Mercedes AdBlue System Malfunction: Expert Solutions Guide

The Mercedes AdBlue system malfunction is a frustrating issue for Mercedes-Benz owners, often signaled by a dashboard warning and potential engine performance limitations. At CARDIAGTECH.NET, we understand the complexities of modern automotive systems and offer solutions to keep your Mercedes running smoothly. Let’s explore the causes, symptoms, and effective fixes for AdBlue system troubles, ensuring you get back on the road with confidence and optimal engine performance.

1. Understanding the Mercedes AdBlue System

The Mercedes AdBlue system, also known as Selective Catalytic Reduction (SCR), is a critical component in reducing harmful nitrogen oxide (NOx) emissions from diesel vehicles. This system injects AdBlue, a urea-based solution, into the exhaust stream, where it reacts with NOx in the catalytic converter to produce harmless nitrogen and water. Proper functioning of the AdBlue system is essential for meeting emission standards and maintaining your vehicle’s performance.

- Purpose: Reduces NOx emissions

- Component: Includes a tank, pump, injector, and control unit

- Function: Injects AdBlue into the exhaust to neutralize harmful gases

Mercedes AdBlue Tank Location

Mercedes AdBlue Tank Location

2. Common Causes of Mercedes AdBlue System Malfunction

Several factors can contribute to an AdBlue system malfunction in your Mercedes. Identifying these causes is the first step in effectively addressing the issue.

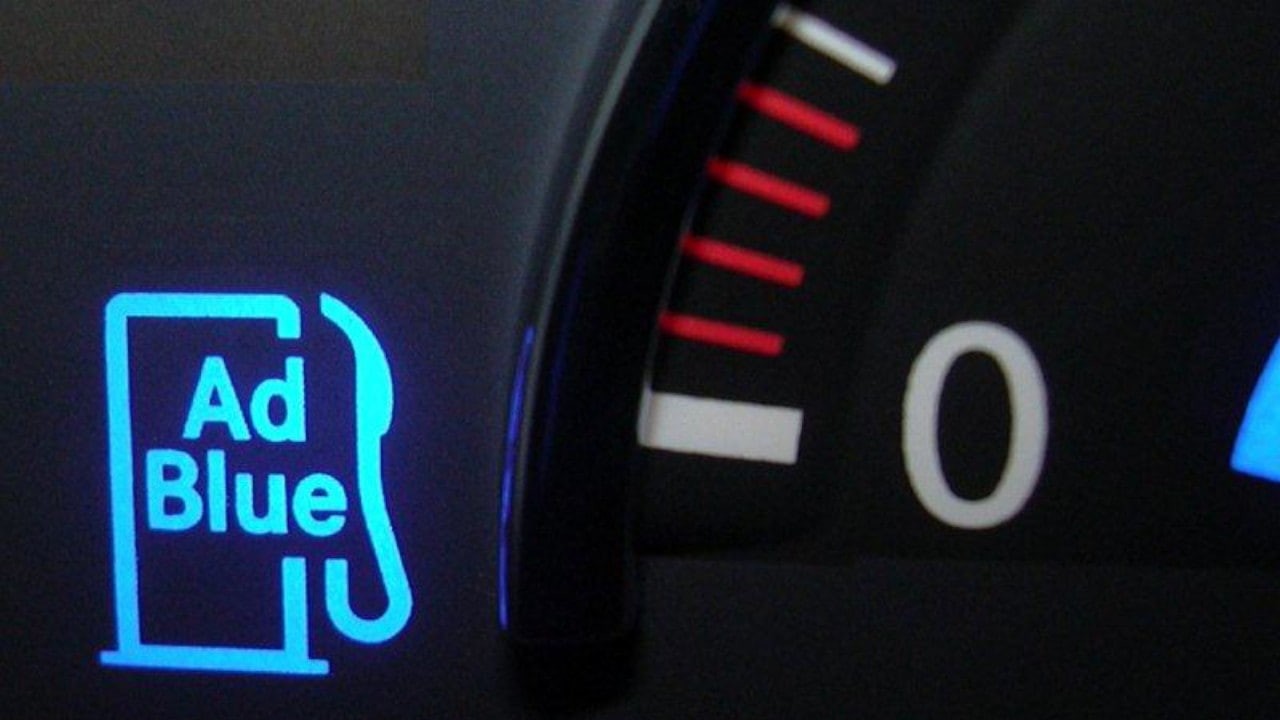

2.1. Low AdBlue Level

The most straightforward cause is simply a low level of AdBlue in the tank. The system will trigger a warning when the level drops below a certain threshold.

