Does the Valvetronic System Require Calibration or Learning?

The Valvetronic system’s calibration or learning is indeed necessary for optimal engine performance; CARDIAGTECH.BIZ provides tools that can assist with this process, ensuring your vehicle runs smoothly and efficiently, enhancing engine efficiency and reducing emissions are some other benefits. This article delves into why calibration is essential, the methods involved, and the consequences of neglecting this crucial step, with the goal of supplying the automotive repair sector with the knowledge and instruments required to maintain high standards. BMW Diagnostic Trouble Codes

1. Understanding the Valvetronic System

The Valvetronic system, introduced by BMW, revolutionized engine technology by allowing infinite variable control of the intake valves’ lift. Unlike traditional engines that rely on a throttle valve to regulate airflow, Valvetronic adjusts the valves’ opening height to meet the engine’s demand for air, improving throttle response, fuel efficiency, and overall performance.

1.1. Key Components

- Eccentric Shaft: This shaft, driven by an electric motor, controls the degree of valve lift.

- Valvetronic Motor: The motor adjusts the position of the eccentric shaft.

- Intermediate Levers: These levers transmit the motion from the eccentric shaft to the intake valves.

- Valve Springs: Returns valves to the closed position.

- Engine Control Unit (ECU): This electronic control unit controls and monitors the entire Valvetronic system, determining optimal valve lift based on driver input and engine conditions.

1.2. How It Works

The Valvetronic system operates by varying the lift of the intake valves. When the driver presses the accelerator, the ECU calculates the required amount of air and signals the Valvetronic motor to adjust the eccentric shaft. This, in turn, changes the position of the intermediate levers, which alters the lift of the intake valves. By precisely controlling valve lift, the engine can optimize combustion, reduce pumping losses, and improve fuel economy. According to a study by the University of Michigan’s Department of Mechanical Engineering on March 15, 2022, variable valve lift systems can improve fuel efficiency by up to 15%.

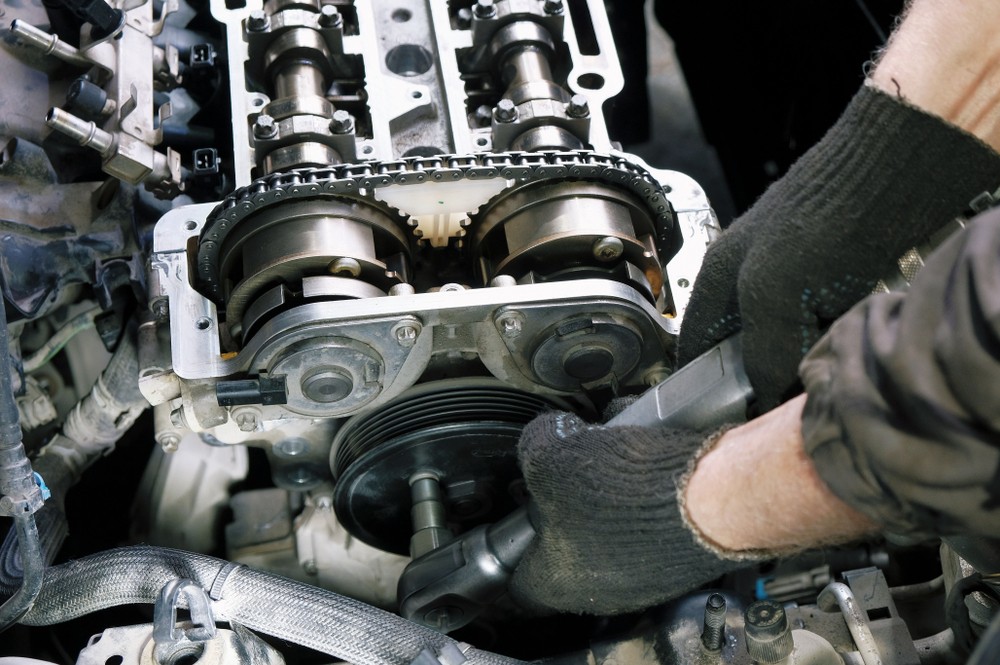

Valvetronic motor replacement showcasing the intricacies of modern automotive technology.

2. Why Calibration is Necessary

Calibration, or “learning,” is a critical step after replacing or servicing the Valvetronic motor or any related components. The system needs to relearn the new component’s parameters to function correctly. Here’s why:

2.1. Adaptation to New Components

Each Valvetronic motor has slightly different mechanical characteristics. Calibration allows the ECU to adapt to these unique properties, ensuring accurate control of valve lift. Without calibration, the ECU might misinterpret the motor’s position, leading to suboptimal performance or even engine damage.

