How to Replace the Fuel Filter? (Often Integrated With Pump/Sender Unit)

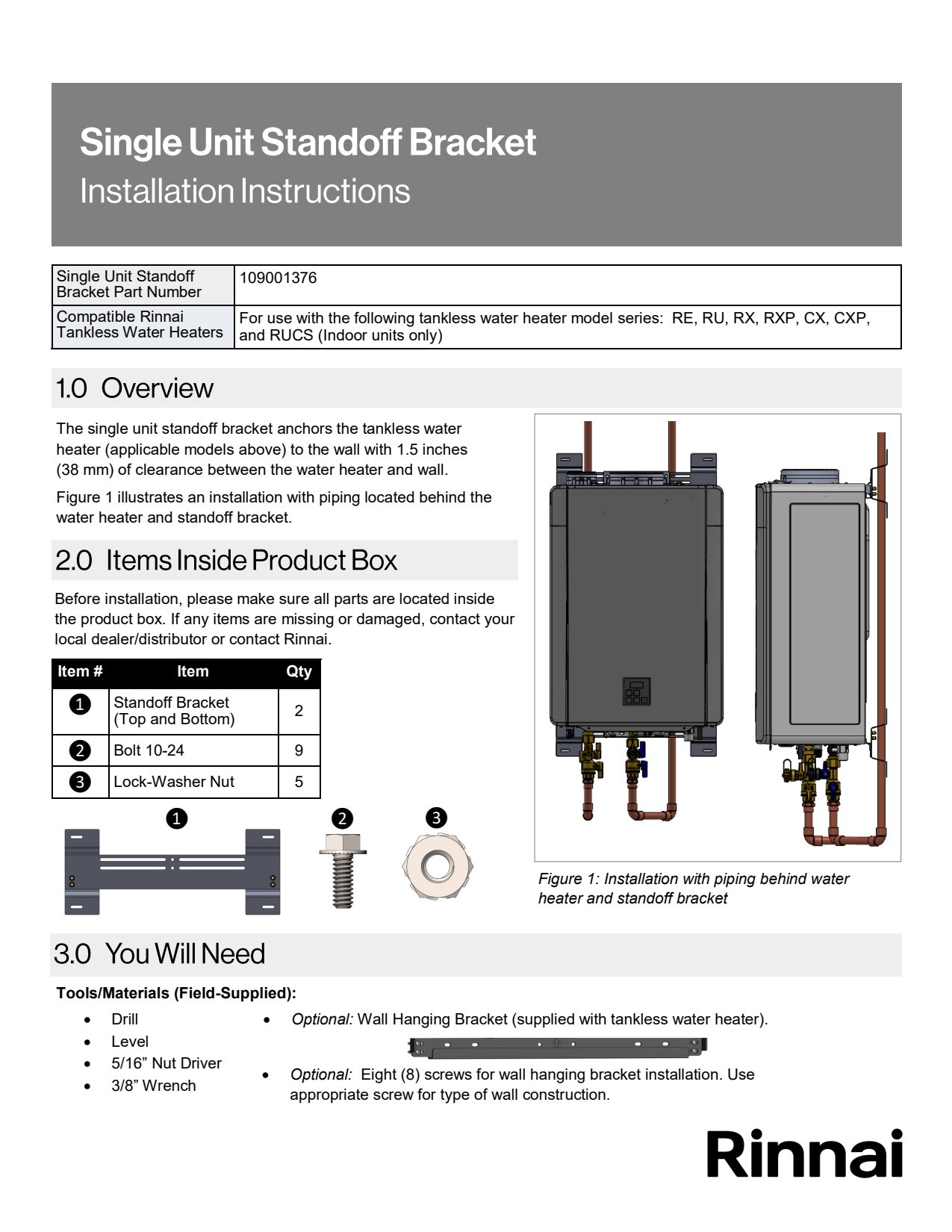

Replacing your fuel filter, often integrated with the pump/sender unit, is a crucial maintenance task that ensures optimal engine performance and longevity. At CARDIAGTECH.NET, we provide expert guidance and the necessary tools to make this process efficient and straightforward, preventing potential engine problems and maintaining your vehicle’s fuel efficiency. This guide will help you understand the process and highlight why choosing the right tools from CARDIAGTECH.NET can make all the difference.

