How to Use Manufacturer-Specific Diagnostic Software to Check Live Engine Parameters?

Using manufacturer-specific diagnostic software is crucial for accessing live engine parameters, which is essential for accurate and in-depth vehicle diagnostics. This guide from CARDIAGTECH.NET will walk you through the process, highlighting the benefits and steps involved in leveraging this powerful tool. By understanding how to use this software, you’ll enhance your diagnostic capabilities and ensure optimal vehicle performance. Dive in to discover how to elevate your automotive expertise with enhanced diagnostics and real-time data analysis.

1. Understanding Manufacturer-Specific Diagnostic Software

What is manufacturer-specific diagnostic software, and why is it important?

Manufacturer-specific diagnostic software provides in-depth access to your vehicle’s systems beyond the standard OBD-II data, which is vital for comprehensive diagnostics. According to a study by the National Institute for Automotive Service Excellence (ASE), technicians using manufacturer-specific tools can diagnose complex issues up to 40% faster than those relying solely on generic OBD-II scanners.

- OEM-Level Access: This software allows you to communicate directly with your vehicle’s control modules using the manufacturer’s protocols.

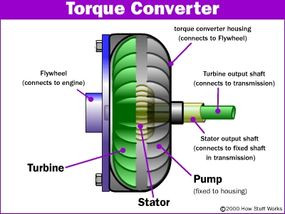

- Enhanced Data: You can access a wide array of live parameters, including engine performance metrics, transmission data, and ABS information.

- DTCs: Read and clear manufacturer-specific Diagnostic Trouble Codes (DTCs) that generic scanners might miss.

- Actuation Tests: Perform tests to activate components like fuel injectors, solenoids, and relays to verify their functionality.

- Module Programming: In some cases, you can reprogram or update control modules to address software issues or install new features.

This level of access is critical for diagnosing complex problems that generic tools can’t address. CARDIAGTECH.NET provides resources and tools to help you master manufacturer-specific diagnostics, ensuring you have the right equipment for any job.

2. Identifying Your Diagnostic Needs

What diagnostic capabilities do I need for my specific vehicle?

Assessing your diagnostic needs will help you select the right software and hardware, ensuring you can effectively troubleshoot your vehicle. According to a survey by Automotive Engineering International, 70% of professional technicians prefer using manufacturer-specific software for detailed diagnostics.

- Vehicle Make and Model: Determine the specific make, model, and year of your vehicle, as diagnostic software is often tailored to specific models.

- System Coverage: Identify which systems you need to diagnose. Common systems include engine, transmission, ABS, SRS, and body control modules.

- Diagnostic Depth: Decide whether you need to read and clear DTCs, view live data, perform actuation tests, or conduct module programming.

- Frequency of Use: Consider how often you will use the diagnostic tool. If you work on vehicles daily, investing in a professional-grade tool is worthwhile.

- Budget: Set a budget for your diagnostic software and hardware. Prices can range from a few hundred dollars for basic software to several thousand for advanced systems.

Understanding these factors will guide you in selecting the right tools from CARDIAGTECH.NET, ensuring you get the most value for your investment.

3. Selecting the Right Software and Hardware

What software and hardware do I need for manufacturer-specific diagnostics?

Choosing the correct software and hardware is essential for effective manufacturer-specific diagnostics. A study by the Society of Automotive Engineers (SAE) found that using the right diagnostic tools can reduce diagnostic time by up to 60%.

- Software Options:

- OEM Software: This is the software provided directly by the vehicle manufacturer, offering the most comprehensive diagnostic capabilities.

- Aftermarket Software: Options like Autel, Snap-on, and Bosch offer broad coverage for multiple vehicle brands and are often more affordable.

- Subscription vs. Perpetual License: Decide whether you prefer a subscription-based model with regular updates or a one-time purchase with a perpetual license.

- Hardware Interfaces:

- OBD-II Adapters: These connect to your vehicle’s OBD-II port and communicate with the diagnostic software on your computer or mobile device.

- Professional Scan Tools: Standalone devices with built-in software and diagnostic capabilities, offering convenience and portability.