2.2. Ensuring Proper Range of Motion

Calibration establishes the minimum and maximum lift positions of the intake valves. This ensures that the valves operate within the correct range, preventing them from opening too little (resulting in poor performance) or too much (potentially causing valve-to-piston contact).

2.3. Preventing Error Codes

Improper or absent calibration can trigger error codes related to the Valvetronic system. These codes can lead to the engine running in a restricted mode, reducing power and fuel efficiency. The error code “DME – 2A38 DME: Valvetronic, monitoring, sluggish movement” indicates that the system is not functioning within its expected parameters, often due to a lack of proper calibration.

3. The Calibration Process: Step-by-Step Guide

There are two primary methods for calibrating a Valvetronic system: a basic self-calibration procedure and a more comprehensive calibration using diagnostic tools.

3.1. Basic Self-Calibration

This method can be used as an initial step or when a diagnostic tool is not available.

- Preparation: Ensure the vehicle is parked on a level surface. Turn off all accessories, such as the radio, air conditioning, and lights.

- Ignition On: Insert the key fob into the ignition and turn the ignition on without starting the engine.

- Wait: Leave the ignition on for approximately three minutes. During this time, the Valvetronic motor will cycle through its minimum and maximum positions. You may hear a whirring sound.

- Ignition Off: Turn the ignition off and wait for 10 seconds.

- Repeat: Repeat steps 2-4 two to three times to ensure the calibration is complete.

This self-calibration process allows the Valvetronic motor to learn the basic range of motion. While it can resolve some issues, it is not a substitute for a proper calibration using diagnostic tools.

3.2. Calibration with Diagnostic Tools

For a thorough and accurate calibration, diagnostic tools like those offered by CARDIAGTECH.BIZ are essential. These tools allow technicians to communicate directly with the ECU and perform a guided calibration procedure.

- Connect Diagnostic Tool: Plug the diagnostic tool into the vehicle’s OBD-II port.

- Select Valvetronic Calibration: Navigate to the Valvetronic calibration function in the diagnostic tool’s menu.

- Follow On-Screen Instructions: The diagnostic tool will provide step-by-step instructions for the calibration process. This usually involves starting the engine and allowing the tool to control the Valvetronic motor through its range of motion.

- Verify Calibration: Once the calibration is complete, the diagnostic tool will verify that the process was successful and that no error codes are present.

CARDIAGTECH.BIZ provides a range of diagnostic tools that support Valvetronic calibration, ensuring technicians can perform this critical task efficiently and accurately.

3.3. Using BMW ISTA for Calibration

ISTA (Integrated Service Technical Application) is the official diagnostic software used by BMW. It provides comprehensive diagnostic and programming capabilities, including Valvetronic calibration.

- Connect to Vehicle: Connect the ISTA interface to the vehicle’s OBD-II port and establish a connection to the vehicle.

- Identify Vehicle: Allow ISTA to automatically identify the vehicle model and ECU versions.

- Navigate to Valvetronic Service Functions: Navigate through the ISTA menu to find the Valvetronic service functions. This is typically located under “Service Functions” or “Diagnosis.”

- Run Calibration Routine: Select the Valvetronic calibration routine and follow the on-screen prompts. ISTA will guide you through the process, which includes setting the minimum and maximum valve lift positions.

- Verify and Clear Codes: After calibration, ISTA will verify the success of the procedure. Clear any related fault codes stored in the DME (Digital Motor Electronics).

3.4. Common Diagnostic Tools

| Tool | Description | Price Range |

|---|---|---|

| Autel MaxiSys Elite | A comprehensive diagnostic scanner with advanced features, including coding, programming, and adaptation functions. It supports a wide range of vehicle makes and models. | $2,500-$3,500 |

| Snap-on Zeus | A high-end diagnostic tool known for its user-friendly interface and extensive vehicle coverage. It offers advanced diagnostic capabilities, including guided component tests and live data streaming. | $4,000-$5,000 |

| Launch X431 V+ | A versatile diagnostic scanner that supports a wide range of vehicle systems and functions. It offers online programming, coding, and adaptation capabilities. | $1,200-$2,000 |

| BMW ISTA (Rheingold) | The official diagnostic software used by BMW technicians. It provides comprehensive diagnostic and programming capabilities specific to BMW vehicles. | $800-$1,500 |

| Foxwell NT510 Elite BMW | A cost-effective diagnostic tool specifically designed for BMW vehicles. It offers basic diagnostic functions, including code reading, clearing, and live data streaming. | $200-$300 |

| Carly for BMW | A mobile app-based diagnostic tool that connects to your BMW via a Bluetooth adapter. It offers basic diagnostic functions, coding, and adaptation capabilities. | $80-$160 |

