:

- Replace the voltage regulator. Some alternators have internal voltage regulators, while others have external ones.

6.3. Slipping Belt

The belt that drives the alternator can slip if it is loose or worn. This reduces the alternator’s speed, decreasing its output.

Symptoms of a Slipping Belt:

- Low Output Current: Reduced current output, especially at low engine speeds.

- Squealing Noise: A squealing noise from the belt, especially when the engine is first started or when accessories are turned on.

- Battery Warning Light: The battery warning light may illuminate.

Solution:

- Tighten or replace the belt. Ensure the belt tension is correct.

6.4. Damaged Stator or Rotor

The stator and rotor are key components of the alternator that generate electrical current. Damage to these components can significantly reduce the alternator’s output.

Symptoms of a Damaged Stator or Rotor:

- Low Output Current: Severely reduced or no current output.

- Overheating: The alternator may overheat.

- Unusual Noises: Grinding or whining noises from the alternator.

Solution:

- Replace the alternator. Internal damage to the stator or rotor usually requires replacing the entire unit.

6.5. Poor Connections

Corroded or loose connections can restrict current flow, reducing the alternator’s output.

Symptoms of Poor Connections:

- Low Output Current: Reduced current output.

- Intermittent Charging: The battery may not charge consistently.

- Voltage Drop: Significant voltage drop across connections.

Solution:

- Clean and tighten all connections. Use a wire brush to remove corrosion and ensure connections are secure.

6.6. Overloading the Alternator

Continuously running too many high-demand accessories can overload the alternator, reducing its lifespan and output.

Symptoms of Overloading the Alternator:

- Low Output Current: Reduced current output, especially when accessories are turned on.

- Overheating: The alternator may overheat.

- Shortened Lifespan: The alternator may fail prematurely.

Solution:

- Reduce the electrical load by minimizing the use of high-demand accessories.

- Upgrade to a higher-output alternator if necessary.

By addressing these common issues, you can maintain your alternator’s performance and ensure your vehicle’s electrical system operates efficiently. CARDIAGTECH.NET offers the tools and expertise to help you diagnose and repair alternator problems effectively.

7. Maintaining Your Alternator for Optimal Performance

Proper maintenance is essential for ensuring your alternator operates at its best and lasts longer. Here are some key maintenance tips:

7.1. Regular Visual Inspections

Conduct regular visual inspections of the alternator and its components. Look for signs of wear, damage, or corrosion.

What to Look For:

- Belt Condition: Check the belt for cracks, wear, and proper tension.

- Wiring and Connections: Inspect wiring for damage, corrosion, and loose connections.

- Alternator Housing: Look for cracks, dents, or other damage to the alternator housing.

- Pulley Condition: Ensure the pulley is not damaged or worn.

7.2. Keep Connections Clean and Tight

Ensure all electrical connections to the alternator are clean and tight. Corrosion can impede current flow and reduce alternator performance.

How to Clean Connections:

- Disconnect the battery negative (-) terminal.

- Remove the connections from the alternator.

- Use a wire brush or sandpaper to clean the terminals and connectors.

- Apply dielectric grease to the connections to prevent corrosion.

- Reattach the connections and ensure they are tight.

- Reconnect the battery negative (-) terminal.

7.3. Check Belt Tension

Proper belt tension is crucial for the alternator to operate efficiently. A loose belt can slip, reducing the alternator’s speed and output.

How to Check Belt Tension:

- Locate the longest span of the belt between pulleys.

- Use a belt tension gauge to measure the tension.

- Compare the reading to the manufacturer’s specifications.

- Adjust the tension as needed by loosening or tightening the adjustment bolts.

7.4. Avoid Overloading the Electrical System

Avoid continuously running too many high-demand accessories, as this can overload the alternator and reduce its lifespan.

Tips for Avoiding Overloading:

- Use Accessories Wisely: Turn off accessories when they are not needed.

- Upgrade Components: If you frequently use high-demand accessories, consider upgrading to more efficient components.

- Monitor Voltage: Keep an eye on your vehicle’s voltage gauge to ensure the electrical system is operating within normal parameters.

7.5. Battery Maintenance

A healthy battery is essential for the alternator to function properly. Maintain your battery to ensure it is in good condition.

Battery Maintenance Tips:

- Keep Terminals Clean: Clean battery terminals regularly to prevent corrosion.