1. What is a Fuel Filter and Why is Replacing It Important?

A fuel filter is a vital component in your vehicle’s fuel system. It screens out dirt, rust, and other contaminants from the fuel before it reaches the engine. Over time, this filter can become clogged, reducing fuel flow and potentially causing serious engine issues. According to a study by the University of Northwestern’s Transportation Center, replacing a clogged fuel filter can improve fuel efficiency by as much as 2%, enhancing vehicle performance significantly.

Why is replacing the fuel filter important?

- Improved Engine Performance: A clean fuel filter ensures a consistent and adequate fuel supply to the engine, preventing issues like stalling, misfires, and rough idling.

- Enhanced Fuel Efficiency: As stated by the University of Northwestern’s Transportation Center, replacing a clogged fuel filter can boost fuel economy by up to 2%.

- Protection of Fuel Injectors: Clean fuel prevents debris from clogging or damaging the fuel injectors, which are costly to replace.

- Prevention of Costly Repairs: Regularly replacing the fuel filter can prevent serious engine damage and save you money on extensive repairs down the line.

2. Identifying the Need to Replace Your Fuel Filter

Knowing when to replace your fuel filter is crucial for maintaining your vehicle’s performance. Several symptoms indicate that your fuel filter may be failing and needs replacement.

What are the symptoms of a failing fuel filter?

- Difficulty Starting the Engine: A clogged fuel filter restricts fuel flow, making it difficult for the engine to start, especially in cold weather.

- Engine Misfires: Insufficient fuel supply can cause the engine to misfire, leading to a rough ride and decreased performance.

- Stalling: A severely clogged filter can cause the engine to stall, particularly under load or during acceleration.

- Poor Acceleration: If your vehicle hesitates or struggles to accelerate, it could be due to a lack of fuel caused by a clogged filter.

- Decreased Fuel Efficiency: A clogged filter forces the engine to work harder, reducing fuel economy.

- Unusual Noises: You may hear a whining or sputtering sound from the fuel pump as it struggles to draw fuel through the clogged filter.

3. Understanding Different Types of Fuel Filters and Integration

Fuel filters come in various designs, often integrated with the fuel pump and sender unit. Knowing the type of filter in your vehicle is essential for proper replacement.

What are the common types of fuel filters?

- In-line Fuel Filters: These filters are located in the fuel line between the fuel tank and the engine. They are typically cylindrical and easy to access.

- Fuel Tank Filters: These filters are integrated into the fuel tank, often as part of the fuel pump and sender unit assembly. Replacing these filters requires accessing the fuel tank.

- Integrated Fuel Filter Modules: These modules combine the fuel filter, fuel pump, and fuel level sensor into a single unit, simplifying the installation and replacement process.

How do I determine which type of fuel filter my vehicle uses?

Consult your vehicle’s repair manual or contact a professional mechanic. CARDIAGTECH.NET’s experts can provide guidance on identifying the correct fuel filter for your vehicle and recommend the appropriate tools for the job. Contact us via Whatsapp at +1 (641) 206-8880 for immediate assistance.

4. Tools and Materials Needed for Fuel Filter Replacement

Having the right tools and materials is essential for a successful fuel filter replacement. Using high-quality tools from CARDIAGTECH.NET ensures precision and safety.

What tools and materials are required for fuel filter replacement?

- New Fuel Filter: Ensure you have the correct fuel filter for your vehicle’s make and model. CARDIAGTECH.NET offers a wide range of fuel filters to meet your needs.

- Wrench Set: A set of standard and metric wrenches is necessary to disconnect fuel lines and mounting hardware.

- Screwdrivers: Both flathead and Phillips head screwdrivers may be needed to remove access panels and other components.

- Fuel Line Disconnect Tool: This tool is essential for safely disconnecting fuel lines without damaging them.

- Jack and Jack Stands: If the fuel filter is located under the vehicle, you’ll need a jack and jack stands to safely lift and support the car.

