P0301 Mercedes Code: Diagnosis, Causes, and Solutions

The P0301 Mercedes code indicates a misfire in cylinder 1, leading to potential engine damage if left unaddressed, but CARDIAGTECH.NET can help you diagnose and fix the problem. Addressing this promptly by identifying the root cause and implementing the appropriate repairs is crucial for maintaining your Mercedes-Benz’s performance and longevity. Explore misfire causes, repair solutions, and diagnostic tools.

1. Understanding the P0301 Mercedes Code

What does the P0301 Mercedes code signify? The P0301 Mercedes code indicates that the engine’s control module (ECM) has detected a misfire in cylinder number 1. This means that the cylinder is not firing correctly or consistently. A misfire can occur when there is an insufficient combustion in the cylinder, leading to reduced engine performance, increased emissions, and potential damage to other engine components. The Society of Automotive Engineers (SAE) defines a misfire as “a lack of combustion in a cylinder when it is expected.”

1.1. What are the Symptoms of a P0301 Code?

Experiencing a P0301 code can manifest in several noticeable symptoms. Recognizing these signs early can help prevent further damage and ensure timely repairs.

Here’s a breakdown of the most common symptoms:

- Check Engine Light: The most obvious sign is the illumination of the check engine light on your dashboard. This light may flash, indicating a more severe misfire condition.

- Rough Idle: The engine may vibrate or shake noticeably when the vehicle is idling. This is due to the inconsistent firing of the cylinders.

- Loss of Power: You may experience a decrease in acceleration and overall engine power, especially when climbing hills or carrying heavy loads.

- Poor Fuel Economy: Misfires can cause the engine to burn more fuel than usual, leading to a noticeable drop in gas mileage.

- Stalling: The engine may stall or die unexpectedly, particularly at low speeds or when coming to a stop.

- Hesitation: The engine may hesitate or stumble during acceleration, making it difficult to maintain a consistent speed.

- Unusual Noises: You might hear popping or sputtering sounds coming from the engine or exhaust.

- Smell of Fuel: Unburnt fuel may be present in the exhaust, resulting in a strong fuel odor.

1.2. Diagnostic Tools for P0301

Identifying the root cause of the P0301 code requires the use of several diagnostic tools. These tools help pinpoint the exact issue, saving time and ensuring accurate repairs. CARDIAGTECH.NET offers a range of these tools to assist in diagnosing the problem efficiently.

| Diagnostic Tool | Description | Benefits |

|---|---|---|

| OBD-II Scanner | Reads diagnostic trouble codes (DTCs) stored in the vehicle’s computer. | Provides a quick and easy way to identify the P0301 code and any other related codes. |

| Multimeter | Measures voltage, current, and resistance in electrical circuits. | Helps test the functionality of spark plugs, ignition coils, and fuel injectors. |

| Compression Tester | Measures the compression pressure in each cylinder. | Identifies issues such as worn piston rings, damaged valves, or a blown head gasket. |

| Fuel Pressure Tester | Measures the fuel pressure in the fuel system. | Helps determine if the fuel pump is delivering adequate fuel to the engine. |

| Noid Light | A small light that plugs into the fuel injector connector to indicate whether the injector is receiving a signal from the engine control module. | Verifies that the fuel injectors are being properly activated. |

| Spark Plug Tester | Tests the spark plugs to ensure they are producing a strong spark. | Identifies weak or non-functioning spark plugs. |

| Smoke Machine | Used to detect vacuum leaks in the engine. | Helps identify leaks in hoses, gaskets, and seals that can cause misfires. |

| Oscilloscope | Displays electrical signals over time, allowing for detailed analysis of ignition and fuel injection systems. | Provides a visual representation of the electrical signals, making it easier to diagnose intermittent or complex issues. |

