Can VCX SE Read MAF Sensor Readings in g/s? The Definitive Guide

Can VCX SE accurately read MAF (Mass Air Flow) sensor readings in grams per second (g/s)? Yes, the VCX SE diagnostic tool is capable of reading MAF sensor readings in g/s, providing valuable data for diagnosing engine performance issues. CARDIAGTECH.BIZ provides top-notch VCX SE tools that offer precise and reliable data, enabling technicians to diagnose issues effectively and improve repair quality, enhancing diagnostic precision and repair efficacy.

1. Understanding the VCX SE Diagnostic Tool

The VCX SE is a versatile diagnostic tool used for vehicle diagnostics and reprogramming. It supports various communication protocols and vehicle models, making it an essential tool for automotive technicians.

1.1 Key Features of VCX SE

VCX SE offers a wide range of functionalities:

- Comprehensive Diagnostics: Reads and clears diagnostic trouble codes (DTCs) from various vehicle systems.

- Data Streaming: Provides real-time data from sensors and modules.

- Actuation Tests: Performs tests on components like fuel injectors, solenoids, and relays.

- ECU Programming: Allows reprogramming of engine control units (ECUs).

- Multi-Protocol Support: Supports various communication protocols such as CAN, J1850, and ISO9141.

1.2 Benefits of Using VCX SE

- Improved Diagnostic Accuracy: Provides accurate data for diagnosing complex issues.

- Increased Efficiency: Reduces diagnostic time with comprehensive features.

- Wide Vehicle Coverage: Supports a broad range of vehicle makes and models.

- Cost-Effective: Offers a cost-effective solution for professional diagnostics.

2. MAF Sensor Basics

The Mass Air Flow (MAF) sensor measures the amount of air entering the engine. This data is crucial for the engine control unit (ECU) to calculate the correct amount of fuel to inject, ensuring optimal combustion.

2.1 Function of MAF Sensor

The MAF sensor works by measuring the mass of air flowing into the engine. It provides this information to the ECU, which then adjusts the fuel injection to maintain the ideal air-fuel ratio.

2.2 Types of MAF Sensors

There are mainly two types of MAF sensors:

- Hot-Wire MAF Sensor: Uses a heated wire to measure air flow. The ECU maintains the wire at a constant temperature, and the current required to do so is proportional to the air flow.

- Hot-Film MAF Sensor: Employs a heated film instead of a wire. It offers faster response times and is less susceptible to contamination.

2.3 Common MAF Sensor Issues

- Contamination: Dust, oil, or debris can contaminate the sensor, leading to inaccurate readings.

- Electrical Faults: Wiring issues, such as shorts or open circuits, can cause sensor failure.

- Sensor Drift: Over time, the sensor’s accuracy can degrade, resulting in incorrect readings.

3. Why MAF Sensor Readings are Important

Accurate MAF sensor readings are essential for maintaining optimal engine performance. Incorrect readings can lead to various issues, affecting fuel efficiency, emissions, and overall drivability.

3.1 Impact on Fuel Efficiency

If the MAF sensor provides incorrect readings, the ECU might inject too much or too little fuel. This can result in poor fuel economy as the engine is not running at its most efficient air-fuel ratio.

3.2 Effect on Engine Performance

Inaccurate MAF sensor data can lead to:

- Rough Idling: The engine may idle roughly due to an improper air-fuel mixture.

- Stalling: The engine may stall, especially at low speeds.

- Hesitation: The vehicle may hesitate during acceleration.

- Reduced Power: The engine might produce less power than expected.

3.3 Emissions Implications

An improperly functioning MAF sensor can cause the engine to produce higher emissions. This can lead to the vehicle failing emissions tests and contributing to environmental pollution. According to the EPA, faulty sensors contribute significantly to increased vehicle emissions.

4. VCX SE and MAF Sensor Readings: A Detailed Look

VCX SE’s ability to read MAF sensor data in grams per second (g/s) is crucial for diagnosing MAF-related issues. The tool provides real-time data, allowing technicians to monitor the sensor’s performance under various conditions.

