How To Fix A Leaking AC In Car: Expert Guide

Fixing a leaking AC in your car can be a daunting task, but with the right knowledge and tools, it’s achievable. At CARDIAGTECH.NET, we provide you with a comprehensive guide on diagnosing and fixing AC leaks, ensuring your car’s AC system is running efficiently. Contact us via WhatsApp at +1 (641) 206-8880 for immediate assistance and to explore our range of automotive tools designed to make your repairs easier. Our expert guidance covers refrigerant leak detection, AC recharge procedures, and essential maintenance tips to keep your vehicle cool and comfortable.

1. Understanding the Basics of Car AC Systems

What are the key components of a car AC system?

A car’s air conditioning system is a complex network of components working in harmony to deliver cool air. Understanding these parts is crucial for diagnosing and fixing leaks. The main components include the compressor, condenser, expansion valve or orifice tube, evaporator, receiver/drier or accumulator, and refrigerant lines.

- Compressor: The heart of the AC system, responsible for compressing the refrigerant and circulating it through the system.

- Condenser: Located in front of the radiator, the condenser dissipates heat from the refrigerant, turning it into a high-pressure liquid.

- Expansion Valve/Orifice Tube: This component regulates the flow of refrigerant into the evaporator, causing it to expand and cool.

- Evaporator: Located inside the dashboard, the evaporator absorbs heat from the cabin air, cooling it down.

- Receiver/Drier or Accumulator: These components filter and store refrigerant, removing moisture and contaminants.

- Refrigerant Lines: Hoses and pipes that carry the refrigerant between the different components.

How does the AC system work?

The AC system operates on a closed-loop cycle. The compressor pumps refrigerant as a high-pressure, high-temperature gas to the condenser, where it cools and becomes a high-pressure liquid. This liquid then flows through the expansion valve, which reduces the pressure and temperature, turning it into a low-pressure, low-temperature mist. This mist enters the evaporator, where it absorbs heat from the cabin air, turning back into a gas. The gas then returns to the compressor, and the cycle repeats.

What is refrigerant and its role?

Refrigerant is a chemical compound that absorbs heat and cools the air. Common refrigerants include R-134a and the newer R-1234yf. According to a study by the EPA, refrigerants must be handled carefully to prevent environmental damage. A refrigerant leak can lead to inefficient cooling and environmental pollution, emphasizing the importance of prompt repairs.

2. Identifying a Leaking AC: Symptoms and Signs

What are the common symptoms of a leaking AC?

Recognizing the symptoms of a leaking AC is the first step in addressing the problem. Common symptoms include:

- Weak or warm airflow: The AC blows warm air instead of cold air.

- Hissing sounds: A hissing noise coming from the engine compartment or dashboard.

- Odor: A musty or chemical odor inside the car.

- Visible leaks: Oil stains or refrigerant residue around AC components.

- AC compressor not engaging: The AC compressor fails to turn on.

How to perform a visual inspection for leaks?

A visual inspection can often reveal the source of an AC leak. Follow these steps:

- Locate AC components: Identify the compressor, condenser, evaporator, hoses, and connections.

- Check for oil stains: Look for oily residue on or around these components, which indicates a refrigerant leak.

- Inspect hoses and connections: Examine hoses for cracks, damage, or loose connections.

- Use a UV light: If your AC system has UV dye, use a UV light to detect leaks. The dye will glow under the UV light, making leaks easier to spot.

Using a UV dye to detect leaks

Adding UV dye to your AC system can make leak detection easier. Here’s how to use it:

- Purchase UV dye: Buy AC UV dye compatible with your refrigerant type.

- Add dye to system: Inject the dye into the AC system using a dye injector tool.

- Run AC: Operate the AC system for a few minutes to circulate the dye.

- Inspect with UV light: Use a UV light in a dark area to scan the AC components. Leaks will appear as glowing spots.

According to a study by the Society of Automotive Engineers, UV dye is an effective method for detecting small refrigerant leaks that might otherwise go unnoticed.

Listening for unusual sounds

Unusual sounds can also indicate an AC leak. Listen for:

- Hissing: A hissing sound often indicates a refrigerant leak escaping from a hose or connection.

- Whistling: A whistling noise may indicate a leak in the evaporator or expansion valve.

- Gurgling: A gurgling sound can suggest air or moisture in the system due to a leak.