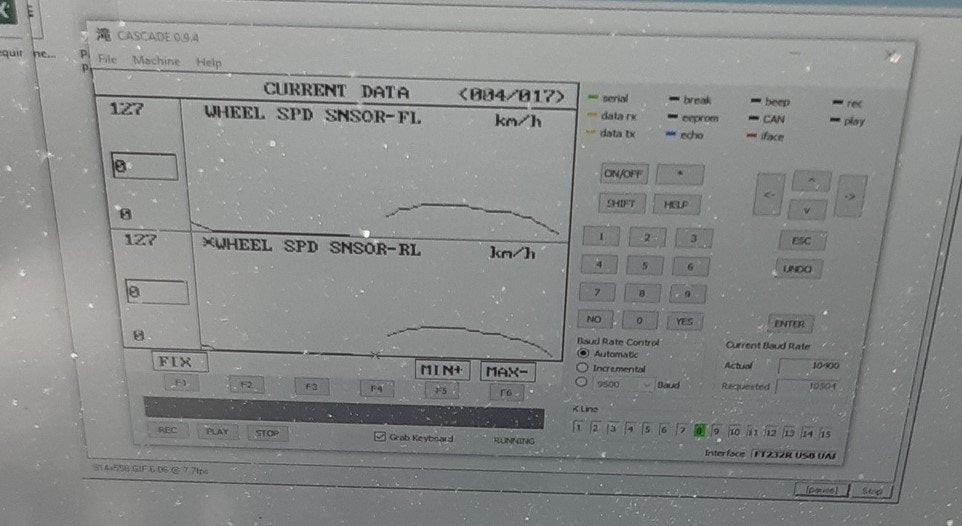

| Scan Tool with Live Data | Displays real-time data from the engine control module, such as engine speed, fuel trim, and sensor readings. | Allows for monitoring of engine parameters to identify abnormalities that may be causing the misfire. |

| Infrared Thermometer | Measures the temperature of each exhaust manifold runner. | Helps identify cylinders that are not firing properly by detecting temperature differences. |

1.3. Common Misconceptions About Misfires

Several misconceptions surround the topic of engine misfires. Addressing these can lead to more accurate diagnoses and effective repairs.

- Misfires Always Mean Major Engine Damage: While a persistent misfire can lead to engine damage over time, it doesn’t automatically indicate a catastrophic problem. Often, the issue is a simple fix, such as replacing a spark plug or cleaning a sensor.

- Misfires Only Occur in Old Cars: Misfires can occur in vehicles of any age, although they are more common in older cars with worn components. Newer vehicles can also experience misfires due to issues like faulty sensors or fuel injectors.

- Premium Fuel Prevents Misfires: While using the correct octane fuel is important, premium fuel alone won’t prevent misfires if there are underlying mechanical or electrical issues.

- Resetting the Check Engine Light Fixes the Problem: Resetting the check engine light will only temporarily clear the code. If the underlying issue is not addressed, the light will eventually return.

- All Misfires are the Same: Misfires can vary in severity and frequency. Some misfires are intermittent and barely noticeable, while others are constant and cause significant performance issues.

- Misfires are Always Obvious: Some misfires are subtle and may not be immediately apparent. They may only occur under certain conditions, such as during acceleration or at high speeds.

- Only One Cylinder Can Misfire at a Time: Multiple cylinders can misfire simultaneously, especially if the issue is related to a common component like the fuel pump or ignition coil.

- Aftermarket Parts Cause Misfires: While poorly designed or incompatible aftermarket parts can cause misfires, high-quality aftermarket parts that meet or exceed OEM specifications are generally safe to use.

- Misfires Only Affect Engine Performance: Misfires can also affect fuel economy, emissions, and the lifespan of other engine components, such as the catalytic converter.

- Misfires Can Be Diagnosed Without Tools: While some basic issues can be identified visually (e.g., a cracked spark plug), accurately diagnosing a misfire often requires specialized tools like OBD-II scanners, multimeters, and compression testers.

2. Diagnosing the P0301 Code: A Step-by-Step Guide

Diagnosing the P0301 code involves a systematic approach to identify the root cause of the misfire. Here’s a step-by-step guide to help you through the process, with tools and parts available at CARDIAGTECH.NET.

2.1. Initial Inspection

Begin with a thorough visual inspection of the engine components. This can often reveal obvious issues that are contributing to the misfire.

- Check the Spark Plugs: Examine the spark plugs in cylinder #1. Look for signs of wear, damage, or fouling. Replace the spark plug if necessary. According to Bosch, spark plugs should be replaced every 30,000 to 50,000 miles to maintain optimal engine performance.

