Mercedes AdBlue Pump Replacement: A Comprehensive Guide

Mercedes AdBlue pump replacement is a repair many diesel vehicle owners will face. At CARDIAGTECH.NET, we provide the tools and knowledge to confidently tackle this job, saving time and money while ensuring optimal performance. Discover the solutions for DEF pump replacement, diesel exhaust fluid systems, and SCR system repairs.

1. Understanding the Mercedes AdBlue System

The Mercedes-Benz AdBlue system, also known as Selective Catalytic Reduction (SCR), is designed to reduce harmful nitrogen oxide (NOx) emissions from diesel engines. Understanding its components and function is vital before attempting any repairs.

1.1. Key Components of the AdBlue System

- AdBlue Tank: This tank stores the Diesel Exhaust Fluid (DEF), a urea-based solution essential for the SCR process.

- AdBlue Pump: The AdBlue pump transfers DEF from the tank to the injector.

- AdBlue Injector: The injector sprays DEF into the exhaust stream.

- SCR Catalyst: This catalyst converts NOx into nitrogen and water.

- NOx Sensors: These sensors monitor NOx levels and provide feedback to the engine control unit (ECU).

- ECU: The ECU controls the entire AdBlue system, managing DEF injection and monitoring system performance.

1.2. How the AdBlue System Works

- DEF Injection: The AdBlue pump delivers DEF from the tank to the injector. The injector sprays DEF into the exhaust stream upstream of the SCR catalyst.

- SCR Process: As the exhaust gases pass through the SCR catalyst, the DEF reacts with NOx to form harmless nitrogen and water.

- Monitoring: NOx sensors monitor the levels of NOx in the exhaust. The ECU adjusts the DEF injection rate to maintain optimal NOx reduction.

1.3. Importance of a Properly Functioning AdBlue System

- Environmental Compliance: Ensures the vehicle meets strict emissions standards, helping to reduce air pollution.

- Vehicle Performance: A malfunctioning AdBlue system can trigger limp mode, reducing engine power and fuel efficiency.

- Prevents Costly Repairs: Addressing AdBlue system issues early can prevent damage to other components, such as the catalytic converter.

2. Common Symptoms of a Failing Mercedes AdBlue Pump

Identifying the symptoms of a failing AdBlue pump early can save you time and money. Here’s what to look for:

