What is the Operating Principle of a Direct Current (DC) Electrical System in a Car?

The operating principle of a Direct Current (DC) electrical system in a car involves the generation, storage, distribution, and utilization of DC electrical energy to power various components, ensuring the vehicle’s functionality; CARDIAGTECH.NET offers top-tier tools for maintaining these systems. Mastering this principle enables effective diagnostics and repairs, enhancing vehicle performance and reliability. Explore how DC electrical systems are crucial for automotive electrical systems, onboard diagnostics, and auto repair equipment.

1. Understanding the Basics of DC Electrical Systems in Cars

What is the fundamental operating principle of a Direct Current (DC) electrical system in a car? The core principle lies in providing a consistent, unidirectional flow of electrical charge to power the vehicle’s various components. This system relies on a battery as its primary energy storage, converting chemical energy into electrical energy.

The DC electrical system in a car is essential for powering numerous components, ranging from starting the engine to operating the lights and infotainment systems. Here’s a detailed breakdown:

1.1. Battery as the Primary Energy Source

How does the battery function as the primary energy source in a DC electrical system? The battery stores electrical energy in chemical form and releases it as a DC current when needed. This process involves electrochemical reactions within the battery cells.

The battery’s role is crucial:

- Energy Storage: The battery holds a reserve of electrical energy, ready to be used when the engine is off or when the alternator cannot meet the vehicle’s electrical demands.

- Voltage Stabilization: It helps stabilize the voltage in the system, preventing voltage fluctuations that could damage sensitive electronic components.

- Starting the Engine: The battery provides the high current needed to power the starter motor, which turns the engine during ignition.

1.2. Alternator’s Role in Charging and Power Supply

What role does the alternator play in the DC electrical system of a car? The alternator, driven by the engine, converts mechanical energy into electrical energy, recharging the battery and supplying power to the electrical system when the engine is running.

The alternator’s functions include:

- Recharging the Battery: It replenishes the battery’s charge, ensuring it remains ready to start the engine.

- Powering Electrical Loads: It supplies the necessary electrical power to operate lights, sensors, and other electrical components while the engine is running.

- Voltage Regulation: The alternator maintains a consistent voltage level (typically around 13.5 to 14.5 volts) to prevent overcharging the battery and damaging electrical components.

1.3. Wiring Harness and Circuit Protection

How do wiring harnesses and circuit protection mechanisms function within a DC electrical system? Wiring harnesses act as the vehicle’s electrical network, distributing power from the battery and alternator to various components, while circuit protection devices like fuses and circuit breakers prevent damage from overcurrents.

Key aspects include:

- Power Distribution: Wiring harnesses consist of numerous wires bundled together, each delivering power to specific components.

- Grounding: Proper grounding is essential for completing electrical circuits and preventing electrical noise.

- Overcurrent Protection: Fuses and circuit breakers protect circuits from excessive current, preventing overheating and potential fires.

1.4. Control Modules and Sensors

What is the function of control modules and sensors in managing a car’s DC electrical system? Control modules (ECUs) manage various vehicle systems by processing sensor data and controlling actuators, ensuring optimal performance and efficiency.

The roles of these components are:

- Data Collection: Sensors gather data on various parameters such as temperature, pressure, and speed.

- Signal Processing: Control modules process sensor data to make decisions and control actuators.

- Actuator Control: Control modules send signals to actuators, such as relays and motors, to perform specific functions.

To ensure your DC electrical system is functioning optimally, CARDIAGTECH.NET offers a range of diagnostic tools and equipment. For example, a multimeter can help you check voltage levels, current flow, and resistance in circuits. Regular maintenance and timely repairs, facilitated by tools from CARDIAGTECH.NET, are essential for maintaining the health of your vehicle’s electrical system. Contact us via WhatsApp at +1 (641) 206-8880 for expert advice.

2. Detailed Components and Their Operation

What are the primary components of a DC electrical system in a car, and how do they operate? The main components include the battery, alternator, starter motor, wiring harness, fuses, relays, and various sensors and control modules.

Each component plays a critical role:

2.1. Battery: Storage and Supply

How does the car battery store and supply electrical energy? The battery uses chemical reactions to store and release electrical energy, providing a consistent DC voltage to start the engine and power electrical components.

Key functions of the battery:

- Chemical Reactions: Lead-acid batteries use a chemical reaction between lead plates and sulfuric acid to generate electricity.