- Inspect the Ignition Coil: Check the ignition coil for cracks, corrosion, or other damage. Use a multimeter to test the coil’s resistance and ensure it meets the manufacturer’s specifications.

- Examine the Wiring: Inspect the wiring and connectors for the spark plug and ignition coil. Look for loose connections, frayed wires, or corrosion.

- Check for Vacuum Leaks: Listen for hissing sounds around the engine, which could indicate a vacuum leak. Use a smoke machine to pinpoint the exact location of the leak.

- Inspect the Fuel Injector: Check the fuel injector for leaks or damage. Use a noid light to verify that the injector is receiving a signal from the engine control module.

- Review Other Error Codes: Check for any other error codes that may be present. These codes can provide valuable clues about the underlying cause of the misfire.

2.2. Advanced Diagnostics

If the initial inspection does not reveal the cause of the misfire, further diagnostics may be necessary. This involves using specialized tools to test the engine’s components and systems.

- Perform a Compression Test: Use a compression tester to measure the compression pressure in cylinder #1. Compare the results to the manufacturer’s specifications. Low compression can indicate a problem with the piston rings, valves, or head gasket.

- Test the Fuel Pressure: Use a fuel pressure tester to measure the fuel pressure in the fuel system. Low fuel pressure can indicate a problem with the fuel pump, fuel filter, or fuel pressure regulator.

- Check the Engine Timing: Verify that the engine timing is correct. Incorrect timing can cause misfires and other performance issues.

- Monitor Sensor Readings: Use a scan tool to monitor the readings from the camshaft sensor, crankshaft sensor, and O2 sensor. Abnormal readings can indicate a problem with these sensors.

- Inspect the Catalytic Converter: Check the catalytic converter for damage or clogs. A clogged catalytic converter can cause backpressure that leads to misfires.

2.3. Using an OBD-II Scanner

An OBD-II scanner is an essential tool for diagnosing the P0301 code. It allows you to read diagnostic trouble codes (DTCs) stored in the vehicle’s computer and access live data from the engine’s sensors.

- Connect the Scanner: Plug the OBD-II scanner into the diagnostic port, typically located under the dashboard.

- Read the Codes: Turn on the ignition and allow the scanner to retrieve the stored codes. Record any codes that are present.

- Clear the Codes: After recording the codes, clear them from the vehicle’s computer.

- Test Drive the Vehicle: Take the vehicle for a test drive to see if the P0301 code returns.

- Analyze Live Data: If the code returns, use the scanner to monitor live data from the engine’s sensors. Pay close attention to the readings from the O2 sensor, MAF sensor, and fuel trims.

2.4. Compression Testing Explained

A compression test is a critical diagnostic procedure used to evaluate the health of an engine’s cylinders. It measures the amount of pressure that each cylinder can build, providing valuable insights into the condition of the piston rings, valves, and cylinder head.

- Prepare the Engine: Warm up the engine to its normal operating temperature. Turn off the engine and disconnect the fuel injector and ignition coil for the cylinder being tested.

- Remove the Spark Plug: Remove the spark plug from the cylinder being tested.

- Insert the Compression Tester: Screw the compression tester into the spark plug hole.

- Crank the Engine: Crank the engine for several seconds while observing the compression tester gauge.

- Record the Reading: Record the highest reading on the gauge.

- Repeat for All Cylinders: Repeat the test for all cylinders and compare the readings.

3. Common Causes of the P0301 Code

Identifying the specific cause of the P0301 code is essential for effective repair. Here are some of the most common culprits, each with detailed explanations:

3.1. Faulty Spark Plugs

Faulty spark plugs are one of the most frequent causes of misfires. Spark plugs ignite the air-fuel mixture in the cylinders, and if they are worn, damaged, or fouled, they may not produce a strong enough spark to properly ignite the mixture.

- Worn Electrodes: Over time, the electrodes of the spark plugs can wear down, increasing the gap between them. This larger gap requires more voltage to create a spark, which can strain the ignition system and lead to misfires.

- Fouled Spark Plugs: Spark plugs can become fouled by oil, fuel, or carbon deposits. These deposits can insulate the electrodes, preventing them from sparking properly.