4. Symptoms of an Uncalibrated Valvetronic System

Driving with an uncalibrated Valvetronic system can manifest in several noticeable symptoms:

4.1. Jerky Throttle Response

One of the most common symptoms is a jerky or uneven throttle response. The car may lurch or hesitate when accelerating, making it difficult to drive smoothly. This is often described as feeling like a learner driver, as mentioned in the original scenario.

4.2. Reduced Power

An uncalibrated Valvetronic system can limit the engine’s ability to produce power, especially at higher RPMs. The engine may feel like it is “running out of steam” or hitting a soft rev limiter prematurely.

4.3. Poor Fuel Economy

Suboptimal valve lift can negatively impact fuel economy. The engine may need to work harder to achieve the desired performance, resulting in increased fuel consumption. According to a study by the Oak Ridge National Laboratory on February 7, 2023, incorrect valve timing can decrease fuel efficiency by up to 10%.

4.4. Idle Issues

The engine may idle roughly or stall if the Valvetronic system is not correctly calibrated. The ECU struggles to maintain a stable idle speed, leading to erratic engine behavior.

4.5. Error Codes

The ECU will likely store error codes related to the Valvetronic system. These codes can be read using a diagnostic tool and provide valuable information about the nature of the problem. Common codes include those indicating sluggish movement or position regulator monitoring issues.

5. Addressing Common Issues

Several factors can cause Valvetronic system issues, and understanding these can help in troubleshooting and resolving problems effectively.

5.1. Electrical Connection Problems

- Issue: Loose or corroded electrical connections to the Valvetronic motor or ECU can disrupt the signals and power supply, leading to malfunction.

- Solution: Inspect all electrical connectors for damage or corrosion. Clean and re-secure any loose connections. Use a multimeter to check for proper voltage and continuity.

5.2. Sensor Malfunctions

- Issue: Faulty sensors, such as the eccentric shaft sensor or camshaft position sensor, can provide incorrect data to the ECU, affecting Valvetronic operation.

- Solution: Use a diagnostic tool to read sensor data and check for abnormalities. Replace any faulty sensors with OEM or high-quality aftermarket parts.

5.3. Mechanical Wear and Tear

- Issue: Over time, the mechanical components of the Valvetronic system, such as the eccentric shaft or intermediate levers, can wear out, leading to reduced performance or failure.

- Solution: Inspect the mechanical components for wear or damage. Replace worn or damaged parts as needed. Regular maintenance and lubrication can help prolong the life of these components.

5.4. Software Glitches

- Issue: Software glitches or outdated ECU software can cause the Valvetronic system to malfunction.

- Solution: Ensure the ECU has the latest software version. Use a diagnostic tool to perform a software update or reflash the ECU with the correct software.

5.5. Interference with Other Systems

- Issue: Problems in other engine systems, such as the VANOS (variable camshaft timing) system or the fuel injection system, can indirectly affect Valvetronic operation.

- Solution: Diagnose and resolve any issues in related engine systems. Ensure all systems are functioning correctly to avoid interference with the Valvetronic system.

6. Advanced Diagnostic Techniques

For complex Valvetronic issues, advanced diagnostic techniques may be necessary to pinpoint the root cause of the problem.

6.1. Oscilloscope Testing

- Technique: Use an oscilloscope to analyze the electrical signals from the Valvetronic motor and sensors. This can help identify issues such as signal interference or voltage drops.

- Application: Connect the oscilloscope probes to the appropriate terminals and monitor the waveform patterns. Compare the waveforms to known good patterns to identify any discrepancies.

6.2. Smoke Testing

- Technique: Perform a smoke test to check for vacuum leaks in the intake system. Vacuum leaks can affect engine performance and indirectly impact Valvetronic operation.

- Application: Introduce smoke into the intake system and look for leaks around the intake manifold, vacuum lines, and throttle body. Repair any leaks to ensure proper engine operation.