- Check Electrolyte Levels: For flooded batteries, check and maintain electrolyte levels.

- Test Battery Regularly: Use a battery load tester to assess the battery’s condition.

- Replace as Needed: Replace the battery when it reaches the end of its lifespan.

7.6. Professional Inspections

Consider having your vehicle’s electrical system professionally inspected periodically. A qualified technician can identify potential issues and perform necessary maintenance to keep your alternator operating at its best.

By following these maintenance tips, you can extend the life of your alternator and ensure your vehicle’s electrical system remains reliable. CARDIAGTECH.NET offers a wide range of tools and equipment to help you maintain your alternator and electrical system effectively.

8. Upgrading Your Alternator for Increased Output

If you frequently use high-demand electrical accessories or have upgraded your vehicle with additional electrical components, you may need to upgrade your alternator to a higher-output model. Here’s what you need to know:

8.1. Assessing Your Electrical Needs

Before upgrading your alternator, assess your vehicle’s electrical needs to determine the appropriate output capacity.

Factors to Consider:

- Factory Electrical Load: Determine the electrical load of your vehicle’s factory components (lights, radio, etc.).

- Aftermarket Accessories: Calculate the electrical load of any aftermarket accessories you have added (stereo systems, lights, etc.).

- Future Needs: Consider any future electrical upgrades you may plan.

8.2. Calculating Total Electrical Load

Add up the electrical load of all components to determine the total current draw. This will help you choose an alternator with sufficient output capacity.

Example Calculation:

- Factory Electrical Load: 50 amps

- Aftermarket Stereo System: 30 amps

- Additional Lights: 20 amps

- Total Electrical Load: 100 amps

In this example, you would need an alternator with an output capacity of at least 100 amps.

8.3. Choosing the Right Alternator

Select an alternator with an output capacity that meets or exceeds your vehicle’s total electrical load. Consider factors such as:

- Output Capacity: Choose an alternator with sufficient output capacity to meet your needs.

- Vehicle Compatibility: Ensure the alternator is compatible with your vehicle’s make and model.

- Quality and Reliability: Choose a reputable brand known for quality and reliability.

- Warranty: Look for an alternator with a good warranty.

8.4. Installation

Installing a new alternator typically involves the following steps:

- Disconnect the battery negative (-) terminal.

- Remove the old alternator.

- Install the new alternator.

- Connect the wiring to the new alternator.

- Tighten the belt and ensure proper tension.

- Reconnect the battery negative (-) terminal.

It is recommended to consult your vehicle’s repair manual or seek professional assistance if you are not comfortable performing the installation yourself.

8.5. Testing the New Alternator

After installation, test the new alternator to ensure it is functioning properly. Use a multimeter or clamp meter to check the output voltage and current.

Testing Procedure:

- Start the engine.

- Check the battery voltage. It should be around 13.5-14.5 volts with the engine running.

- Turn on accessories such as headlights, the radio, and the air conditioner.

- Check the alternator output current. It should increase to meet the increased demand.

8.6. Benefits of Upgrading

Upgrading to a higher-output alternator can provide several benefits:

- Improved Electrical Performance: Ensures your vehicle’s electrical system can handle increased demand.

- Increased Reliability: Reduces the risk of electrical issues and breakdowns.

- Longer Lifespan: Prevents overloading, extending the lifespan of the alternator.

By upgrading your alternator, you can ensure your vehicle’s electrical system is capable of meeting your needs. CARDIAGTECH.NET offers a variety of high-quality alternators and accessories to help you upgrade your vehicle’s electrical system effectively.

9. Diagnosing Electrical Problems Related to Alternator Output Current

When your car exhibits electrical issues, the alternator’s output current is one of the first things to check. Here are some common problems and how to diagnose them:

9.1. Battery Not Charging

If your battery is not charging, the alternator may not be producing enough output current.

Diagnosis:

- Check the battery voltage with the engine off. It should be around 12.6 volts.

- Start the engine and check the battery voltage again. It should increase to 13.5-14.5 volts if the alternator is charging properly.

- If the voltage does not increase, check the alternator output current using a multimeter or clamp meter.

- If the output current is low, the alternator may be faulty.

9.2. Dim Headlights

Dim or flickering headlights can indicate that the alternator is not providing enough power to the electrical system.

Diagnosis:

- Start the engine and turn on the headlights.

- Check the voltage at the battery terminals. It should be around 13.5-14.5 volts.