- Symptom: “Refill AdBlue” warning message

- Solution: Refill the AdBlue tank with the correct fluid

2.2. Faulty AdBlue Injector

The AdBlue injector can become clogged or fail, preventing the proper amount of fluid from being injected into the exhaust.

- Symptom: Reduced AdBlue consumption

- Solution: Clean or replace the injector

2.3. Malfunctioning AdBlue Pump

The AdBlue pump is responsible for delivering the fluid from the tank to the injector. A faulty pump can disrupt this process.

- Symptom: Inconsistent AdBlue flow

- Solution: Replace the pump

2.4. Clogged AdBlue Filter

The AdBlue system has a filter to prevent contaminants from entering the injector. A clogged filter can restrict AdBlue flow.

- Symptom: Reduced system performance

- Solution: Replace the filter

2.5. Defective NOx Sensor

The NOx sensor monitors the levels of nitrogen oxides in the exhaust. A faulty sensor can provide incorrect readings, leading to system errors.

- Symptom: Incorrect NOx readings

- Solution: Replace the NOx sensor

2.6. Issues with the AdBlue Control Unit

The AdBlue control unit manages the entire system. Software glitches or hardware failures can cause malfunctions.

- Symptom: Erratic system behavior

- Solution: Reprogram or replace the control unit

2.7. Poor Quality AdBlue

Using AdBlue that does not meet the required standards can lead to system damage and malfunctions.

- Symptom: System corrosion or blockages

- Solution: Use only high-quality AdBlue that meets ISO 22241 standards

3. Identifying Symptoms of AdBlue System Problems

Recognizing the symptoms of an AdBlue system malfunction is crucial for early diagnosis and repair.

3.1. Dashboard Warning Lights

The most common symptom is a warning light on the dashboard, often accompanied by a message such as “AdBlue System Fault See Owner’s Manual.”

- Action: Immediately investigate the cause

3.2. Reduced Engine Power

Many Mercedes models will limit engine power if an AdBlue system fault is detected to prevent excessive emissions.

- Action: Address the issue promptly to restore full power

3.3. Increased Emissions

A malfunctioning AdBlue system will result in higher NOx emissions, which can be detected during an emissions test.

- Action: Repair the system to comply with emission standards

3.4. Difficulty Starting the Engine

In some cases, a severe AdBlue system fault can prevent the engine from starting.

- Action: Refill AdBlue tank, if empty. If issue persists, seek professional help.

3.5. Error Codes

Using an OBD-II scanner can reveal specific error codes related to the AdBlue system, aiding in diagnosis. Common codes include:

- P20E8: Reductant pressure too low

- P20EE: SCR NOx catalyst efficiency below threshold

- P204F: Reductant system performance

3.6. Unusual Noises

Unusual noises from the AdBlue pump or injector area can indicate a problem.

- Action: Inspect the components for damage or blockages

4. Step-by-Step Diagnostic Process for Mercedes AdBlue System

A systematic diagnostic approach is essential for accurately identifying and resolving AdBlue system issues.

4.1. Initial Inspection

- Check AdBlue Level: Ensure the AdBlue tank is filled to the appropriate level.

- Visual Inspection: Look for any visible leaks or damage to the AdBlue tank, pump, injector, and lines.

- Inspect the Cap: Make sure the cap is properly sealed.

Technician inspecting the components of an AdBlue system.