4.1 Reading MAF Data with VCX SE

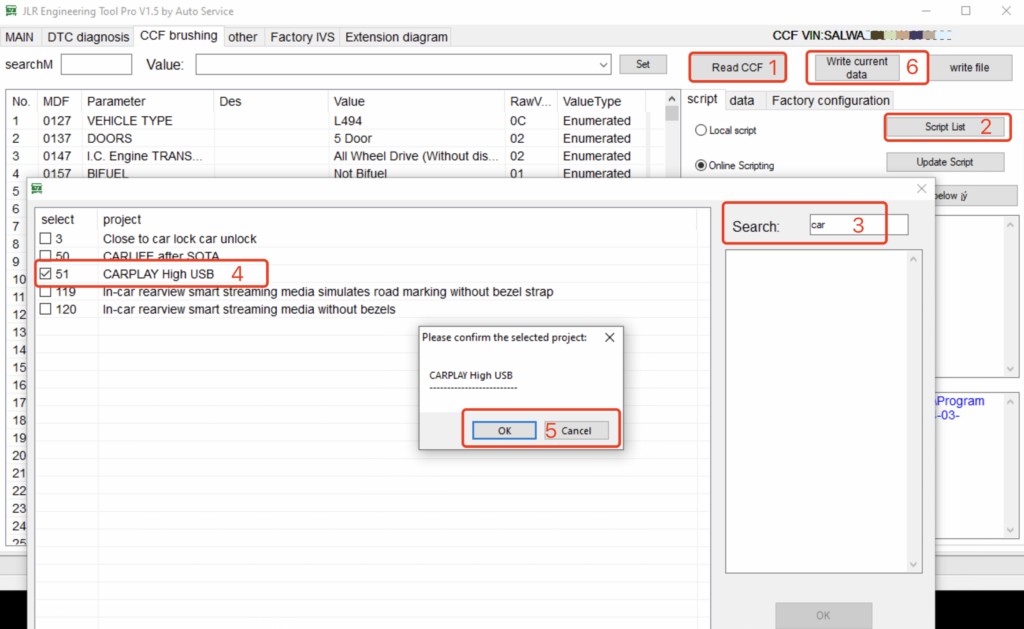

To read MAF sensor data using VCX SE, follow these steps:

- Connect VCX SE: Connect the VCX SE interface to the vehicle’s OBD-II port.

- Launch Diagnostic Software: Open the diagnostic software on your computer and select the appropriate vehicle make and model.

- Access Live Data: Navigate to the live data or data stream section.

- Select MAF Sensor: Choose the MAF sensor parameter from the list of available sensors.

- Monitor Readings: Observe the MAF sensor readings in g/s as the engine runs.

4.2 Interpreting MAF Sensor Readings

MAF sensor readings should correspond to the engine’s operating conditions. Here’s a general guideline:

- Idle: At idle, a typical MAF sensor reading for a 4-cylinder engine might be around 2-7 g/s.

- Acceleration: During acceleration, the readings should increase proportionally with engine speed and load.

- Wide Open Throttle (WOT): At WOT, the MAF sensor should read close to the engine’s maximum airflow capacity.

4.3 Common MAF Reading Issues and Solutions

- Low Readings: Could indicate a contaminated sensor or a vacuum leak. Clean the sensor or check for vacuum leaks.

- High Readings: May suggest a faulty sensor or an issue with the air intake system. Inspect the sensor and air intake system.

- Erratic Readings: Can indicate a failing sensor or electrical issues. Replace the sensor or repair wiring problems.

5. Step-by-Step Guide: Diagnosing MAF Sensor Issues with VCX SE

This section provides a step-by-step guide on how to diagnose MAF sensor issues using the VCX SE diagnostic tool.

5.1 Preliminary Checks

- Visual Inspection: Check the MAF sensor for any visible damage or contamination.

- Wiring Inspection: Inspect the wiring harness and connectors for damage or corrosion.

- Air Filter Check: Ensure the air filter is clean and not restricting airflow.

5.2 Connecting VCX SE

- Connect Interface: Plug the VCX SE interface into the vehicle’s OBD-II port.

- Launch Software: Open the diagnostic software on your computer.

- Select Vehicle: Choose the correct vehicle make, model, and year.

5.3 Reading Diagnostic Trouble Codes (DTCs)

- Access DTCs: Navigate to the DTC section in the diagnostic software.

- Read Codes: Retrieve any stored DTCs related to the MAF sensor. Common codes include P0100, P0101, P0102, and P0103.

