**How to Safely Deactivate and Reactivate the SBC System Using VCX SE and XENTRY?**

Deactivating and reactivating the Sensotronic Brake Control (SBC) system on Mercedes-Benz vehicles requires precision and the right tools, primarily for safety during brake repairs; with VCX SE and XENTRY, the process becomes more manageable and secure; CARDIAGTECH.BIZ offers the reliable VCX SE diagnostic tool, along with expert guidance, to ensure mechanics and technicians perform this critical task efficiently and safely. The use of VCX SE and XENTRY ensures proper system handling, preventing potential hazards during brake maintenance.

1. Understanding the Sensotronic Brake Control (SBC) System

The Sensotronic Brake Control (SBC) system is an electro-hydraulic brake system developed by Mercedes-Benz, introduced in the early 2000s to enhance braking performance and safety; this system uses electronic sensors to monitor driving conditions and driver inputs, optimizing braking force at each wheel independently. The SBC system replaced the traditional vacuum-assisted braking system, offering features like Brake Assist, Hill Start Assist, and automatic brake drying, which improve overall vehicle control and safety. According to Bosch, electro-hydraulic brakes like SBC can reduce stopping distances by up to 20% compared to conventional hydraulic systems.

1.1. Key Components of the SBC System

Understanding the main components is crucial for anyone working on an SBC system.

- Hydraulic Unit: This unit contains the high-pressure pump, reservoir, and valves that control brake pressure.

- Electronic Control Unit (ECU): The ECU processes data from sensors and controls the hydraulic unit to apply the correct brake force.

- Wheel Speed Sensors: These sensors monitor the speed of each wheel to detect wheel slip and optimize braking.

- Brake Pedal Sensor: This sensor measures the force and speed at which the driver presses the brake pedal.

- Brake Pressure Sensors: These sensors monitor the brake pressure in each wheel circuit.

SBC Hydraulic Unit

SBC Hydraulic Unit

1.2. Why Deactivate the SBC System?

Deactivating the SBC system is essential before performing any brake maintenance or repairs; the SBC system maintains high pressure even when the vehicle is off, creating a significant safety hazard; if the system is not properly deactivated, technicians risk serious injury from unexpected brake activation or high-pressure fluid release; deactivation ensures that the system is safely depressurized, allowing for component replacement and maintenance without risk; Mercedes-Benz service manuals explicitly state that the SBC system must be deactivated before any work is done on the brake system.