Is water leakage normal? Distinguishing between condensation and refrigerant leaks

It’s normal for condensation to form and drip from under the car when the AC is running. This is simply water that has condensed from the air as it passes over the cold evaporator core. However, if the fluid is oily or has a distinct chemical smell, it’s likely a refrigerant leak.

3. Tools and Equipment Needed for AC Repair

What tools are essential for diagnosing AC leaks?

Having the right tools is crucial for diagnosing and repairing AC leaks. Essential tools include:

- AC manifold gauge set: Measures pressures in the AC system.

- Vacuum pump: Removes air and moisture from the system before recharging.

- Refrigerant scale: Measures the amount of refrigerant added to the system.

- Leak detector: Electronic or UV leak detector to pinpoint leaks.

- Wrenches and sockets: For removing and installing AC components.

Refrigerant handling equipment

Handling refrigerant requires specialized equipment to ensure safety and compliance with environmental regulations. Essential equipment includes:

- Refrigerant recovery machine: Recovers refrigerant from the AC system.

- Refrigerant identifier: Identifies the type of refrigerant in the system.

- Refrigerant recharge machine: Recharges the AC system with the correct amount of refrigerant.

According to the EPA, it is illegal to knowingly vent refrigerants into the atmosphere. Using proper recovery and recharge equipment is essential for compliance.

Safety gear

Safety should always be a top priority when working on AC systems. Essential safety gear includes:

- Safety glasses: Protect eyes from refrigerant and debris.

- Gloves: Protect hands from refrigerant and chemicals.

- Respirator: Protects against inhaling refrigerant vapors.

Other useful tools and materials

Other useful tools and materials include:

- UV dye and UV light: For leak detection.

- O-ring assortment: For replacing seals.

- AC system flush: Cleans contaminants from the system.

- Thread sealant: Seals connections to prevent leaks.

4. Step-by-Step Guide to Fixing Common AC Leaks

How to replace O-rings and seals?

Replacing O-rings and seals is a common repair for AC leaks. Follow these steps:

- Recover refrigerant: Use a refrigerant recovery machine to remove refrigerant from the system.

- Disconnect AC lines: Disconnect the AC lines at the leaking connection.

- Remove old O-ring: Remove the old O-ring or seal from the connection.

- Install new O-ring: Install a new O-ring or seal, making sure it is the correct size and type.

- Lubricate O-ring: Lubricate the new O-ring with AC oil.

- Reconnect AC lines: Reconnect the AC lines, tightening the connections to the correct torque.

- Evacuate system: Use a vacuum pump to remove air and moisture from the system.

- Recharge system: Recharge the system with the correct amount of refrigerant.

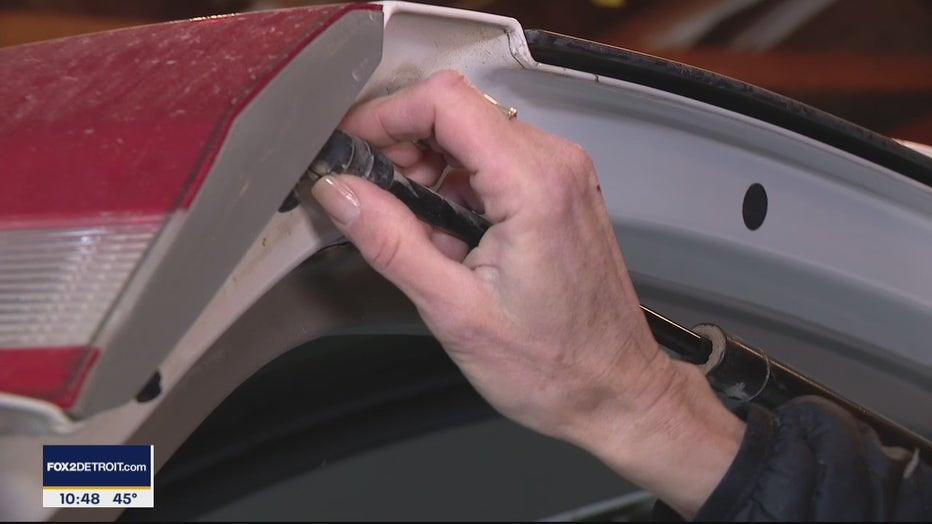

Repairing or replacing hoses

Damaged hoses can also cause AC leaks. Here’s how to repair or replace them:

- Recover refrigerant: Use a refrigerant recovery machine to remove refrigerant from the system.

