Mercedes AdBlue Level Sensor: Troubleshooting and Solutions

The Mercedes AdBlue level sensor is a crucial component in your vehicle’s Selective Catalytic Reduction (SCR) system, ensuring proper emissions control. At CARDIAGTECH.NET, we understand the frustration a malfunctioning sensor can cause. We offer a wide range of diagnostic tools and replacement parts to help you resolve AdBlue system issues efficiently and get you back on the road. Discover the reasons behind AdBlue sensor failures, troubleshooting steps, and how to find the right solutions.

1. Understanding the Mercedes AdBlue System

The AdBlue system, also known as the Diesel Exhaust Fluid (DEF) system, is designed to reduce harmful nitrogen oxide (NOx) emissions from diesel engines. It works by injecting AdBlue, a urea-based solution, into the exhaust stream. This triggers a chemical reaction within the catalytic converter, converting NOx into harmless nitrogen and water.

1.1. Key Components of the AdBlue System

- AdBlue Tank: Stores the AdBlue solution.

- AdBlue Level Sensor: Monitors the level of AdBlue in the tank.

- AdBlue Pump: Transfers AdBlue from the tank to the injector.

- AdBlue Injector: Sprays AdBlue into the exhaust stream.

- SCR Catalyst: Facilitates the chemical reaction to reduce NOx emissions.

- NOx Sensors: Monitor NOx levels in the exhaust and provide feedback to the engine control unit (ECU).

- Engine Control Unit (ECU): Controls the entire AdBlue system based on sensor inputs and programmed parameters.

1.2. The Role of the AdBlue Level Sensor

The AdBlue level sensor plays a vital role in the system’s operation. It continuously monitors the amount of AdBlue in the tank and sends this information to the ECU. The ECU uses this data to:

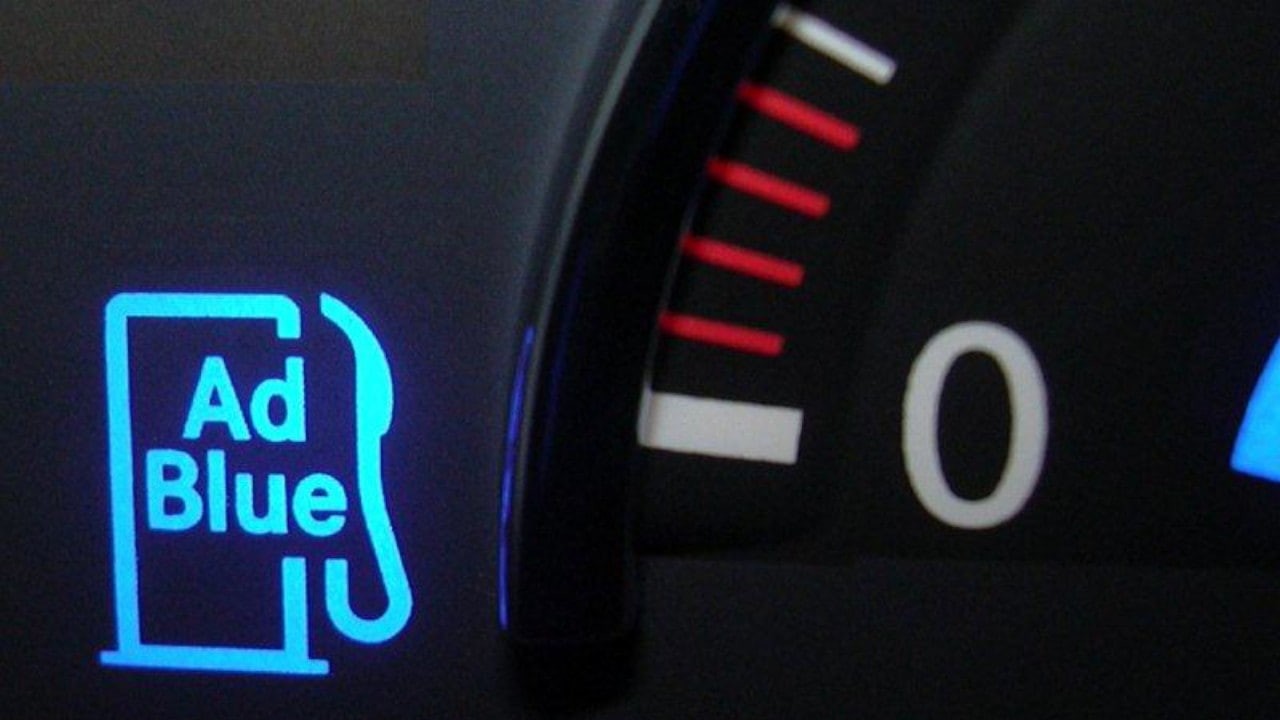

- Display AdBlue Level: Inform the driver of the remaining AdBlue range via the dashboard display.