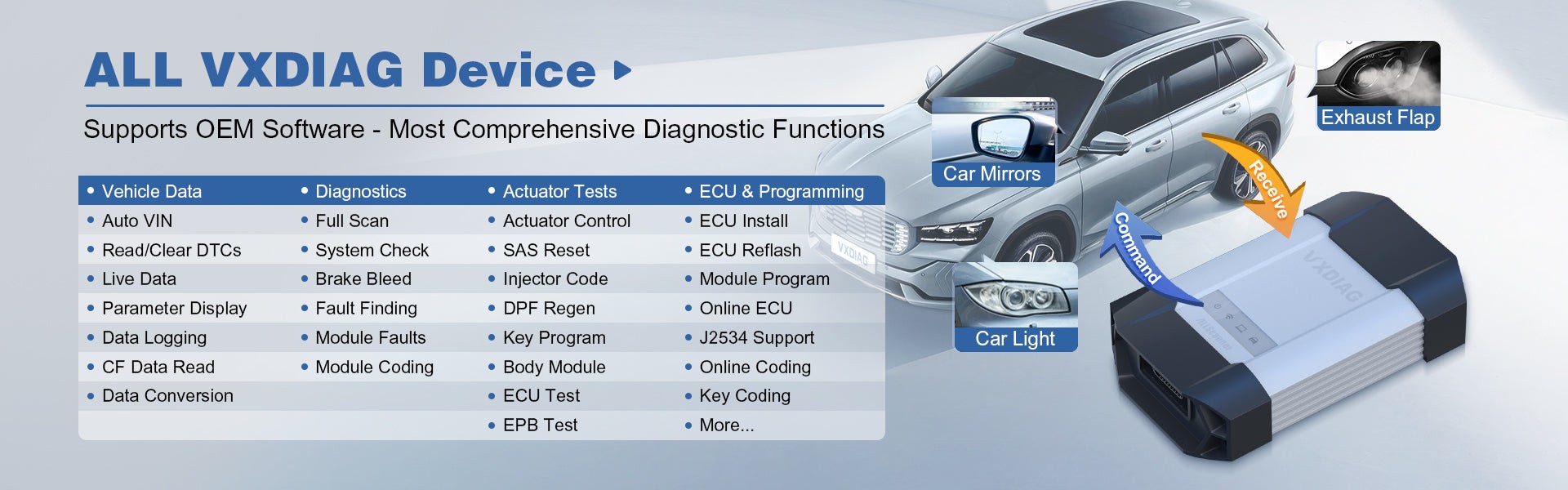

2. Essential Tools: VCX SE and XENTRY

To safely deactivate and reactivate the SBC system, having the right tools is paramount; the VCX SE diagnostic tool, paired with the XENTRY software, provides the necessary interface and capabilities to perform this task accurately and safely.

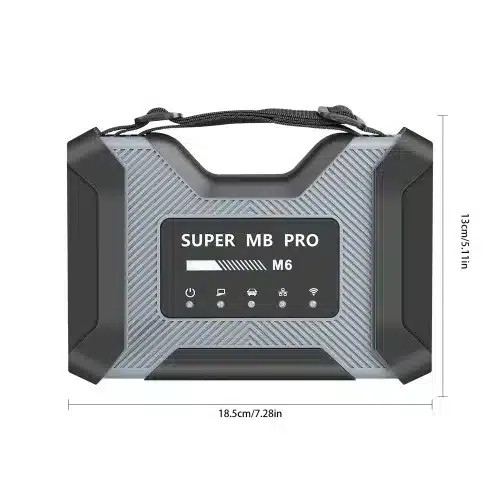

2.1. What is VCX SE?

The VCX SE is a professional-grade diagnostic tool designed for Mercedes-Benz vehicles; it provides comprehensive diagnostic capabilities, including reading and clearing fault codes, performing control unit adaptations, and executing guided tests; its key advantage is its compatibility with XENTRY, the official diagnostic software used by Mercedes-Benz dealerships and authorized service centers; according to CARDIAGTECH.BIZ, the VCX SE offers a stable and reliable connection, ensuring accurate data transmission during critical procedures like SBC deactivation.

2.2. What is XENTRY?

XENTRY is the official diagnostic software for Mercedes-Benz vehicles; it offers a wide range of functions, including detailed diagnostics, ECU programming, and system calibrations; XENTRY provides step-by-step instructions for various procedures, including SBC deactivation and reactivation, ensuring technicians follow the correct process; the software is regularly updated to support the latest Mercedes-Benz models and diagnostic protocols, making it an indispensable tool for any Mercedes-Benz technician; Bosch Automotive Service Solutions recommends using XENTRY for all diagnostic and programming tasks on Mercedes-Benz vehicles to ensure accuracy and safety.

2.3. Why Choose VCX SE and XENTRY?

Using VCX SE with XENTRY offers several advantages:

- Comprehensive Compatibility: Supports a wide range of Mercedes-Benz models, including those with advanced SBC systems.

- Guided Procedures: XENTRY provides step-by-step instructions, reducing the risk of errors.

- Safety Assurance: Ensures the SBC system is safely deactivated and reactivated, protecting technicians from injury.

- Reliable Connection: VCX SE offers a stable and secure connection, crucial for data transmission during critical operations.

- Regular Updates: XENTRY is regularly updated, ensuring compatibility with the latest Mercedes-Benz vehicles and diagnostic protocols.

Purchasing the VCX SE diagnostic tool from CARDIAGTECH.BIZ ensures you receive a high-quality, reliable tool backed by expert support; with CARDIAGTECH.BIZ, you gain access to the tools and knowledge necessary to perform complex diagnostic and repair tasks safely and efficiently; for inquiries, contact CARDIAGTECH.BIZ at 276 Reock St, City of Orange, NJ 07050, United States or via WhatsApp at +1 (641) 206-8880; visit CARDIAGTECH.BIZ for more information.

3. Step-by-Step Guide: Deactivating the SBC System

Follow these detailed steps to safely deactivate the SBC system using VCX SE and XENTRY.