2.1. Warning Lights and Error Messages

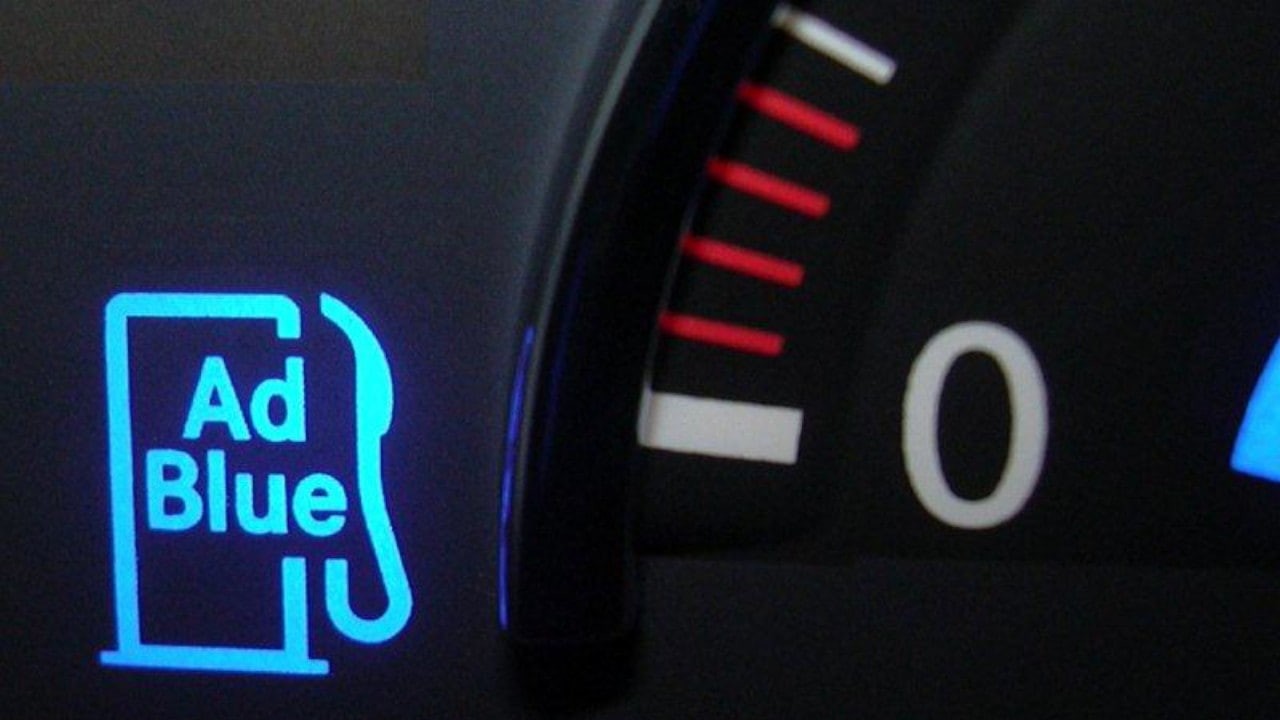

The most obvious sign is the appearance of warning lights on your dashboard. Common error messages include:

- “Check AdBlue System”

- “AdBlue Malfunction”

- “Incorrect AdBlue Dosage”

- “Engine Start Not Possible in [distance]”

2.2. Reduced Engine Power (Limp Mode)

When the AdBlue system detects a problem, it may trigger limp mode, which limits engine power to prevent further damage and reduce emissions.

2.3. Increased Emissions

A faulty AdBlue pump can lead to increased NOx emissions, which may be detected during an emissions test.

2.4. AdBlue Fluid Leaks

Check for leaks around the AdBlue pump or tank. DEF is corrosive and can damage other components if left unattended.

2.5. Unusual Noises from the Pump

Listen for unusual noises, such as loud humming, buzzing, or grinding sounds, coming from the AdBlue pump area. These noises can indicate a failing pump motor.

3. Diagnosing a Faulty Mercedes AdBlue Pump

Proper diagnosis is essential before replacing the AdBlue pump. Here’s a step-by-step guide to help you pinpoint the issue:

3.1. Visual Inspection

- Check for Leaks: Look for signs of DEF leaks around the pump, tank, and lines.

- Inspect Wiring: Examine the wiring and connectors for damage, corrosion, or loose connections.

- Examine the Tank: Ensure the AdBlue tank is not damaged and the fluid level is correct.

3.2. Using an OBD-II Scanner

An OBD-II scanner can provide valuable diagnostic information.

- Connect the Scanner: Plug the scanner into the OBD-II port, typically located under the dashboard.

- Read Diagnostic Trouble Codes (DTCs): Look for codes related to the AdBlue system, such as P203A, P203B, P203C, P203D, P2047, and P2048.

- Live Data: Use the scanner to monitor live data from the AdBlue system, such as pump pressure, injector activity, and NOx sensor readings.

3.3. Testing the AdBlue Pump

- Voltage Test: Use a multimeter to check the voltage at the pump connector. Ensure the pump is receiving the correct voltage (typically 12V).

- Continuity Test: Check the continuity of the pump motor windings. An open circuit indicates a faulty motor.

- Activation Test: Use a diagnostic tool to activate the pump and check its operation. Listen for any unusual noises or vibrations.

3.4. Professional Diagnostic Services

If you’re unsure about diagnosing the problem yourself, consider seeking professional diagnostic services from a qualified mechanic. They have specialized tools and expertise to accurately diagnose AdBlue system issues. CARDIAGTECH.NET can recommend trusted professionals in your area.