- Prevent System Damage: Prevent the AdBlue pump from running dry, which can cause damage.

- Ensure Emissions Compliance: Guarantee that there is sufficient AdBlue for proper NOx reduction.

- Trigger Warnings: Provide timely warnings to the driver when the AdBlue level is low, prompting a refill.

2. Common Symptoms of a Failing Mercedes AdBlue Level Sensor

When the AdBlue level sensor malfunctions, it can lead to various issues affecting your vehicle’s performance and emissions. Recognizing these symptoms early can help you address the problem promptly and avoid more serious complications.

2.1. Inaccurate AdBlue Level Readings

One of the primary symptoms of a failing AdBlue level sensor is inaccurate readings on the dashboard display. This can manifest in several ways:

- Constantly Showing “AdBlue Level Low”: Even after refilling the AdBlue tank, the system might still indicate a low level.

- Displaying Incorrect AdBlue Range: The estimated driving range based on the AdBlue level may be significantly different from the actual range.

- Fluctuating Readings: The AdBlue level display may jump erratically, showing full one moment and empty the next.

2.2. Warning Messages and Error Codes

A faulty AdBlue level sensor often triggers warning messages and error codes on the vehicle’s dashboard. Common messages include:

- “AdBlue Level Low – Refill”: This message may appear even when the AdBlue tank is full.

- “AdBlue System Malfunction”: This indicates a general problem with the AdBlue system, which could be due to the level sensor.

- “Check Engine Light”: The check engine light may illuminate, accompanied by specific AdBlue-related error codes.

These error codes can be read using an OBD-II scanner. Some typical codes associated with a faulty AdBlue level sensor include:

- P203E: Reductant Level Sensor Circuit

- P203F: Reductant Level Sensor Circuit Range/Performance

- P204A: Reductant Injection System Malfunction

2.3. Reduced Engine Performance

In some cases, a malfunctioning AdBlue level sensor can lead to reduced engine performance. This is because the ECU may limit engine power to prevent excessive emissions if it believes the AdBlue system is not functioning correctly.

- Limited Speed: The vehicle’s speed may be restricted.

- Reduced Acceleration: The engine may feel sluggish and unresponsive.

- Limp Mode: The vehicle may enter limp mode, severely limiting its performance to protect the engine and emissions system.

2.4. AdBlue System Shut Down

In severe cases, a faulty AdBlue level sensor can cause the entire AdBlue system to shut down. This is a protective measure to prevent damage to the engine and emissions components.

- No AdBlue Injection: The system stops injecting AdBlue into the exhaust stream.

- Increased Emissions: The vehicle emits higher levels of NOx, potentially violating emissions regulations.

- Engine Shutdown: The engine may eventually refuse to start if the AdBlue system is not functioning.

2.5. Other Potential Issues

Besides the above symptoms, a failing AdBlue level sensor can also contribute to other related problems:

- Crystallization of AdBlue: Inaccurate readings can lead to overfilling or underfilling the AdBlue tank, increasing the risk of crystallization.

- Pump Failure: If the sensor incorrectly indicates a full tank, the pump may run dry, leading to premature failure.

- NOx Sensor Problems: The ECU may misinterpret data from the NOx sensors due to the AdBlue system malfunction, leading to further diagnostic challenges.

3. Causes of Mercedes AdBlue Level Sensor Failure

Several factors can contribute to the failure of the Mercedes AdBlue level sensor. Understanding these causes can help you prevent future issues and maintain the health of your AdBlue system.

3.1. Contamination of AdBlue Fluid

One of the most common causes of AdBlue level sensor failure is contamination of the AdBlue fluid. The AdBlue solution is highly sensitive to impurities, and even small amounts of contaminants can damage the sensor.

- Poor Quality AdBlue: Using low-quality or expired AdBlue can introduce contaminants into the system.

- Dirty Filling Equipment: Filling the AdBlue tank with dirty funnels or containers can introduce debris and contaminants.

- Foreign Particles: Dust, dirt, and other foreign particles can enter the tank, especially if the filler cap is not properly sealed.