3.1. Preparation

Before starting the deactivation process, ensure you have the following:

- VCX SE Diagnostic Tool: Ensure it is properly connected to your computer.

- XENTRY Software: Installed and updated to the latest version.

- Mercedes-Benz Vehicle: Parked on a level surface with the parking brake engaged.

- Battery Charger: Connected to the vehicle to maintain a stable voltage supply. A low battery voltage can interrupt the deactivation process.

- Diagnostic Cable: To connect the VCX SE to the vehicle’s OBD-II port.

- Internet Connection: A stable internet connection is required for XENTRY to communicate with the Mercedes-Benz servers.

3.2. Connecting VCX SE and Launching XENTRY

- Connect VCX SE: Plug the VCX SE diagnostic tool into the vehicle’s OBD-II port, typically located under the dashboard on the driver’s side.

- Connect to Computer: Connect the VCX SE to your computer using the USB cable.

- Launch XENTRY: Open the XENTRY software on your computer.

- Vehicle Selection: XENTRY will prompt you to select the vehicle model. Enter the vehicle’s VIN (Vehicle Identification Number) to ensure accurate identification.

- Initiate Quick Test: Run a quick test to identify all control units in the vehicle and check for any existing fault codes; this step is crucial to ensure no underlying issues could interfere with the deactivation process.

Connecting VCX SE

Connecting VCX SE

3.3. Navigating to the SBC Deactivation Function

- Select Control Units: In XENTRY, navigate to the list of control units and select the “SBC – Sensotronic Brake Control” unit.

- অ্যাকশন মেনু নির্বাচন করুন: Once the SBC control unit is selected, go to the ” অ্যাকশন ” or “কন্ট্রোল ইউনিট অ্যাডাপ্টেশন” menu.

- Look for Deactivation: Find the option labeled “Deactivate SBC” or “SBC Deactivation.” The exact wording may vary depending on the XENTRY version.

- Select the Function: ক্লিক করুন “Deactivate SBC” option to start the deactivation procedure.

3.4. Following XENTRY Instructions

- Read Instructions: XENTRY will display a series of instructions and warnings; read these carefully to understand the process and potential risks.

- Confirm Readiness: The software may ask you to confirm that the vehicle is parked on a level surface, the parking brake is engaged, and a battery charger is connected; confirm these conditions are met before proceeding.

- Initiate Deactivation: ক্লিক করুন “Start” or “execute” button to start the deactivation process; XENTRY will communicate with the SBC control unit to depressurize the system.

- Monitor Progress: XENTRY will display a progress bar and status messages during the deactivation process; it is crucial not to interrupt the process; wait for XENTRY to confirm that the SBC system has been successfully deactivated.

3.5. Verifying Deactivation

- Check Status: After the deactivation process is complete, XENTRY will display a confirmation message; the message should indicate that the SBC system is now in a deactivated state.

- Verify Manually: To ensure the system is fully deactivated, try pressing the brake pedal; it should feel soft and offer little resistance, confirming that the hydraulic pressure has been released.

- Fault Codes: Check for any new fault codes related to the SBC deactivation; if any codes appear, follow the troubleshooting steps in XENTRY to resolve them.

4. Step-by-Step Guide: Reactivating the SBC System

Once the necessary repairs or maintenance have been completed, follow these steps to reactivate the SBC system.

4.1. Preparation for Reactivation

- Complete Repairs: Ensure all brake components have been correctly installed and all connections are secure; double-check your work to avoid any issues during reactivation.

- Reconnect Components: Reconnect any sensors or modules that were disconnected during the repair process.

- Verify Fluid Levels: Check and top up the brake fluid level to the correct specification; air in the system can affect brake performance.

4.2. Navigating to the SBC Reactivation Function

- Connect VCX SE and Launch XENTRY: Repeat the steps in Section 3.2 to connect the VCX SE to the vehicle and launch XENTRY.

- Vehicle Selection and Quick Test: As before, select the vehicle model by entering the VIN and run a quick test to check for any fault codes.

- Select Control Units: Navigate to the list of control units and select the “SBC – Sensotronic Brake Control” unit.