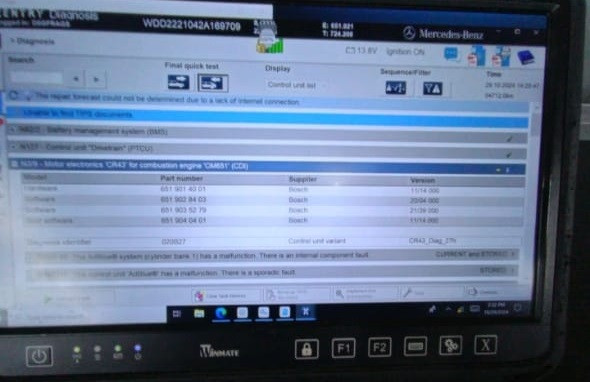

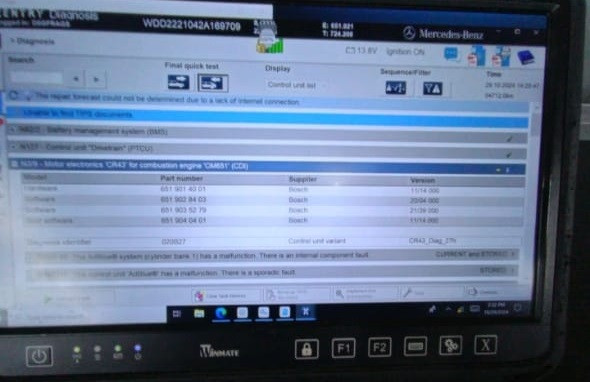

4.2. Using Diagnostic Tools

- Connect OBD-II Scanner: Use an OBD-II scanner to retrieve any stored error codes.

- Live Data Monitoring: Monitor live data from the NOx sensor, AdBlue injector, and pump to check for irregularities.

- Mercedes-Specific Tools: For more in-depth diagnostics, use Mercedes-specific tools like XENTRY to access detailed system information and perform component tests.

4.3. Component Testing

- AdBlue Injector Test: Remove the injector and test its spray pattern. Clean or replace if necessary.

- AdBlue Pump Test: Check the pump’s pressure and flow rate. Replace if it does not meet specifications.

- NOx Sensor Test: Verify the sensor’s accuracy using a multimeter or diagnostic tool.

4.4. Wiring and Electrical Checks

- Inspect Wiring: Check the wiring and connectors for any signs of damage or corrosion.

- Voltage Test: Use a multimeter to check the voltage at the AdBlue pump and injector.

4.5. AdBlue Quality Test

- Refractometer Test: Use a refractometer to verify the concentration of the AdBlue fluid.

- Visual Inspection: Check the fluid for any signs of contamination.

5. Repairing Mercedes AdBlue System Malfunctions

Once you’ve identified the cause of the AdBlue system malfunction, you can proceed with the necessary repairs.

5.1. Refilling AdBlue

- Procedure: Locate the AdBlue filler cap (usually near the fuel filler or in the trunk) and add AdBlue until the tank is full.

- Caution: Avoid overfilling, as this can damage the system.

5.2. Replacing the AdBlue Injector

- Procedure: Disconnect the electrical connector and AdBlue line from the injector. Remove the old injector and install the new one, ensuring a proper seal.

- Torque: Tighten to manufacturer specifications.

5.3. Replacing the AdBlue Pump

- Procedure: Disconnect the electrical connector and AdBlue lines from the pump. Remove the old pump and install the new one.

- Priming: Prime the pump to remove any air from the system.

Replacing a faulty AdBlue delivery pump.

5.4. Replacing the NOx Sensor

- Procedure: Disconnect the electrical connector and remove the old sensor. Install the new sensor and tighten to the correct torque.

- Calibration: Some sensors may require calibration using a diagnostic tool.

5.5. Cleaning or Replacing the AdBlue Filter

- Procedure: Locate the AdBlue filter and remove it. Clean the filter if it is only slightly clogged, or replace it if it is heavily contaminated.

- Orientation: Ensure the new filter is installed in the correct orientation.

5.6. Reprogramming the Control Unit

- Procedure: Use a Mercedes-specific diagnostic tool like XENTRY to reprogram the AdBlue control unit with the latest software.