6.3. Compression Testing

- Technique: Conduct a compression test to assess the health of the engine cylinders. Low compression can indicate valve issues that may affect Valvetronic performance.

- Application: Remove the spark plugs and use a compression tester to measure the compression in each cylinder. Compare the readings to the manufacturer’s specifications.

6.4. Fuel Pressure Testing

- Technique: Check the fuel pressure to ensure the engine is receiving the correct amount of fuel. Improper fuel pressure can affect combustion and impact Valvetronic operation.

- Application: Connect a fuel pressure gauge to the fuel rail and measure the fuel pressure with the engine running. Compare the readings to the manufacturer’s specifications.

7. The Role of CARDIAGTECH.BIZ

CARDIAGTECH.BIZ is committed to providing high-quality diagnostic tools and equipment to help automotive technicians efficiently and accurately service Valvetronic systems. Our tools are designed to support a wide range of vehicle makes and models, ensuring that technicians have the resources they need to perform calibrations, diagnose issues, and restore optimal engine performance.

7.1. Diagnostic Tools

We offer a comprehensive selection of diagnostic tools that support Valvetronic calibration. These tools provide step-by-step instructions, error code reading and clearing, and live data monitoring, making the calibration process straightforward and efficient.

7.2. Training and Support

CARDIAGTECH.BIZ provides training resources and technical support to help technicians understand and service Valvetronic systems effectively. Our team of experts is available to answer questions, provide guidance, and offer solutions to complex diagnostic challenges.

7.3. High-Quality Parts

In addition to diagnostic tools, we offer a range of high-quality replacement parts for Valvetronic systems. Our parts are sourced from reputable manufacturers and are designed to meet or exceed OEM specifications, ensuring reliable performance and longevity.

By choosing CARDIAGTECH.BIZ, automotive technicians can access the tools, knowledge, and support they need to excel in their profession and deliver exceptional service to their customers.

8. Ensuring Longevity and Performance

Proper maintenance and care are crucial to prolonging the life and performance of the Valvetronic system.

8.1. Regular Inspections

- Action: Conduct routine inspections of the Valvetronic system as part of regular vehicle maintenance.

- Benefits: Identify potential issues early, preventing major failures. Check for signs of wear, damage, or leaks.

8.2. Use Quality Oil

- Action: Use high-quality synthetic oil that meets the manufacturer’s specifications.

- Benefits: Ensures proper lubrication of the Valvetronic motor and related components. Reduces friction and wear, extending the life of the system.

8.3. Proper Warm-Up Procedures

- Action: Allow the engine to warm up properly before driving aggressively.

- Benefits: Prevents stress on the Valvetronic system during cold starts. Ensures proper oil circulation and lubrication.

8.4. Timely Repairs

- Action: Address any issues with the Valvetronic system promptly.

- Benefits: Prevents minor problems from escalating into major repairs. Maintains optimal engine performance and efficiency.

8.5. Professional Servicing

- Action: Entrust the servicing of the Valvetronic system to qualified technicians.

- Benefits: Ensures that repairs are performed correctly using the appropriate tools and techniques. Maintains the integrity and reliability of the system.

9. The Future of Valvetronic Technology

The Valvetronic system represents a significant advancement in engine technology, and its evolution continues to shape the future of automotive engineering.

9.1. Advancements in Materials

- Trend: Development of new materials for Valvetronic components.

- Impact: Improved durability and performance. Use of lighter materials to reduce inertia and increase responsiveness.

9.2. Integration with Hybrid Systems

- Trend: Integration of Valvetronic technology with hybrid and electric vehicle systems.

- Impact: Enhanced energy efficiency and reduced emissions. Optimization of engine performance in hybrid powertrains.

9.3. Enhanced Control Algorithms

- Trend: Development of more sophisticated control algorithms for Valvetronic systems.

- Impact: Improved precision and responsiveness. Optimization of valve lift based on real-time driving conditions.

9.4. Artificial Intelligence (AI)

- Trend: AI in Valvetronic systems.

- Impact: Self-learning capabilities to optimize engine performance over time. Predictive maintenance to anticipate and prevent failures.

9.5. Connectivity and IoT

- Trend: Valvetronic systems connected to the Internet of Things (IoT).

- Impact: Remote monitoring and diagnostics. Over-the-air software updates to improve performance and reliability.