- Access Reactivation: Navigate to the ” অ্যাকশন ” or “কন্ট্রোল ইউনিট অ্যাডাপ্টেশন” menu.

- Find Reactivation Option: Look for the option labeled “Activate SBC” or “SBC Activation.” Select this function to start the reactivation procedure.

4.3. Following XENTRY Instructions for Reactivation

- Read Instructions: XENTRY will display a new set of instructions and warnings specific to the reactivation process; read these carefully.

- Confirm Readiness: XENTRY may ask you to confirm that all brake components are correctly installed and the brake fluid level is correct; ensure these conditions are met.

- Initiate Reactivation: ক্লিক করুন “Start” or “execute” button to start the reactivation process; XENTRY will communicate with the SBC control unit to re-pressurize the system.

- Monitor Progress: Monitor the progress bar and status messages during the reactivation process; do not interrupt the process.

4.4. System Calibration and Testing

- Calibration Routines: After reactivation, XENTRY may prompt you to perform calibration routines, such as calibrating the brake pressure sensors or performing a system self-test; follow the on-screen instructions to complete these routines.

- Clear Fault Codes: Once the calibration routines are complete, clear any remaining fault codes from the SBC control unit.

- Test Drive: Perform a test drive to ensure the SBC system is functioning correctly; check for proper brake performance, ABS activation, and any unusual noises or vibrations.

4.5. Final Verification

- Final Scan: After the test drive, perform a final scan with XENTRY to ensure no new fault codes have appeared.

- Confirm System Status: Verify that the SBC system is operating within normal parameters; check live data streams in XENTRY to monitor brake pressure, sensor readings, and system response.

- Inform Customer: If you are performing this procedure as part of a service, inform the customer about the work done and any recommendations for future maintenance.

By following these detailed steps, you can safely deactivate and reactivate the SBC system using VCX SE and XENTRY; this ensures the safety of technicians and the proper functioning of the vehicle’s braking system.

5. Common Issues and Troubleshooting

Even with careful execution, some issues may arise during the deactivation or reactivation process; here are some common problems and how to address them.

5.1. Communication Errors

- Problem: XENTRY fails to communicate with the SBC control unit.

- Possible Causes:

- Loose connection between VCX SE and the vehicle’s OBD-II port.

- Faulty USB cable connecting VCX SE to the computer.

- Outdated VCX SE firmware.

- Firewall or antivirus software blocking XENTRY communication.

- Troubleshooting Steps:

- Check all cable connections to ensure they are secure.

- Try a different USB cable.

- Update the VCX SE firmware using the VCX Manager software.

- Temporarily disable firewall or antivirus software to see if it resolves the issue.

5.2. Deactivation or Reactivation Failure

- Problem: The SBC system fails to deactivate or reactivate.

- Possible Causes:

- Low battery voltage.

- Faulty SBC control unit.

- Incorrect procedure followed.

- Underlying fault codes preventing deactivation or reactivation.

- Troubleshooting Steps:

- Ensure the battery voltage is stable by connecting a battery charger.

- Check for any fault codes in the SBC control unit and address them before attempting to deactivate or reactivate the system.

- Carefully review the XENTRY instructions and ensure each step is followed correctly.

- If the problem persists, the SBC control unit may be faulty and require replacement.

5.3. Error Messages in XENTRY

- Problem: XENTRY displays error messages during the deactivation or reactivation process.

- Possible Causes:

- Software glitches.

- Incompatible XENTRY version.

- Corrupted XENTRY installation.

- Troubleshooting Steps:

- Restart the computer and try again.

- Ensure you are using a compatible version of XENTRY for the vehicle model.

- Reinstall XENTRY to ensure a clean installation.

- Check the Mercedes-Benz online forums for known issues and solutions related to the error message.

5.4. Brake Pedal Issues

- Problem: The brake pedal feels spongy or has excessive travel after reactivation.

- Possible Causes:

- Air in the brake lines.

- Incorrect brake fluid level.

- Faulty brake components.

- Troubleshooting Steps:

- Bleed the brake lines to remove any air.

- Check and top up the brake fluid level to the correct specification.

- Inspect brake components, such as calipers and brake lines, for leaks or damage.

5.5. Calibration Problems

- Problem: Calibration routines fail to complete successfully.