- Disconnect hose: Disconnect the damaged hose from the AC components.

- Inspect hose: Inspect the hose for damage, such as cracks, holes, or leaks.

- Replace hose: If the hose is damaged, replace it with a new hose of the correct size and type.

- Reconnect hose: Reconnect the hose to the AC components, tightening the connections to the correct torque.

- Evacuate system: Use a vacuum pump to remove air and moisture from the system.

- Recharge system: Recharge the system with the correct amount of refrigerant.

Addressing leaks in the condenser or evaporator

Leaks in the condenser or evaporator often require component replacement. Follow these steps:

- Recover refrigerant: Use a refrigerant recovery machine to remove refrigerant from the system.

- Disconnect component: Disconnect the damaged condenser or evaporator from the AC lines.

- Remove component: Remove the damaged component from the vehicle.

- Install new component: Install a new condenser or evaporator of the correct size and type.

- Reconnect component: Reconnect the component to the AC lines, tightening the connections to the correct torque.

- Evacuate system: Use a vacuum pump to remove air and moisture from the system.

- Recharge system: Recharge the system with the correct amount of refrigerant.

According to a study by the National Institute for Automotive Service Excellence (ASE), proper evacuation and recharge procedures are critical for ensuring the AC system functions efficiently and reliably.

Step-by-step guide to AC recharge

Recharging the AC system involves adding refrigerant to the correct level. Here’s how to do it:

- Connect manifold gauge set: Connect the manifold gauge set to the AC system service ports.

- Connect vacuum pump: Connect a vacuum pump to the manifold gauge set.

- Evacuate system: Run the vacuum pump for at least 30 minutes to remove air and moisture from the system.

- Close valves: Close the valves on the manifold gauge set.

- Disconnect vacuum pump: Disconnect the vacuum pump from the manifold gauge set.

- Connect refrigerant source: Connect a refrigerant source to the manifold gauge set.

- Recharge system: Open the valves on the manifold gauge set to allow refrigerant to flow into the system. Use a refrigerant scale to add the correct amount of refrigerant.

- Monitor pressures: Monitor the pressures on the manifold gauge set to ensure they are within the correct range.

- Close valves: Close the valves on the manifold gauge set.

- Disconnect refrigerant source: Disconnect the refrigerant source from the manifold gauge set.

- Disconnect manifold gauge set: Disconnect the manifold gauge set from the AC system service ports.

Pressure testing the system for leaks after repair

After making repairs, it’s essential to pressure test the system to ensure there are no remaining leaks. Here’s how:

- Connect manifold gauge set: Connect the manifold gauge set to the AC system service ports.

- Pressurize system: Pressurize the system with nitrogen to a pressure slightly above the normal operating pressure.

- Monitor pressure: Monitor the pressure on the manifold gauge set for at least 30 minutes. If the pressure drops, there is still a leak in the system.

- Locate leak: Use a leak detector to locate the remaining leak.

- Repair leak: Repair the leak and repeat the pressure test until the system holds pressure.

- Evacuate system: Use a vacuum pump to remove nitrogen from the system.

- Recharge system: Recharge the system with the correct amount of refrigerant.

5. Common Mistakes to Avoid When Fixing AC Leaks

Overcharging or undercharging refrigerant

Adding too much or too little refrigerant can cause AC system problems. Overcharging can damage the compressor, while undercharging can result in poor cooling performance. Always use a refrigerant scale to add the correct amount of refrigerant.

Not evacuating the system properly

Failing to evacuate the system properly can leave air and moisture in the system, which can cause corrosion and reduce cooling efficiency. Always use a vacuum pump to evacuate the system for at least 30 minutes.

Using the wrong type of refrigerant

Using the wrong type of refrigerant can damage the AC system and may be illegal. Always use the correct type of refrigerant specified for your vehicle.

Neglecting safety precautions

Neglecting safety precautions can result in injury. Always wear safety glasses, gloves, and a respirator when working on AC systems.

Ignoring small leaks

Ignoring small leaks can lead to bigger problems down the road. Address leaks promptly to prevent further damage and maintain AC system efficiency.

