Mercedes AdBlue Sensor: Troubleshooting, Replacement & Solutions

Mercedes AdBlue sensor problems can be a real headache. This comprehensive guide, brought to you by CARDIAGTECH.NET, dives deep into the intricacies of the Mercedes AdBlue system, focusing on the AdBlue sensor. We’ll explore troubleshooting techniques, replacement procedures, and preventative measures to keep your Mercedes running smoothly and efficiently. We aim to provide you with expert insights and practical solutions for your Mercedes diesel exhaust fluid (DEF) system.

1. Understanding the Mercedes AdBlue System and Its Components

The Mercedes AdBlue system, also known as Selective Catalytic Reduction (SCR), is designed to reduce harmful nitrogen oxide (NOx) emissions from diesel engines. This system uses a diesel exhaust fluid (DEF), commonly known as AdBlue, which is a mixture of urea and deionized water. The AdBlue is injected into the exhaust stream, where it reacts with NOx in the catalytic converter, converting them into harmless nitrogen and water. A properly functioning AdBlue system is crucial for meeting emission standards and ensuring optimal engine performance. The key components include the AdBlue tank, pump, injector, and, of course, the AdBlue sensor.

1.1 Key Components of the AdBlue System

Here’s a detailed look at the main parts:

- AdBlue Tank: Stores the AdBlue fluid. Its size varies depending on the vehicle model.

- AdBlue Pump: Delivers AdBlue from the tank to the injector. It is responsible for maintaining the correct pressure and flow rate.

- AdBlue Injector: Sprays AdBlue into the exhaust stream.

- AdBlue Sensor: Monitors the level and quality of AdBlue in the tank. It sends data to the engine control unit (ECU).

1.2 The Role of the AdBlue Sensor

The AdBlue sensor plays a critical role in the system. It monitors the level and quality of the AdBlue fluid in the tank, relaying this information to the engine control unit (ECU). This data is crucial for:

- Preventing System Malfunctions: If the AdBlue level is too low, the sensor alerts the driver and eventually restricts engine performance to prevent damage.

- Ensuring Proper Emission Control: The sensor ensures the AdBlue fluid meets the required quality standards for effective NOx reduction.

- Facilitating Diagnostics: The sensor provides data that can help diagnose issues within the AdBlue system.

2. Common Symptoms of a Faulty Mercedes AdBlue Sensor

When a Mercedes AdBlue sensor malfunctions, it can trigger a range of symptoms, some of which can severely impact your vehicle’s performance. Recognizing these signs early can help prevent further damage and costly repairs. Here’s what to look out for:

2.1 Warning Lights and Error Messages

One of the first indicators of an AdBlue sensor issue is the illumination of the check engine light or specific AdBlue warning lights on the dashboard. These lights are often accompanied by error messages displayed on the vehicle’s information screen. Common messages include “AdBlue level low,” “Check AdBlue system,” or “AdBlue quality poor.”

2.2 Inaccurate AdBlue Level Readings

A faulty sensor might provide incorrect readings of the AdBlue level. This can manifest as the gauge showing full when the tank is nearly empty, or vice versa. Such inaccuracies can lead to unnecessary top-ups or, more critically, running out of AdBlue when the system indicates otherwise, potentially causing engine performance limitations.

2.3 Engine Performance Issues

The AdBlue system is directly linked to the engine’s performance management. If the AdBlue sensor isn’t functioning correctly, the ECU might restrict engine power to prevent excessive emissions. This can result in reduced acceleration, decreased top speed, and overall sluggish performance. In some cases, the engine might enter a limp mode, limiting its speed to a crawl.

2.4 AdBlue System Failure

In severe cases, a faulty AdBlue sensor can lead to the complete failure of the AdBlue system. This can happen if the sensor provides consistently incorrect data, causing the ECU to shut down the system to prevent potential damage. A complete system failure often requires professional intervention and could lead to significant repair costs.