- Possible Causes:

- Incorrect sensor readings.

- Vehicle not on a level surface.

- Faulty sensors.

- Troubleshooting Steps:

- Check sensor readings in XENTRY to ensure they are within the specified range.

- Ensure the vehicle is parked on a level surface before attempting calibration.

- Replace any faulty sensors as needed.

6. Benefits of Using CARDIAGTECH.BIZ for Your Diagnostic Needs

When it comes to maintaining and repairing advanced automotive systems like the Mercedes-Benz SBC, having access to reliable tools and expert support is essential; CARDIAGTECH.BIZ provides both, ensuring you can perform your job safely and efficiently.

6.1. High-Quality Tools

CARDIAGTECH.BIZ offers a range of high-quality diagnostic tools, including the VCX SE, designed to meet the needs of professional technicians; these tools are rigorously tested to ensure they provide accurate and reliable performance, giving you confidence in your diagnostic and repair work; purchasing from CARDIAGTECH.BIZ ensures you receive genuine products that are fully compatible with your vehicle’s systems.

6.2. Expert Support

In addition to providing top-notch tools, CARDIAGTECH.BIZ offers expert technical support to assist you with any questions or issues you may encounter; our team of experienced technicians can provide guidance on using the tools, troubleshooting problems, and performing complex procedures like SBC deactivation and reactivation; this support ensures you can get the job done right, even if you are new to working with these systems.

6.3. Comprehensive Training Resources

CARDIAGTECH.BIZ provides access to comprehensive training resources, including video tutorials, user manuals, and online forums; these resources are designed to help you expand your knowledge and skills, allowing you to tackle even the most challenging diagnostic and repair tasks; with our training resources, you can stay up-to-date with the latest automotive technologies and best practices.

6.4. Cost-Effective Solutions

Investing in high-quality diagnostic tools from CARDIAGTECH.BIZ can save you time and money in the long run; by accurately diagnosing and repairing issues the first time, you can avoid costly mistakes and reduce the need for repeat repairs; our tools are priced competitively, offering excellent value for your investment; according to a study by the Automotive Management Institute (AMI), shops that invest in advanced diagnostic equipment see a 20% increase in efficiency and a 15% reduction in repair times.

6.5. Customer Satisfaction

CARDIAGTECH.BIZ is committed to customer satisfaction; we stand behind our products and services, offering a hassle-free return policy and responsive customer support; our goal is to ensure you are completely satisfied with your purchase and have the tools and support you need to succeed; with CARDIAGTECH.BIZ, you can trust that you are getting the best possible value and service.

7. Real-World Applications and Benefits

Understanding the practical applications and benefits of safely deactivating and reactivating the SBC system can highlight the importance of this procedure in automotive maintenance.

7.1. Enhancing Brake Pad Replacement

When replacing brake pads on vehicles equipped with SBC, deactivating the system is crucial; without deactivation, the high pressure in the hydraulic unit can cause the calipers to retract unexpectedly, potentially leading to injury or damage; by safely deactivating the SBC system, technicians can perform brake pad replacements with confidence, knowing that the system is depressurized and safe to work on; a survey by the National Institute for Automotive Service Excellence (ASE) found that technicians who follow proper safety procedures during brake repairs are 50% less likely to experience injuries.

7.2. Improving Caliper and Rotor Service

Servicing calipers and rotors also requires SBC deactivation; removing a caliper without deactivating the SBC system can result in the piston being ejected with considerable force, posing a significant safety risk; deactivation ensures that the hydraulic pressure is released, allowing for safe removal and installation of these components; additionally, proper rotor service, such as resurfacing or replacement, benefits from a stable and depressurized system, ensuring accurate measurements and installation.

7.3. Facilitating Hydraulic Line Repairs

Repairing or replacing hydraulic brake lines on SBC-equipped vehicles demands meticulous attention to safety; the high pressure maintained by the SBC system can cause brake fluid to spray out forcefully if a line is disconnected without prior deactivation; deactivating the system eliminates this risk, allowing technicians to work on hydraulic lines without the danger of high-pressure fluid release; this not only protects the technician but also prevents damage to other vehicle components.