- Cracked or Damaged Insulator: The ceramic insulator of the spark plug can crack or break, allowing the spark to short circuit to the engine block instead of jumping across the electrodes.

Solution: Replace the faulty spark plugs with new ones that meet the manufacturer’s specifications. Ensure the spark plug gap is properly set before installation.

3.2. Ignition Coil Problems

The ignition coil is responsible for providing the high-voltage spark needed to ignite the air-fuel mixture in the cylinders. A faulty ignition coil can result in a weak or non-existent spark, leading to misfires.

- Cracked or Damaged Housing: The housing of the ignition coil can crack or break due to heat, vibration, or physical damage. This can allow moisture and contaminants to enter the coil, causing it to short circuit.

- Internal Short Circuit: The internal windings of the ignition coil can short circuit, reducing its ability to generate a high-voltage spark.

- Weak Spark Output: The ignition coil may produce a weak spark, which is not strong enough to ignite the air-fuel mixture properly.

Solution: Test the ignition coil using a multimeter to check its resistance and output voltage. Replace the faulty ignition coil with a new one that meets the manufacturer’s specifications.

3.3. Fuel Injector Issues

Fuel injectors are responsible for spraying fuel into the cylinders. A faulty fuel injector can disrupt the proper air-fuel mixture, leading to misfires.

- Clogged Fuel Injector: The fuel injector can become clogged with dirt, debris, or fuel deposits, restricting the flow of fuel into the cylinder.

- Leaking Fuel Injector: The fuel injector can leak fuel into the cylinder, causing an overly rich mixture that is difficult to ignite.

- Faulty Fuel Injector Solenoid: The solenoid that controls the fuel injector can fail, preventing the injector from opening or closing properly.

Solution: Clean the fuel injectors using a fuel injector cleaner or have them professionally cleaned. If the fuel injector is damaged or faulty, replace it with a new one that meets the manufacturer’s specifications.

3.4. Vacuum Leaks

Vacuum leaks can disrupt the air-fuel mixture by allowing unmetered air to enter the engine. This can lead to a lean mixture, which is difficult to ignite and can cause misfires.

- Cracked or Damaged Hoses: Vacuum hoses can crack or break over time, creating leaks that allow unmetered air to enter the engine.

- Loose or Disconnected Hoses: Vacuum hoses can become loose or disconnected from their fittings, creating leaks.

- Damaged Intake Manifold Gasket: The intake manifold gasket can become damaged or worn, creating leaks between the intake manifold and the cylinder head.

Solution: Inspect all vacuum hoses and connections for cracks, leaks, or damage. Replace any damaged hoses or gaskets. Use a smoke machine to pinpoint the location of vacuum leaks.

3.5. Low Compression

Low compression in a cylinder can prevent the air-fuel mixture from igniting properly, leading to misfires.

- Worn Piston Rings: The piston rings can wear down over time, reducing their ability to seal the cylinder and maintain compression.

- Damaged Valves: The valves can become damaged or worn, preventing them from sealing properly and maintaining compression.

- Blown Head Gasket: The head gasket can blow, creating a leak between the cylinder and the cooling system or the atmosphere.

Solution: Perform a compression test to measure the compression pressure in each cylinder. If low compression is detected, further diagnostics may be necessary to determine the cause. Depending on the cause, the engine may need to be rebuilt or replaced.

3.6. Sensor Malfunctions

Faulty sensors can provide incorrect data to the engine control module (ECM), leading to misfires.

- Oxygen (O2) Sensor: The O2 sensor measures the amount of oxygen in the exhaust and provides feedback to the ECM to adjust the air-fuel mixture. A faulty O2 sensor can cause the ECM to incorrectly adjust the air-fuel mixture, leading to misfires.

- Mass Airflow (MAF) Sensor: The MAF sensor measures the amount of air entering the engine. A faulty MAF sensor can provide incorrect data to the ECM, causing it to incorrectly adjust the air-fuel mixture.

- Crankshaft Position Sensor (CKP): The CKP sensor monitors the position of the crankshaft and provides data to the ECM to control ignition timing and fuel injection. A faulty CKP sensor can cause misfires and other performance issues.