2.5 Mileage Countdown

Some Mercedes models feature a mileage countdown that activates when an AdBlue issue is detected. This countdown indicates the number of miles or kilometers the vehicle can travel before it enters a restricted performance mode or shuts down completely. If you’re experiencing this countdown despite having sufficient AdBlue, it’s a strong sign of a sensor problem.

These are typical warning signs and failure patterns. If you experience any of these, it’s recommended to seek immediate professional assistance.

3. Diagnosing a Mercedes AdBlue Sensor Problem

Diagnosing an AdBlue sensor problem requires a systematic approach. Here are the key steps involved:

3.1 Initial Inspection

Begin with a visual inspection of the AdBlue system. Check for any signs of leaks, damage, or corrosion around the AdBlue tank, pump, and injector. Ensure the AdBlue tank is properly filled with high-quality fluid.

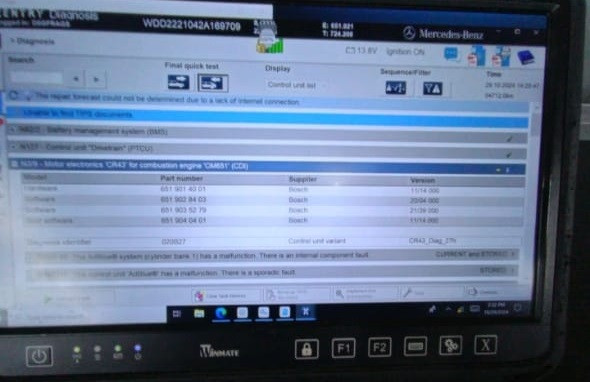

3.2 Using an OBD-II Scanner

An OBD-II scanner is an essential tool for diagnosing AdBlue system issues. Connect the scanner to your vehicle’s diagnostic port and retrieve any stored trouble codes. Common codes related to the AdBlue sensor include:

- P203B: Reductant Level Sensor Circuit Range/Performance

- P203A: Reductant Level Sensor Circuit

- P2047: Reductant Injector Circuit Open

- P204F: Reductant System Performance

3.3 Live Data Analysis

Use the OBD-II scanner to access live data from the AdBlue sensor. Monitor the sensor’s readings for AdBlue level and quality. Compare these readings with the actual AdBlue level in the tank and the manufacturer’s specifications for fluid quality. Inconsistencies indicate a potential sensor malfunction.

3.4 Multimeter Testing

A multimeter can be used to test the electrical continuity and voltage of the AdBlue sensor and its wiring. Refer to the vehicle’s service manual for the correct testing procedures and voltage ranges.

3.5 Component Testing

If the above tests are inconclusive, you may need to perform component-specific tests. This could involve testing the sensor’s resistance or using a specialized diagnostic tool to simulate different AdBlue levels and observe the sensor’s response.

4. Step-by-Step Guide to Replacing a Mercedes AdBlue Sensor

Replacing a Mercedes AdBlue sensor can be a straightforward process if you have the right tools and follow the correct steps. Here’s a detailed guide:

4.1 Tools and Materials Needed

- New Mercedes AdBlue sensor (Part number: A0145428717 or equivalent)

- OBD-II scanner

- Socket set

- Wrench set

- Screwdrivers (flathead and Phillips)

- Multimeter

- Safety glasses

- Gloves

- Drain pan (if draining the AdBlue tank)

- Torque wrench

4.2 Preparation

- Safety First: Wear safety glasses and gloves to protect yourself from AdBlue fluid, which can be corrosive.

- Locate the AdBlue Sensor: The AdBlue sensor is typically located on the AdBlue tank, either on top or on the side. Refer to your vehicle’s service manual for the exact location.

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical shorts during the replacement process.

4.3 Removal of the Old Sensor

- Drain the AdBlue Tank (If Necessary): If the sensor is located at the bottom of the tank, you may need to drain the AdBlue fluid to prevent spillage. Use a drain pan to collect the fluid.