7.4. Supporting ABS System Maintenance

The Anti-lock Braking System (ABS) is closely integrated with the SBC system; maintenance or repairs to the ABS system often require deactivating the SBC to ensure safe access and prevent unintended activation; for example, when replacing an ABS sensor or module, deactivating the SBC system ensures that the hydraulic unit does not interfere with the process; this integration highlights the importance of understanding and properly handling the SBC system when working on related components.

7.5. Ensuring Accurate Diagnostic Testing

Accurate diagnostic testing of the SBC system itself requires the ability to safely deactivate and reactivate the system; when performing diagnostic tests, technicians may need to isolate certain components or simulate specific conditions; deactivation allows for controlled testing without the risk of unexpected system responses; furthermore, reactivation after testing ensures that the system returns to its normal operating state, providing a comprehensive assessment of its functionality.

8. Integrating SBC System Maintenance into Your Service Offerings

Offering SBC system maintenance as part of your automotive service offerings can attract more customers and increase revenue; however, it is essential to approach this service with the right tools, training, and safety protocols.

8.1. Marketing Your Expertise

Promote your expertise in SBC system maintenance to attract Mercedes-Benz owners who value specialized service; highlight your use of advanced tools like VCX SE and XENTRY, as well as your commitment to safety and precision; use online marketing, social media, and local advertising to reach your target audience; consider offering discounts or package deals for SBC system maintenance services to incentivize customers.

8.2. Pricing Your Services

Price your SBC system maintenance services competitively while reflecting the specialized knowledge and equipment required; research the market rates for similar services in your area and adjust your pricing accordingly; factor in the cost of tools, training, and labor when determining your pricing; consider offering different service tiers to cater to a range of customer needs and budgets.

8.3. Training Your Technicians

Invest in comprehensive training for your technicians to ensure they are proficient in SBC system maintenance; provide ongoing training to keep them updated with the latest technologies and best practices; consider partnering with automotive training institutions or industry experts to provide specialized training; encourage technicians to pursue certifications related to brake systems and diagnostics.

8.4. Implementing Safety Protocols

Establish strict safety protocols for SBC system maintenance to protect your technicians and customers; provide technicians with the necessary personal protective equipment (PPE), such as gloves, safety glasses, and hearing protection; ensure that all tools and equipment are properly maintained and calibrated; conduct regular safety audits to identify and address potential hazards; foster a safety-conscious culture within your shop to promote safe work practices.

8.5. Ensuring Customer Satisfaction

Provide excellent customer service to ensure satisfaction with your SBC system maintenance services; communicate clearly with customers about the work performed, the costs involved, and any recommendations for future maintenance; address any concerns or complaints promptly and professionally; follow up with customers after the service to ensure they are satisfied with the results; build long-term relationships with customers by providing reliable, trustworthy service.

9. Future Trends in Automotive Brake Systems

As automotive technology continues to advance, brake systems are also evolving; staying informed about future trends can help you prepare your business for the changes ahead.

9.1. Increased Electrification

Electric vehicles (EVs) and hybrid electric vehicles (HEVs) are becoming increasingly popular, leading to new developments in braking technology; regenerative braking, which uses the electric motor to slow the vehicle and recharge the battery, is a key feature of EVs and HEVs; this technology reduces wear on traditional brake components and improves energy efficiency; however, it also requires sophisticated control systems to seamlessly blend regenerative braking with friction braking.

9.2. Autonomous Driving

Autonomous vehicles rely on advanced braking systems to ensure safety and reliability; these systems must be capable of making split-second decisions and executing precise braking maneuvers; future braking systems will likely incorporate artificial intelligence (AI) and machine learning (ML) to optimize performance and adapt to changing driving conditions; redundancy and fail-safe mechanisms will be essential to prevent accidents in the event of system failures.

9.3. Brake-by-Wire Technology

Brake-by-wire technology, which replaces mechanical linkages with electronic controls, is gaining traction in the automotive industry; this technology offers several advantages, including improved brake response, enhanced stability control, and reduced weight; brake-by-wire systems also enable new features, such as customizable brake pedal feel and automated emergency braking; however, these systems require robust cybersecurity measures to prevent hacking and ensure safe operation.

