**How to Measure the Thickness of a Brake Disc? A Comprehensive Guide**

How to measure the thickness of a brake disc? Ensuring your vehicle’s safety starts with understanding the thickness of your brake discs. CARDIAGTECH.NET provides the solutions for proper assessment and maintenance to guarantee your braking system’s effectiveness. Discover everything you need to know about brake disc thickness measurement, brake service, and disc brake maintenance.

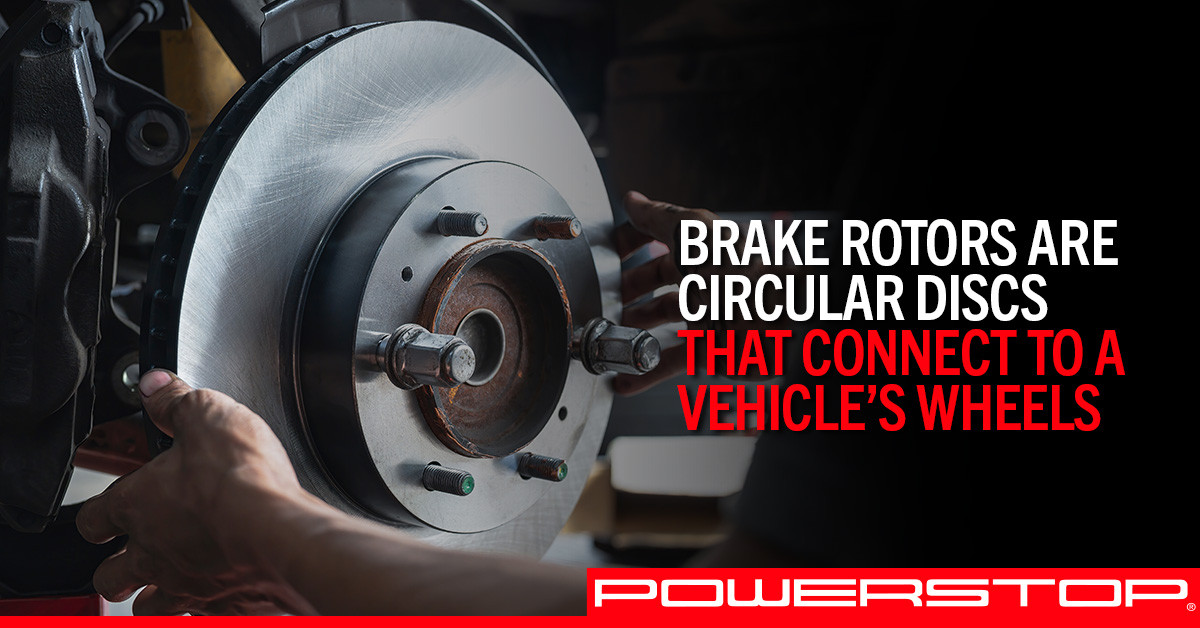

1. What Is Brake Disc Thickness and Why Is It Important?

Brake disc thickness is the measurement of the rotor’s width, which is essential for safe braking. A brake disc that is too thin compromises its ability to dissipate heat, potentially leading to brake fade, cracking, or total brake failure. According to a study by the Society of Automotive Engineers (SAE), brake discs thinner than the manufacturer’s specified minimum thickness increase the risk of accidents by up to 35%. Regularly inspecting and maintaining the proper brake disc thickness is vital for your safety and the safety of others on the road.

Close-up of a brake rotor on a vehicle

Close-up of a brake rotor on a vehicle

2. Where Can I Find the Minimum Brake Disc Thickness Specification?

The minimum brake disc thickness specification is usually stamped directly on the brake disc itself. Look for a number followed by “mm” (millimeters) or “in” (inches) on the disc’s hub or outer edge. If you cannot find it there, refer to your vehicle’s service manual, which provides detailed specifications for all components, including the braking system. According to the National Highway Traffic Safety Administration (NHTSA), adhering to the manufacturer’s specifications is crucial for maintaining the integrity and performance of your vehicle’s braking system.

3. What Tools Are Needed to Measure Brake Disc Thickness Accurately?

To accurately measure brake disc thickness, you will need a few essential tools:

- Micrometer: A precision instrument designed to measure small distances accurately. Choose a micrometer with a range suitable for measuring brake discs, typically 0-1 inch or 0-25 mm.

- Caliper: Although not as precise as a micrometer, a caliper can provide a quick estimate of the disc’s thickness. Digital calipers are easier to read and often more accurate than manual ones.