3.2. Crystallization of AdBlue Fluid

AdBlue fluid can crystallize over time, especially when exposed to air or high temperatures. These crystals can accumulate on the sensor, causing it to malfunction.

- Prolonged Storage: Leaving the AdBlue tank partially full for extended periods can promote crystallization.

- High Temperatures: Exposure to high temperatures can accelerate the crystallization process.

- Leaks and Exposure to Air: Leaks in the AdBlue system can allow air to enter the tank, leading to crystallization.

3.3. Electrical Issues

Electrical problems can also lead to AdBlue level sensor failure. These issues can range from simple wiring faults to more complex ECU problems.

- Wiring Damage: Damaged, corroded, or loose wiring can disrupt the signal between the sensor and the ECU.

- Short Circuits: Short circuits in the sensor or related circuits can cause the sensor to fail.

- ECU Malfunctions: Problems with the ECU can lead to incorrect readings or a complete loss of signal from the sensor.

3.4. Physical Damage

Physical damage to the AdBlue level sensor can result in its malfunction. This damage can occur due to accidents, impacts, or improper handling during maintenance.

- Impact Damage: Impacts to the AdBlue tank can damage the sensor.

- Improper Installation: Incorrect installation of the sensor can cause physical stress and damage.

- Wear and Tear: Over time, the sensor can degrade due to normal wear and tear.

3.5. Corrosion

Corrosion can affect the AdBlue level sensor, especially in regions with harsh weather conditions or where road salts are used.

- Exposure to Road Salts: Road salts can corrode the sensor and its electrical connections.

- Moisture Intrusion: Moisture can penetrate the sensor, leading to corrosion and malfunction.

- Chemical Exposure: Exposure to certain chemicals can accelerate the corrosion process.

3.6. Age and Wear

Like any other component in your vehicle, the AdBlue level sensor can fail due to age and wear. Over time, the sensor’s internal components can degrade, leading to inaccurate readings or complete failure.

- Material Degradation: The materials used in the sensor can degrade over time due to exposure to AdBlue fluid and temperature fluctuations.

- Component Fatigue: Internal components can experience fatigue due to continuous use, leading to failure.

4. Diagnosing a Faulty Mercedes AdBlue Level Sensor

Diagnosing a faulty AdBlue level sensor requires a systematic approach to identify the root cause of the problem. Here are the steps you can take to diagnose the issue effectively.

4.1. Visual Inspection

Begin with a thorough visual inspection of the AdBlue system components, including the AdBlue tank, level sensor, wiring, and connections.

- Check for Leaks: Look for any signs of AdBlue leaks around the tank, sensor, and connections.

- Inspect Wiring: Examine the wiring for damage, corrosion, or loose connections.

- Check the Sensor: Inspect the sensor for any visible damage or signs of corrosion.

4.2. Using an OBD-II Scanner

An OBD-II scanner is essential for diagnosing AdBlue system issues. Connect the scanner to your vehicle’s OBD-II port and retrieve any stored error codes.

- Read Error Codes: Note any error codes related to the AdBlue system, such as P203E, P203F, or P204A.

- Clear Codes: After noting the codes, clear them and see if they reappear. This can help determine if the issue is intermittent or persistent.

- Live Data: Use the scanner to monitor live data from the AdBlue level sensor. This can help you see if the sensor is providing accurate readings.

At CARDIAGTECH.NET, we offer a range of OBD-II scanners that can help you diagnose AdBlue system issues quickly and accurately. Contact us at +1 (641) 206-8880 for more information.

4.3. Testing the Sensor with a Multimeter

If you suspect the AdBlue level sensor is faulty, you can test it using a multimeter. This involves checking the sensor’s resistance and voltage to determine if it is functioning correctly.

- Locate the Sensor Connector: Identify the connector for the AdBlue level sensor.

- Check Resistance: Use a multimeter to measure the resistance across the sensor terminals. Compare the reading to the manufacturer’s specifications.

- Check Voltage: With the ignition on, use a multimeter to check the voltage at the sensor connector. Again, compare the reading to the manufacturer’s specifications.

4.4. Checking AdBlue Fluid Quality

The quality of the AdBlue fluid can significantly impact the performance of the AdBlue level sensor. Check the fluid for contamination and crystallization.

- Visual Inspection: Inspect the AdBlue fluid for any signs of contamination, such as particles or discoloration.

- Refractometer Test: Use a refractometer to measure the concentration of urea in the AdBlue fluid. The concentration should be around 32.5%.