4. Tools and Materials Needed for Mercedes AdBlue Pump Replacement

Having the right tools and materials on hand will make the replacement process smoother and more efficient. Here’s a comprehensive list:

4.1. Essential Tools

- Socket Set: Metric socket set for removing and installing bolts and nuts.

- Wrench Set: Metric wrench set for various fasteners.

- Hex Key Set (Allen Wrenches): For removing the pump from the heater.

- Screwdrivers: Phillips head and flathead screwdrivers.

- Pliers: For removing hoses and connectors.

- OBD-II Scanner: To read and clear diagnostic trouble codes (DTCs).

- Multimeter: For testing voltage and continuity.

- Fluid Drain Pan: To catch any spilled AdBlue fluid.

- Torque Wrench: To ensure bolts are tightened to the correct torque specifications.

4.2. Necessary Materials

- New AdBlue Pump: Purchase a high-quality replacement pump from a reputable supplier like Bosch, available through CARDIAGTECH.NET.

- New AdBlue Fluid: To refill the tank after the replacement.

- Gloves: To protect your hands from DEF.

- Safety Glasses: To protect your eyes from splashes.

- Rags or Shop Towels: To clean up any spills.

- Penetrating Oil: To loosen any corroded bolts.

4.3. Optional but Helpful Tools

- Vehicle Lift: Makes accessing the AdBlue pump much easier.

- AdBlue Refractometer: To check the quality of the AdBlue fluid.

- Diagnostic Software: Mercedes-specific diagnostic software for advanced troubleshooting.

5. Step-by-Step Guide to Mercedes AdBlue Pump Replacement

Replacing the AdBlue pump on your Mercedes can be a straightforward process if you follow these steps carefully.

5.1. Preparation

- Safety First: Wear safety glasses and gloves to protect yourself from DEF, which can be corrosive.

- Gather Tools and Materials: Ensure you have all the necessary tools and materials on hand.

- Park the Vehicle: Park the vehicle on a level surface and engage the parking brake.

- Disconnect the Battery: Disconnect the negative battery terminal to prevent electrical shorts.

5.2. Accessing the AdBlue Pump

- Locate the AdBlue Tank: The AdBlue tank is typically located under the vehicle, near the fuel tank.

- Remove the Underbody Shield: Remove the underbody shield to access the AdBlue tank and pump.

- Lower the Tank (if necessary): If you are replacing the pump only, you may not need to remove the tank completely. However, lowering it slightly can provide easier access. Use a jack or stand to support the tank.

5.3. Removing the Old AdBlue Pump

Alternative Text: Leaking and crystallized old AdBlue pump, indicating failure and need for replacement.

- Disconnect Electrical Connectors: Disconnect the electrical connectors from the AdBlue pump. Be careful not to damage the connectors.

- Disconnect Fluid Lines: Disconnect the fluid lines from the pump. Use pliers to loosen the clamps if necessary. Have a drain pan ready to catch any spilled DEF.

- Remove Mounting Bolts: Use a hex key (Allen wrench) to remove the three socket head cap screws holding the pump to the heater.

- Remove the Pump: Carefully remove the old AdBlue pump.

5.4. Installing the New AdBlue Pump

Alternative Text: New Bosch AdBlue pump, a high-quality replacement part ensuring optimal performance and reliability.

- Install New Seals: Install the new rubber washer in the heater and the smaller O-ring on the pump. These come new with the replacement kit.

- Position the Pump: Position the new AdBlue pump in place.

- Install Mounting Bolts: Install the mounting bolts and tighten them to the correct torque specifications.

- Connect Fluid Lines: Connect the fluid lines to the pump and secure them with clamps.

- Connect Electrical Connectors: Connect the electrical connectors to the pump.

5.5. Final Steps

- Reinstall the Underbody Shield: Reinstall the underbody shield.

- Reconnect the Battery: Reconnect the negative battery terminal.

- Refill AdBlue Tank: Refill the AdBlue tank with new AdBlue fluid.

- Clear Diagnostic Trouble Codes: Use an OBD-II scanner to clear any diagnostic trouble codes.