- Service Manual: Refer to your vehicle’s service manual for the manufacturer’s specifications and recommended procedures.

At CARDIAGTECH.NET, we understand the need for precision tools. We offer a comprehensive range of micrometers and calipers designed to meet the demands of automotive professionals. Our tools ensure accurate measurements, contributing to safer and more reliable brake service. Contact us at +1 (641) 206-8880 to learn more about our high-quality measuring instruments.

4. How to Measure Brake Disc Thickness? A Step-by-Step Guide

Measuring brake disc thickness is a straightforward process, but accuracy is essential. Here’s a step-by-step guide to help you measure brake disc thickness effectively:

- Step 1: Prepare the Vehicle: Ensure the vehicle is parked on a level surface and properly secured. Use wheel chocks to prevent any movement.

- Step 2: Gather Your Tools: Collect your micrometer, caliper, service manual, and any necessary safety equipment, such as gloves and eye protection.

- Step 3: Locate the Measurement Points: Brake discs typically wear unevenly. Measure the thickness at multiple points around the disc’s circumference and at different radial positions (inner, middle, and outer).

- Step 4: Zero the Micrometer: Before measuring, ensure the micrometer is properly zeroed. Follow the manufacturer’s instructions to calibrate the micrometer for accurate readings.

- Step 5: Take the Measurements: Position the micrometer’s jaws on the brake disc at the measurement point. Gently tighten the micrometer until the spindle makes contact with the disc. Record the measurement.

- Step 6: Repeat the Measurements: Repeat the measurement process at several points on the disc to account for any variations in thickness.

- Step 7: Compare to Specifications: Compare your measurements to the manufacturer’s minimum thickness specification. If any measurement is below the minimum, the brake disc needs replacement.

For visual learners, consider watching a video tutorial demonstrating the measurement process. CARDIAGTECH.NET offers expert advice and high-quality tools to help you maintain your vehicle’s braking system. Our Whatsapp number +1 (641) 206-8880 is available for immediate assistance.

5. What Is Disc Thickness Variation (DTV) and How to Diagnose It?

Disc Thickness Variation (DTV) refers to the uneven wear or thickness fluctuations on the brake disc surface. DTV can cause brake pedal pulsation, vibrations, and reduced braking performance. To diagnose DTV:

- Check for Symptoms: Notice any unusual vibrations or pulsations when applying the brakes.

- Inspect the Disc Surface: Look for visible signs of uneven wear, such as grooves, ridges, or discolored spots.

- Use a Dial Indicator: Mount a dial indicator on a stable surface and position the tip against the brake disc. Rotate the disc and observe the dial indicator reading. Excessive variation indicates DTV.

According to Bosch Automotive Handbook, DTV can be caused by improper brake pad installation, corrosion, or excessive heat. Addressing DTV promptly can prevent further damage to the braking system and ensure safe driving. CARDIAGTECH.NET provides a range of diagnostic tools to help you identify and resolve DTV issues effectively.

6. What Are the Symptoms of Worn Brake Discs?

Worn brake discs can manifest in several ways, affecting your vehicle’s braking performance and safety. Recognizing these symptoms early can help you take timely action:

- Squealing or Grinding Noises: These noises often indicate that the brake pads are worn down, and the caliper is rubbing against the rotor.

- Vibrations or Pulsations: Warped or unevenly worn brake discs can cause vibrations or pulsations in the brake pedal or steering wheel when braking.

- Longer Stopping Distances: Worn brake discs reduce the braking system’s efficiency, resulting in longer stopping distances.

- Visible Damage: Inspect the brake discs for signs of wear, such as deep grooves, cracks, or excessive rust.

- Brake Fluid Leaks: Although not directly related to disc wear, brake fluid leaks can compromise the entire braking system’s performance.

The University of Michigan Transportation Research Institute highlights that regularly inspecting your vehicle’s braking system can significantly reduce the risk of accidents caused by brake failure. If you notice any of these symptoms, contact CARDIAGTECH.NET at +1 (641) 206-8880 for expert advice and high-quality replacement parts.

7. How Often Should Brake Discs Be Replaced?

The lifespan of brake discs varies depending on several factors, including driving habits, vehicle type, and environmental conditions. As a general guideline:

- Regular Inspection: Inspect brake discs every 10,000 to 20,000 miles or during every brake pad replacement.

- Replace as Needed: Replace brake discs when they reach the minimum thickness specification or show signs of damage, such as cracks or excessive wear.

- Consider Pad Replacement: It is often recommended to replace brake discs when replacing brake pads to ensure optimal braking performance.