- Safety Glasses and Gloves: Protect your eyes and hands from fuel and debris.

- Drain Pan: To catch any spilled fuel and prevent environmental contamination.

- Shop Towels: For cleaning up spills and wiping down components.

- Fuel Stabilizer: Adding a fuel stabilizer to the fuel tank can help prevent future contamination.

- Torque Wrench: To ensure bolts and fittings are tightened to the manufacturer’s specifications.

- Scan Tool: After replacing the fuel filter, a scan tool can help clear any error codes and ensure the fuel system is functioning correctly. CARDIAGTECH.NET offers advanced scan tools for comprehensive diagnostics.

5. Step-by-Step Guide: Replacing a Fuel Filter Integrated with the Fuel Pump/Sender Unit

Replacing a fuel filter integrated with the fuel pump/sender unit can seem daunting, but with the right tools and guidance, it can be manageable.

What are the steps for replacing an integrated fuel filter?

-

Safety First: Disconnect the negative battery cable to prevent electrical sparks. Work in a well-ventilated area to avoid inhaling fuel vapors.

-

Access the Fuel Tank: The fuel pump/sender unit is typically located inside the fuel tank. Access can be gained either through an access panel under the rear seat or by dropping the fuel tank.

- Access Panel Method:

- Remove the rear seat to expose the access panel.

- Disconnect any electrical connectors and fuel lines connected to the unit.

- Use a fuel line disconnect tool to safely detach the fuel lines.

- Dropping the Fuel Tank Method:

- Use a jack and jack stands to safely lift and support the vehicle.

- Drain as much fuel as possible from the tank using a siphon or pump.

- Disconnect the fuel lines, electrical connectors, and any other attachments to the tank.

- Carefully lower the fuel tank.

- Access Panel Method:

-

Remove the Old Unit:

- Once the fuel tank is accessible, remove the retaining ring or bolts holding the fuel pump/sender unit in place.

- Carefully remove the old unit from the tank, being mindful of any remaining fuel.

-

Install the New Fuel Filter/Pump/Sender Unit:

- Install the new fuel filter/pump/sender unit into the fuel tank, ensuring it is properly seated and aligned.

- Secure the unit with the retaining ring or bolts, tightening them to the manufacturer’s specified torque using a torque wrench.

-

Reassemble:

- Reconnect the fuel lines and electrical connectors.

- If you dropped the fuel tank, carefully raise it back into position and secure it.

- If you used the access panel method, reinstall the access panel and rear seat.

-

Final Steps:

- Reconnect the negative battery cable.

- Add a fuel stabilizer to the fuel tank to prevent future contamination.

- Start the engine and check for any leaks or unusual noises.

- Use a scan tool to clear any error codes and ensure the fuel system is functioning correctly.

6. Detailed Steps with Images

To further illustrate the process, let’s break down the fuel filter replacement with detailed steps and corresponding images.

Step 1: Gather Your Tools and Materials

Before you begin, gather all the necessary tools and materials. This includes the new fuel filter, wrench set, screwdrivers, fuel line disconnect tool, jack and jack stands (if needed), safety glasses, gloves, drain pan, shop towels, fuel stabilizer, torque wrench, and scan tool.

Alt Text: Essential tools and materials arranged for fuel filter replacement procedure

Step 2: Disconnect the Negative Battery Cable

Disconnect the negative battery cable to prevent electrical sparks. This is a crucial safety step to avoid potential hazards during the replacement process.

Alt Text: Safely disconnecting negative battery cable to prevent electrical hazards during fuel filter replacement

Step 3: Access the Fuel Tank

Depending on your vehicle, you will either access the fuel tank through an access panel under the rear seat or by dropping the fuel tank.

Access Panel Method:

Remove the rear seat to expose the access panel. Disconnect any electrical connectors and fuel lines connected to the unit. Use a fuel line disconnect tool to safely detach the fuel lines.

Alt Text: Access panel location under rear seat for accessing fuel pump assembly in car

Dropping the Fuel Tank Method:

Use a jack and jack stands to safely lift and support the vehicle. Drain as much fuel as possible from the tank using a siphon or pump. Disconnect the fuel lines, electrical connectors, and any other attachments to the tank. Carefully lower the fuel tank.