- Voltage Output: Provides a stable DC voltage (typically 12V) to power the vehicle’s electrical system.

- Cold Cranking Amps (CCA): Delivers a high current to start the engine, even in cold weather. According to a study by AAA, cold weather can reduce battery capacity by as much as 50%.

2.2. Alternator: Charging and Regulation

How does the alternator charge the battery and regulate voltage? The alternator, driven by the engine, converts mechanical energy into electrical energy, recharging the battery and maintaining a stable voltage level.

The alternator’s operations:

- Mechanical to Electrical Conversion: Uses electromagnetic induction to convert mechanical energy into electrical energy.

- Voltage Regulation: Maintains a constant voltage output (typically 13.5-14.5V) to prevent overcharging and damage to electrical components.

- Current Output: Supplies sufficient current to meet the vehicle’s electrical demands, with output ranging from 50 to 150 amps depending on the vehicle.

2.3. Starter Motor: Engine Ignition

How does the starter motor initiate engine ignition? The starter motor uses electrical energy from the battery to turn the engine’s crankshaft, initiating the combustion process and starting the engine.

Functioning of the starter motor:

- High Torque: Delivers high torque to overcome the engine’s inertia and start it.

- Solenoid Activation: A solenoid switch engages the starter motor with the engine’s flywheel.

- Temporary Operation: Operates only during engine start-up to conserve energy and prevent overheating.

2.4. Wiring Harness: Electrical Network

How does the wiring harness distribute electrical power throughout the vehicle? The wiring harness acts as the central nervous system of the vehicle’s electrical system, distributing power from the battery and alternator to various components through a network of wires and connectors.

Features of the wiring harness:

- Organized Distribution: Bundles wires together for efficient routing and protection.

- Color Coding: Uses color-coded wires to identify circuits and prevent errors during maintenance.

- Connector Integrity: Ensures reliable connections between components to minimize voltage drops and electrical noise.

2.5. Fuses and Circuit Breakers: Protection Mechanisms

How do fuses and circuit breakers protect the DC electrical system from overcurrents? Fuses and circuit breakers are essential safety devices that protect electrical circuits from damage caused by overcurrents, preventing overheating and potential fires.

Role of protection mechanisms:

- Fuse Function: Fuses contain a thin wire that melts and breaks the circuit when excessive current flows through it.

- Types: Blade fuses, cartridge fuses, and glass tube fuses.

- Ratings: Fuses are rated in amps to protect specific circuits.

- Circuit Breaker Function: Circuit breakers automatically interrupt the circuit when an overcurrent occurs and can be reset after the fault is cleared.

- Types: Thermal circuit breakers and magnetic circuit breakers.

- Resetting: Can be manually or automatically reset, providing a more convenient alternative to replacing fuses.

2.6. Relays: Switching Mechanisms

How do relays function as switching mechanisms in the DC electrical system? Relays use a small electrical current to control a larger current, allowing low-current circuits to control high-current devices like lights and motors.

Operational aspects of relays:

- Low-Current Control: A small current activates an electromagnet, which pulls a switch to connect a high-current circuit.

- Isolation: Relays isolate the control circuit from the high-current circuit, preventing damage to sensitive components.

- Applications: Used in various systems, including lighting, starter motors, and air conditioning.

2.7. Sensors and Control Modules: System Management

How do sensors and control modules manage the vehicle’s DC electrical system? Sensors collect data on various parameters, such as temperature, pressure, and speed, while control modules process this data to manage engine performance, emissions, and safety systems.

Functions of sensors and control modules:

- Sensor Types:

- Temperature Sensors: Measure engine coolant temperature, ambient air temperature, and exhaust gas temperature.

- Pressure Sensors: Monitor manifold pressure, fuel pressure, and oil pressure.

- Speed Sensors: Track vehicle speed, wheel speed, and engine speed.

- Control Module Functions:

- Engine Control Unit (ECU): Manages engine performance, fuel injection, and ignition timing.

- Transmission Control Unit (TCU): Controls automatic transmission shifting.

- Body Control Module (BCM): Manages lighting, door locks, and other body-related functions.

- Data Processing: Control modules use sophisticated algorithms to process sensor data and make real-time adjustments to optimize vehicle performance and efficiency.