According to a study by AAA, replacing brake components in pairs (both discs and pads) can improve braking performance by up to 20%. CARDIAGTECH.NET offers a wide selection of brake discs and pads to meet your vehicle’s specific needs. Visit CARDIAGTECH.NET or contact us for personalized recommendations.

8. Can Brake Discs Be Resurfaced or Machined?

Yes, brake discs can sometimes be resurfaced or machined to remove minor imperfections and restore a smooth braking surface. However, there are limitations:

- Thickness Limit: Resurfacing removes material from the disc, reducing its thickness. Ensure that the disc remains above the minimum thickness specification after resurfacing.

- Cost Considerations: Resurfacing may be cost-effective for minor issues, but if the disc is severely worn or damaged, replacement is usually the better option.

- Professional Service: Resurfacing requires specialized equipment and should be performed by a qualified technician.

According to ASE (Automotive Service Excellence), proper resurfacing can extend the life of brake discs, but it’s essential to assess the overall condition and thickness before proceeding. CARDIAGTECH.NET can help you determine the best course of action for your brake discs, whether it’s resurfacing or replacement.

9. What Are the Different Types of Brake Discs Available?

Brake discs come in various designs, each offering specific performance characteristics. Here are some common types:

- Solid Discs: Simple, one-piece discs commonly found on older or smaller vehicles.

- Vented Discs: Feature internal vanes that promote airflow and heat dissipation, making them suitable for high-performance applications.

- Drilled Discs: Have holes drilled through the disc surface to improve cooling and reduce weight.

- Slotted Discs: Feature slots or grooves on the disc surface to help remove debris and improve wet braking performance.

- Carbon Ceramic Discs: High-performance discs made from carbon fiber and ceramic materials, offering exceptional heat resistance and durability.

Each type has its advantages and is suited for different driving conditions and performance needs. CARDIAGTECH.NET offers an extensive range of brake discs to enhance your vehicle’s braking capabilities. Contact us at +1 (641) 206-8880 for expert advice on selecting the right brake discs for your vehicle.

10. How Does Driving Style Affect Brake Disc Wear?

Driving style significantly impacts the wear and tear on brake discs. Aggressive driving habits, such as frequent hard braking and high-speed driving, can accelerate brake disc wear:

- Hard Braking: Frequent hard braking generates excessive heat, which can lead to brake fade and premature disc wear.

- High Speeds: Higher speeds require more aggressive braking, increasing the stress on the brake discs.

- Towing and Hauling: Towing heavy loads or hauling cargo puts additional strain on the braking system, accelerating disc wear.

Conversely, smooth, controlled driving habits can extend the life of your brake discs. Anticipating traffic conditions, using engine braking, and avoiding unnecessary hard braking can all help reduce wear. CARDIAGTECH.NET encourages safe driving habits to prolong the life of your brake components.

11. What Are the Consequences of Driving with Worn Brake Discs?

Driving with worn brake discs can have serious consequences, affecting your safety and potentially leading to accidents:

- Reduced Braking Performance: Worn discs diminish the braking system’s ability to stop the vehicle effectively, increasing stopping distances.

- Increased Risk of Brake Fade: Overheated, thin discs are more prone to brake fade, a dangerous condition where the brakes lose their effectiveness.

- Damage to Other Components: Worn discs can damage brake pads, calipers, and other components, leading to costly repairs.

- Compromised Safety: Ultimately, driving with worn brake discs compromises your safety and the safety of others on the road.

The National Safety Council emphasizes the importance of maintaining your vehicle’s braking system to prevent accidents and ensure safe driving. CARDIAGTECH.NET is committed to providing high-quality brake components and expert advice to keep you safe on the road.

12. How to Choose the Right Brake Discs for Your Vehicle?

Selecting the right brake discs for your vehicle involves considering several factors:

- Vehicle Type: Choose brake discs designed for your specific vehicle make and model.

- Driving Conditions: Consider your driving habits and the types of roads you typically drive on. For aggressive driving or towing, opt for high-performance discs.

- Budget: Balance performance with cost. There are various options available at different price points.

- Material and Design: Choose between solid, vented, drilled, or slotted discs based on your performance needs.

- Brand Reputation: Opt for reputable brands known for quality and reliability.

According to Consumer Reports, investing in quality brake components can improve safety and performance. CARDIAGTECH.NET offers a wide range of brake discs from trusted brands, ensuring you find the perfect match for your vehicle.

13. What Safety Precautions Should Be Taken When Working on Brakes?

Working on brakes involves potential hazards, so it’s essential to take appropriate safety precautions:

- Wear Safety Glasses: Protect your eyes from brake dust and debris.