- Camshaft Position Sensor (CMP): The CMP sensor monitors the position of the camshaft and provides data to the ECM to control ignition timing and fuel injection. A faulty CMP sensor can cause misfires and other performance issues.

Solution: Use a scan tool to monitor the readings from the sensors. If abnormal readings are detected, replace the faulty sensor with a new one that meets the manufacturer’s specifications.

4. Step-by-Step Solutions to Fix the P0301 Code

Once the cause of the P0301 code has been identified, the next step is to implement the appropriate solution. Here are some step-by-step solutions for common causes of the P0301 code:

4.1. Replacing Spark Plugs

Replacing spark plugs is a straightforward process that can often resolve misfires caused by worn or fouled plugs.

- Gather Your Tools and Materials: You’ll need new spark plugs, a spark plug socket, a ratchet, an extension, a torque wrench, and a spark plug gap tool.

- Disconnect the Ignition Coil: Disconnect the ignition coil from the spark plug you’re replacing.

- Remove the Old Spark Plug: Use the spark plug socket and ratchet to remove the old spark plug.

- Inspect the Spark Plug: Examine the spark plug for signs of wear, damage, or fouling.

- Set the Gap: Use the spark plug gap tool to set the gap on the new spark plug to the manufacturer’s specifications.

- Install the New Spark Plug: Carefully thread the new spark plug into the cylinder head by hand.

- Torque the Spark Plug: Use the torque wrench to tighten the spark plug to the manufacturer’s specifications.

- Reconnect the Ignition Coil: Reconnect the ignition coil to the spark plug.

- Repeat for Other Cylinders: Repeat the process for the other cylinders, if necessary.

4.2. Replacing Ignition Coils

Replacing ignition coils is a simple process that can often resolve misfires caused by a faulty coil.

- Gather Your Tools and Materials: You’ll need a new ignition coil, a socket, a ratchet, and a torque wrench.

- Disconnect the Ignition Coil: Disconnect the wiring harness from the ignition coil you’re replacing.

- Remove the Old Ignition Coil: Use the socket and ratchet to remove the old ignition coil.

- Install the New Ignition Coil: Install the new ignition coil in the same location as the old one.

- Torque the Ignition Coil: Use the torque wrench to tighten the ignition coil to the manufacturer’s specifications.

- Reconnect the Wiring Harness: Reconnect the wiring harness to the ignition coil.

4.3. Cleaning Fuel Injectors

Cleaning fuel injectors can help restore proper fuel flow and resolve misfires caused by clogged injectors.

- Gather Your Tools and Materials: You’ll need fuel injector cleaner, a fuel pressure tester, and a fuel injector cleaning kit.

- Add Fuel Injector Cleaner to the Fuel Tank: Add fuel injector cleaner to the fuel tank according to the manufacturer’s instructions.

- Run the Engine: Run the engine for at least 15 minutes to allow the fuel injector cleaner to circulate through the fuel system.

- Use a Fuel Injector Cleaning Kit: If the fuel injectors are still clogged, use a fuel injector cleaning kit to clean them more thoroughly.

4.4. Repairing Vacuum Leaks

Repairing vacuum leaks can help restore the proper air-fuel mixture and resolve misfires caused by unmetered air entering the engine.

- Locate the Vacuum Leak: Use a smoke machine or a vacuum gauge to locate the vacuum leak.

- Repair the Leak: Repair the leak by replacing damaged hoses, tightening loose connections, or replacing damaged gaskets.

4.5. Addressing Low Compression

Addressing low compression requires more extensive repairs, as it often indicates internal engine damage.

- Perform a Compression Test: Perform a compression test to confirm that low compression is present.

- Determine the Cause: Determine the cause of the low compression by inspecting the piston rings, valves, and cylinder head.

- Repair or Replace Damaged Components: Repair or replace any damaged components, such as piston rings, valves, or the cylinder head.

4.6. Replacing Sensors

Replacing faulty sensors can help restore proper engine operation and resolve misfires caused by incorrect data being sent to the ECM.

- Identify the Faulty Sensor: Use a scan tool to identify the faulty sensor.

- Disconnect the Sensor: Disconnect the wiring harness from the sensor you’re replacing.