- Record Codes: Note down the DTCs for further diagnosis.

5.4 Analyzing Live Data

- Access Live Data: Go to the live data or data stream section.

- Select MAF Parameter: Choose the MAF sensor parameter (usually measured in g/s).

- Start Engine: Start the engine and monitor the MAF sensor readings at idle.

- Compare Readings: Compare the readings to the expected values for the vehicle.

- Perform Tests: Perform tests such as snap-throttle and wide-open throttle to assess the sensor’s response.

5.5 Interpreting Results

- Consistent Low Readings: May indicate a vacuum leak or a contaminated sensor.

- Consistent High Readings: Could suggest a faulty sensor or an issue with the air intake system.

- Erratic Readings: Often point to a failing sensor or electrical problems.

5.6 Additional Tests

- Voltage Check: Use a multimeter to check the voltage at the MAF sensor connector.

- Ground Check: Verify the sensor has a good ground connection.

- Signal Check: Check the signal wire for proper voltage fluctuations as airflow changes.

6. Case Studies: Real-World Examples

This section presents real-world case studies illustrating how VCX SE can be used to diagnose MAF sensor issues effectively.

6.1 Case Study 1: Diagnosing a P0101 Code on a Toyota Camry

Vehicle: 2010 Toyota Camry

Issue: The customer reported poor fuel economy and occasional stalling. The check engine light was on.

Diagnosis:

- DTC Retrieval: Using VCX SE, code P0101 (MAF Sensor Circuit Range/Performance Problem) was retrieved.

- Visual Inspection: The MAF sensor appeared clean, but the air filter was dirty.

- Live Data Analysis: MAF sensor readings at idle were around 1.5 g/s, significantly lower than the expected 3-5 g/s.

- Additional Tests: Voltage checks were normal.

Solution:

- The air filter was replaced.

- The MAF sensor was cleaned using a MAF sensor cleaner.

- After cleaning, the MAF sensor readings improved to 3.5 g/s at idle.

- The P0101 code was cleared, and the vehicle’s performance returned to normal.

6.2 Case Study 2: Resolving a P0102 Code on a Ford F-150

Vehicle: 2015 Ford F-150

Issue: The vehicle had a rough idle and lacked power during acceleration. The check engine light was illuminated.

Diagnosis:

- DTC Retrieval: VCX SE revealed a P0102 code (MAF Sensor Circuit Low Input).

- Visual Inspection: The wiring harness to the MAF sensor was damaged.

- Live Data Analysis: MAF sensor readings were consistently low, even during acceleration.

- Additional Tests: Voltage checks showed a low voltage signal from the MAF sensor.

Solution:

- The damaged wiring harness was repaired.

- The MAF sensor was replaced due to suspected internal damage.

- After the repair, the MAF sensor readings returned to normal.

- The P0102 code was cleared, and the vehicle’s performance was restored.

6.3 Case Study 3: Identifying Intermittent Issues on a Honda Civic

Vehicle: 2017 Honda Civic

Issue: The customer reported intermittent hesitation and occasional stalling. The check engine light would sometimes come on and then turn off.

Diagnosis:

- DTC Retrieval: VCX SE initially showed no DTCs. However, after driving the vehicle, a pending P0100 code (MAF Sensor Circuit Malfunction) appeared.

- Visual Inspection: The MAF sensor looked normal, but the connector seemed loose.

- Live Data Analysis: MAF sensor readings were erratic, fluctuating wildly at idle and during acceleration.

- Additional Tests: A wiggle test on the MAF sensor connector caused the engine to stumble, confirming a connection issue.

Solution:

- The MAF sensor connector was cleaned and tightened.

- The wiring was inspected for any signs of damage or corrosion.

- After the repair, the MAF sensor readings stabilized.

- The P0100 code was cleared, and the vehicle’s performance improved.

7. Maintaining Your MAF Sensor

Proper maintenance of the MAF sensor can prolong its lifespan and ensure accurate readings. Regular cleaning and inspections are crucial.

7.1 Cleaning the MAF Sensor

- Disconnect Sensor: Disconnect the MAF sensor from the vehicle.

- Use MAF Cleaner: Use a dedicated MAF sensor cleaner. Avoid using other solvents, as they can damage the sensor.