- Use Gloves: Wear gloves to protect your hands from brake fluid and contaminants.

- Work in a Well-Ventilated Area: Brake dust can be harmful if inhaled, so work in a well-ventilated space.

- Use Proper Tools: Use the correct tools for the job to avoid damaging components or injuring yourself.

- Follow Manufacturer’s Instructions: Adhere to the manufacturer’s instructions for disassembly, inspection, and reassembly.

- Dispose of Brake Fluid Properly: Brake fluid is hazardous waste and should be disposed of according to local regulations.

OSHA (Occupational Safety and Health Administration) provides detailed guidelines for working safely with automotive components. CARDIAGTECH.NET prioritizes safety and encourages all technicians and DIYers to follow these precautions.

14. How to Maintain Brake Discs to Prolong Their Lifespan?

Proper maintenance can significantly extend the lifespan of your brake discs:

- Regular Inspections: Inspect brake discs regularly for wear, damage, and uneven wear patterns.

- Proper Brake Pad Selection: Use high-quality brake pads that are compatible with your brake discs.

- Clean Brake Components: Keep brake components clean and free from debris.

- Lubricate Moving Parts: Lubricate caliper slides and other moving parts to ensure smooth operation.

- Avoid Aggressive Driving: Practice smooth, controlled driving habits to reduce wear and tear on the braking system.

- Follow Maintenance Schedule: Adhere to the manufacturer’s recommended maintenance schedule for the braking system.

Following these maintenance tips can help you get the most out of your brake discs and ensure safe, reliable braking performance. CARDIAGTECH.NET is your trusted partner for all your brake maintenance needs.

15. How to Troubleshoot Common Brake Disc Problems?

Troubleshooting common brake disc problems can help you identify and resolve issues quickly:

- Squealing Noises: Check for worn brake pads or glazed discs. Replace pads or resurface discs as needed.

- Vibrations or Pulsations: Inspect discs for warping or uneven wear. Resurface or replace discs as needed.

- Longer Stopping Distances: Check for worn pads, damaged discs, or brake fluid leaks. Replace or repair components as needed.

- Uneven Wear: Check for caliper issues or suspension problems. Repair or replace components as needed.

The National Institute for Automotive Service Excellence (ASE) provides valuable resources for diagnosing and repairing brake system issues. CARDIAGTECH.NET is here to support you with expert advice and high-quality replacement parts.

16. What Are the Latest Innovations in Brake Disc Technology?

Brake disc technology continues to evolve, with innovations aimed at improving performance, durability, and safety:

- Carbon Ceramic Brakes: These advanced brakes offer exceptional heat resistance and stopping power, making them ideal for high-performance vehicles.

- Lightweight Designs: Manufacturers are using lighter materials and innovative designs to reduce weight and improve fuel efficiency.

- Improved Cooling Systems: Advanced cooling systems, such as enhanced venting and integrated cooling fins, help dissipate heat more effectively.

- Wear Sensors: Some brake discs are equipped with wear sensors that alert the driver when the disc reaches its minimum thickness.

These innovations are pushing the boundaries of brake technology, offering enhanced performance and safety. CARDIAGTECH.NET stays at the forefront of these advancements, providing you with the latest and greatest brake solutions.

17. Understanding Brake Disc Materials: Which One Is Right for You?

The material of your brake discs plays a crucial role in their performance and longevity. Here are some common materials used in brake disc manufacturing:

- Cast Iron: A traditional and cost-effective material that offers good braking performance for everyday driving.

- High-Carbon Cast Iron: Provides improved heat resistance and durability compared to standard cast iron.

- Composite Materials: Combine different materials, such as carbon fiber and ceramics, to offer exceptional performance and heat resistance.

- Steel: Used in some high-performance applications, offering good strength and heat dissipation.

The right material depends on your driving needs and performance expectations. CARDIAGTECH.NET offers brake discs made from various materials, ensuring you find the perfect match for your vehicle and driving style.

18. How Do Environmental Factors Affect Brake Disc Wear?

Environmental factors can significantly impact the wear and tear on brake discs:

- Road Salt: Road salt used in winter can accelerate corrosion and wear on brake discs.

- Extreme Temperatures: Extreme heat or cold can affect the performance and durability of brake discs.

- Dust and Debris: Dust, dirt, and debris can accumulate on brake discs, causing wear and reducing braking efficiency.

- Humidity: High humidity can promote rust and corrosion on brake discs.