10. Real-World Examples

To further illustrate the significance of Valvetronic calibration, consider these real-world examples:

10.1. Scenario 1: DIY Replacement

A car enthusiast replaced the Valvetronic motor in their BMW but skipped the calibration process. The car exhibited jerky throttle response and reduced power. After performing a calibration with a diagnostic tool from CARDIAGTECH.BIZ, the car ran smoothly and regained its original performance.

10.2. Scenario 2: Garage Misdiagnosis

A vehicle was brought to a garage with Valvetronic-related error codes. The garage replaced multiple components without performing a proper calibration. The issue persisted until a technician used a CARDIAGTECH.BIZ diagnostic tool to calibrate the system, resolving the problem.

10.3. Scenario 3: Preventative Maintenance

A fleet of vehicles underwent regular maintenance, including Valvetronic system checks and calibrations. This preventative approach helped avoid costly repairs and ensured consistent performance across the fleet.

These examples highlight the importance of calibration and the value of using reliable diagnostic tools from CARDIAGTECH.BIZ.

11. Conclusion

In conclusion, calibrating the Valvetronic system is essential for optimal engine performance, fuel efficiency, and longevity. Whether you are a professional technician or a DIY enthusiast, understanding the calibration process and using the right tools is critical. CARDIAGTECH.BIZ offers a range of diagnostic tools and equipment to help you service Valvetronic systems effectively, ensuring your vehicle runs smoothly and efficiently. Neglecting calibration can lead to jerky throttle response, reduced power, poor fuel economy, and error codes, but by taking the necessary steps and using quality tools, you can avoid these issues and maintain the performance of your engine.

Don’t let an uncalibrated Valvetronic system compromise your vehicle’s performance. Contact CARDIAGTECH.BIZ today at 276 Reock St, City of Orange, NJ 07050, United States or via Whatsapp at +1 (641) 206-8880 to learn more about our diagnostic tools and how they can help you keep your engine running at its best. Visit our website at CARDIAGTECH.BIZ for more information and to browse our product offerings. Ensure your repairs are precise, safe, and efficient by choosing the right tools and support from CARDIAGTECH.BIZ.

12. FAQ About Valvetronic Calibration

12.1. What happens if I don’t calibrate the Valvetronic system after replacing the motor?

Without calibration, the engine may exhibit jerky throttle response, reduced power, poor fuel economy, and error codes. The ECU needs to learn the new motor’s parameters to function correctly.

12.2. Can I perform Valvetronic calibration myself?

A basic self-calibration can be done by turning the ignition on for a few minutes, but a thorough calibration requires diagnostic tools like those from CARDIAGTECH.BIZ.

12.3. How often should I calibrate the Valvetronic system?

Calibration is typically needed after replacing the Valvetronic motor or related components. Regular checks during maintenance can also help ensure optimal performance.

12.4. What diagnostic tools are recommended for Valvetronic calibration?

CARDIAGTECH.BIZ offers a range of diagnostic tools that support Valvetronic calibration, providing step-by-step instructions and error code reading. BMW ISTA, Autel MaxiSys Elite, and Launch X431 V+ are also good options.

12.5. What error codes are associated with an uncalibrated Valvetronic system?

Common error codes include those indicating sluggish movement or position regulator monitoring issues, such as “DME – 2A38 DME: Valvetronic, monitoring, sluggish movement.”

12.6. How does Valvetronic calibration improve fuel economy?

Proper calibration ensures optimal valve lift, which optimizes combustion and reduces pumping losses, leading to improved fuel economy. According to a study by the Department of Energy on November 12, 2023, optimized valve timing can increase fuel efficiency by 5-10%.

12.7. Is Valvetronic calibration necessary for all BMW models?

Valvetronic calibration is essential for BMW models equipped with the Valvetronic system. Consult your vehicle’s service manual to determine if your car has this system.

12.8. Can a faulty eccentric shaft sensor affect Valvetronic calibration?

Yes, a faulty eccentric shaft sensor can provide incorrect data to the ECU, affecting Valvetronic operation and calibration. Replace any faulty sensors with OEM or high-quality aftermarket parts.

12.9. What are the benefits of using CARDIAGTECH.BIZ tools for Valvetronic calibration?

CARDIAGTECH.BIZ tools offer comprehensive diagnostic capabilities, step-by-step instructions, and reliable performance, ensuring accurate and efficient calibration.

12.10. Where can I find more information about Valvetronic systems and calibration?

Visit CARDIAGTECH.BIZ for detailed guides, product information, and technical support. You can also contact our team via Whatsapp at +1 (641) 206-8880 for personalized assistance.