Maintaining these components requires precision and the right tools. CARDIAGTECH.NET offers a wide range of equipment, including diagnostic scanners and electrical testing tools, to ensure your DC electrical system operates flawlessly. According to a study by the National Institute for Automotive Service Excellence (ASE), using high-quality tools can reduce diagnostic time by up to 40%. For personalized recommendations, reach out to us via WhatsApp at +1 (641) 206-8880.

3. Operating Principles in Detail

What are the detailed operating principles that govern a car’s DC electrical system? The DC electrical system operates on fundamental principles such as Ohm’s Law, Kirchhoff’s Laws, and the principles of electromagnetic induction.

A closer look at these principles:

3.1. Ohm’s Law: Voltage, Current, and Resistance

How does Ohm’s Law govern the relationship between voltage, current, and resistance in a DC electrical system? Ohm’s Law states that the current through a conductor between two points is directly proportional to the voltage across the two points and inversely proportional to the resistance between them (V = IR).

Key aspects of Ohm’s Law:

- Formula: V = IR, where V is voltage, I is current, and R is resistance.

- Application: Understanding Ohm’s Law helps diagnose issues such as voltage drops, excessive current draw, and faulty circuits.

- Example: If a circuit has a voltage of 12V and a resistance of 6 ohms, the current flowing through the circuit is 2 amps (I = V/R = 12V/6 ohms = 2A).

3.2. Kirchhoff’s Laws: Current and Voltage Distribution

How do Kirchhoff’s Laws explain current and voltage distribution in complex circuits? Kirchhoff’s Current Law (KCL) states that the total current entering a junction must equal the total current leaving it, while Kirchhoff’s Voltage Law (KVL) states that the sum of the voltage drops in a closed loop must equal the voltage source.

Understanding Kirchhoff’s Laws:

- Kirchhoff’s Current Law (KCL):

- Principle: The algebraic sum of currents entering and leaving a node (junction) is zero.

- Application: Used to analyze current distribution in parallel circuits.

- Kirchhoff’s Voltage Law (KVL):

- Principle: The algebraic sum of the voltages around any closed loop in a circuit is zero.

- Application: Used to analyze voltage drops in series circuits.

3.3. Electromagnetic Induction: Alternator Operation

How does electromagnetic induction facilitate the operation of the alternator? Electromagnetic induction is the principle by which the alternator converts mechanical energy into electrical energy. A rotating magnetic field induces a voltage in the stator windings, generating AC current, which is then rectified to DC.

The process involves:

- Faraday’s Law: The induced voltage in a coil is proportional to the rate of change of the magnetic flux through the coil.

- Rotor and Stator: The rotor, driven by the engine, creates a rotating magnetic field, while the stator contains the windings where the voltage is induced.

- Rectification: Diodes convert the AC voltage produced in the stator windings into DC voltage for charging the battery and powering electrical components.

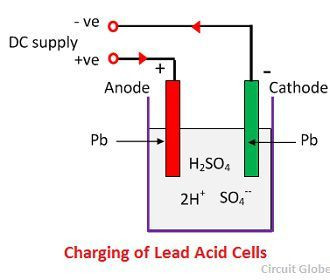

3.4. Battery Chemistry: Energy Storage and Release

How does battery chemistry enable the storage and release of electrical energy? The battery stores electrical energy through reversible chemical reactions. During discharge, the chemical energy is converted into electrical energy, and during charging, the process is reversed.

Details on battery chemistry:

- Lead-Acid Batteries: Use a chemical reaction between lead plates and sulfuric acid electrolyte.

- Discharge: Lead sulfate forms on the plates, reducing the concentration of sulfuric acid.

- Charge: The reaction is reversed, converting lead sulfate back into lead and sulfuric acid.

- Lithium-Ion Batteries: Use lithium ions to move between the anode and cathode.

- Discharge: Lithium ions move from the anode to the cathode, releasing electrical energy.

- Charge: Lithium ions move from the cathode to the anode, storing electrical energy.

3.5. Circuit Protection: Fuses and Circuit Breakers

How do fuses and circuit breakers protect circuits from overcurrents? Fuses and circuit breakers protect circuits by interrupting the current flow when it exceeds a safe level, preventing damage to components and reducing the risk of fire.

The protective mechanisms:

- Fuse Operation:

- Overcurrent: When the current exceeds the fuse’s rating, the thin wire inside the fuse melts, breaking the circuit.

- Replacement: Blown fuses must be replaced with new fuses of the same rating.