Taking steps to protect your brake discs from these environmental factors can help prolong their lifespan. Regularly cleaning your brakes and using protective coatings can help mitigate the effects of road salt and humidity. CARDIAGTECH.NET offers a range of products to help you protect and maintain your brake discs.

19. What Role Do Brake Pads Play in Brake Disc Wear?

Brake pads and brake discs work together, and the type of brake pads you use can significantly impact brake disc wear:

- Aggressive Compounds: Aggressive brake pad compounds can cause more wear on brake discs.

- Proper Bedding: Proper bedding of new brake pads is essential for optimal performance and to minimize wear on brake discs.

- Compatibility: Using brake pads that are not compatible with your brake discs can lead to premature wear and damage.

Choosing the right brake pads for your vehicle and driving conditions is crucial for maximizing the lifespan of your brake discs. CARDIAGTECH.NET offers a wide selection of high-quality brake pads to complement our brake discs.

20. Maximizing Brake Performance: Tips and Tricks

To maximize brake performance and ensure safe driving, consider these tips and tricks:

- Regular Maintenance: Adhere to the manufacturer’s recommended maintenance schedule for the braking system.

- Proper Brake Fluid: Use the correct type of brake fluid and replace it according to the manufacturer’s recommendations.

- Inspect Calipers: Regularly inspect calipers for leaks, damage, and proper operation.

- Bed New Pads: Properly bed new brake pads to ensure optimal performance and minimize wear.

- Avoid Overloading: Avoid overloading your vehicle, as this can put extra strain on the braking system.

By following these tips, you can ensure that your braking system performs at its best and keeps you safe on the road. CARDIAGTECH.NET is your trusted resource for all your brake maintenance and performance needs.

21. Where to Buy High-Quality Brake Discs and Tools?

When it comes to purchasing high-quality brake discs and tools, CARDIAGTECH.NET is your ultimate destination. We offer a wide selection of brake components from trusted brands, ensuring you get the best performance, reliability, and safety.

- Extensive Selection: We carry a comprehensive range of brake discs, pads, calipers, and tools to meet your specific needs.

- Trusted Brands: We partner with leading manufacturers known for their quality and innovation.

- Expert Advice: Our team of knowledgeable professionals is here to help you choose the right products for your vehicle.

- Competitive Prices: We offer competitive prices on all our products, ensuring you get the best value for your money.

- Convenient Ordering: You can easily browse our online catalog and place your order from the comfort of your home or shop.

Visit CARDIAGTECH.NET today or contact us at +1 (641) 206-8880 to learn more about our products and services. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let CARDIAGTECH.NET be your trusted partner for all your automotive needs.

Take Action Now:

Are you facing challenges with worn brake discs or unsure about measuring their thickness? Don’t let these issues compromise your safety. Contact CARDIAGTECH.NET today for a personalized consultation. Our team of experts will guide you through the process, recommend the best tools and replacement parts, and ensure your vehicle’s braking system is in top condition. Call us now at +1 (641) 206-8880 or visit CARDIAGTECH.NET to explore our extensive range of automotive solutions. Your safety is our priority, and we are here to help you every step of the way.

FAQ: Measuring Brake Disc Thickness

- Why is measuring brake disc thickness important? Measuring brake disc thickness is crucial for ensuring safe braking performance. Thin discs can overheat, leading to brake fade or failure.

- How often should I measure my brake disc thickness? It’s recommended to measure brake disc thickness every 10,000 to 20,000 miles, or whenever you replace your brake pads.

- What tools do I need to measure brake disc thickness? You’ll need a micrometer or caliper to accurately measure the thickness of the brake disc.

- Where can I find the minimum thickness specification for my brake discs? The minimum thickness specification is usually stamped on the brake disc itself or listed in your vehicle’s service manual.

- What is Disc Thickness Variation (DTV)? DTV refers to uneven wear or thickness fluctuations on the brake disc surface, which can cause vibrations and reduced braking performance.

- Can I resurface my brake discs instead of replacing them? Resurfacing is possible if the disc is not too thin and remains above the minimum thickness specification after machining.

- What are the signs of worn brake discs? Signs include squealing noises, vibrations, longer stopping distances, and visible damage like deep grooves or cracks.

- How does driving style affect brake disc wear? Aggressive driving habits like frequent hard braking can accelerate brake disc wear.

- What type of brake discs should I choose for my vehicle? Choose brake discs designed for your vehicle’s make and model, considering your driving conditions and performance needs.

- Where can I buy high-quality brake discs and tools? CARDIAGTECH.NET offers a wide selection of brake discs and tools from trusted brands, ensuring you get the best performance and reliability.