4.5. Inspecting the AdBlue Injector

A malfunctioning AdBlue injector can also cause issues that may be mistaken for a faulty level sensor. Inspect the injector for clogs or damage.

- Visual Inspection: Check the injector for any signs of crystallization or damage.

- Injector Test: Use a diagnostic tool to activate the injector and check its spray pattern.

4.6. Verifying System Grounds

Ensure that all ground connections for the AdBlue system are clean and secure. Poor grounding can cause electrical issues that affect sensor readings.

- Locate Ground Points: Identify the ground points for the AdBlue system.

- Clean Connections: Clean any corroded or loose ground connections.

- Test Continuity: Use a multimeter to test the continuity between the ground points and the vehicle’s chassis.

5. Step-by-Step Guide to Replacing a Mercedes AdBlue Level Sensor

Replacing a faulty Mercedes AdBlue level sensor requires careful attention to detail. Follow these steps to ensure a successful replacement.

5.1. Gather Necessary Tools and Materials

Before starting the replacement process, gather all the necessary tools and materials. This will help you work efficiently and avoid delays.

- New AdBlue Level Sensor: Purchase a replacement sensor from a reputable supplier like CARDIAGTECH.NET.

- Socket Set: You’ll need a socket set with various sizes to remove and install the sensor.

- Wrench Set: A set of wrenches will be helpful for tightening and loosening connections.

- Screwdrivers: Both flathead and Phillips screwdrivers may be needed.

- Multimeter: For testing the new sensor before installation.

- OBD-II Scanner: To clear error codes after the replacement.

- Safety Glasses: Protect your eyes from fluid splashes and debris.

- Gloves: Protect your hands from AdBlue fluid and chemicals.

- Drain Pan: To catch any spilled AdBlue fluid.

- Torque Wrench: To tighten bolts to the correct specifications.

- AdBlue Fluid: To top off the tank after the replacement.

5.2. Prepare the Vehicle

Properly prepare the vehicle to ensure a safe and efficient replacement process.

- Park on a Level Surface: Park the vehicle on a level surface and engage the parking brake.

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical shorts.

- Locate the AdBlue Tank: Identify the location of the AdBlue tank in your vehicle. It is typically located in the trunk, under the vehicle, or in the engine compartment.

5.3. Drain the AdBlue Tank (If Necessary)

In some cases, you may need to drain the AdBlue tank before replacing the sensor. This is especially important if the tank is full or if the sensor is located at the bottom of the tank.

- Locate the Drain Plug: Find the drain plug on the AdBlue tank.

- Place a Drain Pan: Position a drain pan under the drain plug to catch the fluid.

- Remove the Drain Plug: Carefully remove the drain plug and allow the AdBlue fluid to drain completely.

- Reinstall the Drain Plug: Once the tank is empty, reinstall the drain plug and tighten it securely.

5.4. Disconnect the Old Sensor

Carefully disconnect the old AdBlue level sensor from the vehicle.

- Locate the Sensor Connector: Find the electrical connector for the AdBlue level sensor.

- Disconnect the Connector: Disconnect the connector by pressing the release tab and pulling it apart.

- Remove the Sensor: Depending on the design, the sensor may be held in place by screws, bolts, or a retaining clip. Remove the fasteners and carefully remove the sensor from the tank.

5.5. Install the New Sensor

Install the new AdBlue level sensor, ensuring it is properly seated and connected.

- Position the New Sensor: Align the new sensor with the mounting location on the AdBlue tank.

- Secure the Sensor: Secure the sensor in place using the screws, bolts, or retaining clip. Tighten the fasteners to the manufacturer’s specifications using a torque wrench.

- Connect the Electrical Connector: Connect the electrical connector to the new sensor, ensuring it clicks into place securely.

5.6. Refill the AdBlue Tank

If you drained the AdBlue tank earlier, refill it with fresh AdBlue fluid.

- Use a Clean Funnel: Use a clean funnel to pour the AdBlue fluid into the tank.

- Fill to the Correct Level: Fill the tank to the recommended level, as indicated in your vehicle’s owner’s manual.

- Check for Leaks: After filling the tank, check for any leaks around the sensor and drain plug.

5.7. Reconnect the Battery

Reconnect the negative terminal of the battery to restore power to the vehicle.

5.8. Clear Error Codes

Use an OBD-II scanner to clear any error codes related to the AdBlue system.

- Connect the Scanner: Connect the scanner to the vehicle’s OBD-II port.

- Clear Codes: Select the option to clear error codes and follow the on-screen instructions.