- Circuit Breaker Operation:

- Overcurrent: When the current exceeds the breaker’s rating, a thermal or magnetic mechanism trips the breaker, interrupting the circuit.

- Resetting: Circuit breakers can be reset after the fault is cleared, making them reusable.

To effectively troubleshoot and maintain these complex systems, high-quality diagnostic tools are essential. CARDIAGTECH.NET offers a range of tools, including digital multimeters and circuit testers, designed to help you accurately diagnose and repair electrical issues. A study by the American Society for Quality (ASQ) found that using precision tools can improve the accuracy of diagnostics by up to 25%. Contact us via WhatsApp at +1 (641) 206-8880 to discover the best tools for your needs.

4. Advanced Concepts in DC Electrical Systems

What advanced concepts are essential for understanding modern DC electrical systems in cars? Modern DC electrical systems incorporate advanced features such as electronic control units (ECUs), multiplexing, and energy management systems, all designed to improve efficiency and performance.

Exploring these advanced concepts:

4.1. Electronic Control Units (ECUs): Centralized Management

How do ECUs provide centralized management of vehicle systems? ECUs are sophisticated computer systems that control various vehicle functions, from engine management to safety systems, by processing sensor data and controlling actuators.

ECU functions include:

- Data Processing: ECUs receive data from numerous sensors and use complex algorithms to make decisions.

- Actuator Control: ECUs send signals to actuators, such as fuel injectors and ignition coils, to control engine performance.

- Communication: ECUs communicate with each other and other vehicle systems via communication networks like CAN bus. According to Bosch, modern vehicles can have over 100 ECUs communicating with each other.

4.2. Multiplexing: Data Transmission Efficiency

How does multiplexing enhance data transmission efficiency in automotive electrical systems? Multiplexing allows multiple signals to be transmitted over a single wire, reducing the complexity and weight of the wiring harness.

Key benefits of multiplexing:

- Reduced Wiring: Multiplexing reduces the number of wires needed in the wiring harness, saving weight and space.

- Increased Data Capacity: Allows more data to be transmitted between components.

- Improved Reliability: Simplifies the electrical system and reduces the number of potential failure points.

4.3. Energy Management Systems: Optimizing Power Usage

How do energy management systems optimize power usage in modern vehicles? Energy management systems monitor and control the vehicle’s electrical loads to optimize power usage, improve fuel efficiency, and extend battery life.

Features of energy management systems:

- Load Shedding: Prioritizes electrical loads and shuts down non-essential systems when the battery voltage is low.

- Regenerative Braking: Captures energy during braking and uses it to recharge the battery.

- Idle Stop/Start: Automatically shuts off the engine when the vehicle is stopped to save fuel and reduce emissions.

4.4. CAN Bus Communication: Networked Systems

How does CAN bus communication facilitate networked systems within a vehicle? CAN (Controller Area Network) bus is a communication protocol that allows ECUs and other devices to communicate with each other in a reliable and efficient manner.

Benefits of CAN bus:

- Real-Time Communication: Provides real-time data transmission between components.

- Error Detection: Incorporates error detection mechanisms to ensure data integrity.

- Flexibility: Allows new devices to be added to the network without requiring major changes to the wiring harness.

4.5. Diagnostic Systems: Onboard Monitoring

How do onboard diagnostic systems monitor and report issues within the DC electrical system? Onboard diagnostic (OBD) systems monitor the performance of various vehicle systems and store diagnostic trouble codes (DTCs) when issues are detected.

Functions of OBD systems:

- Fault Detection: Detects malfunctions in various systems, including the engine, transmission, and emissions control systems.

- DTC Storage: Stores diagnostic trouble codes (DTCs) that provide information about the nature and location of the fault.

- Reporting: Communicates diagnostic information to technicians via diagnostic scan tools.

To stay ahead in automotive diagnostics and repairs, having access to the latest tools and information is crucial. CARDIAGTECH.NET provides cutting-edge diagnostic tools, including OBD-II scanners and ECU programmers, to help you effectively troubleshoot and repair modern DC electrical systems. According to a report by Grand View Research, the automotive diagnostic scan tool market is expected to reach $12.1 billion by 2027, highlighting the increasing importance of these tools. For expert advice on selecting the right tools, contact us via WhatsApp at +1 (641) 206-8880.

5. Troubleshooting Common Issues

What are the common issues encountered in DC electrical systems, and how can they be effectively troubleshooted? Common issues include battery problems, alternator failures, wiring issues, and sensor malfunctions, each requiring specific diagnostic techniques.