- If the voltage is low, check the alternator output current.

- If the output current is low, the alternator may be faulty.

9.3. Slow or Malfunctioning Accessories

If accessories such as power windows, the radio, or the air conditioner are operating slowly or malfunctioning, it could be due to insufficient alternator output.

Diagnosis:

- Start the engine and turn on the accessories.

- Check the voltage at the battery terminals. It should be around 13.5-14.5 volts.

- If the voltage is low, check the alternator output current.

- If the output current is low, the alternator may be faulty.

9.4. Battery Warning Light On

The battery warning light on the dashboard indicates a problem with the charging system, which could be related to the alternator.

Diagnosis:

- Check the battery voltage with the engine running. It should be around 13.5-14.5 volts.

- If the voltage is outside this range, use a scan tool to check for diagnostic trouble codes (DTCs).

- Check the alternator output current.

- If the output current is low or fluctuating, the alternator may be faulty.

9.5. Unusual Noises from the Alternator

Grinding, whining, or squealing noises from the alternator can indicate internal problems.

Diagnosis:

- Listen to the alternator while the engine is running.

- If you hear unusual noises, inspect the alternator for signs of damage.

- Check the belt tension and condition.

- If the noises persist, the alternator may need to be replaced.

9.6. Using a Scan Tool for Diagnosis

A scan tool can provide valuable diagnostic information about the alternator and charging system.

How to Use a Scan Tool:

- Connect the scan tool to the vehicle’s diagnostic port.

- Turn on the ignition.

- Select the appropriate vehicle make and model.

- Read any diagnostic trouble codes (DTCs) related to the charging system.

- Use the scan tool to monitor the alternator output voltage and current.

By following these diagnostic steps, you can identify electrical problems related to alternator output current and take appropriate action. CARDIAGTECH.NET offers a range of diagnostic tools and equipment to help you troubleshoot and repair your vehicle’s electrical system effectively.

10. Frequently Asked Questions (FAQs) About Alternator Output Current

Here are some frequently asked questions about alternator output current:

1. What is the normal output current for an alternator?

The normal output current for an alternator varies depending on the vehicle and the electrical load. Typically, it should be around 10-30 amps at idle and 40-70 amps or more at higher engine speeds under load.

2. How do I check the output current of my alternator?

You can check the output current using a digital multimeter or a clamp meter. Connect the meter in series with the alternator output wire and measure the current while the engine is running.

3. What does low alternator output current indicate?

Low alternator output current indicates that the alternator is not producing enough power to meet the vehicle’s electrical demands, which can lead to a discharged battery and other electrical issues.

4. What can cause low alternator output current?

Possible causes include worn brushes, a faulty voltage regulator, a slipping belt, a damaged stator or rotor, and poor connections.

5. Can a bad battery affect alternator output current?

Yes, a bad battery can affect alternator output current. A failing battery may draw excessive current as it tries to charge, which can overload the alternator.

6. How often should I check my alternator output current?

You should check your alternator output current if you notice any signs of electrical issues, such as dim headlights, a battery warning light, or slow-operating accessories. Regular inspections can help identify potential problems early.

7. What tools do I need to check alternator output current?

Essential tools include a digital multimeter or clamp meter, safety glasses, and gloves. A battery load tester and scan tool can also be helpful.

8. Can I upgrade my alternator to increase its output current?

Yes, you can upgrade your alternator to a higher-output model if you frequently use high-demand electrical accessories or have upgraded your vehicle with additional electrical components.

9. What is the role of the voltage regulator in alternator output current?

The voltage regulator controls the alternator’s output voltage to prevent overcharging and maintain a stable voltage. A faulty voltage regulator can cause various issues, including low or excessive output current.

10. How do I maintain my alternator for optimal performance?

Regular maintenance tips include performing visual inspections, keeping connections clean and tight, checking belt tension, avoiding overloading the electrical system, and maintaining the battery.

By understanding these FAQs, you can better maintain and troubleshoot your vehicle’s alternator and electrical system. CARDIAGTECH.NET is here to provide you with the tools and information you need to keep your vehicle running smoothly.

Don’t let alternator issues leave you stranded. Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States or Whatsapp: +1 (641) 206-8880 for expert advice and top-quality tools to check and maintain your alternator output current. Ensure your vehicle’s electrical system is in top shape with our comprehensive solutions. Visit CARDIAGTECH.NET now and take control of your car’s performance.