6. When to Seek Professional Help

Complex AC issues

Some AC issues are too complex for DIY repairs. If you encounter any of the following problems, seek professional help:

- Compressor failure: Replacing a compressor requires specialized knowledge and tools.

- Evaporator core replacement: Replacing the evaporator core involves disassembling the dashboard, which can be a complex and time-consuming task.

- Electrical issues: Electrical problems in the AC system require diagnostic skills and specialized equipment.

Lack of experience or tools

If you lack the experience or tools to perform AC repairs safely and effectively, it’s best to seek professional help. Attempting repairs without the necessary skills and equipment can result in further damage to the AC system.

Environmental regulations

Handling refrigerant requires compliance with environmental regulations. If you’re not certified to handle refrigerant, it’s illegal to perform AC repairs. Seek professional help to ensure compliance with environmental regulations.

Warranty considerations

Performing DIY AC repairs may void your vehicle’s warranty. Check your warranty terms before attempting any repairs.

7. Maintaining Your Car AC System

Regular inspections

Regular inspections can help prevent AC problems and extend the life of your AC system. Inspect AC components for leaks, damage, and wear.

Changing cabin air filter

A dirty cabin air filter can restrict airflow and reduce cooling efficiency. Change the cabin air filter regularly, following the manufacturer’s recommendations.

AC system flush

An AC system flush can remove contaminants and restore cooling efficiency. Perform an AC system flush every few years or as needed.

Professional AC service

Schedule regular professional AC service to ensure your system is functioning properly. A professional technician can diagnose and repair problems before they become major issues.

According to a study by the Air Conditioning Contractors of America (ACCA), regular maintenance can improve AC system efficiency by as much as 20%.

8. The Environmental Impact of Refrigerant Leaks

Understanding the environmental consequences

Refrigerant leaks can have significant environmental consequences. Refrigerants are greenhouse gases that contribute to climate change. Leaking refrigerant into the atmosphere can deplete the ozone layer and increase global warming.

Responsible refrigerant handling

Responsible refrigerant handling is essential for protecting the environment. Always recover refrigerant properly and dispose of it according to environmental regulations.

Regulations and compliance

Comply with all regulations regarding refrigerant handling. The EPA has strict rules regarding the recovery, recycling, and disposal of refrigerants.

Choosing eco-friendly refrigerants

Consider using eco-friendly refrigerants that have a lower global warming potential. The newer R-1234yf refrigerant is more environmentally friendly than R-134a.

9. Innovative Solutions and Products from CARDIAGTECH.NET

Introducing CARDIAGTECH.NET’s AC Repair Solutions

At CARDIAGTECH.NET, we understand the challenges of maintaining and repairing car AC systems. That’s why we offer a comprehensive range of innovative tools and equipment designed to make AC repair easier, more efficient, and environmentally responsible. Our products are tailored to meet the needs of both professional technicians and DIY enthusiasts.

Highlight specific tools and equipment

- AC Manifold Gauge Sets: Our AC manifold gauge sets are engineered for precision and durability, allowing you to accurately measure pressures in the AC system. With easy-to-read gauges and robust construction, our sets ensure reliable performance every time.

- Features: High-accuracy gauges, durable hoses, and secure connections

- Benefits: Precise measurements, reduced risk of leaks, and extended lifespan

- Vacuum Pumps: Essential for removing air and moisture from the AC system, our vacuum pumps are designed for efficient and thorough evacuation. By ensuring a clean system, our pumps help maximize cooling efficiency and prevent corrosion.

- Features: High CFM rating, deep vacuum capability, and oil-less design

- Benefits: Fast and effective evacuation, improved cooling performance, and reduced maintenance

- Refrigerant Scales: Accurately measuring the amount of refrigerant added to the system is crucial for optimal performance. Our refrigerant scales provide precise measurements, preventing overcharging or undercharging.

- Features: Digital display, high-precision sensors, and durable construction

- Benefits: Accurate refrigerant levels, optimized cooling, and reduced risk of damage

- Leak Detectors: Pinpointing the source of an AC leak can be challenging, but our leak detectors make the process quick and easy. Whether you prefer electronic or UV leak detectors, we have the tools to help you find leaks fast.

- Features: High sensitivity, audible and visual alerts, and ergonomic design

- Benefits: Rapid leak detection, reduced downtime, and cost savings

- Refrigerant Recovery Machines: Complying with environmental regulations is essential when handling refrigerants. Our refrigerant recovery machines ensure the safe and efficient recovery of refrigerant, preventing harmful emissions.