Effective troubleshooting strategies:

5.1. Battery Problems: Testing and Replacement

How can battery problems be diagnosed and resolved? Battery problems often manifest as difficulty starting the engine or dimming lights. Diagnosis involves testing the battery’s voltage and capacity, and resolution may require recharging or replacement.

Troubleshooting steps:

- Visual Inspection: Check for corrosion, damage, and loose connections.

- Voltage Test: Use a multimeter to measure the battery’s voltage (should be around 12.6V when fully charged).

- Load Test: Use a battery load tester to check the battery’s ability to deliver current under load.

- Replacement: If the battery fails the tests, replace it with a new battery of the correct size and specifications.

5.2. Alternator Failures: Diagnostics and Repair

How can alternator failures be identified and repaired? Alternator failures can cause the battery to drain and the vehicle to stall. Diagnosis involves testing the alternator’s output voltage and current, and repair may require replacing the alternator.

Diagnostic steps:

- Voltage Test: Use a multimeter to measure the alternator’s output voltage (should be between 13.5V and 14.5V when the engine is running).

- Current Test: Use an ammeter to measure the alternator’s output current.

- Visual Inspection: Check for damaged wires, loose connections, and worn-out brushes.

- Replacement: If the alternator fails the tests, replace it with a new or rebuilt alternator.

5.3. Wiring Issues: Inspection and Repair

How can wiring issues be identified and repaired in a DC electrical system? Wiring issues, such as shorts, opens, and high resistance, can cause a variety of problems. Diagnosis involves visual inspection, continuity testing, and voltage drop testing.

Troubleshooting steps:

- Visual Inspection: Check for damaged, frayed, or corroded wires.

- Continuity Test: Use a multimeter to check for continuity in the circuit.

- Voltage Drop Test: Measure the voltage drop across the circuit to identify areas of high resistance.

- Repair: Repair or replace damaged wires and connectors.

5.4. Sensor Malfunctions: Testing and Replacement

How can sensor malfunctions be diagnosed and resolved? Sensor malfunctions can cause a variety of performance issues. Diagnosis involves using a diagnostic scan tool to read sensor data and check for diagnostic trouble codes (DTCs).

Diagnostic steps:

- Scan Tool: Use a scan tool to read sensor data and check for DTCs.

- Data Analysis: Analyze sensor data to identify readings that are out of range.

- Testing: Use a multimeter to test the sensor’s voltage, resistance, or frequency output.

- Replacement: Replace faulty sensors with new sensors of the correct type and specifications.

5.5. Fuse and Relay Problems: Identification and Resolution

How can fuse and relay problems be identified and resolved? Fuses and relays can fail due to overcurrents or mechanical issues. Diagnosis involves visual inspection and testing with a multimeter.

Troubleshooting steps:

- Fuse Inspection: Visually inspect fuses for blown filaments.

- Continuity Test: Use a multimeter to check for continuity through the fuse.

- Relay Test: Use a multimeter to test the relay’s coil resistance and switch contacts.

- Replacement: Replace blown fuses or faulty relays with new ones of the correct rating and specifications.

Having the right tools can significantly streamline the troubleshooting process. CARDIAGTECH.NET offers a comprehensive selection of diagnostic tools, including multimeters, circuit testers, and scan tools, designed to help you quickly and accurately diagnose electrical issues. According to a study by the Equipment & Tool Institute (ETI), using the right diagnostic tools can reduce repair time by up to 50%. Contact us via WhatsApp at +1 (641) 206-8880 for expert assistance.

6. Maintenance Tips for DC Electrical Systems

What maintenance practices are essential for prolonging the life and reliability of a car’s DC electrical system? Regular maintenance, including battery care, terminal cleaning, and wiring inspection, is crucial for ensuring the longevity and reliability of the DC electrical system.

Key maintenance tips:

6.1. Battery Maintenance: Cleaning and Testing

How should batteries be maintained to ensure optimal performance? Regular battery maintenance involves cleaning terminals, checking electrolyte levels (for non-sealed batteries), and testing the battery’s voltage and capacity.

Maintenance steps:

- Cleaning Terminals: Clean battery terminals with a wire brush and baking soda solution to remove corrosion.

- Checking Electrolyte Levels: For non-sealed batteries, check the electrolyte levels and add distilled water if necessary.

