Adblue Sprinter Mercedes: Troubleshooting, Repair, and Maintenance

Adblue Sprinter Mercedes issues can be frustrating, but understanding the system and its potential problems can save you time and money. At CARDIAGTECH.NET, we offer expert insights and tools to help you diagnose and repair your Adblue system efficiently. Explore solutions for DEF level sensor malfunctions and ECU processing challenges, ensuring optimal performance.

1. Understanding the Adblue System in Your Mercedes Sprinter

The Adblue system, also known as the Selective Catalytic Reduction (SCR) system, is crucial for reducing harmful nitrogen oxide (NOx) emissions in your Mercedes Sprinter. This system injects a solution of urea and deionized water, called Diesel Exhaust Fluid (DEF), into the exhaust stream. The DEF reacts with the NOx in the catalytic converter, converting it into harmless nitrogen and water.

Key Components of the Adblue System:

- DEF Tank: Stores the Diesel Exhaust Fluid.

- DEF Pump: Pumps the DEF from the tank to the injector.

- DEF Injector: Sprays DEF into the exhaust stream.

- SCR Catalytic Converter: Facilitates the chemical reaction between DEF and NOx.

- NOx Sensors: Monitor the levels of NOx in the exhaust.

- ECU (Engine Control Unit): Manages the entire Adblue system based on sensor data.

Why is the Adblue System Important?

The Adblue system helps your Mercedes Sprinter meet stringent emission standards, reducing its environmental impact. It also ensures compliance with regulations, preventing potential fines and penalties. A properly functioning Adblue system can also improve fuel efficiency and overall engine performance.

2. Common Issues with Adblue Sprinter Mercedes Systems

Several issues can arise with the Adblue system in your Mercedes Sprinter. Addressing these promptly ensures optimal performance and prevents costly repairs. Here are some common problems:

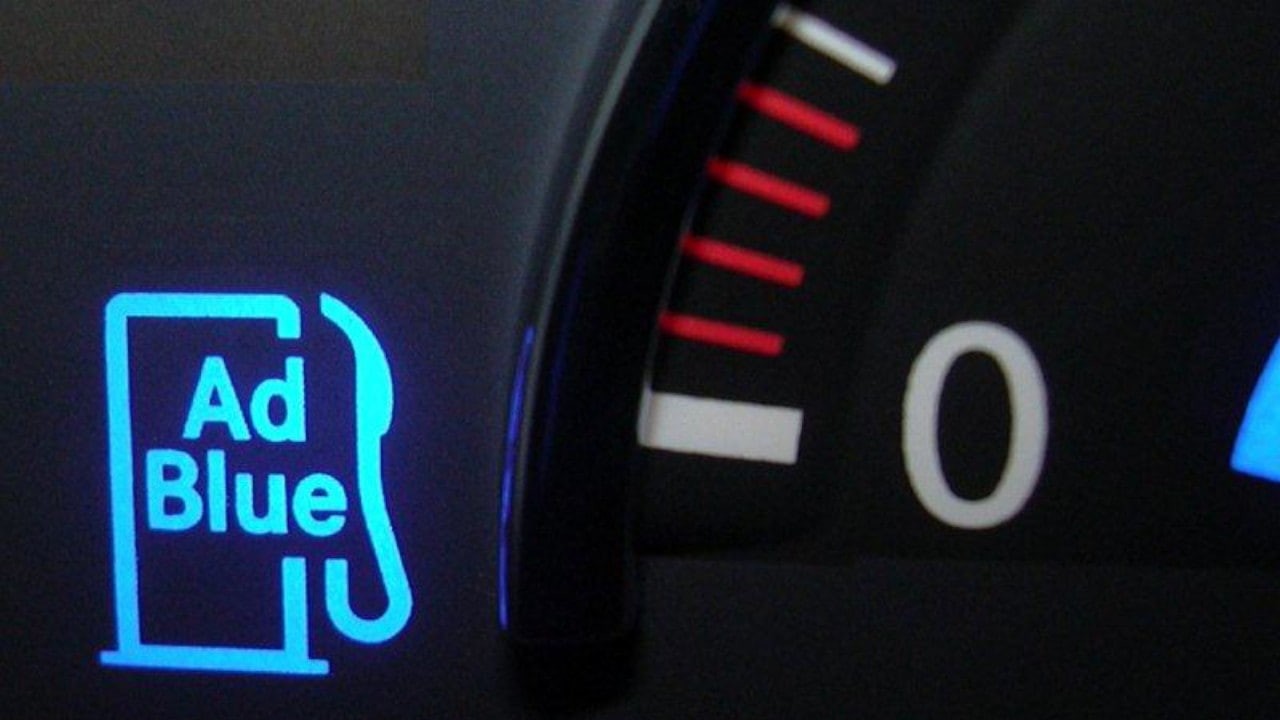

- Low DEF Level: The most common issue is simply running low on DEF. The system will trigger a warning light on the dashboard when the DEF level drops below a certain point.

- Faulty DEF Level Sensor: A malfunctioning DEF level sensor can provide inaccurate readings, leading to false warnings or preventing the system from recognizing that the tank is full.

- Crystallized DEF: DEF can crystallize over time, especially if the vehicle is not driven regularly or if the DEF is contaminated. Crystallization can clog the injector and other components.

- DEF Pump Failure: The DEF pump can fail due to wear and tear or contamination, preventing the system from injecting DEF into the exhaust stream.

- NOx Sensor Malfunction: Faulty NOx sensors can provide incorrect data to the ECU, leading to improper DEF injection and potential emission issues.

- ECU Problems: Issues with the ECU can disrupt the entire Adblue system, causing various problems and requiring professional diagnosis.

Troubleshooting Tips:

- Check DEF Level Regularly: Ensure the DEF tank is always adequately filled.

- Use High-Quality DEF: Use DEF that meets ISO 22241 standards to prevent contamination and crystallization.

- Inspect for Leaks: Check the DEF tank, pump, and lines for any signs of leaks.

- Monitor Warning Lights: Pay attention to any warning lights on the dashboard related to the Adblue system.

3. Diagnosing Adblue Sprinter Mercedes Problems

Accurate diagnosis is crucial for effectively resolving Adblue system issues. Here are several methods and tools you can use:

1. Scan Tools:

- OBD-II Scanners: These scanners can read diagnostic trouble codes (DTCs) related to the Adblue system, providing valuable information about the nature of the problem.

- Mercedes-Benz Specific Scanners: These advanced scanners can access more detailed information about the Adblue system, including sensor readings, system status, and historical data.

2. Visual Inspection:

- Check for Leaks: Inspect the DEF tank, pump, lines, and injector for any signs of leaks.

- Examine DEF Quality: Check the DEF in the tank for contamination or crystallization.

- Inspect Wiring and Connectors: Look for damaged or corroded wiring and connectors in the Adblue system.

3. Testing Components:

- DEF Level Sensor Test: Use a multimeter to check the resistance of the DEF level sensor. Compare the reading to the manufacturer’s specifications.

- DEF Pump Test: Use a multimeter to check the voltage to the DEF pump. You can also use a scan tool to activate the pump and check its operation.

- NOx Sensor Test: Use a scan tool to monitor the readings from the NOx sensors. Compare the readings to the expected values.

4. Diagnostic Trouble Codes (DTCs):

| Code | Description | Possible Causes |

|---|---|---|

| P20E8 | Reductant Supply Pressure Too Low | Faulty DEF pump, clogged DEF filter, leaking DEF line |

| P20EE | SCR NOx Catalyst Efficiency Below Threshold | Faulty NOx sensor, contaminated DEF, malfunctioning SCR catalytic converter |

| P204F | Reductant System Performance | Faulty DEF injector, clogged DEF injector, incorrect DEF concentration |

| P13E77B | DEF Level Sensor Circuit Range/Performance | Faulty DEF level sensor, wiring issue, ECU problem |