Alt Text: Lowering fuel tank with jack and stands for fuel filter access during automotive maintenance

Step 4: Remove the Old Unit

Once the fuel tank is accessible, remove the retaining ring or bolts holding the fuel pump/sender unit in place. Carefully remove the old unit from the tank, being mindful of any remaining fuel.

Alt Text: Removing old fuel pump unit from tank for replacement and automotive maintenance

Step 5: Install the New Fuel Filter/Pump/Sender Unit

Install the new fuel filter/pump/sender unit into the fuel tank, ensuring it is properly seated and aligned. Secure the unit with the retaining ring or bolts, tightening them to the manufacturer’s specified torque using a torque wrench.

Alt Text: Installing new fuel filter unit into the fuel tank, ensuring secure seating and alignment for proper operation

Step 6: Reassemble

Reconnect the fuel lines and electrical connectors. If you dropped the fuel tank, carefully raise it back into position and secure it. If you used the access panel method, reinstall the access panel and rear seat.

Alt Text: Reconnecting fuel lines to ensure proper fuel flow and secure connections during fuel system maintenance

Step 7: Final Steps

Reconnect the negative battery cable. Add a fuel stabilizer to the fuel tank to prevent future contamination. Start the engine and check for any leaks or unusual noises. Use a scan tool to clear any error codes and ensure the fuel system is functioning correctly.

Alt Text: Checking for fuel leaks after completing the fuel filter replacement process

7. Common Mistakes to Avoid During Fuel Filter Replacement

Even with careful attention, some common mistakes can occur during fuel filter replacement. Avoiding these mistakes can save you time and prevent damage to your vehicle.

What are the common mistakes to avoid?

- Not Relieving Fuel Pressure: Before disconnecting any fuel lines, relieve the fuel pressure to prevent fuel spillage and potential injury.

- Using Incorrect Tools: Using the wrong tools can damage fuel lines and fittings. Always use the correct fuel line disconnect tool.

- Forgetting Safety Precautions: Always disconnect the negative battery cable and work in a well-ventilated area to avoid electrical sparks and fuel vapor inhalation.

- Over-tightening Fittings: Over-tightening fuel line fittings can damage the threads and cause leaks. Use a torque wrench to tighten fittings to the manufacturer’s specified torque.

- Installing the Filter Backward: Ensure the fuel filter is installed in the correct direction. Most filters have an arrow indicating the direction of fuel flow.

- Ignoring Error Codes: After replacing the fuel filter, use a scan tool to check for and clear any error codes. Ignoring these codes can lead to further issues.

8. The Role of CARDIAGTECH.NET in Your Fuel Filter Replacement

CARDIAGTECH.NET is your reliable partner for high-quality tools and expert guidance for fuel filter replacement. We offer a wide range of tools and equipment to make your repair process smooth and efficient.

How does CARDIAGTECH.NET support your fuel filter replacement needs?

- Wide Range of Tools: CARDIAGTECH.NET offers a comprehensive selection of tools, including wrench sets, screwdrivers, fuel line disconnect tools, torque wrenches, and scan tools.

- High-Quality Products: Our tools are made from durable materials and designed for precision, ensuring reliable performance and longevity.

- Expert Guidance: CARDIAGTECH.NET provides expert advice and support to help you choose the right tools and complete your fuel filter replacement successfully. Contact us via Whatsapp at +1 (641) 206-8880 for personalized assistance.

- Competitive Pricing: We offer competitive prices on all our tools and equipment, making quality repairs accessible to everyone.

- Customer Satisfaction: At CARDIAGTECH.NET, customer satisfaction is our top priority. We are committed to providing excellent service and support to ensure you have a positive experience.

9. Why Choose CARDIAGTECH.NET for Your Automotive Tool Needs?

Choosing the right supplier for your automotive tools is crucial for ensuring quality, reliability, and performance. CARDIAGTECH.NET stands out as a premier provider of high-quality tools and equipment, offering numerous advantages over the competition.