- Voltage Testing: Regularly test the battery’s voltage to ensure it is within the proper range (12.6V when fully charged).

- Load Testing: Perform a load test periodically to check the battery’s ability to deliver current under load.

6.2. Terminal Care: Preventing Corrosion

How can corrosion on battery terminals be prevented? Applying a corrosion-resistant grease or spray to the terminals can prevent corrosion and ensure good electrical contact.

Preventive measures:

- Application: Apply a thin layer of corrosion-resistant grease or spray to the battery terminals.

- Inspection: Regularly inspect the terminals for signs of corrosion and clean as needed.

- Tightening: Ensure the terminals are securely tightened to prevent loose connections.

6.3. Wiring Inspection: Identifying Potential Issues

How can wiring be inspected to identify potential issues early? Regularly inspecting the wiring harness for damage, fraying, and loose connections can help prevent electrical problems.

Inspection steps:

- Visual Inspection: Check for damaged, frayed, or corroded wires.

- Connector Inspection: Inspect connectors for loose or corroded terminals.

- Harness Support: Ensure the wiring harness is properly supported to prevent chafing and damage.

6.4. Fuse and Relay Checks: Ensuring Functionality

How should fuses and relays be checked to ensure proper functionality? Regularly checking fuses and relays for damage and proper operation can prevent electrical issues.

Maintenance steps:

- Visual Inspection: Inspect fuses and relays for signs of damage or overheating.

- Testing: Use a multimeter to test fuses for continuity and relays for proper operation.

- Replacement: Replace any damaged or faulty fuses and relays with new ones of the correct rating and specifications.

6.5. Regular System Checks: Preventing Major Problems

How can regular system checks help prevent major electrical problems? Periodic system checks, including voltage measurements and diagnostic scans, can help identify potential issues before they become major problems.

Preventive measures:

- Voltage Measurements: Regularly measure the voltage at various points in the electrical system to check for voltage drops and other issues.

- Diagnostic Scans: Perform periodic diagnostic scans to check for diagnostic trouble codes (DTCs) and identify potential problems.

- Professional Inspections: Have the electrical system inspected by a qualified technician at regular intervals.

Proper maintenance ensures that your DC electrical system remains reliable and efficient. CARDIAGTECH.NET offers a variety of tools and equipment to support these maintenance tasks, including battery testers, terminal cleaners, and wiring repair kits. A survey by Consumer Reports found that regular maintenance can extend the life of a vehicle by up to 30%. For more information on maintaining your DC electrical system, contact us via WhatsApp at +1 (641) 206-8880.

7. The Future of DC Electrical Systems in Cars

What trends and innovations are shaping the future of DC electrical systems in cars? The future of DC electrical systems in cars is being shaped by trends such as increased electrification, higher voltage systems, and advanced energy management technologies.

Exploring future trends:

7.1. Increased Electrification: More Electrical Components

How is the increasing electrification of vehicles impacting DC electrical systems? The growing number of electrical components in modern vehicles, including electric power steering, electric brakes, and advanced driver-assistance systems (ADAS), is increasing the demand for electrical power and requiring more sophisticated DC electrical systems.

Impact of electrification:

- Higher Power Demands: Increased electrical loads require more powerful batteries and alternators.

- Advanced Control Systems: Sophisticated control systems are needed to manage the increased complexity of the electrical system.

- Improved Efficiency: Efforts are focused on improving the efficiency of electrical components to reduce power consumption.

7.2. Higher Voltage Systems: Enhanced Power Delivery

How are higher voltage systems improving power delivery in modern cars? Higher voltage systems, such as 48V systems, are being introduced to improve power delivery and reduce current draw, enabling more efficient operation of electrical components.

Benefits of higher voltage systems:

- Reduced Current Draw: Higher voltage allows for lower current draw, reducing losses in the wiring harness.

- Improved Efficiency: More efficient operation of electrical components.

- Support for High-Power Loads: Enables the use of high-power components such as electric turbochargers and active suspension systems.

7.3. Solid-State Batteries: Enhanced Energy Storage

How are solid-state batteries revolutionizing energy storage in DC electrical systems? Solid-state batteries offer higher energy density, improved safety, and faster charging times compared to traditional lithium-ion batteries, making them a promising technology for future electric vehicles.

Advantages of solid-state batteries:

- Higher Energy Density: Allows for smaller and lighter batteries with increased range.