- Spray Carefully: Spray the cleaner onto the sensor’s sensing element.

- Allow to Dry: Let the sensor dry completely before reinstalling.

- Reinstall Sensor: Reinstall the sensor and reconnect the wiring harness.

7.2 Regular Inspections

- Visual Checks: Periodically check the sensor for any visible signs of contamination or damage.

- Wiring Inspections: Inspect the wiring harness and connectors for damage or corrosion.

- Data Monitoring: Use VCX SE to monitor MAF sensor readings regularly to catch any potential issues early.

8. The Science Behind MAF Sensor Technology

Understanding the underlying science of MAF sensors can help technicians better diagnose and troubleshoot issues.

8.1 Hot-Wire MAF Sensors

Hot-wire MAF sensors operate on the principle of heat transfer. A thin wire is heated to a constant temperature. As air flows over the wire, it cools down. The ECU increases the current to maintain the wire’s temperature. The amount of current required is directly proportional to the mass of air flowing through the sensor. According to research from the University of Michigan’s Department of Mechanical Engineering, hot-wire sensors provide reliable measurements across a wide range of flow rates.

8.2 Hot-Film MAF Sensors

Hot-film MAF sensors use a thin film instead of a wire. The film is heated to a constant temperature, and the air flowing over it causes it to cool. The ECU monitors the amount of power required to maintain the film’s temperature. Hot-film sensors are more durable and less prone to contamination than hot-wire sensors. A study by the Society of Automotive Engineers (SAE) found that hot-film sensors offer faster response times and improved accuracy in modern engine management systems.

8.3 Signal Processing

The signal from the MAF sensor is typically an analog voltage signal. The ECU converts this analog signal into a digital signal using an analog-to-digital converter (ADC). The ECU then uses this digital signal to calculate the mass of air flowing into the engine. The accuracy of this calculation depends on the calibration of the MAF sensor and the precision of the ADC. Research from Carnegie Mellon University’s Electrical and Computer Engineering Department highlights the importance of precise signal processing in achieving accurate MAF sensor readings.

9. Benefits of Purchasing Diagnostic Tools from CARDIAGTECH.BIZ

Purchasing diagnostic tools from CARDIAGTECH.BIZ offers several advantages, ensuring you get the best tools and support for your automotive diagnostic needs.

9.1 High-Quality Products

CARDIAGTECH.BIZ provides high-quality diagnostic tools that are rigorously tested for accuracy and reliability. Our VCX SE tools are designed to meet the demands of professional automotive technicians.

9.2 Expert Support

We offer expert technical support to help you get the most out of your diagnostic tools. Our team of experienced technicians can provide guidance on using the tools and interpreting diagnostic data.

9.3 Competitive Pricing

CARDIAGTECH.BIZ offers competitive pricing on all our diagnostic tools. We strive to provide cost-effective solutions without compromising on quality.

9.4 Wide Range of Products

In addition to VCX SE, we offer a wide range of diagnostic tools and equipment to meet all your automotive diagnostic needs. Whether you need a simple code reader or a comprehensive diagnostic system, we have you covered.

10. How VCX SE Enhances Automotive Repair Quality

VCX SE enhances the quality of automotive repairs by providing accurate diagnostic data and comprehensive testing capabilities. It helps technicians identify and resolve issues quickly and effectively.

10.1 Improved Diagnostic Accuracy

VCX SE provides real-time data from various vehicle systems, allowing technicians to diagnose issues accurately. The tool supports multiple communication protocols and vehicle models, making it versatile for different diagnostic scenarios.

10.2 Faster Repair Times

With its comprehensive diagnostic features, VCX SE helps technicians identify the root cause of problems quickly. This reduces repair times and allows technicians to service more vehicles efficiently.

10.3 Comprehensive Testing Capabilities

VCX SE supports actuation tests, which allow technicians to test components such as fuel injectors, solenoids, and relays. This helps verify the functionality of these components and ensures they are working correctly.

10.4 Enhanced Customer Satisfaction

By providing accurate and efficient diagnostic and repair services, VCX SE helps enhance customer satisfaction. Customers appreciate the quick turnaround times and the assurance that their vehicles are being serviced with the best tools and equipment.