What makes CARDIAGTECH.NET the best choice for automotive tools?

- Unmatched Quality: Our tools are crafted from premium materials, ensuring durability and long-lasting performance.

- Extensive Selection: We offer a wide range of tools to meet all your automotive repair and maintenance needs.

- Expert Support: Our team of experienced professionals is always ready to provide expert advice and guidance.

- Competitive Prices: We offer competitive pricing, making high-quality tools accessible to everyone.

- Customer Satisfaction: We are committed to providing exceptional customer service and ensuring your complete satisfaction.

10. Step-by-Step Instructions: Fuel Filter Replacement (Integrated with Pump/Sender Unit)

For detailed instructions, consider the following steps when replacing the fuel filter integrated with the pump/sender unit:

| Step | Action | Tools Required |

|---|---|---|

| 1. Preparation | Gather necessary tools and materials, including the new fuel filter, wrench set, screwdrivers, fuel line disconnect tool, jack and jack stands, safety gear. | Wrench set, screwdrivers, fuel line disconnect tool, jack and jack stands, safety glasses, gloves, drain pan, shop towels |

| 2. Safety Precautions | Disconnect the negative battery cable and work in a well-ventilated area. | Safety glasses, gloves |

| 3. Access Fuel Tank | Access the fuel tank either through an access panel under the rear seat or by dropping the fuel tank. | Jack and jack stands, screwdrivers, fuel line disconnect tool |

| 4. Remove Old Unit | Remove the retaining ring or bolts holding the fuel pump/sender unit in place and carefully remove the old unit from the tank. | Wrench set, screwdrivers |

| 5. Install New Unit | Install the new fuel filter/pump/sender unit into the fuel tank, ensuring it is properly seated and aligned. | Wrench set, torque wrench |

| 6. Reassemble | Reconnect the fuel lines and electrical connectors. If you dropped the fuel tank, carefully raise it back into position and secure it. | Wrench set, screwdrivers, jack and jack stands |

| 7. Final Checks | Reconnect the negative battery cable, add fuel stabilizer, start the engine, check for leaks, and use a scan tool to clear any error codes. | Fuel stabilizer, scan tool |

11. Ensuring a Proper Seal and Preventing Leaks

One of the most critical aspects of fuel filter replacement is ensuring a proper seal to prevent fuel leaks. Leaks can lead to fuel wastage, fire hazards, and potential damage to your vehicle.

How can I ensure a proper seal and prevent leaks?

- Inspect Fittings: Before installing the new fuel filter, inspect all fittings and connections for damage or corrosion. Replace any damaged components.

- Use New O-Rings and Seals: Always use new O-rings and seals when installing the new fuel filter. Old seals can be brittle and may not provide a proper seal.

- Tighten to Specification: Use a torque wrench to tighten all fittings to the manufacturer’s specified torque. Over-tightening can damage the fittings, while under-tightening can lead to leaks.

- Check for Leaks: After completing the installation, start the engine and carefully check all connections for leaks. If you detect any leaks, immediately shut off the engine and address the issue.

12. Maximizing Fuel Efficiency After Filter Replacement

After replacing your fuel filter, there are several steps you can take to maximize your vehicle’s fuel efficiency and ensure optimal performance.

What steps can I take to maximize fuel efficiency?

- Use High-Quality Fuel: Use high-quality fuel from reputable gas stations. High-quality fuel contains additives that help keep your fuel system clean and prevent deposits.

- Add Fuel Stabilizer: Add a fuel stabilizer to the fuel tank to prevent fuel degradation and contamination.

- Maintain Proper Tire Pressure: Ensure your tires are properly inflated. Under-inflated tires can reduce fuel efficiency.

- Drive Smoothly: Avoid aggressive acceleration and braking. Smooth driving can significantly improve fuel economy.

- Regular Maintenance: Follow your vehicle’s recommended maintenance schedule, including regular oil changes and tune-ups.

13. Troubleshooting Common Issues After Fuel Filter Replacement

Even with careful installation, you may encounter some issues after replacing your fuel filter. Troubleshooting these common problems can help you resolve them quickly and efficiently.