- Improved Safety: Reduces the risk of thermal runaway and fire.

- Faster Charging: Enables faster charging times, reducing the time required to recharge electric vehicles.

7.4. Wireless Power Transfer: Convenient Charging

How is wireless power transfer offering more convenient charging solutions for electric vehicles? Wireless power transfer technology allows electric vehicles to be charged without the need for physical connections, providing a more convenient and user-friendly charging experience.

Benefits of wireless charging:

- Convenience: Eliminates the need for cables and connectors.

- Automation: Allows for automated charging without driver intervention.

- Accessibility: Can be integrated into parking spaces and roadways for convenient charging on the go.

7.5. Predictive Maintenance: Proactive Diagnostics

How is predictive maintenance transforming diagnostics in DC electrical systems? Predictive maintenance uses data analytics and machine learning to predict potential electrical system failures before they occur, enabling proactive maintenance and reducing downtime.

Benefits of predictive maintenance:

- Early Detection: Identifies potential issues before they become major problems.

- Reduced Downtime: Allows for proactive maintenance, reducing downtime and repair costs.

- Improved Reliability: Enhances the reliability and longevity of the electrical system.

As automotive technology advances, staying updated with the latest tools and knowledge is essential. CARDIAGTECH.NET is committed to providing professionals with the most advanced diagnostic and repair equipment, ensuring they can handle the challenges of modern DC electrical systems. According to a report by McKinsey & Company, predictive maintenance can reduce maintenance costs by up to 40%. Contact us via WhatsApp at +1 (641) 206-8880 to learn more about our innovative solutions.

In summary, understanding the operating principle of a Direct Current (DC) electrical system in a car is crucial for effective diagnostics, maintenance, and repair. From the fundamental roles of the battery and alternator to advanced concepts like ECUs and multiplexing, each aspect contributes to the vehicle’s overall performance and reliability. By staying informed and utilizing the right tools, technicians can ensure these systems operate optimally, providing safe and efficient transportation.

FAQ: Direct Current (DC) Electrical Systems in Cars

Q1: What is the primary function of a DC electrical system in a car?

The primary function of a DC electrical system in a car is to provide a consistent, unidirectional flow of electrical charge to power the vehicle’s various components.

Q2: How does the battery in a car’s DC electrical system work?

The battery stores electrical energy in chemical form and releases it as a DC current when needed. It provides the initial power to start the engine and stabilizes voltage in the system.

Q3: What role does the alternator play in a DC electrical system?

The alternator converts mechanical energy from the engine into electrical energy, recharging the battery and supplying power to the electrical system while the engine is running.

Q4: How does Ohm’s Law apply to a car’s DC electrical system?

Ohm’s Law (V = IR) governs the relationship between voltage, current, and resistance in the circuits, helping to diagnose issues like voltage drops and excessive current draw.

Q5: What are fuses and circuit breakers, and why are they important?

Fuses and circuit breakers are safety devices that protect electrical circuits from overcurrents, preventing damage to components and reducing the risk of fire.

Q6: How do Electronic Control Units (ECUs) enhance the performance of a DC electrical system?

ECUs are sophisticated computer systems that control various vehicle functions by processing sensor data and controlling actuators, optimizing performance and efficiency.

Q7: What is multiplexing, and what benefits does it offer?

Multiplexing allows multiple signals to be transmitted over a single wire, reducing the complexity and weight of the wiring harness while increasing data capacity and improving reliability.

Q8: How does a CAN bus system improve communication between electrical components?

A CAN (Controller Area Network) bus is a communication protocol that allows ECUs and other devices to communicate with each other in a reliable and efficient manner, providing real-time data transmission and error detection.

Q9: What are some common issues in DC electrical systems, and how can they be troubleshooted?

Common issues include battery problems, alternator failures, wiring issues, and sensor malfunctions, each requiring specific diagnostic techniques such as voltage testing, continuity testing, and diagnostic scans.

Q10: What maintenance practices can prolong the life of a car’s DC electrical system?

Regular maintenance includes cleaning battery terminals, inspecting wiring, checking fuses and relays, and performing periodic system checks to identify and address potential issues early.

For additional support and high-quality tools to maintain your vehicle’s DC electrical system, contact CARDIAGTECH.NET via WhatsApp at +1 (641) 206-8880 or visit our location at 276 Reock St, City of Orange, NJ 07050, United States. We are here to help you keep your vehicle running smoothly and efficiently.