- Verify Operation: Start the engine and verify that the AdBlue system is functioning correctly and that no new error codes appear.

5.9. Test Drive the Vehicle

Take the vehicle for a test drive to ensure that the AdBlue system is functioning correctly and that there are no issues.

- Monitor Performance: Pay attention to the engine’s performance and any warning messages on the dashboard.

- Check AdBlue Level: Verify that the AdBlue level is being displayed correctly on the dashboard.

6. Tips for Maintaining Your Mercedes AdBlue System

Proper maintenance is crucial for prolonging the life of your Mercedes AdBlue system and preventing costly repairs. Here are some tips to keep your system in top condition.

6.1. Use High-Quality AdBlue Fluid

Always use high-quality AdBlue fluid that meets the ISO 22241 standard. Low-quality fluid can contain contaminants that damage the sensor and other components.

- Check for Certification: Look for AdBlue fluid that is certified to meet the ISO 22241 standard.

- Purchase from Reputable Suppliers: Buy AdBlue fluid from reputable suppliers to ensure its quality.

- Avoid Expired Fluid: Check the expiration date on the AdBlue container and avoid using expired fluid.

6.2. Store AdBlue Fluid Properly

Proper storage of AdBlue fluid is essential to prevent contamination and crystallization.

- Store in a Cool, Dry Place: Store AdBlue fluid in a cool, dry place away from direct sunlight.

- Use a Sealed Container: Keep the AdBlue fluid in a tightly sealed container to prevent exposure to air and contaminants.

- Avoid Extreme Temperatures: Avoid storing AdBlue fluid in extreme temperatures, as this can accelerate crystallization.

6.3. Fill the AdBlue Tank Carefully

When filling the AdBlue tank, take care to avoid contamination.

- Use a Clean Funnel: Use a clean funnel to pour the AdBlue fluid into the tank.

- Avoid Overfilling: Do not overfill the AdBlue tank, as this can damage the system.

- Clean the Filler Cap: Clean the filler cap before replacing it to prevent dirt and debris from entering the tank.

6.4. Regularly Inspect the AdBlue System

Regularly inspect the AdBlue system for leaks, damage, and other issues.

- Check for Leaks: Look for any signs of AdBlue leaks around the tank, sensor, and connections.

- Inspect Wiring: Examine the wiring for damage, corrosion, or loose connections.

- Monitor AdBlue Level: Keep an eye on the AdBlue level display and refill the tank when necessary.

6.5. Address Issues Promptly

If you notice any issues with your AdBlue system, address them promptly to prevent further damage.

- Diagnose the Problem: Use an OBD-II scanner to diagnose the problem and identify the root cause.

- Replace Faulty Components: Replace any faulty components, such as the AdBlue level sensor, pump, or injector.

- Seek Professional Help: If you are not comfortable working on the AdBlue system yourself, seek professional help from a qualified mechanic.

7. Benefits of Purchasing Automotive Repair Tools from CARDIAGTECH.NET

At CARDIAGTECH.NET, we are committed to providing high-quality automotive repair tools and equipment to help you keep your vehicle in top condition. Here are some of the benefits of purchasing from us:

7.1. Wide Selection of Products

We offer a wide selection of automotive repair tools, including OBD-II scanners, multimeters, socket sets, and more.

7.2. High-Quality Products

We only offer high-quality products from trusted brands. This ensures that you get reliable and durable tools that will last for years to come.

7.3. Competitive Prices

We offer competitive prices on all of our products. This allows you to get the tools you need without breaking the bank.

7.4. Expert Advice

Our team of experts is always available to provide advice and assistance. We can help you choose the right tools for your needs and provide guidance on how to use them effectively. Contact us at +1 (641) 206-8880 for expert assistance.

7.5. Fast Shipping

We offer fast shipping on all orders. This ensures that you get your tools quickly and can start working on your vehicle right away.

7.6. Excellent Customer Service

We are committed to providing excellent customer service. If you have any questions or concerns, please do not hesitate to contact us.

8. Case Studies and Examples

To further illustrate the importance of a properly functioning AdBlue level sensor, let’s examine a few case studies and examples.

8.1. Case Study 1: The C-Class with Intermittent AdBlue Warnings

A 2016 Mercedes C-Class with 65,000 miles experienced intermittent “AdBlue Level Low” warnings despite the tank being full. The owner initially suspected a faulty AdBlue injector but after diagnostic tests, it was confirmed that the AdBlue level sensor was malfunctioning. The sensor was replaced, and the issue was resolved.