What are the common issues after fuel filter replacement and how can I troubleshoot them?

- Engine Won’t Start:

- Possible Cause: Air in the fuel line.

- Troubleshooting: Cycle the ignition key several times to allow the fuel pump to prime the system.

- Engine Misfires:

- Possible Cause: Incorrect fuel filter installation or a faulty new filter.

- Troubleshooting: Double-check the fuel filter installation and replace the filter if necessary.

- Fuel Leaks:

- Possible Cause: Improperly tightened fittings or damaged seals.

- Troubleshooting: Check all fittings and connections for leaks and tighten them to the manufacturer’s specified torque. Replace any damaged seals.

- Check Engine Light:

- Possible Cause: Error codes related to the fuel system.

- Troubleshooting: Use a scan tool to read and clear any error codes.

14. The Importance of Using Quality Parts and Tools

Using quality parts and tools is paramount when performing any automotive repair, including fuel filter replacement. Inferior parts and tools can lead to poor performance, premature failure, and potential safety hazards.

Why is it important to use quality parts and tools?

- Reliability: Quality parts and tools are designed and manufactured to meet or exceed OEM specifications, ensuring reliable performance and longevity.

- Safety: Quality parts and tools are tested and certified to meet safety standards, reducing the risk of accidents and injuries.

- Performance: Quality parts and tools can improve your vehicle’s performance, fuel efficiency, and overall driving experience.

- Cost Savings: While quality parts and tools may cost more upfront, they can save you money in the long run by reducing the need for frequent repairs and replacements.

15. Addressing Specific Vehicle Models

Fuel filter replacement procedures can vary slightly depending on the vehicle model. Addressing specific models ensures that you follow the correct steps for your particular vehicle.

How do fuel filter replacement procedures vary by vehicle model?

- Location of the Fuel Filter: The location of the fuel filter can vary depending on the vehicle model. Some vehicles have the filter located in the fuel line, while others have it integrated into the fuel tank.

- Access to the Fuel Tank: Accessing the fuel tank can also vary. Some vehicles have an access panel under the rear seat, while others require dropping the fuel tank.

- Fuel Line Connections: The type of fuel line connections can also vary. Some vehicles use quick-disconnect fittings, while others use threaded fittings.

How can I find specific instructions for my vehicle model?

- Vehicle Repair Manual: Consult your vehicle’s repair manual for detailed instructions and diagrams.

- Online Forums: Search online forums and communities specific to your vehicle model for tips and advice from other owners.

- Professional Mechanic: Consult a professional mechanic for expert guidance and assistance.

16. Fuel Filter Replacement and Environmental Responsibility

Fuel filter replacement can have environmental implications, particularly regarding the disposal of used fuel and parts. Following environmentally responsible practices can help minimize your impact on the environment.

How can I practice environmental responsibility during fuel filter replacement?

- Proper Disposal of Used Fuel: Collect any used fuel in a sealed container and dispose of it at a designated recycling center or hazardous waste facility.

- Recycle Used Parts: Recycle the old fuel filter and any other used parts whenever possible.

- Use Eco-Friendly Products: Use eco-friendly cleaners and solvents to minimize environmental contamination.

- Prevent Spills: Take precautions to prevent fuel spills during the replacement process. Use a drain pan to catch any spills and clean up any messes immediately.

17. The Future of Fuel Filter Technology

Fuel filter technology continues to evolve, with advancements aimed at improving filtration efficiency, extending filter life, and reducing environmental impact.

What are the trends in fuel filter technology?

- Advanced Filtration Media: New filtration media, such as synthetic fibers and multi-layer designs, are being developed to improve filtration efficiency and capture smaller particles.

- Extended Life Filters: Extended life filters are designed to last longer, reducing the need for frequent replacements and minimizing waste.

- Biodegradable Filters: Biodegradable filters are made from sustainable materials that can decompose naturally, reducing environmental impact.

- Smart Filters: Smart filters incorporate sensors and electronic controls to monitor filter performance and provide real-time alerts when the filter needs to be replaced.