- Remove the Old Sensor: Remove the old sensor.

- Install the New Sensor: Install the new sensor in the same location as the old one.

- Reconnect the Wiring Harness: Reconnect the wiring harness to the sensor.

5. Preventive Maintenance to Avoid P0301 Code

Preventive maintenance is crucial for avoiding the P0301 code and maintaining the health of your Mercedes-Benz. Regular maintenance can help identify and address potential issues before they lead to misfires and other performance problems.

5.1. Regular Spark Plug Replacement

Replacing spark plugs at the recommended intervals is essential for maintaining proper ignition and preventing misfires.

- Check the Owner’s Manual: Consult your owner’s manual for the recommended spark plug replacement interval.

- Inspect Spark Plugs Regularly: Inspect spark plugs regularly for signs of wear, damage, or fouling.

- Replace Spark Plugs as Needed: Replace spark plugs as needed, even if they have not reached the recommended replacement interval.

5.2. Fuel System Maintenance

Maintaining the fuel system can help prevent fuel injector clogs and other issues that can lead to misfires.

- Use Quality Fuel: Use quality fuel from reputable gas stations to minimize the risk of fuel contamination.

- Add Fuel Injector Cleaner: Add fuel injector cleaner to the fuel tank periodically to help keep the fuel injectors clean.

- Replace Fuel Filter: Replace the fuel filter at the recommended intervals to prevent dirt and debris from clogging the fuel injectors.

5.3. Regular Engine Check-Ups

Regular engine check-ups can help identify potential issues before they lead to misfires and other performance problems.

- Check for Vacuum Leaks: Check for vacuum leaks regularly by listening for hissing sounds around the engine.

- Monitor Sensor Readings: Monitor sensor readings using a scan tool to identify any abnormal readings.

- Perform Compression Tests: Perform compression tests periodically to check the health of the engine’s cylinders.

5.4. Keeping Your Engine Clean

Keeping your engine clean can help prevent dirt and debris from damaging engine components and causing misfires.

- Clean the Engine Regularly: Clean the engine regularly to remove dirt, grease, and other contaminants.

- Use a Quality Air Filter: Use a quality air filter to prevent dirt and debris from entering the engine.

- Check Air Filter Regularly: Check the air filter regularly and replace it as needed.

5.5. Monitoring Vehicle Performance

Monitoring your vehicle’s performance can help you identify potential issues before they lead to misfires and other problems.

- Pay Attention to Warning Lights: Pay attention to warning lights on the dashboard and address any issues promptly.

- Listen for Unusual Noises: Listen for unusual noises coming from the engine or exhaust.

- Monitor Fuel Economy: Monitor fuel economy and address any sudden drops in gas mileage.

6. How CARDIAGTECH.NET Can Help

CARDIAGTECH.NET is your trusted partner in diagnosing and resolving the P0301 Mercedes code. We offer a wide range of diagnostic tools, replacement parts, and expert advice to help you get your Mercedes-Benz running smoothly again.

6.1. High-Quality Diagnostic Tools

We offer a comprehensive selection of high-quality diagnostic tools to help you pinpoint the cause of the P0301 code.

- OBD-II Scanners: Our OBD-II scanners allow you to read diagnostic trouble codes and access live data from the engine’s sensors.

- Multimeters: Our multimeters help you test the functionality of spark plugs, ignition coils, and fuel injectors.

- Compression Testers: Our compression testers allow you to measure the compression pressure in each cylinder.

- Fuel Pressure Testers: Our fuel pressure testers help you measure the fuel pressure in the fuel system.

- Smoke Machines: Our smoke machines help you detect vacuum leaks in the engine.

6.2. Genuine Replacement Parts

We offer a wide range of genuine replacement parts for your Mercedes-Benz, ensuring the highest quality and compatibility.

- Spark Plugs: We offer a variety of spark plugs to meet the specific needs of your Mercedes-Benz.

- Ignition Coils: Our ignition coils are designed to provide a strong, reliable spark for optimal engine performance.

- Fuel Injectors: Our fuel injectors are designed to deliver the precise amount of fuel needed for efficient combustion.

- Sensors: We offer a variety of sensors, including O2 sensors, MAF sensors, CKP sensors, and CMP sensors.