- Disconnect the Electrical Connector: Carefully disconnect the electrical connector from the AdBlue sensor.

- Remove the Sensor: Use the appropriate socket or wrench to remove the AdBlue sensor from the tank. Be careful not to damage the tank or surrounding components.

4.4 Installation of the New Sensor

- Install the New Sensor: Carefully install the new AdBlue sensor into the tank. Ensure it is properly seated and tightened to the manufacturer’s specified torque.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the new AdBlue sensor.

- Refill the AdBlue Tank (If Drained): If you drained the AdBlue tank, refill it with high-quality AdBlue fluid to the correct level.

4.5 Verification and Testing

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Clear Trouble Codes: Use the OBD-II scanner to clear any trouble codes related to the AdBlue system.

- Test the System: Start the engine and monitor the AdBlue level readings on the dashboard. Ensure the system is functioning correctly and there are no warning lights or error messages.

- Road Test: Take the vehicle for a short road test to ensure the AdBlue system is working properly under normal driving conditions.

5. Preventing AdBlue Sensor Failures

While AdBlue sensor failures can be frustrating, there are several steps you can take to prevent them.

5.1 Use High-Quality AdBlue Fluid

Always use high-quality AdBlue fluid that meets the ISO 22241 standard. Avoid using generic or low-quality fluids, as they may contain impurities that can damage the sensor and other components.

5.2 Regular AdBlue Level Maintenance

Maintain the AdBlue level in the tank above the minimum level. Running the tank completely empty can cause the pump to run dry and potentially damage the sensor.

5.3 Avoid Contamination

Prevent contamination of the AdBlue fluid. Use a clean funnel when filling the tank and avoid introducing any foreign materials.

5.4 Regular System Checks

Perform regular checks of the AdBlue system. Monitor the AdBlue level, inspect for leaks, and use an OBD-II scanner to check for any trouble codes.

5.5 Proper Storage

Store AdBlue fluid in a cool, dry place away from direct sunlight. Avoid storing it in metal containers, as this can cause corrosion and contamination.

5.6 AdBlue Additives

Consider using AdBlue additives that help prevent crystallization and maintain the cleanliness of the system.

6. The Importance of Professional Servicing

While some AdBlue sensor issues can be resolved with DIY repairs, others require professional servicing.

6.1 When to Seek Professional Help

Seek professional help if:

- You are not comfortable performing the repairs yourself.

- You lack the necessary tools or diagnostic equipment.

- The problem persists after attempting DIY repairs.

- The AdBlue system has suffered significant damage.

6.2 Benefits of Professional Servicing

Professional servicing offers several benefits:

- Expert Diagnosis: Trained technicians have the knowledge and experience to accurately diagnose complex AdBlue system issues.

- Specialized Tools: Professionals have access to specialized diagnostic tools and equipment.

- Quality Parts: They use high-quality replacement parts.

- Warranty: Professional repairs often come with a warranty.

7. Factors Affecting the Lifespan of a Mercedes AdBlue Sensor

The lifespan of a Mercedes AdBlue sensor can vary depending on several factors. Understanding these factors can help you take proactive measures to extend the sensor’s life.

7.1 Quality of AdBlue Fluid

As mentioned earlier, using high-quality AdBlue fluid is crucial. Low-quality fluids can contain contaminants that accelerate sensor wear and tear.

7.2 Environmental Conditions

Extreme temperatures, humidity, and exposure to corrosive elements can affect the sensor’s lifespan.

7.3 Driving Habits

Aggressive driving habits and frequent short trips can put extra strain on the AdBlue system, potentially shortening the sensor’s life.

7.4 Maintenance Practices

Regular maintenance, including fluid level checks and system inspections, can help identify and address potential issues before they cause sensor failure.

7.5 Vehicle Age and Mileage

Like any other component, the AdBlue sensor is subject to wear and tear over time. Older vehicles with high mileage are more likely to experience sensor failures.