18. Partnering with CARDIAGTECH.NET for Your Automotive Needs

CARDIAGTECH.NET is your dedicated partner for all your automotive tool and equipment needs. We offer a wide range of products and services to help you keep your vehicle running smoothly and efficiently.

How can CARDIAGTECH.NET help you with your automotive needs?

- Comprehensive Product Selection: We offer a wide range of tools and equipment, including wrench sets, screwdrivers, fuel line disconnect tools, torque wrenches, and scan tools.

- Expert Guidance: Our team of experienced professionals is always ready to provide expert advice and guidance.

- Competitive Prices: We offer competitive pricing, making high-quality tools accessible to everyone.

- Customer Satisfaction: We are committed to providing exceptional customer service and ensuring your complete satisfaction.

19. Call to Action: Contact CARDIAGTECH.NET Today

Ready to replace your fuel filter and ensure optimal engine performance? Contact CARDIAGTECH.NET today for expert advice and high-quality tools.

Why should you contact CARDIAGTECH.NET now?

- Expert Advice: Our knowledgeable team can help you choose the right tools and equipment for your specific needs.

- Quality Products: We offer a wide range of high-quality tools designed for precision and durability.

- Competitive Prices: We offer competitive prices, making quality repairs accessible to everyone.

- Immediate Assistance: Contact us via Whatsapp at +1 (641) 206-8880 for immediate assistance and personalized service.

Don’t wait until your fuel filter causes engine problems. Contact CARDIAGTECH.NET today and take the first step towards maintaining your vehicle’s performance and fuel efficiency.

Contact Information:

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- Whatsapp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

20. Frequently Asked Questions (FAQ) About Fuel Filter Replacement

Here are some frequently asked questions about fuel filter replacement to provide you with additional information and guidance.

FAQ: Fuel Filter Replacement

- How often should I replace my fuel filter?

- The recommended replacement interval varies depending on the vehicle model and manufacturer. Consult your vehicle’s repair manual for specific recommendations, typically every 20,000 to 30,000 miles.

- Can I drive with a clogged fuel filter?

- Driving with a clogged fuel filter can cause engine damage and reduce fuel efficiency. It’s best to replace the filter as soon as you notice symptoms of a failing filter.

- Is it difficult to replace a fuel filter myself?

- Replacing a fuel filter can be relatively straightforward, but it requires some mechanical knowledge and the right tools. If you’re not comfortable performing the replacement yourself, it’s best to consult a professional mechanic.

- What are the symptoms of a clogged fuel filter?

- Symptoms of a clogged fuel filter include difficulty starting the engine, engine misfires, stalling, poor acceleration, decreased fuel efficiency, and unusual noises.

- Can a clogged fuel filter damage my engine?

- Yes, a clogged fuel filter can restrict fuel flow and cause damage to the fuel injectors and other engine components.

- What tools do I need to replace a fuel filter?

- You’ll need a new fuel filter, wrench set, screwdrivers, fuel line disconnect tool, jack and jack stands (if needed), safety glasses, gloves, drain pan, shop towels, fuel stabilizer, torque wrench, and scan tool.

- How do I relieve fuel pressure before replacing the fuel filter?

- Consult your vehicle’s repair manual for specific instructions on relieving fuel pressure. Typically, this involves disconnecting the fuel pump relay and running the engine until it stalls.

- How do I dispose of used fuel?

- Collect any used fuel in a sealed container and dispose of it at a designated recycling center or hazardous waste facility.

- Can I reuse the old fuel filter?

- No, it’s not recommended to reuse the old fuel filter. Once a fuel filter is clogged, it cannot be effectively cleaned and reused.

- What is the cost of replacing a fuel filter?

- The cost of replacing a fuel filter can vary depending on the vehicle model, the type of filter, and the labor costs (if you hire a professional mechanic). Contact CARDIAGTECH.NET for competitive pricing on high-quality fuel filters and tools.

By following this comprehensive guide and utilizing the high-quality tools and expert guidance from CARDIAGTECH.NET, you can confidently replace your fuel filter, ensure optimal engine performance, and save money on costly repairs. Contact us today via Whatsapp at +1 (641) 206-8880 for all your automotive needs.