6.3. Expert Advice and Support

Our team of expert technicians is available to provide advice and support throughout the diagnostic and repair process.

- Technical Support: Contact our technical support team for assistance with diagnosing the P0301 code and selecting the appropriate replacement parts.

- Online Resources: Access our online resources, including articles, videos, and troubleshooting guides, for additional information and support.

- Community Forum: Join our community forum to connect with other Mercedes-Benz owners and share your experiences.

6.4. Why Choose CARDIAGTECH.NET?

Choosing CARDIAGTECH.NET means choosing quality, reliability, and expertise. We are committed to providing our customers with the best products and services to help them keep their Mercedes-Benz vehicles running smoothly.

- Quality Products: We offer only the highest quality diagnostic tools and replacement parts.

- Competitive Prices: Our prices are competitive, ensuring that you get the best value for your money.

- Fast Shipping: We offer fast shipping to get you the parts you need quickly.

- Excellent Customer Service: Our customer service team is dedicated to providing exceptional support and assistance.

Don’t let the P0301 Mercedes code keep you off the road. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET to explore our range of diagnostic tools and replacement parts. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let us help you diagnose and fix the problem so you can get back to enjoying your Mercedes-Benz.

7. Real-World Examples and Case Studies

To further illustrate the process of diagnosing and resolving the P0301 Mercedes code, let’s examine a few real-world examples and case studies.

7.1. Case Study 1: Faulty Spark Plug

Vehicle: 2015 Mercedes-Benz C300

Symptoms: Check engine light, rough idle, loss of power

Diagnostic Steps:

- The technician connected an OBD-II scanner and retrieved the P0301 code.

- A visual inspection revealed that the spark plug in cylinder #1 was heavily worn and had a cracked insulator.

Solution:

- The technician replaced all spark plugs with new ones that met the manufacturer’s specifications.

- The check engine light was cleared, and the vehicle was test-driven.

Outcome: The rough idle and loss of power were resolved, and the check engine light did not return.

7.2. Case Study 2: Ignition Coil Failure

Vehicle: 2012 Mercedes-Benz E350

Symptoms: Check engine light, misfire under acceleration, poor fuel economy

Diagnostic Steps:

- The technician connected an OBD-II scanner and retrieved the P0301 code.

- The technician used a multimeter to test the ignition coil in cylinder #1 and found that it had a weak output.

Solution:

- The technician replaced the faulty ignition coil with a new one.

- The check engine light was cleared, and the vehicle was test-driven.

Outcome: The misfire under acceleration and poor fuel economy were resolved, and the check engine light did not return.

7.3. Case Study 3: Vacuum Leak

Vehicle: 2018 Mercedes-Benz GLC300

Symptoms: Check engine light, rough idle, hesitation during acceleration

Diagnostic Steps:

- The technician connected an OBD-II scanner and retrieved the P0301 code.

- The technician used a smoke machine to identify a vacuum leak in a cracked hose connected to the intake manifold.

Solution:

- The technician replaced the cracked vacuum hose with a new one.

- The check engine light was cleared, and the vehicle was test-driven.

Outcome: The rough idle and hesitation during acceleration were resolved, and the check engine light did not return.

7.4. Case Study 4: Fuel Injector Clog

Vehicle: 2014 Mercedes-Benz CLA250

Symptoms: Check engine light, rough idle, loss of power

Diagnostic Steps:

- The technician connected an OBD-II scanner and retrieved the P0301 code.

- The technician used a fuel injector cleaning kit to clean the fuel injectors and restored proper fuel flow.

Solution:

- The technician cleaned the fuel injectors using a fuel injector cleaning kit.

- The check engine light was cleared, and the vehicle was test-driven.

Outcome: The rough idle and loss of power were resolved, and the check engine light did not return.

7.5. Case Study 5: Low Compression

Vehicle: 2010 Mercedes-Benz S550

Symptoms: Check engine light, severe misfire, rough running engine

Diagnostic Steps:

- The technician connected an OBD-II scanner and retrieved the P0301 code.

- The technician performed a compression test and found that cylinder #1 had significantly low compression.

- Further inspection revealed worn piston rings.