8. Cost Analysis: AdBlue Sensor Replacement

The cost of replacing a Mercedes AdBlue sensor can vary depending on several factors, including the vehicle model, the location of the repair shop, and whether you opt for a genuine Mercedes part or an aftermarket alternative. Here’s a general breakdown:

8.1 Component Costs

The AdBlue sensor itself typically costs between $75 and $200, depending on the brand and supplier. Genuine Mercedes parts tend to be more expensive than aftermarket options.

8.2 Labor Costs

Labor costs can range from $150 to $400, depending on the complexity of the job and the hourly rate of the repair shop. Some models may require more extensive disassembly to access the sensor, increasing labor time.

8.3 Additional Costs

In some cases, additional costs may include:

- Diagnostic fees (if the shop charges separately for diagnosis)

- AdBlue fluid (if the tank needs to be drained and refilled)

- Taxes

8.4 Cost-Saving Tips

- Shop Around: Get quotes from multiple repair shops to compare prices.

- Consider Aftermarket Parts: Aftermarket parts can be a cost-effective alternative to genuine Mercedes parts.

- DIY Repair: If you are comfortable with DIY repairs, you can save on labor costs by replacing the sensor yourself.

9. The Role of CARDIAGTECH.NET in AdBlue System Maintenance

At CARDIAGTECH.NET, we understand the importance of maintaining your Mercedes AdBlue system for optimal performance and emissions control. We offer a wide range of diagnostic tools and equipment to help you troubleshoot and repair AdBlue system issues.

9.1 Diagnostic Tools

We provide high-quality OBD-II scanners that can read and clear AdBlue system trouble codes, as well as access live data from the AdBlue sensor.

9.2 Replacement Parts

We offer a comprehensive selection of genuine and aftermarket AdBlue sensors, pumps, and other components.

9.3 Expert Support

Our team of experienced technicians is available to provide expert advice and support to help you diagnose and resolve AdBlue system problems.

9.4 Why Choose CARDIAGTECH.NET

- Quality Products: We offer only the highest quality diagnostic tools and replacement parts.

- Competitive Prices: Our prices are competitive and transparent.

- Expert Support: Our team of experienced technicians is here to help you every step of the way.

- Customer Satisfaction: We are committed to providing excellent customer service.

Don’t let AdBlue system issues keep you off the road. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 for expert advice and high-quality products. Our address is 276 Reock St, City of Orange, NJ 07050, United States. You can also visit our website CARDIAGTECH.NET for more information.

10. AdBlue Sensor Technology: Current Innovations and Future Trends

AdBlue sensor technology is continuously evolving to meet stricter emission standards and improve vehicle performance. Here are some current innovations and future trends:

10.1 Advanced Sensor Materials

Researchers are developing new sensor materials that are more durable, resistant to corrosion, and capable of operating in extreme temperatures.

10.2 Wireless Sensors

Wireless AdBlue sensors are being developed to eliminate the need for physical wiring, reducing the risk of electrical failures and simplifying installation.

10.3 Smart Sensors

Smart sensors incorporate microprocessors that can perform onboard diagnostics and provide more detailed information about AdBlue fluid quality and system performance.

10.4 Integrated Systems

Future AdBlue systems may integrate the sensor with other components, such as the pump and injector, to create a more compact and efficient system.

10.5 Predictive Maintenance

Advanced diagnostic tools and algorithms are being developed to predict potential AdBlue sensor failures before they occur, enabling proactive maintenance and preventing downtime.

11. Case Studies: Real-World AdBlue Sensor Issues and Resolutions

Examining real-world case studies can provide valuable insights into common AdBlue sensor issues and their resolutions. Here are a few examples:

11.1 Case Study 1: Inaccurate AdBlue Level Reading

Problem: A Mercedes C-Class owner reported that the AdBlue level gauge showed full despite the tank being nearly empty. The check engine light was illuminated, and the vehicle entered a reduced performance mode.