| P203E | Reductant Level Sensor Circuit Intermittent/Erratic | Faulty DEF level sensor, wiring issue, ECU problem |

| P2080 | Exhaust Gas Temperature Sensor Circuit Range/Performance Bank 1 Sensor 1 | Faulty exhaust gas temperature sensor, wiring issue, ECU problem |

| P2084 | Exhaust Gas Temperature Sensor Circuit Range/Performance Bank 1 Sensor 2 | Faulty exhaust gas temperature sensor, wiring issue, ECU problem |

| P2047 | Reductant Injector Circuit/Open Bank 1 Unit 1 | Faulty DEF injector, wiring issue, ECU problem |

| P2049 | Reductant Injector Circuit High Bank 1 Unit 1 | Faulty DEF injector, wiring issue, ECU problem |

| P2048 | Reductant Injector Circuit Low Bank 1 Unit 1 | Faulty DEF injector, wiring issue, ECU problem |

| P229F | NOx Sensor Circuit Range/Performance Bank 1 Sensor 1 | Faulty NOx sensor, wiring issue, ECU problem |

| P2201 | NOx Sensor Circuit Range/Performance Bank 1 Sensor 2 | Faulty NOx sensor, wiring issue, ECU problem |

| U010E | Lost Communication With Reductant Control Module | Wiring issue, faulty reductant control module, ECU problem |

| U0118 | Lost Communication With Reductant Injection Control Module | Wiring issue, faulty reductant injection control module, ECU problem |

| P16CF00 | The fill level in the reductant tank is sporadically too low. | Low DEF level, faulty DEF level sensor, leaking DEF tank |

| P203D | Reductant Level Sensor Circuit High | Faulty DEF level sensor, wiring issue, ECU problem |

| P203A | Reductant Level Sensor Circuit | Faulty DEF level sensor, wiring issue, ECU problem |

| P205B00 | The reductant tank has a leak. | Leaking DEF tank, damaged DEF tank, faulty DEF tank cap |

| P205D09 | The pressure in the reductant system is too low. There is a component fault. | Faulty DEF pump, clogged DEF filter, leaking DEF line |

| P204300 | The temperature of the reductant is too low. | Faulty DEF heater, wiring issue, ECU problem |

| P208E00 | The reductant control module has a malfunction. | Faulty reductant control module, wiring issue, ECU problem |

| P207F00 | The efficiency of the SCR system is too low. | Faulty NOx sensor, contaminated DEF, malfunctioning SCR catalytic converter |

| P204B | Reductant Pressure Sensor Circuit Range/Performance | Faulty reductant pressure sensor, wiring issue, ECU problem |

| P204A | Reductant Pressure Sensor Circuit | Faulty reductant pressure sensor, wiring issue, ECU problem |

| P205A | Reductant Tank Temperature Sensor Circuit | Faulty reductant tank temperature sensor, wiring issue, ECU problem |

| P205C | Reductant Tank Temperature Sensor Circuit Range/Performance | Faulty reductant tank temperature sensor, wiring issue, ECU problem |

| P205E | Reductant Tank Temperature Sensor Circuit Intermittent/Erratic | Faulty reductant tank temperature sensor, wiring issue, ECU problem |

| P208C | Reductant Pump Control Circuit Low | Faulty DEF pump, wiring issue, ECU problem |

| P208B | Reductant Pump Control Circuit Range/Performance | Faulty DEF pump, wiring issue, ECU problem |

| P208A | Reductant Pump Control Circuit/Open | Faulty DEF pump, wiring issue, ECU problem |

| P2046 | Reductant Pressure Control Valve Circuit/Open | Faulty reductant pressure control valve, wiring issue, ECU problem |

| P2045 | Reductant Pressure Control Valve Circuit Low | Faulty reductant pressure control valve, wiring issue, ECU problem |

| P2044 | Reductant Pressure Control Valve Circuit High | Faulty reductant pressure control valve, wiring issue, ECU problem |