8.2. Example 2: The GLC with Reduced Engine Performance

A Mercedes GLC experienced reduced engine performance and a “Check Engine Light.” An OBD-II scan revealed a P203F error code, indicating a problem with the AdBlue level sensor circuit range/performance. Replacing the sensor restored the engine’s performance and cleared the error code.

8.3. Case Study 3: AdBlue System Shutdown in an E-Class

A Mercedes E-Class experienced a complete AdBlue system shutdown due to a faulty level sensor. The owner initially tried resetting the system with an iCarsoft reader but the problem persisted. The level sensor was replaced, and the system was reset, resolving the issue.

9. AdBlue System Regulations and Compliance

AdBlue systems are designed to help vehicles meet stringent emissions regulations. Understanding these regulations and ensuring compliance is crucial for avoiding penalties and maintaining your vehicle’s performance.

9.1. Euro 6 Standards

The Euro 6 standards are a set of European Union regulations that limit the amount of harmful emissions vehicles can produce. AdBlue systems are essential for diesel vehicles to meet these standards.

9.2. EPA Regulations in the United States

In the United States, the Environmental Protection Agency (EPA) sets emissions standards for vehicles. AdBlue systems are used to comply with these regulations and reduce NOx emissions.

9.3. Consequences of Non-Compliance

Failure to comply with emissions regulations can result in significant penalties, including fines, vehicle impoundment, and legal action.

10. Frequently Asked Questions (FAQs) about Mercedes AdBlue Level Sensors

Here are some frequently asked questions about Mercedes AdBlue level sensors to help you better understand the system and its maintenance.

Q1: What is the purpose of the AdBlue level sensor?

The AdBlue level sensor monitors the amount of AdBlue in the tank and sends this information to the ECU. The ECU uses this data to display the AdBlue level, prevent system damage, ensure emissions compliance, and trigger warnings.

Q2: How do I know if my AdBlue level sensor is faulty?

Common symptoms of a faulty AdBlue level sensor include inaccurate AdBlue level readings, warning messages and error codes, reduced engine performance, and AdBlue system shutdown.

Q3: Can I replace the AdBlue level sensor myself?

Yes, you can replace the AdBlue level sensor yourself if you have the necessary tools and experience. Follow the step-by-step guide provided in this article.

Q4: What tools do I need to replace the AdBlue level sensor?

You will need a new AdBlue level sensor, socket set, wrench set, screwdrivers, multimeter, OBD-II scanner, safety glasses, gloves, drain pan, torque wrench, and AdBlue fluid.

Q5: How often should I refill the AdBlue tank?

The frequency of AdBlue refills depends on your driving habits and vehicle model. Generally, you will need to refill the tank every few thousand miles.

Q6: Can I use any type of AdBlue fluid?

No, you should only use high-quality AdBlue fluid that meets the ISO 22241 standard. Low-quality fluid can damage the sensor and other components.

Q7: What happens if I run out of AdBlue fluid?

If you run out of AdBlue fluid, your vehicle may enter limp mode or refuse to start. This is to prevent excessive emissions and protect the engine.

Q8: How do I clear the error codes after replacing the AdBlue level sensor?

Use an OBD-II scanner to clear any error codes related to the AdBlue system.

Q9: Can a faulty AdBlue level sensor affect my vehicle’s emissions?

Yes, a faulty AdBlue level sensor can prevent the AdBlue system from functioning correctly, leading to increased NOx emissions.

Q10: Where can I purchase a high-quality AdBlue level sensor?

You can purchase a high-quality AdBlue level sensor from reputable suppliers like CARDIAGTECH.NET. Contact us at +1 (641) 206-8880 for more information.

Conclusion

The Mercedes AdBlue level sensor is a critical component for maintaining your vehicle’s emissions compliance and performance. Recognizing the symptoms of a failing sensor, understanding the causes of failure, and following the proper diagnostic and replacement procedures are essential for keeping your AdBlue system in top condition. At CARDIAGTECH.NET, we offer a wide range of diagnostic tools and replacement parts to help you resolve AdBlue system issues efficiently.

Don’t let a faulty AdBlue level sensor compromise your vehicle’s performance and emissions. Contact CARDIAGTECH.NET at +1 (641) 206-8880 or visit our website CARDIAGTECH.NET today to explore our selection of high-quality automotive repair tools and equipment. Our team of experts is ready to assist you with all your automotive needs. Reach us at 276 Reock St, City of Orange, NJ 07050, United States.