Diagnosis: An OBD-II scanner revealed a P203B code, indicating a problem with the reductant level sensor circuit. Live data analysis confirmed that the sensor was providing inaccurate readings.

Resolution: The AdBlue sensor was replaced with a new unit from CARDIAGTECH.NET. The trouble codes were cleared, and the system was tested to ensure proper functionality. The vehicle’s performance returned to normal.

11.2 Case Study 2: AdBlue System Failure Due to Contamination

Problem: A Mercedes E-Class owner experienced a complete AdBlue system failure. The vehicle displayed an “AdBlue system malfunction” message, and the engine would not start.

Diagnosis: Inspection revealed that the AdBlue tank was contaminated with debris. The AdBlue sensor was clogged and unable to provide accurate readings.

Resolution: The AdBlue tank was drained and cleaned. The AdBlue sensor and injector were replaced. High-quality AdBlue fluid was used to refill the tank. The system was tested, and the vehicle was returned to service.

11.3 Case Study 3: Premature Sensor Failure Due to Low-Quality Fluid

Problem: A Mercedes S-Class owner experienced premature AdBlue sensor failure after using low-quality AdBlue fluid. The sensor failed after only 20,000 miles.

Diagnosis: Analysis of the failed sensor revealed corrosion and damage caused by impurities in the low-quality fluid.

Resolution: The AdBlue sensor was replaced with a new unit. The AdBlue tank was drained and refilled with high-quality fluid. The owner was advised to use only high-quality AdBlue fluid in the future.

12. Mercedes AdBlue Sensor: FAQs

Here are some frequently asked questions about Mercedes AdBlue sensors:

12.1 What is an AdBlue sensor?

An AdBlue sensor monitors the level and quality of AdBlue fluid in the tank, providing data to the engine control unit (ECU) for proper emissions control.

12.2 Where is the AdBlue sensor located?

The AdBlue sensor is typically located on the AdBlue tank, either on top or on the side. Refer to your vehicle’s service manual for the exact location.

12.3 What are the symptoms of a faulty AdBlue sensor?

Symptoms include warning lights, inaccurate AdBlue level readings, engine performance issues, and AdBlue system failure.

12.4 How can I diagnose an AdBlue sensor problem?

Use an OBD-II scanner to retrieve trouble codes and access live data from the sensor. Perform visual inspections and multimeter testing.

12.5 Can I replace the AdBlue sensor myself?

Yes, if you have the necessary tools and follow the correct steps. However, some repairs may require professional servicing.

12.6 How much does it cost to replace an AdBlue sensor?

The cost can range from $225 to $600, depending on the vehicle model, the location of the repair shop, and the parts used.

12.7 How can I prevent AdBlue sensor failures?

Use high-quality AdBlue fluid, maintain the AdBlue level, avoid contamination, and perform regular system checks.

12.8 What is the lifespan of an AdBlue sensor?

The lifespan can vary depending on several factors, including the quality of the AdBlue fluid, environmental conditions, and driving habits.

12.9 What is ISO 22241?

ISO 22241 is the international standard for AdBlue fluid. It specifies the quality requirements for AdBlue to ensure proper performance and prevent damage to the SCR system.

12.10 Where can I buy a Mercedes AdBlue sensor?

You can purchase a Mercedes AdBlue sensor from CARDIAGTECH.NET. We offer high-quality diagnostic tools and replacement parts. Contact us today at +1 (641) 206-8880 for expert advice and high-quality products. Our address is 276 Reock St, City of Orange, NJ 07050, United States. You can also visit our website CARDIAGTECH.NET for more information.

Don’t let AdBlue system issues compromise your vehicle’s performance. Trust CARDIAGTECH.NET for all your diagnostic and repair needs. Contact us today and experience the difference. Remember, maintaining your Mercedes AdBlue system is crucial for optimal performance and environmental responsibility.