- Features: High recovery rate, automatic shut-off, and built-in filters

- Benefits: Environmentally responsible refrigerant handling, compliance with regulations, and reduced risk of fines

- AC System Flush Kits: Over time, contaminants can build up in the AC system, reducing cooling efficiency. Our AC system flush kits remove these contaminants, restoring performance and extending the life of the system.

- Features: High-flow design, multiple adapters, and solvent compatibility

- Benefits: Improved cooling performance, extended system lifespan, and reduced maintenance

CARDIAGTECH.NET offers a wide range of AC repair tools and equipment to suit every need.

How CARDIAGTECH.NET’s products solve common AC repair challenges

Our products are designed to address the common challenges faced by technicians and DIY enthusiasts when repairing AC systems:

- Precision: Our AC manifold gauge sets and refrigerant scales ensure accurate measurements, preventing overcharging or undercharging.

- Efficiency: Our vacuum pumps and AC system flush kits improve cooling performance and extend the life of the system.

- Safety: Our leak detectors and refrigerant recovery machines help prevent refrigerant leaks and ensure compliance with environmental regulations.

- Reliability: All our products are built to last, with durable construction and high-quality components.

Customer success stories

“I’ve been using CARDIAGTECH.NET’s AC manifold gauge set for years, and it’s never let me down. The gauges are accurate, and the hoses are durable. I highly recommend it.” – John, Professional Technician

“I was able to fix my car’s AC leak quickly and easily with CARDIAGTECH.NET’s UV leak detector. It saved me a lot of money compared to taking it to a shop.” – Mary, DIY Enthusiast

Call to action: Explore CARDIAGTECH.NET for your AC repair needs

Visit CARDIAGTECH.NET today to explore our full range of AC repair solutions. Whether you’re a professional technician or a DIY enthusiast, we have the tools and equipment you need to keep your car’s AC system running smoothly. Contact us via WhatsApp at +1 (641) 206-8880 for personalized assistance and expert advice.

10. Maximizing the Lifespan of Your AC System

Best practices for long-term AC health

Maximizing the lifespan of your AC system requires a proactive approach to maintenance and care. By following these best practices, you can ensure your AC system operates efficiently and reliably for years to come:

- Regular Use: Running your AC system regularly, even during cooler months, helps keep the components lubricated and prevents seals from drying out.

- Proper Refrigerant Levels: Maintaining the correct refrigerant levels is essential for optimal performance. Have your AC system checked periodically to ensure it is properly charged.

- Clean Condenser: Keep the condenser free of debris, such as leaves, dirt, and bugs. A clean condenser allows for efficient heat transfer, improving cooling performance.

- Inspect Hoses and Belts: Regularly inspect hoses and belts for cracks, wear, and damage. Replace them as needed to prevent leaks and system failures.

- Professional Service: Schedule regular professional AC service to ensure your system is functioning properly. A professional technician can diagnose and repair problems before they become major issues.

- Use Quality Parts: When replacing AC components, always use high-quality parts that meet or exceed OEM specifications. This ensures reliable performance and extends the life of the system.

- Avoid Overloading the System: Avoid running the AC system at maximum settings for extended periods. This can put unnecessary strain on the compressor and other components.

Seasonal AC maintenance tips

Adjusting your AC maintenance routine to the seasons can help ensure optimal performance year-round. Here are some seasonal tips:

- Spring: Inspect the AC system for leaks and damage. Clean the condenser and evaporator coils. Check the refrigerant level and recharge if necessary.

- Summer: Use the AC system regularly to keep the components lubricated. Monitor cooling performance and address any issues promptly.

- Fall: Change the cabin air filter to remove dust and allergens. Inspect hoses and belts for wear and damage.

- Winter: Run the AC system periodically to prevent seals from drying out. Store the vehicle in a dry place to prevent corrosion.

The role of proper ventilation

Proper ventilation is essential for maintaining a comfortable and healthy cabin environment. Here’s how to ensure proper ventilation:

- Use the Recirculation Mode Sparingly: The recirculation mode recirculates air from inside the cabin, which can reduce cooling efficiency and increase humidity. Use it sparingly and switch to fresh air mode periodically.