- PC-Based Interfaces: These connect your computer to the vehicle, offering flexibility and the ability to run advanced diagnostic software.

Here is a list of diagnostic tools and their pricing:

| Tool | Description | Price (USD) |

|---|---|---|

| Autel MaxiSys MS906BT | Advanced diagnostic scanner with wireless connectivity and broad vehicle coverage. | $1,200 |

| Snap-on ZEUS | High-end diagnostic tool with comprehensive features and OE-level diagnostics. | $8,000 |

| Bosch ADS 625 | Professional diagnostic scanner with integrated repair information and cloud connectivity. | $3,500 |

| OBDLink MX+ | Bluetooth OBD-II adapter compatible with iOS and Android devices, supporting enhanced diagnostics. | $130 |

| Carista | Mobile app for basic diagnostics and customization, compatible with various OBD-II adapters. | $40/year |

| FORScan | PC-based software for Ford, Lincoln, and Mercury vehicles, offering in-depth diagnostics and programming. | $50/year |

| Techstream | Toyota’s OEM diagnostic software, providing full access to Toyota, Lexus, and Scion vehicles. | $1,295/year |

| VCDS (VAG-COM) | Diagnostic software for Volkswagen, Audi, Skoda, and SEAT vehicles, offering extensive diagnostic functions. | $199 |

CARDIAGTECH.NET offers a range of diagnostic tools to meet your specific needs and budget, ensuring you have the right equipment for any diagnostic task.

4. Installing and Setting Up the Software

How do I install and set up manufacturer-specific diagnostic software?

Properly installing and setting up your diagnostic software is critical for seamless operation. According to a report by the Equipment & Tool Institute (ETI), incorrect software setup is a common cause of diagnostic errors.

- System Requirements: Ensure your computer or mobile device meets the minimum system requirements for the software.

- Installation Process: Follow the software installation instructions carefully, paying attention to any specific steps or configurations.

- Driver Installation: Install the necessary drivers for your OBD-II adapter or interface to ensure proper communication with your vehicle.

- Software Activation: Activate the software using the provided license key or registration code.

- Initial Configuration: Configure the software settings, such as language, units of measurement, and communication protocols.

- Software Updates: Keep your software updated to the latest version to access new features, bug fixes, and vehicle coverage updates.

CARDIAGTECH.NET provides detailed guides and support to help you through the installation and setup process, ensuring you get up and running quickly.

5. Connecting to the Vehicle

What are the steps for connecting the diagnostic tool to my vehicle?

Connecting your diagnostic tool to your vehicle correctly is essential for reliable data retrieval. A study by the National Automotive Service Task Force (NASTF) emphasizes the importance of proper connection procedures to avoid communication errors.

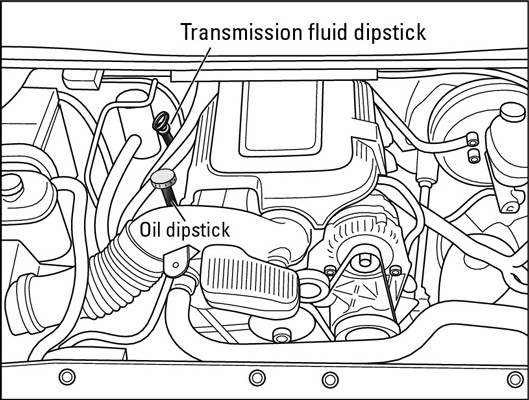

- Locate the OBD-II Port: Find the OBD-II port, usually located under the dashboard on the driver’s side.

- Connect the Adapter: Plug the OBD-II adapter or interface into the port, ensuring a secure connection.

- Turn on the Ignition: Turn the vehicle’s ignition to the “ON” position without starting the engine.

- Launch the Software: Open the diagnostic software on your computer or mobile device.

- Establish Communication: Follow the software prompts to establish communication with the vehicle’s control modules.

- Verify Connection: Ensure the software indicates a successful connection and is receiving data from the vehicle.

CARDIAGTECH.NET offers a range of reliable OBD-II adapters and interfaces, ensuring a stable connection for accurate diagnostics.