9.4. Lightweight Materials

The automotive industry is increasingly using lightweight materials, such as aluminum, carbon fiber, and composites, to improve fuel efficiency and performance; these materials are also being used in brake components, such as calipers and rotors, to reduce weight and improve heat dissipation; lightweight brake components can improve braking performance, reduce stopping distances, and enhance vehicle handling.

9.5. Advanced Sensor Technology

Advanced sensor technology is playing an increasingly important role in brake systems; sensors are used to monitor brake pad wear, brake fluid level, and other critical parameters; this information can be used to provide timely maintenance alerts and prevent system failures; future braking systems may also incorporate sensors to detect road conditions, such as rain or ice, and adjust braking performance accordingly.

By staying informed about these future trends and investing in the necessary tools and training, you can position your business for success in the evolving automotive landscape; CARDIAGTECH.BIZ is committed to providing you with the resources you need to stay ahead of the curve and deliver exceptional service to your customers.

10. FAQs About SBC System Deactivation and Reactivation

Here are some frequently asked questions about deactivating and reactivating the SBC system, along with detailed answers.

10.1. What is the SBC system?

The Sensotronic Brake Control (SBC) system is an electro-hydraulic brake system developed by Mercedes-Benz to enhance braking performance and safety; it uses electronic sensors to monitor driving conditions and driver inputs, optimizing braking force at each wheel independently.

10.2. Why is it necessary to deactivate the SBC system before performing brake work?

Deactivating the SBC system is essential to ensure technician safety; the system maintains high pressure even when the vehicle is off, posing a risk of injury from unexpected brake activation or high-pressure fluid release.

10.3. What tools are needed to deactivate and reactivate the SBC system?

The VCX SE diagnostic tool and XENTRY software are required to safely deactivate and reactivate the SBC system; these tools provide the necessary interface and capabilities to perform the task accurately.

10.4. Can I use other diagnostic tools besides VCX SE and XENTRY?

While other diagnostic tools may claim to support SBC deactivation, using VCX SE and XENTRY is recommended because they are the official tools used by Mercedes-Benz dealerships, ensuring the highest level of compatibility and safety.

10.5. What steps should I take before deactivating the SBC system?

Before deactivating the SBC system, ensure the vehicle is parked on a level surface, the parking brake is engaged, and a battery charger is connected to maintain a stable voltage supply.

10.6. What should I do if I encounter communication errors during the deactivation process?

If you encounter communication errors, check all cable connections, try a different USB cable, update the VCX SE firmware, and temporarily disable firewall or antivirus software.

10.7. How do I verify that the SBC system has been successfully deactivated?

After deactivation, XENTRY will display a confirmation message; you can also manually check by pressing the brake pedal, which should feel soft and offer little resistance.

10.8. What steps should I take after reactivating the SBC system?

After reactivation, perform calibration routines, clear any remaining fault codes, and perform a test drive to ensure the system is functioning correctly; also, conduct a final scan with XENTRY to confirm no new fault codes have appeared.

10.9. What are some common issues that can arise during the deactivation or reactivation process?

Common issues include communication errors, deactivation or reactivation failure, error messages in XENTRY, brake pedal issues, and calibration problems; troubleshooting steps for each of these issues are detailed in Section 5.

10.10. Where can I purchase reliable diagnostic tools and receive expert support for SBC system maintenance?

CARDIAGTECH.BIZ offers high-quality diagnostic tools, expert technical support, and comprehensive training resources to help you perform SBC system maintenance safely and effectively; contact CARDIAGTECH.BIZ at 276 Reock St, City of Orange, NJ 07050, United States, via WhatsApp at +1 (641) 206-8880, or visit CARDIAGTECH.BIZ for more information.

Safely deactivating and reactivating the SBC system using VCX SE and XENTRY is critical for Mercedes-Benz maintenance, requiring precision and the right tools, CARDIAGTECH.BIZ provides reliable VCX SE tools and expert guidance, ensuring technicians perform this task safely and efficiently; contact CARDIAGTECH.BIZ for expert advice and support in diagnostic tool selection; connect with us at 276 Reock St, City of Orange, NJ 07050, United States, via WhatsApp at +1 (641) 206-8880, or visit CARDIAGTECH.BIZ for all your diagnostic needs; by choosing CARDIAGTECH.BIZ, you ensure optimal vehicle maintenance.