- Ensure Proper Airflow: Make sure vents are open and unobstructed. Adjust the vent settings to direct airflow where it is needed.

- Address Odors Promptly: If you notice any unusual odors, address them promptly. Odors can indicate mold growth or other problems that can affect air quality.

- Regular Cleaning: Clean the interior of the vehicle regularly to remove dust and allergens. Vacuum carpets and upholstery, and wipe down surfaces with a damp cloth.

Choosing the right AC service provider

Selecting the right AC service provider is crucial for ensuring your AC system receives the proper care and attention. Here are some factors to consider when choosing a service provider:

- Experience and Expertise: Choose a service provider with experience and expertise in AC repair. Look for technicians who are certified and have a proven track record of success.

- Reputation: Check online reviews and ratings to get an idea of the service provider’s reputation. Look for positive feedback and testimonials from satisfied customers.

- Equipment and Tools: Ensure the service provider has the proper equipment and tools to perform AC repairs safely and effectively.

- Warranty: Ask about warranty options for AC repairs. A reputable service provider will stand behind their work and offer a warranty on parts and labor.

- Customer Service: Choose a service provider who is responsive, helpful, and committed to customer satisfaction.

By following these tips and choosing the right AC service provider, you can maximize the lifespan of your AC system and enjoy a comfortable and reliable driving experience. And remember, for all your AC repair tool needs, CARDIAGTECH.NET is here to help.

11. Understanding AC System Diagnostics

The importance of accurate diagnostics

Accurate diagnostics are the cornerstone of effective AC system repair. Proper diagnostics not only identify the root cause of AC issues but also prevent unnecessary repairs and ensure that the correct components are addressed.

Common diagnostic tools

- Manifold Gauge Set: The manifold gauge set is a fundamental tool for assessing AC system performance. It measures the high-side and low-side pressures within the system, providing critical insights into its overall health.

- Thermometer: A thermometer helps in measuring the temperature of the air coming from the AC vents.

- Multimeter: This versatile tool measures voltage, current, and resistance, helping technicians diagnose electrical issues within the AC system, such as faulty sensors or wiring problems.

- Scan Tool: A scan tool connects to the vehicle’s onboard computer and retrieves diagnostic trouble codes (DTCs) related to the AC system.

Interpreting diagnostic results

- Pressure Readings: Analyzing pressure readings from the manifold gauge set helps identify issues such as refrigerant leaks, compressor problems, or restrictions in the system.

- Temperature Measurements: Comparing the temperature of the air coming from the AC vents with the ambient temperature helps assess cooling performance.

- Diagnostic Trouble Codes (DTCs): DTCs provide valuable clues about the nature and location of AC system faults. Technicians use DTCs to guide their diagnostic efforts and pinpoint specific components that require attention.

Advanced diagnostic techniques

- Smoke Testing: This technique involves introducing a non-toxic smoke into the AC system and observing where it escapes. Smoke testing is particularly useful for locating small leaks that may be difficult to detect by other means.

- Ultrasonic Leak Detection: Ultrasonic leak detectors use sound waves to locate refrigerant leaks. These detectors are highly sensitive and can detect even the smallest leaks in hard-to-reach areas.

- Thermal Imaging: Thermal imaging cameras capture infrared radiation, allowing technicians to visualize temperature variations within the AC system.

Ensuring a precise diagnosis

- Gather Information: Before beginning the diagnostic process, gather as much information as possible about the AC system’s symptoms and history.

- Follow a Systematic Approach: Use a systematic approach to diagnostics, starting with basic checks and progressing to more advanced tests as needed.

- Verify Results: Always verify diagnostic results by performing additional tests or inspections. This helps ensure that the diagnosis is accurate and that the correct repairs are performed.

12. Financial Benefits of Maintaining Your AC System

Reduced repair costs

Regular maintenance can prevent minor issues from escalating into major problems, saving you money on costly repairs. For instance, catching a small refrigerant leak early can prevent compressor damage, which can be an expensive repair.

Improved fuel efficiency

A well-maintained AC system operates more efficiently, reducing the load on your engine and improving fuel economy. Studies show that a properly functioning AC system can improve fuel efficiency by as much as 10-20%.

Extended lifespan of components

Regular maintenance can extend the lifespan of AC system components, such as the compressor, condenser, and evaporator. By keeping these components clean and properly lubricated, you can prevent premature wear and tear.