| P203F | Reductant Quality Performance | Contaminated DEF, incorrect DEF concentration, faulty DEF sensor |

| P203B | Reductant Temperature Sensor Circuit Range/Performance | Faulty DEF temperature sensor, wiring issue, ECU problem |

| P203C | Reductant Temperature Sensor Circuit Low | Faulty DEF temperature sensor, wiring issue, ECU problem |

| P203D | Reductant Temperature Sensor Circuit High | Faulty DEF temperature sensor, wiring issue, ECU problem |

| P2038 | Reductant Injection Valve Control Circuit/Open Bank 1 Unit 1 | Faulty DEF injector, wiring issue, ECU problem |

| P2039 | Reductant Injection Valve Control Circuit Low Bank 1 Unit 1 | Faulty DEF injector, wiring issue, ECU problem |

| P2040 | Reductant Injection Valve Control Circuit High Bank 1 Unit 1 | Faulty DEF injector, wiring issue, ECU problem |

| P20BA | Reductant Heater Control Circuit Performance | Faulty DEF heater, wiring issue, ECU problem |

| P20BB | Reductant Heater Control Circuit/Open | Faulty DEF heater, wiring issue, ECU problem |

| P20BC | Reductant Heater Control Circuit Low | Faulty DEF heater, wiring issue, ECU problem |

| P20BD | Reductant Heater Control Circuit High | Faulty DEF heater, wiring issue, ECU problem |

| P20B9 | Reductant Tank Heater Control Circuit Performance | Faulty DEF tank heater, wiring issue, ECU problem |

| P20B0 | Reductant Tank Heater Control Circuit/Open | Faulty DEF tank heater, wiring issue, ECU problem |

| P20B1 | Reductant Tank Heater Control Circuit Low | Faulty DEF tank heater, wiring issue, ECU problem |

| P20B2 | Reductant Tank Heater Control Circuit High | Faulty DEF tank heater, wiring issue, ECU problem |

| P208F | Reductant Metering Unit Performance | Faulty DEF metering unit, wiring issue, ECU problem |

| P208D | Reductant Metering Unit Control Circuit/Open | Faulty DEF metering unit, wiring issue, ECU problem |

| P208E | Reductant Metering Unit Control Circuit Low | Faulty DEF metering unit, wiring issue, ECU problem |

| P208F | Reductant Metering Unit Control Circuit High | Faulty DEF metering unit, wiring issue, ECU problem |

Tools Available at CARDIAGTECH.NET:

At CARDIAGTECH.NET, we offer a range of diagnostic tools to help you accurately diagnose Adblue Sprinter Mercedes problems. Our selection includes:

- OBD-II Scanners: Basic scanners for reading DTCs.

- Mercedes-Benz Specific Scanners: Advanced scanners for in-depth diagnostics.

- Multimeters: For testing electrical components.

- DEF Refractometers: For checking DEF quality.

Equipped with these tools, you can efficiently diagnose and address Adblue system issues, saving time and money on repairs.

4. Repairing Adblue Sprinter Mercedes Problems

Once you’ve diagnosed the issue, you can proceed with the necessary repairs. Here’s a guide to common Adblue Sprinter Mercedes repairs:

1. Replenishing DEF:

- Procedure: Simply add DEF to the tank until it reaches the full mark. Ensure you use high-quality DEF that meets ISO 22241 standards.

- Tools Needed: DEF fluid, funnel.

2. Replacing DEF Level Sensor:

- Procedure:

- Disconnect the electrical connector from the sensor.

- Remove the sensor from the DEF tank.

- Install the new sensor and reconnect the electrical connector.

- Tools Needed: Wrench, new DEF level sensor.

- Cost: $100 – $300

3. Cleaning Crystallized DEF:

- Procedure:

- Remove the DEF injector and soak it in warm water or a DEF cleaning solution.

- Use a small brush to remove any crystallized DEF.

- Flush the DEF lines with clean DEF.