- Caution: This should only be performed by a qualified technician.

5.7. Addressing Wiring Issues

- Procedure: Repair or replace any damaged wiring or connectors. Use dielectric grease to protect connections from corrosion.

- Testing: Verify the repair by testing the circuit with a multimeter.

6. Preventive Maintenance for Mercedes AdBlue System

Preventive maintenance is key to avoiding AdBlue system malfunctions.

6.1. Use High-Quality AdBlue

- Recommendation: Always use AdBlue that meets ISO 22241 standards.

- Storage: Store AdBlue in a cool, dry place to prevent degradation.

6.2. Regular Inspections

- Frequency: Inspect the AdBlue system at least once a year.

- Focus: Check for leaks, damage, and proper fluid levels.

6.3. AdBlue Filter Replacement

- Interval: Replace the AdBlue filter according to the manufacturer’s recommended interval (typically every 20,000 to 30,000 miles).

- Benefit: Prevents contaminants from damaging the injector and pump.

6.4. Proper AdBlue Storage

- Containers: Store AdBlue in sealed, original containers to prevent contamination.

- Temperature: Avoid extreme temperatures, as this can affect the fluid’s quality.

6.5. Monitoring AdBlue Consumption

- Tracking: Keep track of your AdBlue consumption to identify any potential issues early.

- Normal Usage: A sudden increase in consumption may indicate a leak or other problem.

7. Tools and Equipment for AdBlue System Repair

Having the right tools and equipment is essential for effectively diagnosing and repairing AdBlue system malfunctions. At CARDIAGTECH.NET, we provide high-quality tools tailored to meet the needs of automotive professionals.

7.1. Diagnostic Scanners

- OBD-II Scanners: Basic scanners for reading and clearing error codes.

- Mercedes-Specific Tools (XENTRY): Advanced tools for in-depth diagnostics, component testing, and reprogramming.

- Benefits: Accurate diagnostics and efficient troubleshooting

7.2. Multimeters

- Purpose: Testing electrical circuits and components.

- Features: Digital display, voltage, current, and resistance measurements.

- Benefits: Reliable electrical testing

7.3. Refractometers

- Purpose: Measuring the concentration of AdBlue fluid.

- Benefits: Ensuring the fluid meets the required standards.

7.4. Pressure Testers

- Purpose: Checking the pressure of the AdBlue pump.

- Benefits: Identifying pump failures.

7.5. Socket Sets and Wrenches

- Purpose: Removing and installing AdBlue system components.

- Benefits: Ensuring proper torque and secure connections.

7.6. AdBlue Filling Equipment

- Purpose: Refilling the AdBlue tank without spills or contamination.

- Benefits: Clean and efficient refilling.

8. Benefits of Using Quality Tools from CARDIAGTECH.NET

Investing in high-quality tools from CARDIAGTECH.NET ensures accurate diagnostics, efficient repairs, and long-term reliability.

8.1. Precision and Accuracy

Our tools are designed for precision and accuracy, providing reliable results that help you diagnose and repair AdBlue system issues effectively.

- Impact: Reduces guesswork and ensures accurate repairs

8.2. Durability and Longevity

Made from high-quality materials, our tools are built to withstand the demands of a professional automotive environment.

- Impact: Long-lasting performance and value for money

8.3. Enhanced Efficiency

Our tools are designed to streamline the diagnostic and repair process, saving you time and increasing your productivity.

- Impact: Faster turnaround times and increased customer satisfaction

8.4. Comprehensive Support

We offer comprehensive support and training to help you get the most out of your tools.

- Impact: Expert guidance and ongoing assistance

8.5. Cost-Effectiveness

Investing in quality tools can save you money in the long run by reducing the need for repeat repairs and minimizing downtime.

- Impact: Improved profitability and reduced operating costs

9. Addressing Customer Concerns and Building Trust

Understanding and addressing customer concerns is crucial for building trust and ensuring customer satisfaction.

9.1. Clear Communication

- Explanation: Clearly explain the AdBlue system malfunction, its causes, and the necessary repairs.