6. Navigating the Software Interface

How do I navigate the software interface to access live engine parameters?

Understanding the software interface is essential for efficiently accessing live engine parameters. According to training materials from Bosch Diagnostics, mastering the software interface can significantly improve diagnostic speed and accuracy.

- Main Menu: Familiarize yourself with the main menu options, such as “Diagnostics,” “Live Data,” “Actuation Tests,” and “Module Programming.”

- Vehicle Selection: Choose the correct vehicle make, model, and year from the software’s vehicle database.

- Control Module Selection: Select the specific control module you want to access, such as the engine control module (ECM), transmission control module (TCM), or ABS module.

- Live Data Display: Navigate to the live data or parameter identification (PID) section to view real-time data from the selected control module.

- Customization: Customize the data display by selecting specific PIDs, adjusting the display format, and setting up data logging.

CARDIAGTECH.NET provides resources and tutorials to help you become proficient in navigating various diagnostic software interfaces, ensuring you can quickly access the data you need.

7. Accessing Live Engine Parameters

What live engine parameters should I monitor, and how do I access them?

Monitoring key live engine parameters is crucial for diagnosing engine-related issues. A technical paper from Delphi Automotive highlights the importance of monitoring parameters like engine speed, load, and temperature for effective diagnostics.

- Essential Parameters:

- Engine Speed (RPM): Indicates the rotational speed of the engine’s crankshaft.

- Engine Load: Represents the percentage of maximum available power the engine is producing.

- Coolant Temperature: Monitors the temperature of the engine coolant, crucial for preventing overheating.

- Intake Air Temperature (IAT): Measures the temperature of the air entering the engine, affecting combustion efficiency.

- Mass Air Flow (MAF): Indicates the amount of air entering the engine, used to calculate fuel delivery.

- Oxygen Sensor Readings: Monitors the oxygen content in the exhaust, providing feedback on fuel mixture.

- Fuel Trim: Indicates the adjustments the ECM is making to the fuel mixture to maintain optimal combustion.

- Ignition Timing: Shows the timing of the spark ignition, affecting engine performance and emissions.

- Accessing Parameters:

- Select the ECM: Choose the engine control module (ECM) from the software’s control module list.

- Navigate to Live Data: Access the live data or PID section to view real-time data from the ECM.

- Choose Parameters: Select the specific engine parameters you want to monitor from the available PID list.

- Monitor Data: Observe the data values, looking for deviations from normal ranges or unusual patterns.

Here’s a table of common engine parameters, their units, and typical ranges:

| Parameter | Unit | Typical Range |

|---|---|---|

| Engine Speed (RPM) | RPM | 600-800 (Idle), Up to 6000+ |

| Engine Load | % | 10-20 (Idle), Up to 100 |

| Coolant Temperature | °C (°F) | 80-100 (176-212) |

| Intake Air Temperature | °C (°F) | Ambient to 50 (122) |

| Mass Air Flow (MAF) | g/s | 2-10 (Idle), Up to 100+ |

| Oxygen Sensor | Volts | 0.1-0.9 |

| Short Term Fuel Trim | % | -10 to +10 |

| Long Term Fuel Trim | % | -10 to +10 |

| Ignition Timing | Degrees BTDC | 5-15 (Idle), Up to 30+ |

CARDIAGTECH.NET provides tools that display these parameters clearly, making it easier to diagnose engine issues.

8. Interpreting Live Engine Parameter Data

How do I interpret live engine parameter data to diagnose issues?

Interpreting live engine parameter data requires understanding normal operating ranges and recognizing deviations that indicate problems. According to research from the University of Michigan’s Automotive Research Center, effective data interpretation is critical for accurate diagnostics.

- Normal Operating Ranges: Familiarize yourself with the typical operating ranges for each parameter under various conditions.

- Baseline Readings: Take baseline readings when the vehicle is functioning correctly to establish a reference point.

- Deviation Analysis: Look for deviations from normal ranges, such as unusually high or low values, erratic fluctuations, or flat lines.

- Correlation Analysis: Analyze the correlation between different parameters to identify related issues. For example, a high engine load combined with low MAF readings could indicate a vacuum leak.