Solution:

- The technician recommended an engine rebuild to address the worn piston rings.

- The engine was rebuilt with new piston rings.

- The check engine light was cleared, and the vehicle was test-driven.

Outcome: The severe misfire and rough-running engine were resolved, and the check engine light did not return.

8. The Importance of Addressing P0301 Promptly

Addressing the P0301 Mercedes code promptly is crucial for maintaining the health and performance of your vehicle. Ignoring the issue can lead to more severe problems and costly repairs down the road.

8.1. Potential for Further Engine Damage

A persistent misfire can cause significant damage to the engine and other components. Unburnt fuel can enter the exhaust system, damaging the catalytic converter. Misfires can also cause excessive vibration, which can damage engine mounts and other parts.

8.2. Increased Emissions

Misfires can cause the engine to produce excessive emissions, which can harm the environment. Additionally, failing an emissions test can result in fines and prevent you from renewing your vehicle’s registration.

8.3. Reduced Fuel Economy

Misfires can cause the engine to burn more fuel than usual, leading to a noticeable drop in gas mileage. This can add up to significant savings over time.

8.4. Safety Concerns

Misfires can cause the engine to stall unexpectedly, which can be dangerous, especially in heavy traffic or on the highway. A sudden loss of power can also make it difficult to control the vehicle.

8.5. Costly Repairs

Ignoring the P0301 code can lead to more costly repairs in the long run. Addressing the issue promptly can prevent further damage and minimize repair costs.

9. FAQ About the P0301 Mercedes Code

Here are some frequently asked questions about the P0301 Mercedes code:

9.1. Can I drive with a P0301 code?

Driving with a P0301 code is not recommended, as it can lead to further engine damage and safety concerns. It’s best to address the issue as soon as possible.

9.2. How much does it cost to fix a P0301 code?

The cost to fix a P0301 code can vary depending on the cause of the misfire. Simple repairs, such as replacing spark plugs or ignition coils, may cost a few hundred dollars. More complex repairs, such as addressing low compression or replacing fuel injectors, may cost thousands of dollars.

9.3. Can a bad O2 sensor cause a P0301 code?

Yes, a faulty O2 sensor can cause a P0301 code. The O2 sensor measures the amount of oxygen in the exhaust and provides feedback to the ECM to adjust the air-fuel mixture. A faulty O2 sensor can cause the ECM to incorrectly adjust the air-fuel mixture, leading to misfires.

9.4. Can a vacuum leak cause a P0301 code?

Yes, a vacuum leak can cause a P0301 code. Vacuum leaks can disrupt the air-fuel mixture by allowing unmetered air to enter the engine. This can lead to a lean mixture, which is difficult to ignite and can cause misfires.

9.5. Can a dirty air filter cause a P0301 code?

A severely clogged air filter can restrict airflow to the engine, potentially causing a lean condition and contributing to a P0301 code, though it’s less common than other causes.

9.6. How do I clear a P0301 code?

You can clear a P0301 code using an OBD-II scanner. Simply connect the scanner to the diagnostic port, retrieve the stored codes, and then select the option to clear the codes. However, keep in mind that the code may return if the underlying issue is not addressed.

9.7. What does cylinder 1 mean?

Cylinder 1 refers to the first cylinder in the engine’s firing order. The location of cylinder 1 can vary depending on the engine configuration, but it is typically located at the front of the engine.

9.8. Is it safe to drive with a flashing check engine light?

No, it is not safe to drive with a flashing check engine light. A flashing check engine light indicates a severe misfire that can cause significant damage to the engine and other components. It’s best to have the vehicle towed to a mechanic for diagnosis and repair.

9.9. Can low fuel pressure cause a P0301 code?

Yes, low fuel pressure can cause a P0301 code. Low fuel pressure can prevent the fuel injectors from delivering the proper amount of fuel to the cylinders, leading to misfires.

9.10. Will a P0301 code affect my car’s emissions?

Yes, a P0301 code can affect your car’s emissions. Misfires can cause the engine to produce excessive emissions, which can cause you to fail an emissions test.

10. Final Thoughts: Resolving Your P0301 Code with Confidence

Dealing with a P0301 Mercedes code can be frustrating,