- Transparency: Provide a detailed estimate of the repair costs.

9.2. Demonstrating Expertise

- Professionalism: Show your expertise by using the right tools and following a systematic diagnostic process.

- Knowledge: Answer customer questions thoroughly and accurately.

9.3. Providing Options

- Flexibility: Offer customers options for repair, such as using OEM parts or aftermarket alternatives.

- Recommendations: Provide your professional recommendation based on their budget and needs.

9.4. Ensuring Quality Repairs

- Attention to Detail: Pay attention to detail during the repair process to ensure a high-quality outcome.

- Testing: Thoroughly test the system after the repair to verify its functionality.

9.5. Offering Warranties

- Assurance: Provide a warranty on parts and labor to give customers peace of mind.

- Confidence: Stand behind your work and demonstrate your commitment to quality.

10. Conclusion: Ensuring Optimal Performance with CARDIAGTECH.NET

The Mercedes AdBlue system is crucial for reducing emissions and maintaining vehicle performance. Addressing malfunctions promptly and effectively is essential for compliance and optimal operation. At CARDIAGTECH.NET, we offer high-quality tools and equipment to help you diagnose, repair, and maintain AdBlue systems with confidence.

By understanding the causes, symptoms, and repair processes outlined in this guide, you can ensure that your Mercedes AdBlue system functions properly, reducing emissions and keeping your vehicle running smoothly.

Ready to take control of your Mercedes AdBlue system repairs? Contact CARDIAGTECH.NET today! Our expert team is ready to assist you with the best tools and solutions for your automotive needs.

Address: 276 Reock St, City of Orange, NJ 07050, United States

WhatsApp: +1 (641) 206-8880

Website: CARDIAGTECH.NET

Don’t let AdBlue system malfunctions slow you down. Trust CARDIAGTECH.NET to provide the tools and expertise you need to keep your Mercedes running at its best.

FAQ: Mercedes AdBlue System Malfunctions

1. What is the Mercedes AdBlue system?

The Mercedes AdBlue system, or Selective Catalytic Reduction (SCR) system, is designed to reduce harmful nitrogen oxide (NOx) emissions from diesel vehicles by injecting AdBlue fluid into the exhaust stream.

2. What are the common causes of AdBlue system malfunctions?

Common causes include low AdBlue levels, faulty injectors or pumps, clogged filters, defective NOx sensors, control unit issues, and poor-quality AdBlue fluid.

3. How do I know if my AdBlue system is malfunctioning?

Symptoms include dashboard warning lights, reduced engine power, increased emissions, difficulty starting the engine, and specific error codes from an OBD-II scanner.

4. Can I drive my Mercedes with an AdBlue system fault?

Driving with an AdBlue system fault can lead to reduced engine power and increased emissions, and in some cases, may prevent the engine from starting. It’s best to address the issue promptly.

5. How often should I refill my AdBlue tank?

The frequency of refills depends on driving conditions and vehicle usage, but typically, you’ll need to refill every 5,000 to 10,000 miles.

6. Can I use any AdBlue fluid in my Mercedes?

No, always use AdBlue fluid that meets ISO 22241 standards to prevent damage to the system.

7. What tools are needed to diagnose and repair AdBlue system malfunctions?

Essential tools include diagnostic scanners, multimeters, refractometers, pressure testers, socket sets, and wrenches. Mercedes-specific tools like XENTRY are also beneficial.

8. How can I prevent AdBlue system malfunctions?

Preventive measures include using high-quality AdBlue, regular inspections, filter replacements, proper fluid storage, and monitoring AdBlue consumption.

9. What are the benefits of using quality tools from CARDIAGTECH.NET?

Quality tools from CARDIAGTECH.NET ensure precision, durability, enhanced efficiency, comprehensive support, and cost-effectiveness in diagnosing and repairing AdBlue systems.

10. How do I address customer concerns when repairing AdBlue systems?

Address customer concerns through clear communication, demonstrating expertise, providing repair options, ensuring quality repairs, and offering warranties to build trust and satisfaction.