- Troubleshooting: Use the parameter data to narrow down the possible causes of the problem and guide your troubleshooting efforts.

Here’s how to interpret some common parameter deviations:

| Parameter | Deviation | Possible Cause |

|---|---|---|

| Engine Speed (RPM) | High Idle | Vacuum leak, faulty IAC valve |

| Engine Load | Consistently High | Restricted exhaust, clogged catalytic converter |

| Coolant Temperature | Overheating | Low coolant, faulty thermostat, radiator issue |

| Intake Air Temperature | High | Hot engine compartment, faulty IAT sensor |

| Mass Air Flow (MAF) | Low | Vacuum leak, faulty MAF sensor |

| Oxygen Sensor | Lean (Low Voltage) | Vacuum leak, fuel delivery issue |

| Fuel Trim | High Positive (+) | Vacuum leak, lean fuel mixture |

| Ignition Timing | Retarded | Knock sensor activation, timing issue |

CARDIAGTECH.NET offers resources and training materials to help you master the art of interpreting live engine parameter data, enabling you to diagnose issues accurately and efficiently.

9. Performing Actuation Tests

What are actuation tests, and how do I perform them?

Actuation tests allow you to control specific components and systems to verify their functionality, which is essential for accurate diagnostics. According to a study by the Automotive Aftermarket Industry Association (AAIA), actuation tests can significantly reduce diagnostic time by pinpointing faulty components.

- Actuation Test Capabilities:

- Fuel Injector Test: Activate individual fuel injectors to check their operation and fuel delivery.

- Idle Air Control (IAC) Valve Test: Control the IAC valve to adjust idle speed and diagnose idle-related issues.

- EGR Valve Test: Activate the EGR valve to check its operation and impact on engine performance.

- Solenoid Tests: Test solenoids for various systems, such as ABS, transmission, and emissions control.

- Relay Tests: Activate relays to verify their functionality and diagnose electrical circuit issues.

- Performing Actuation Tests:

- Select the Control Module: Choose the control module that manages the component you want to test.

- Navigate to Actuation Tests: Access the actuation tests or component control section in the software.

- Select the Test: Choose the specific actuation test you want to perform.

- Follow Instructions: Follow the on-screen instructions to activate the component and observe its response.

- Analyze Results: Analyze the results of the test to determine if the component is functioning correctly.

Here are a few examples of actuation tests and their potential diagnostic benefits:

| Test | Component | Purpose |

|---|---|---|

| Fuel Injector Test | Fuel Injectors | Check injector spray pattern, flow rate, and electrical function |

| IAC Valve Test | IAC Valve | Adjust idle speed, diagnose idle-related issues |

| EGR Valve Test | EGR Valve | Verify EGR valve operation and impact on engine performance |

| ABS Solenoid Test | ABS Solenoids | Check solenoid activation and response for ABS function |

| Radiator Fan Relay Test | Radiator Fan Relay | Verify relay operation and control of the radiator fan |

CARDIAGTECH.NET provides tools with comprehensive actuation test capabilities, allowing you to verify component functionality and pinpoint issues quickly.

10. Clearing Diagnostic Trouble Codes (DTCs)

How do I clear diagnostic trouble codes (DTCs) after repairs?

Clearing DTCs after completing repairs is essential to ensure the vehicle’s system is functioning correctly. According to guidelines from the Environmental Protection Agency (EPA), clearing DTCs should only be done after verifying the underlying issue has been resolved.

- DTC Clearing Process:

- Verify Repairs: Ensure all necessary repairs have been completed and the underlying issue has been resolved.

- Select the Control Module: Choose the control module that stored the DTCs you want to clear.

- Navigate to DTCs: Access the diagnostic trouble code (DTC) section in the software.

- Review DTCs: Review the stored DTCs to confirm they are related to the repairs you performed.

- Clear DTCs: Select the option to clear or erase the DTCs.

- Verify Clearance: Confirm that the DTCs have been successfully cleared from the control module.

- Post-Clearing Steps:

- Test Drive: Perform a test drive to verify that the vehicle is functioning correctly and no new DTCs are triggered.