11. The Future of MAF Sensor Technology

MAF sensor technology is continuously evolving to meet the demands of modern engine management systems. Advances in sensor design, materials, and signal processing are improving accuracy and reliability.

11.1 Digital MAF Sensors

Digital MAF sensors are becoming more common in modern vehicles. These sensors provide a digital output signal, which is less susceptible to noise and interference than analog signals. Digital MAF sensors also offer improved accuracy and faster response times.

11.2 Ultrasonic MAF Sensors

Ultrasonic MAF sensors use sound waves to measure airflow. These sensors are highly accurate and can measure airflow in both directions. Ultrasonic MAF sensors are also less prone to contamination than traditional hot-wire or hot-film sensors.

11.3 Integrated Sensor Systems

Integrated sensor systems combine multiple sensors into a single unit. These systems can measure airflow, temperature, and humidity, providing comprehensive data for the ECU. Integrated sensor systems offer improved accuracy and reliability compared to individual sensors.

12. Tips for Effective MAF Sensor Diagnosis

Effective MAF sensor diagnosis requires a systematic approach and attention to detail. Here are some tips to help you diagnose MAF sensor issues accurately:

12.1 Use a Reliable Diagnostic Tool

Using a reliable diagnostic tool like VCX SE is essential for accurate MAF sensor diagnosis. VCX SE provides real-time data and comprehensive testing capabilities.

12.2 Perform a Thorough Visual Inspection

Always perform a thorough visual inspection of the MAF sensor, wiring harness, and connectors. Look for any signs of damage, contamination, or corrosion.

12.3 Check for Vacuum Leaks

Vacuum leaks can cause inaccurate MAF sensor readings. Use a smoke machine or propane torch to check for vacuum leaks in the intake system.

12.4 Compare Readings to Specifications

Compare the MAF sensor readings to the manufacturer’s specifications. This will help you determine if the sensor is operating within the normal range.

12.5 Perform Additional Tests

Perform additional tests, such as voltage checks and ground checks, to verify the sensor’s functionality.

13. Addressing Common Misconceptions about MAF Sensors

There are several common misconceptions about MAF sensors. Addressing these misconceptions can help technicians avoid misdiagnosis and perform accurate repairs.

13.1 Misconception: Cleaning Always Fixes MAF Issues

While cleaning can often improve MAF sensor performance, it doesn’t always fix the problem. If the sensor is damaged or has drifted out of calibration, it may need to be replaced.

13.2 Misconception: All MAF Sensors are the Same

MAF sensors vary in design, calibration, and operating characteristics. Using the wrong MAF sensor can cause performance issues. Always use the correct MAF sensor for the vehicle.

13.3 Misconception: Aftermarket MAF Sensors are Always Inferior

While some aftermarket MAF sensors may be of lower quality, many reputable aftermarket brands offer high-quality sensors that meet or exceed OEM specifications. Research and choose a reputable brand.

13.4 Misconception: MAF Sensor Problems Always Trigger a DTC

MAF sensor problems don’t always trigger a DTC. Intermittent issues or slight deviations in sensor readings may not be severe enough to set a code but can still affect engine performance.

14. Tools and Equipment for MAF Sensor Diagnosis

Having the right tools and equipment is essential for effective MAF sensor diagnosis. Here are some essential tools and equipment:

14.1 Diagnostic Scan Tool

A diagnostic scan tool like VCX SE is essential for reading DTCs and monitoring live data.

14.2 Multimeter

A multimeter is needed for performing voltage checks and ground checks.

14.3 MAF Sensor Cleaner

A dedicated MAF sensor cleaner is needed for cleaning the sensor.

14.4 Vacuum Leak Detector

A vacuum leak detector, such as a smoke machine or propane torch, is needed for checking for vacuum leaks.

14.5 Wiring Repair Kit

A wiring repair kit is useful for repairing damaged wiring harnesses and connectors.

15. Why Regular Vehicle Diagnostics are Essential

Regular vehicle diagnostics are essential for maintaining optimal performance and preventing costly repairs. Diagnostic tools like VCX SE can help identify potential issues early.

15.1 Early Detection of Problems

Regular diagnostics can help detect potential problems before they become severe. This can save you money on costly repairs and prevent breakdowns.