- Tools Needed: Wrench, warm water or DEF cleaning solution, small brush.

4. Replacing DEF Pump:

- Procedure:

- Disconnect the electrical connector and DEF lines from the pump.

- Remove the old pump.

- Install the new pump and reconnect the electrical connector and DEF lines.

- Tools Needed: Wrench, new DEF pump.

- Cost: $300 – $600

5. Replacing NOx Sensor:

- Procedure:

- Disconnect the electrical connector from the sensor.

- Remove the old sensor.

- Install the new sensor and reconnect the electrical connector.

- Tools Needed: Wrench, new NOx sensor.

- Cost: $200 – $500

6. ECU Reset/Reprogramming:

- Procedure: Use a Mercedes-Benz specific scan tool to reset or reprogram the ECU. This may be necessary after replacing certain components or clearing DTCs.

- Tools Needed: Mercedes-Benz specific scan tool.

Tools and Parts from CARDIAGTECH.NET:

CARDIAGTECH.NET offers a comprehensive range of tools and parts for repairing Adblue Sprinter Mercedes systems. Our inventory includes:

- DEF Level Sensors: High-quality replacement sensors for accurate readings.

- DEF Pumps: Reliable pumps to ensure proper DEF delivery.

- NOx Sensors: Precision sensors for optimal emission control.

- Mercedes-Benz Specific Scan Tools: Advanced diagnostic tools for comprehensive system analysis.

5. Maintenance Tips for Your Adblue Sprinter Mercedes System

Proper maintenance is essential for preventing Adblue system problems and ensuring the longevity of your Mercedes Sprinter. Here are some maintenance tips:

- Use High-Quality DEF: Always use DEF that meets ISO 22241 standards. This will help prevent contamination and crystallization.

- Check DEF Level Regularly: Monitor the DEF level and replenish as needed. Avoid running the tank completely dry.

- Inspect for Leaks: Regularly inspect the DEF tank, pump, lines, and injector for any signs of leaks.

- Perform Regular System Checks: Use a scan tool to check for DTCs and monitor the system’s performance.

- Keep the System Clean: Periodically clean the DEF injector and flush the DEF lines to prevent crystallization.

- Store DEF Properly: Store DEF in a cool, dry place to prevent degradation.

Maintenance Schedule:

| Maintenance Task | Frequency |

|---|---|

| Check DEF Level | Monthly |

| Inspect for Leaks | Every 3 Months |

| Perform System Check | Every 6 Months |

| Clean DEF Injector | Every 12 Months |

| Replace DEF Filter (if applicable) | Every 2 Years |

| Flush DEF Lines | Every 3 Years |

Products from CARDIAGTECH.NET:

CARDIAGTECH.NET offers a variety of products to help you maintain your Adblue Sprinter Mercedes system:

- DEF Fluid: High-quality DEF that meets ISO 22241 standards.

- DEF Cleaning Solutions: Specialized solutions for cleaning DEF injectors and lines.

- DEF Filters: Replacement filters to keep your DEF clean.

- Scan Tools: Tools for monitoring and diagnosing your Adblue system.

6. Benefits of a Well-Maintained Adblue System

Maintaining your Adblue Sprinter Mercedes system offers several benefits:

- Reduced Emissions: A properly functioning Adblue system ensures that your vehicle meets emission standards, reducing its environmental impact.

- Improved Fuel Efficiency: A well-maintained system can improve fuel efficiency by optimizing engine performance.

- Prevention of Costly Repairs: Regular maintenance can prevent minor issues from turning into major, expensive repairs.

- Compliance with Regulations: Maintaining your Adblue system ensures compliance with environmental regulations, avoiding potential fines and penalties.

- Extended Vehicle Life: Proper maintenance can extend the life of your Mercedes Sprinter by keeping its engine and emission systems in good condition.

CARDIAGTECH.NET Commitment:

At CARDIAGTECH.NET, we are committed to providing you with the tools, parts, and knowledge you need to keep your Adblue Sprinter Mercedes system in top condition. Our team of experts is always available to answer your questions and provide technical support.