Increased vehicle resale value

A vehicle with a well-maintained AC system is more attractive to potential buyers and can command a higher resale value. Buyers are more likely to pay a premium for a vehicle that has been properly cared for and has no known issues.

Preventing costly breakdowns

Regular maintenance can help prevent costly breakdowns by identifying and addressing potential problems before they cause a system failure. For example, replacing worn belts or hoses can prevent them from breaking down and causing damage to other components.

Cost-effective maintenance strategies

- DIY Maintenance: Perform basic maintenance tasks yourself, such as cleaning the condenser and changing the cabin air filter.

- Professional Service: Schedule regular professional AC service to ensure your system is functioning properly.

- Use Quality Parts: When replacing AC components, always use high-quality parts that meet or exceed OEM specifications.

Return on investment (ROI)

Investing in regular AC system maintenance can provide a significant return on investment by reducing repair costs, improving fuel efficiency, extending component lifespan, increasing vehicle resale value, and preventing costly breakdowns.

13. FAQ: Addressing Common Questions About Car AC Leaks

Question 1: How often should I recharge my car AC?

Recharging frequency depends on system condition. Generally, every 2-3 years is recommended, but if you notice decreased cooling, it may be time to recharge.

Question 2: Can I use an AC recharge kit from an auto parts store?

Yes, but exercise caution. These kits can be convenient, but it’s crucial to follow instructions carefully to avoid overcharging, which can damage the system.

Question 3: What causes AC leaks in cars?

Leaks often result from damaged seals, corroded components, or punctures from road debris. Regular wear and tear can also contribute to leaks.

Question 4: Is it safe to drive with a leaking AC?

Driving with a minor leak may be okay temporarily, but it reduces cooling efficiency and can worsen over time. It’s best to address the leak promptly to prevent further damage.

Question 5: How much does it cost to fix an AC leak in a car?

Costs vary depending on the leak’s location and severity. Simple fixes like O-ring replacement may cost $50-$150, while more complex repairs like compressor replacement can range from $400-$1200.

Question 6: Can I fix an AC leak myself, or should I hire a professional?

Simple repairs like O-ring replacement can be DIY, but complex issues require professional expertise and specialized tools.

Question 7: What are the environmental regulations for handling refrigerants?

Refrigerants are regulated due to their environmental impact. It’s illegal to knowingly vent refrigerants into the atmosphere. Certified technicians must recover and dispose of refrigerants properly.

Question 8: How do I know what type of refrigerant my car uses?

The refrigerant type is usually indicated on a sticker under the hood or in the owner’s manual. Common refrigerants include R-134a and R-1234yf.

Question 9: What is the difference between R-134a and R-1234yf refrigerants?

R-134a is an older refrigerant with a higher global warming potential. R-1234yf is a newer, more environmentally friendly refrigerant with a lower global warming potential.

Question 10: Can I convert my AC system from R-134a to R-1234yf?

Converting an AC system from R-134a to R-1234yf is not recommended due to compatibility issues and potential damage to the system. It’s best to use the refrigerant specified for your vehicle.

14. Call to Action: Get Expert AC Repair Assistance from CARDIAGTECH.NET

Are you experiencing AC problems in your car? Don’t let a leaking AC system ruin your driving experience. At CARDIAGTECH.NET, we have the tools, equipment, and expertise to diagnose and repair AC leaks quickly and effectively.

Contact us for professional assistance

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

Explore our range of AC repair tools

Visit CARDIAGTECH.NET today to explore our full range of AC repair tools and equipment. Whether you’re a professional technician or a DIY enthusiast, we have the tools you need to keep your car’s AC system running smoothly.

Get personalized advice

Our team of experts is standing by to answer your questions and provide personalized advice on AC repair. Contact us via WhatsApp at +1 (641) 206-8880 for immediate assistance.

Special offer for new customers

As a special offer for new customers, we’re offering a 10% discount on all AC repair tools and equipment. Use the code “ACREPAIR10” at checkout to redeem your discount. Don’t miss out on this limited-time offer!

Customer satisfaction guarantee

At CARDIAGTECH.NET, we’re committed to customer satisfaction. If you’re not completely satisfied with your purchase, simply return it for a full refund.

Take control of your car’s AC system and ensure a comfortable and reliable driving experience. Contact CARDIAGTECH.NET today for expert AC repair assistance.