- Test the System: Start the engine and monitor the AdBlue system for proper operation. Check for leaks and ensure there are no warning lights on the dashboard.

6. Common Mistakes to Avoid During AdBlue Pump Replacement

Even experienced mechanics can make mistakes. Here are some common pitfalls to avoid during AdBlue pump replacement:

6.1. Neglecting Safety Precautions

DEF is corrosive and can cause skin and eye irritation. Always wear safety glasses and gloves when working with the AdBlue system.

6.2. Using Incorrect Tools

Using the wrong tools can damage components and make the job more difficult. Ensure you have the correct tools for the job.

6.3. Overtightening Bolts

Overtightening bolts can strip threads and damage components. Use a torque wrench to tighten bolts to the correct specifications.

6.4. Ignoring Diagnostic Trouble Codes

Failing to clear diagnostic trouble codes can prevent the system from functioning properly. Always clear DTCs after replacing the AdBlue pump.

6.5. Using Low-Quality Replacement Parts

Using low-quality replacement parts can lead to premature failure and further problems. Invest in high-quality parts from reputable suppliers like Bosch, available through CARDIAGTECH.NET.

7. Maintaining Your Mercedes AdBlue System

Proper maintenance can extend the life of your AdBlue system and prevent costly repairs. Here are some tips:

7.1. Use High-Quality AdBlue Fluid

Using high-quality AdBlue fluid ensures the system operates efficiently and prevents contamination. CARDIAGTECH.NET recommends using AdBlue fluid that meets ISO 22241 standards.

7.2. Regular Inspections

Regularly inspect the AdBlue system for leaks, damage, and corrosion. Address any issues promptly to prevent further damage.

7.3. Proper Storage of AdBlue Fluid

Store AdBlue fluid in a cool, dry place, away from direct sunlight. Ensure the container is tightly sealed to prevent contamination.

7.4. Avoid Overfilling the AdBlue Tank

Overfilling the AdBlue tank can damage the system. Fill the tank to the recommended level, as indicated in your vehicle’s owner’s manual.

7.5. Periodic System Checks with Diagnostic Tools

Regularly use a diagnostic tool to check the AdBlue system for any potential issues. Early detection can prevent major problems.

8. The Role of CARDIAGTECH.NET in Your AdBlue Pump Replacement

At CARDIAGTECH.NET, we understand the challenges of maintaining and repairing modern vehicles. We offer a range of tools and resources to help you tackle AdBlue pump replacement with confidence.

8.1. High-Quality Replacement Parts

We offer high-quality Mercedes AdBlue pumps from trusted manufacturers like Bosch. Our pumps are designed to meet or exceed OEM specifications, ensuring reliable performance and long life.

8.2. Comprehensive Diagnostic Tools

Our selection of OBD-II scanners and diagnostic software can help you accurately diagnose AdBlue system issues. These tools provide valuable data and insights, making the repair process more efficient.

8.3. Expert Technical Support

Our team of experienced technicians is available to provide expert technical support. Whether you have questions about diagnosing a problem or need help with the replacement process, we’re here to assist you. Contact us via Whatsapp at +1 (641) 206-8880 for immediate assistance.

8.4. Educational Resources

We offer a range of educational resources, including articles, videos, and guides, to help you understand the AdBlue system and perform repairs with confidence.

8.5. Competitive Pricing

We offer competitive pricing on all our products, ensuring you get the best value for your money.

9. The Financial Benefits of DIY AdBlue Pump Replacement

While professional repairs offer convenience, DIY AdBlue pump replacement can save you significant money.

9.1. Cost Comparison

| Service | Dealership Cost | Independent Mechanic Cost | DIY Cost (Parts & Tools) |

|---|---|---|---|

| AdBlue Pump Replacement | $1,200 – $1,800 | $800 – $1,200 | $300 – $600 |

As the table illustrates, DIY AdBlue pump replacement can save you hundreds of dollars compared to professional services.

9.2. Long-Term Savings

By performing the replacement yourself, you gain the knowledge and skills to handle future repairs. This can save you even more money in the long run.