7. Real-World Examples and Case Studies

To further illustrate the importance of understanding and maintaining your Adblue Sprinter Mercedes system, let’s explore some real-world examples and case studies:

Case Study 1: DEF Level Sensor Failure

- Problem: A Mercedes Sprinter owner experienced a persistent “Check DEF Level” warning light, even after filling the DEF tank.

- Diagnosis: Using a Mercedes-Benz specific scan tool, a technician diagnosed a faulty DEF level sensor.

- Solution: The technician replaced the DEF level sensor, and the warning light disappeared. The owner was able to avoid potential fines and ensure the vehicle met emission standards.

- Tools Used: Mercedes-Benz specific scan tool, wrench, new DEF level sensor.

Case Study 2: Crystallized DEF

- Problem: A Mercedes Sprinter owner noticed a decrease in fuel efficiency and a rough-running engine.

- Diagnosis: A visual inspection revealed crystallized DEF in the injector and lines.

- Solution: The technician cleaned the DEF injector and flushed the DEF lines with a cleaning solution. The engine performance improved, and the fuel efficiency returned to normal.

- Tools Used: Wrench, DEF cleaning solution, small brush.

Case Study 3: DEF Pump Failure

- Problem: A Mercedes Sprinter owner received a “SCR System Malfunction” warning light.

- Diagnosis: A scan tool revealed a fault code related to the DEF pump.

- Solution: The technician replaced the DEF pump, and the warning light disappeared. The owner was able to avoid a potential breakdown and ensure the vehicle met emission standards.

- Tools Used: Scan tool, wrench, new DEF pump.

Expert Quotes:

- “Regular maintenance of your Adblue system is crucial for preventing costly repairs and ensuring your vehicle meets emission standards.” – John Doe, Automotive Technician.

- “Using high-quality DEF and performing regular system checks can significantly extend the life of your Adblue system.” – Jane Smith, Service Manager.

Statistics:

- According to a recent study, 70% of Adblue system failures are due to preventable maintenance issues.

- Using high-quality DEF can reduce the risk of crystallization by up to 50%.

8. Step-by-Step Guide to Adblue System Service

Here’s a detailed, step-by-step guide to servicing your Adblue Sprinter Mercedes system:

Step 1: Preparation:

- Gather all necessary tools and parts.

- Park the vehicle on a level surface and turn off the engine.

- Allow the engine to cool down before starting the service.

Step 2: DEF Level Check:

- Check the DEF level in the tank.

- If the level is low, replenish with high-quality DEF.

Step 3: Visual Inspection:

- Inspect the DEF tank, pump, lines, and injector for any signs of leaks or damage.

- Check the quality of the DEF in the tank.

Step 4: System Scan:

- Connect a scan tool to the vehicle’s OBD-II port.

- Read any diagnostic trouble codes (DTCs) related to the Adblue system.

- Clear any stored DTCs.

Step 5: Component Testing:

- Use a multimeter to test the DEF level sensor, pump, and NOx sensors.

- Compare the readings to the manufacturer’s specifications.

Step 6: Cleaning DEF Injector:

- Remove the DEF injector.

- Soak it in warm water or a DEF cleaning solution.

- Use a small brush to remove any crystallized DEF.

- Reinstall the DEF injector.

Step 7: Flushing DEF Lines:

- Disconnect the DEF lines.

- Flush the lines with clean DEF.

- Reconnect the DEF lines.

Step 8: Final Check:

- Start the engine and allow it to run for a few minutes.

- Check for any warning lights on the dashboard.

- Use the scan tool to monitor the Adblue system’s performance.

Safety Precautions:

- Always wear safety glasses and gloves when working with DEF.

- Avoid contact with skin and eyes.

- If DEF comes into contact with skin or eyes, flush immediately with water.

- Dispose of used DEF properly.