15.2 Improved Fuel Efficiency

Regular diagnostics can help identify issues that affect fuel efficiency. Addressing these issues can improve fuel economy and save you money on gas.

15.3 Enhanced Safety

Regular diagnostics can help identify safety-related issues, such as brake problems or faulty sensors. Addressing these issues can enhance safety and prevent accidents.

15.4 Maintained Vehicle Value

Regular diagnostics and maintenance can help maintain the value of your vehicle. A well-maintained vehicle is more valuable than a neglected one.

16. Benefits of Staying Updated with Automotive Technology

Staying updated with the latest automotive technology is essential for automotive technicians. Advances in technology are continuously changing the way vehicles are diagnosed and repaired.

16.1 Improved Diagnostic Skills

Staying updated with the latest technology can improve your diagnostic skills. You’ll be able to diagnose complex issues more accurately and efficiently.

16.2 Enhanced Repair Techniques

Staying updated with the latest technology can enhance your repair techniques. You’ll be able to perform repairs more effectively and efficiently.

16.3 Increased Earning Potential

Staying updated with the latest technology can increase your earning potential. You’ll be able to offer advanced diagnostic and repair services that command higher prices.

16.4 Professional Growth

Staying updated with the latest technology can foster professional growth. You’ll be able to stay ahead of the curve and remain competitive in the automotive industry.

17. Call to Action: Upgrade Your Diagnostic Capabilities Today

Don’t let outdated diagnostic tools hold you back. Upgrade to VCX SE from CARDIAGTECH.BIZ and experience the benefits of accurate, efficient, and comprehensive vehicle diagnostics.

17.1 Contact Us

Ready to enhance your diagnostic precision and repair efficacy? Contact CARDIAGTECH.BIZ today to learn more about our VCX SE diagnostic tools and how they can benefit your automotive repair shop.

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.BIZ

17.2 Why Choose CARDIAGTECH.BIZ?

- High-Quality Tools: Reliable and accurate diagnostic tools.

- Expert Support: Experienced technicians to assist you.

- Competitive Pricing: Cost-effective solutions for your business.

Take the first step towards optimizing your automotive repair services. Contact CARDIAGTECH.BIZ now and revolutionize your diagnostic approach.

FAQ: Frequently Asked Questions About VCX SE and MAF Sensors

1. Can VCX SE read MAF sensor readings in g/s?

Yes, VCX SE can accurately read MAF sensor readings in g/s, providing essential data for diagnosing engine issues. It offers precise and reliable data for effective diagnostics.

2. What is a MAF sensor and why is it important?

A MAF (Mass Air Flow) sensor measures the amount of air entering the engine, which is crucial for the ECU to calculate the correct fuel injection. Accurate readings ensure optimal combustion and engine performance.

3. How do I connect VCX SE to my vehicle to read MAF sensor data?

Connect the VCX SE interface to the vehicle’s OBD-II port, launch the diagnostic software, select the vehicle make and model, access live data, and choose the MAF sensor parameter.

4. What are common issues that can cause inaccurate MAF sensor readings?

Common issues include contamination from dust or oil, electrical faults in the wiring, and sensor drift over time, all leading to incorrect readings.

5. What should be the typical MAF sensor reading at idle for a 4-cylinder engine?

At idle, a typical MAF sensor reading for a 4-cylinder engine is around 2-7 g/s. Readings should increase during acceleration.

6. How often should I clean my MAF sensor?

It’s recommended to clean the MAF sensor every 12,000 to 15,000 miles, or whenever you notice symptoms like poor fuel economy or rough idling.

7. What type of cleaner should I use to clean my MAF sensor?

Use a dedicated MAF sensor cleaner. Avoid using other solvents, as they can damage the sensor.

8. Can a faulty MAF sensor affect my vehicle’s emissions?

Yes, an improperly functioning MAF sensor can cause the engine to produce higher emissions, leading to the vehicle failing emissions tests.

9. What are the benefits of using VCX SE over other diagnostic tools?

VCX SE offers comprehensive diagnostics, data streaming, actuation tests, ECU programming, and multi-protocol support, making it a versatile and efficient tool for automotive technicians.

10. Where can I purchase VCX SE diagnostic tools?

You can purchase VCX SE diagnostic tools from CARDIAGTECH.BIZ, which offers high-quality products, expert support, and competitive pricing.