9.3. Investing in Quality Tools

While you’ll need to invest in tools, these tools can be used for other repairs, making them a worthwhile investment. CARDIAGTECH.NET offers a wide range of high-quality tools at competitive prices.

10. Environmental Responsibility and the AdBlue System

The AdBlue system plays a vital role in reducing harmful emissions and protecting the environment.

10.1. Reducing NOx Emissions

NOx emissions contribute to smog and acid rain, which can harm human health and the environment. The AdBlue system reduces NOx emissions by up to 90%.

10.2. Compliance with Emissions Standards

By maintaining a properly functioning AdBlue system, you ensure your vehicle complies with emissions standards and avoid potential fines.

10.3. Contributing to Cleaner Air

By reducing emissions, you contribute to cleaner air and a healthier environment for everyone.

11. Advanced Troubleshooting Techniques for the AdBlue System

For those with more experience, advanced troubleshooting techniques can help diagnose complex AdBlue system issues.

11.1. Using Mercedes-Specific Diagnostic Software

Mercedes-specific diagnostic software, such as XENTRY or DAS, provides advanced diagnostic capabilities. This software allows you to perform detailed system tests, access wiring diagrams, and reprogram components.

11.2. Analyzing Live Data Streams

Analyzing live data streams from the AdBlue system can provide valuable insights. Monitor parameters such as pump pressure, injector activity, NOx sensor readings, and temperature to identify anomalies.

11.3. Performing Component-Level Testing

Component-level testing involves testing individual components, such as the NOx sensors, injector, and pump motor, to determine if they are functioning properly. This requires specialized tools and knowledge.

11.4. Checking Wiring and Connections

Thoroughly inspect the wiring and connections for damage, corrosion, and loose connections. Use a multimeter to check for continuity and voltage drops.

11.5. Evaluating AdBlue Fluid Quality

Use an AdBlue refractometer to check the quality of the AdBlue fluid. Contaminated or diluted fluid can cause system problems.

12. Upgrading Your Mercedes AdBlue System

Consider upgrading your AdBlue system for improved performance and reliability.

12.1. High-Performance AdBlue Pumps

Upgrade to a high-performance AdBlue pump for improved flow and pressure. This can enhance the efficiency of the SCR process and reduce emissions.

12.2. Enhanced NOx Sensors

Install enhanced NOx sensors for more accurate readings and faster response times. This can help the ECU optimize DEF injection and reduce emissions.

12.3. Improved Injectors

Upgrade to improved injectors for better atomization and distribution of DEF. This can enhance the efficiency of the SCR process and reduce emissions.

12.4. AdBlue Tank Heaters

Install an AdBlue tank heater to prevent the fluid from freezing in cold weather. This ensures the system operates properly in all conditions.

13. The Future of AdBlue Technology

AdBlue technology is continuously evolving to meet increasingly stringent emissions standards.

13.1. Integrated AdBlue Systems

Future AdBlue systems may be integrated more closely with the engine management system for improved control and efficiency.

13.2. Advanced Monitoring and Diagnostics

Advanced monitoring and diagnostics will provide real-time feedback on system performance, allowing for proactive maintenance and repairs.

13.3. Electric AdBlue Pumps

Electric AdBlue pumps offer improved efficiency and reliability compared to traditional mechanical pumps.

13.4. Solid-State AdBlue Injectors

Solid-state AdBlue injectors offer faster response times and more precise control over DEF injection.

14. Why Choose CARDIAGTECH.NET for Your Automotive Needs?

At CARDIAGTECH.NET, we are committed to providing our customers with the highest quality tools, parts, and services.

14.1. Extensive Product Selection

We offer an extensive selection of automotive tools and parts, including Mercedes AdBlue pumps, diagnostic tools, and more.

14.2. Expert Advice

Our team of experienced technicians is available to provide expert advice and support.

14.3. Competitive Pricing

We offer competitive pricing on all our products, ensuring you get the best value for your money.

14.4. Fast Shipping

We offer fast shipping on all orders, so you can get the parts you need quickly.