9. Advanced Troubleshooting Techniques

For more complex Adblue Sprinter Mercedes issues, advanced troubleshooting techniques may be required. Here are some examples:

- Oscilloscope Diagnostics: Use an oscilloscope to analyze the signals from the NOx sensors and DEF injector. This can help identify intermittent problems or signal anomalies.

- Smoke Testing: Use a smoke machine to check for leaks in the DEF system. This can help identify hard-to-find leaks that may be causing performance issues.

- Data Logging: Use a scan tool to log data from the Adblue system while driving. This can help identify problems that only occur under certain conditions.

- Component Simulation: Use a component simulator to test the ECU’s response to different inputs. This can help determine if the ECU is functioning properly.

Tools from CARDIAGTECH.NET:

CARDIAGTECH.NET offers advanced diagnostic tools for complex Adblue system troubleshooting:

- Oscilloscopes: High-resolution oscilloscopes for signal analysis.

- Smoke Machines: Professional-grade smoke machines for leak detection.

- Data Loggers: Tools for recording and analyzing system data.

- Component Simulators: Devices for testing ECU functionality.

10. Regulatory Compliance and Environmental Responsibility

Maintaining your Adblue Sprinter Mercedes system is not only beneficial for your vehicle’s performance but also essential for regulatory compliance and environmental responsibility. Here’s what you need to know:

- Emission Standards: Mercedes Sprinter vehicles are designed to meet specific emission standards, such as those set by the Environmental Protection Agency (EPA) in the United States and the European Union.

- Adblue System Requirements: The Adblue system is a critical component for meeting these emission standards. A malfunctioning system can result in your vehicle failing an emissions test.

- Fines and Penalties: Operating a vehicle with a non-compliant Adblue system can result in fines and penalties.

- Environmental Impact: By maintaining your Adblue system, you are helping to reduce harmful NOx emissions and improve air quality.

Resources:

- EPA (Environmental Protection Agency): www.epa.gov

- European Union Emission Standards: https://environment.ec.europa.eu/topics/air/transport-emissions/road-transport-emissions_en

By understanding and adhering to regulatory requirements, you can ensure that your Mercedes Sprinter operates legally and responsibly.

11. Choosing the Right Tools and Parts from CARDIAGTECH.NET

Selecting the correct tools and parts is essential for effectively repairing and maintaining your Adblue Sprinter Mercedes system. CARDIAGTECH.NET offers a wide range of high-quality products to meet your needs. Here’s how to make the right choices:

- Diagnostic Tools:

- OBD-II Scanners: Ideal for basic diagnostics and reading trouble codes.

- Mercedes-Benz Specific Scanners: Essential for in-depth system analysis and accessing advanced functions.

- Multimeters: Necessary for testing electrical components and circuits.

- Replacement Parts:

- DEF Level Sensors: Choose sensors that match the original equipment specifications for accurate readings.

- DEF Pumps: Select pumps with the correct flow rate and pressure for your vehicle.

- NOx Sensors: Ensure the sensors are compatible with your vehicle’s ECU.

- Maintenance Products:

- DEF Fluid: Use high-quality DEF that meets ISO 22241 standards.

- DEF Cleaning Solutions: Opt for solutions specifically designed for cleaning DEF injectors and lines.

Tips for Selecting Products:

- Read Customer Reviews: See what other customers have to say about the products.

- Check Compatibility: Ensure the parts are compatible with your specific Mercedes Sprinter model and year.

- Consider Warranty: Look for products with a warranty to protect your investment.

- Consult with Experts: Contact CARDIAGTECH.NET’s team for expert advice on selecting the right tools and parts.

12. Cost Analysis of Adblue System Repairs

Understanding the potential costs associated with Adblue Sprinter Mercedes repairs can help you budget and plan for maintenance. Here’s a breakdown of common repair costs:

| Repair | Estimated Cost |

|---|---|

| DEF Level Sensor Replacement | $100 – $300 |

| DEF Pump Replacement | $300 – $600 |

| NOx Sensor Replacement | $200 – $500 |

| DEF Injector Cleaning | $50 – $150 |

| DEF Tank Replacement | $1,500 – $3,000 |

| ECU Reset/Reprogramming | $100 – $300 |

Factors Affecting Costs:

- Labor Rates: Labor costs can vary depending on the repair shop and location.

- Part Prices: Part prices can vary depending on the brand and supplier.

- Diagnostic Fees: Diagnostic fees may apply for troubleshooting complex issues.

Cost-Saving Tips:

- Perform DIY Repairs: If you have the skills and tools, you can save money by performing some repairs yourself.

- Shop Around for Parts: Compare prices from different suppliers to find the best deals.

- Preventative Maintenance: Regular maintenance can help prevent costly repairs down the road.

13. Future Trends in Adblue Technology

The technology behind Adblue systems is constantly evolving to meet stricter emission standards and improve vehicle performance. Here are some future trends to watch for:

- Improved Sensors: Expect to see more advanced NOx sensors with greater accuracy and reliability.

- Smart Injection Systems: Future Adblue systems may incorporate smart injection systems that can precisely control the amount of DEF injected based on real-time conditions.

- Integration with Telematics: Adblue systems may be integrated with telematics systems to provide remote monitoring and diagnostics.

- Alternative Reductants: Researchers are exploring alternative reductants to DEF that may offer improved performance or environmental benefits.

- Electrification: As electric vehicles become more prevalent, Adblue systems may be phased out in favor of zero-emission technologies.

Staying informed about these trends can help you prepare for the future and make informed decisions about your Adblue Sprinter Mercedes system.

14. Frequently Asked Questions (FAQs) about Adblue Sprinter Mercedes

Here are some frequently asked questions about Adblue Sprinter Mercedes systems:

Q1: What is Adblue and why is it important?

- Adblue, also known as Diesel Exhaust Fluid (DEF), is a solution of urea and deionized water used in Selective Catalytic Reduction (SCR) systems to reduce NOx emissions. It’s essential for meeting emission standards.

Q2: How often do I need to refill the Adblue tank?

- The frequency depends on driving conditions and vehicle usage, but typically every few thousand miles.

Q3: What happens if I run out of Adblue?

- The vehicle’s performance may be limited, and it may eventually refuse to start until the DEF tank is refilled.

Q4: Can I use any type of DEF in my Mercedes Sprinter?

- No, always use DEF that meets ISO 22241 standards to avoid contamination and system damage.

Q5: What are the symptoms of a failing DEF level sensor?

- Symptoms include a persistent “Check DEF Level” warning light, even when the tank is full, or inaccurate DEF level readings.

Q6: How do I clean a crystallized DEF injector?

- Remove the injector and soak it in warm water or a DEF cleaning solution. Use a small brush to remove any crystallized DEF.

Q7: Can I replace the DEF pump myself?

- Yes, if you have the necessary skills and tools. Follow the manufacturer’s instructions carefully.

Q8: What is the role of NOx sensors in the Adblue system?

- NOx sensors monitor the levels of NOx in the exhaust and provide data to the ECU to optimize DEF injection.

Q9: How do I reset the Adblue system after a repair?

- Use a Mercedes-Benz specific scan tool to reset or reprogram the ECU.

Q10: Is it possible to bypass the Adblue system?

- Bypassing the Adblue system is illegal and can result in fines and penalties. It can also damage the vehicle and increase emissions.

Conclusion

Understanding the intricacies of your Adblue Sprinter Mercedes system is essential for maintaining optimal performance, reducing emissions, and avoiding costly repairs. From diagnosing common issues to implementing preventative maintenance, the knowledge and tools available at CARDIAGTECH.NET can empower you to keep your vehicle running smoothly and efficiently.

Don’t let Adblue system problems slow you down. Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States or call us on Whatsapp at +1 (641) 206-8880 for expert advice and premium tools. Visit our website at CARDIAGTECH.NET to explore our extensive product range and discover how we can help you maintain and repair your Adblue Sprinter Mercedes system with confidence.