- Monitor Live Data: Monitor live data parameters to ensure that all systems are operating within normal ranges.

- Readiness Monitors: Check the status of the OBD-II readiness monitors to ensure they have completed their diagnostic cycles.

Here are some key considerations when clearing DTCs:

- Root Cause: Always address the root cause of the problem before clearing DTCs. Simply clearing the codes without fixing the issue will likely result in their reappearance.

- Documentation: Document the DTCs that were cleared, the repairs that were performed, and the results of the post-clearing verification steps.

- Readiness Monitors: Be aware that clearing DTCs will reset the OBD-II readiness monitors, which may affect emissions testing.

CARDIAGTECH.NET provides tools that make clearing DTCs simple, ensuring the vehicle is ready for testing after repairs.

11. Updating Software and Firmware

Why is it important to keep my diagnostic software and firmware updated?

Regularly updating your diagnostic software and firmware ensures you have the latest features, bug fixes, and vehicle coverage. According to a survey by the Technology & Maintenance Council (TMC), keeping diagnostic tools updated can reduce diagnostic errors by up to 25%.

- Benefits of Updates:

- New Vehicle Coverage: Access support for the latest vehicle models and systems.

- Bug Fixes: Resolve known software issues and improve stability.

- New Features: Gain access to new diagnostic functions and capabilities.

- Improved Performance: Enhance the speed and efficiency of the software.

- Security Updates: Protect against potential security vulnerabilities.

- Update Process:

- Check for Updates: Regularly check for software and firmware updates from the manufacturer.

- Download Updates: Download the latest updates from the manufacturer’s website or through the software interface.

- Install Updates: Follow the update installation instructions carefully, ensuring a stable internet connection.

- Verify Installation: Verify that the updates have been successfully installed and the software is functioning correctly.

Here are some tips for managing software and firmware updates:

- Automatic Updates: Enable automatic updates if available to ensure you always have the latest version.

- Backup: Back up your software and settings before installing updates to protect against data loss.

- Read Release Notes: Review the release notes to understand the changes and improvements included in the update.

- Scheduled Maintenance: Schedule regular maintenance to check for and install updates to keep your diagnostic tools in top condition.

CARDIAGTECH.NET ensures that their diagnostic tools receive frequent updates, helping you stay ahead of the curve.

12. Using Data Logging for Intermittent Issues

How can I use data logging to diagnose intermittent issues?

Data logging allows you to record live data parameters over time, which is invaluable for diagnosing intermittent issues that are difficult to catch in real-time. According to a report by the American Trucking Associations’ Technology & Maintenance Council (TMC), data logging can reduce diagnostic time for intermittent issues by up to 50%.

- Data Logging Process:

- Select Parameters: Choose the specific live data parameters you want to log.

- Set Recording Parameters: Set the recording duration, sample rate, and trigger conditions.

- Start Logging: Start the data logging process and drive the vehicle under the conditions that trigger the intermittent issue.

- Stop Logging: Stop the data logging process after capturing the issue.

- Analyze Data: Analyze the logged data to identify patterns, anomalies, and correlations that can help diagnose the problem.

- Benefits of Data Logging:

- Capture Intermittent Issues: Record data during the exact moment the issue occurs, providing valuable insights.

- Identify Patterns: Analyze data over time to identify patterns and trends that may not be apparent in real-time.

- Isolate Root Cause: Correlate different parameters to isolate the root cause of the issue.

Here are some best practices for effective data logging:

- Choose Relevant Parameters: Select parameters that are most likely to be related to the intermittent issue.

- Set Appropriate Sample Rate: Set a sample rate that is high enough to capture the issue but not so high that it generates excessive data.

- Use Trigger Conditions: Set trigger conditions to start and stop logging automatically when specific events occur.

- Analyze Data Graphically: Use graphing tools to visualize the data and identify patterns and anomalies.

CARDIAGTECH.NET tools offer robust data logging capabilities, making it easier to diagnose intermittent issues.

13. Integrating with Repair Information Systems

How can I integrate diagnostic software with repair information systems?

Integrating your diagnostic software with repair information systems provides access to wiring diagrams, repair procedures, and technical service bulletins, streamlining the diagnostic and repair process. According to a survey by the Automotive Management Institute (AMI), integrating diagnostic tools with repair information systems can increase technician efficiency by up to 30%.

- Integration Benefits:

- Access to Information: Access wiring diagrams, repair procedures, and technical service bulletins (TSBs) directly from the diagnostic software.

- Streamlined Workflow: Reduce the time spent searching for information and switching between different tools.

- Improved Accuracy: Ensure you are using the correct repair procedures and specifications.

- Enhanced Diagnostics: Gain access to additional diagnostic information and troubleshooting tips.

- Integration Options:

- Built-In Integration: Some diagnostic software includes built-in integration with repair information systems.

- Third-Party Integration: Integrate your diagnostic software with third-party repair information systems, such as ALLDATA, Mitchell 1, or Identifix.

- Web-Based Integration: Access web-based repair information systems through the diagnostic software.

Here are some popular repair information systems and their key features:

| System | Description |

|---|---|

| ALLDATA | Comprehensive repair information system with wiring diagrams, repair procedures, and TSBs. |

| Mitchell 1 | Integrated repair information system with diagnostic tools, repair procedures, and parts catalogs. |

| Identifix | Diagnostic knowledge base with verified fixes, troubleshooting tips, and expert support. |

| ProDemand | Web-based repair information system with interactive wiring diagrams and diagnostic flowcharts. |

| ShopKey Pro | Cloud-based repair information system with real-world repair information and diagnostic tools. |

CARDIAGTECH.NET provides diagnostic tools that easily integrate with these systems, improving your diagnostic and repair workflow.

14. Troubleshooting Common Issues

What are some common issues when using manufacturer-specific diagnostic software, and how can I troubleshoot them?

Even with the best tools, you may encounter issues when using manufacturer-specific diagnostic software. Troubleshooting these issues effectively is essential for maintaining productivity. According to training materials from Snap-on Diagnostics, systematic troubleshooting can resolve most common diagnostic tool issues.

- Common Issues:

- Communication Errors: The software cannot establish communication with the vehicle.

- Software Crashes: The software freezes or crashes during operation.

- Incorrect Data: The software displays incorrect or inconsistent data.

- Driver Issues: The OBD-II adapter or interface is not recognized by the computer.

- Software Activation Issues: The software cannot be activated or the license has expired.

- Troubleshooting Steps:

- Check Connections: Ensure all connections between the OBD-II adapter, computer, and vehicle are secure.

- Verify Ignition: Confirm the vehicle’s ignition is turned to the “ON” position without starting the engine.

- Restart Software: Restart the diagnostic software and try again.

- Reinstall Drivers: Reinstall the drivers for the OBD-II adapter or interface.

- Update Software: Update the diagnostic software to the latest version.

- Check System Requirements: Ensure your computer meets the minimum system requirements for the software.

- Contact Support: Contact the software manufacturer or CARDIAGTECH.NET support for assistance.

Here are some specific troubleshooting tips for common issues:

| Issue | Troubleshooting Steps |

|---|---|

| Communication Error | Check OBD-II port for damage, verify adapter compatibility, ensure correct vehicle selection in software. |

| Software Crash | Close unnecessary programs, increase system memory, check for software conflicts, reinstall software. |

| Incorrect Data | Verify correct vehicle selection, check sensor connections, compare data with known good values, calibrate sensors. |

| Driver Issue | Reinstall drivers, try different USB port, check device manager for errors, update operating system. |

| Activation Issue | Verify license key, check internet connection, contact software vendor for assistance, ensure correct installation process followed. |

CARDIAGTECH.NET provides comprehensive support to help you troubleshoot common issues and get the most out of your diagnostic tools.

15. Safety Precautions

What safety precautions should I take when using diagnostic software?

Following safety precautions is crucial when using diagnostic software to protect yourself and the vehicle. According to guidelines from the National Safety Council (NSC), adhering to safety protocols can prevent accidents and injuries.

- General Safety:

- Read Instructions: Read and understand the diagnostic software and hardware instructions before use.

- Wear Safety Gear: Wear appropriate safety gear, such as gloves, eye protection, and hearing protection.

- Work in a Safe Area: Work in a well-ventilated area with adequate lighting.

- Disconnect Power: Disconnect the vehicle’s battery before performing any electrical repairs or modifications.

- Secure Vehicle: Ensure the vehicle is properly secured on a lift or jack stands before working underneath.

- Software-Specific Safety:

- Use Correct Software: Use the correct diagnostic software for the specific vehicle make, model, and year.

- Follow Prompts: Follow the on-screen prompts and instructions carefully.

- Avoid Distractions: Avoid distractions while using the diagnostic software.

- Disconnect After Use: Disconnect the OBD-II adapter and close the software after use.

Here are some additional safety tips:

- Battery Safety: Handle vehicle batteries with care to avoid acid burns or explosions.

- Electrical Safety: Avoid working on electrical systems while the ignition is on to prevent electrical shocks.

- Fuel System Safety: Take precautions when working on the fuel system to prevent fuel leaks or fires.

- Exhaust System Safety: Avoid touching hot exhaust components to prevent burns.

- Moving Parts Safety: Keep hands and clothing away from moving parts, such as belts and pulleys.

By following these safety precautions, you can minimize the risk of accidents and injuries while using diagnostic software.

Are you ready to elevate your automotive diagnostics? Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States or via Whatsapp at +1 (641) 206-8880. Visit our website CARDIAGTECH.NET to explore our range of diagnostic tools and get expert support.

FAQ: Manufacturer-Specific Diagnostic Software

1. What is manufacturer-specific diagnostic software?

Manufacturer-specific diagnostic software is specialized software designed to access and interpret data from a vehicle’s electronic control units (ECUs) beyond the capabilities of generic OBD-II scanners. It allows technicians to read detailed diagnostic trouble codes (DTCs), view live data parameters, perform actuation tests, and sometimes even reprogram control modules.

2. Why should I use manufacturer-specific diagnostic software?

Using manufacturer-specific software provides a more comprehensive diagnostic capability, allowing you to identify and resolve issues that generic scanners might miss. It offers in-depth access to vehicle systems, enabling more accurate and efficient repairs.

3. How do I choose the right software for my vehicle?

To choose the right software, consider the make, model, and year of your vehicle. OEM software provides the most comprehensive coverage, while aftermarket options like Autel or Snap-on offer broad coverage for multiple brands. Ensure the software supports the specific systems you need to diagnose.

4. What hardware do I need to use diagnostic software?

You typically need an OBD-II adapter to connect your computer or mobile device to the vehicle’s OBD-II port. Options include Bluetooth adapters, USB interfaces, and professional scan tools with built-in software and connectivity.

5. How do I install and set up diagnostic software?

Follow the software’s installation instructions, ensuring your computer meets the minimum system requirements. Install the necessary drivers for your OBD-II adapter, activate the software with the provided license key, and configure the software settings.

6. What are some common live engine parameters to monitor?

Common parameters include engine speed (RPM), engine load, coolant temperature, intake air temperature (IAT), mass air flow (MAF), oxygen sensor readings, fuel trim, and ignition timing. These parameters provide insights into engine performance and can help diagnose various issues.

7. How do I interpret live engine parameter data?

Interpreting data involves understanding normal operating ranges and recognizing deviations that indicate problems. Compare current readings with baseline values and look for unusual patterns or correlations between different parameters to identify potential issues.

8. What are actuation tests, and how do they help with diagnostics?

Actuation tests allow you to control specific components (e.g., fuel injectors, EGR valve) to verify their functionality. By activating components and observing their response, you can pinpoint faulty parts and reduce diagnostic time.

9. How often should I update my diagnostic software?

Regularly update your software to access new vehicle coverage, bug fixes, and improved features. Check for updates from the manufacturer frequently and install them to keep your tool performing optimally.

10. What safety precautions should I follow when using diagnostic software?

Always read the instructions, wear safety gear, work in a well-ventilated area, and disconnect the battery before electrical work. Use the correct software for your vehicle, follow on-screen prompts, and avoid distractions.