14.5. Customer Satisfaction Guarantee

We are committed to customer satisfaction. If you are not satisfied with your purchase, simply return it for a full refund.

15. Real-World Case Studies: Mercedes AdBlue Pump Replacement

Let’s look at some real-world case studies to illustrate the benefits of DIY AdBlue pump replacement.

15.1. Case Study 1: John’s Mercedes ML350

John, a DIY enthusiast, noticed the “Check AdBlue System” warning light on his Mercedes ML350. Using an OBD-II scanner from CARDIAGTECH.NET, he diagnosed a faulty AdBlue pump. He purchased a replacement pump from us and followed our step-by-step guide to replace the pump himself. John saved over $800 compared to taking his vehicle to the dealership.

15.2. Case Study 2: Sarah’s Mercedes E250

Sarah, a professional mechanic, diagnosed a faulty AdBlue pump on her Mercedes E250. She purchased a high-performance pump from CARDIAGTECH.NET and installed it in her garage. She noticed improved engine performance and reduced emissions after the replacement.

15.3. Case Study 3: Mark’s Mercedes GL320

Mark, a fleet manager, experienced frequent AdBlue system failures on his Mercedes GL320 vehicles. He purchased a bulk order of AdBlue pumps from CARDIAGTECH.NET and trained his mechanics to perform the replacements. This saved his company thousands of dollars in repair costs.

16. AdBlue System FAQs

Here are some frequently asked questions about the AdBlue system:

16.1. What is AdBlue?

AdBlue, also known as Diesel Exhaust Fluid (DEF), is a urea-based solution used in Selective Catalytic Reduction (SCR) systems to reduce NOx emissions from diesel engines.

16.2. How often do I need to refill the AdBlue tank?

The frequency of AdBlue refills depends on your vehicle and driving conditions. Typically, you’ll need to refill the tank every 5,000 to 10,000 miles.

16.3. Can I use any type of AdBlue fluid?

No, you should only use AdBlue fluid that meets ISO 22241 standards. Using the wrong type of fluid can damage the AdBlue system.

16.4. What happens if I run out of AdBlue?

If you run out of AdBlue, your vehicle may enter limp mode, which limits engine power. You may also be unable to start the engine until you refill the tank.

16.5. Can I bypass the AdBlue system?

Bypassing the AdBlue system is illegal and can result in fines. It can also damage your vehicle and increase emissions.

16.6. How do I check the AdBlue fluid level?

You can check the AdBlue fluid level using the vehicle’s information display or by visually inspecting the tank.

16.7. What are the common problems with the AdBlue system?

Common problems include a faulty AdBlue pump, clogged injector, damaged NOx sensors, and contaminated fluid.

16.8. How do I diagnose AdBlue system problems?

You can diagnose AdBlue system problems using an OBD-II scanner to read diagnostic trouble codes and by performing visual inspections and component testing.

16.9. Can I replace the AdBlue pump myself?

Yes, you can replace the AdBlue pump yourself if you have the necessary tools and knowledge. CARDIAGTECH.NET provides the tools and resources to help you with the replacement process.

16.10. How much does it cost to replace the AdBlue pump?

The cost of replacing the AdBlue pump varies depending on the vehicle and the repair method. DIY replacement can cost between $300 and $600, while professional replacement can cost between $800 and $1,800.

17. Contact CARDIAGTECH.NET for Expert Assistance

Don’t let a faulty AdBlue pump compromise your vehicle’s performance and environmental compliance. Contact CARDIAGTECH.NET today for high-quality replacement parts, diagnostic tools, and expert technical support.

17.1. Contact Information

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- Whatsapp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

17.2. Call to Action

Ready to replace your Mercedes AdBlue pump and save money? Contact CARDIAGTECH.NET now for expert advice and the best tools and parts on the market. Our team is ready to help you diagnose the problem, select the right replacement pump, and guide you through the installation process. Don’t wait—ensure your vehicle meets emissions standards and performs optimally. Contact us today via Whatsapp at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET.