Mercedes Sprinter AdBlue System Malfunction: Expert Solutions

Experiencing a Mercedes Sprinter AdBlue system malfunction can be frustrating, potentially leading to limp mode and costly repairs. At CARDIAGTECH.NET, we provide expert solutions and top-quality diagnostic tools to help you resolve these issues efficiently, saving you time and money. Explore our range of automotive tools, including diagnostic scanners, DEF system testers, and NOx sensor analyzers, designed to pinpoint and fix AdBlue problems effectively.

Table of Contents

- Understanding the Mercedes Sprinter AdBlue System

- Common Symptoms of AdBlue System Malfunction

- Diagnostic Trouble Codes (DTCs) Related to AdBlue Issues

- Step-by-Step Diagnostic Process for AdBlue Malfunctions

- Component Testing: DEF Injector, Pump, and Sensors

- Advanced Troubleshooting: NOx Sensors and Wiring

- AdBlue System Reset and Adaptation Procedures

- Preventive Maintenance for a Healthy AdBlue System

- The Role of High-Quality Diagnostic Tools from CARDIAGTECH.NET

- Case Studies: Real-World AdBlue System Repairs

- Cost-Effective Solutions for AdBlue System Issues

- Expert Tips for Maintaining Your Mercedes Sprinter’s AdBlue System

- AdBlue System FAQs: Addressing Common Questions

1. Understanding the Mercedes Sprinter AdBlue System

The AdBlue system, also known as the Selective Catalytic Reduction (SCR) system, is crucial for reducing nitrogen oxide (NOx) emissions in Mercedes Sprinter diesel vehicles. This system injects a Diesel Exhaust Fluid (DEF), a solution of urea and deionized water, into the exhaust stream. The DEF reacts with NOx in the catalytic converter, transforming it into harmless nitrogen and water. Properly functioning AdBlue systems are vital for meeting stringent emission standards, enhancing fuel efficiency, and ensuring optimal engine performance. Without a functioning system, your vehicle may experience reduced power and eventually enter limp mode, limiting its speed and functionality.

2. Common Symptoms of AdBlue System Malfunction

Recognizing the symptoms of an AdBlue system malfunction early can prevent further damage and costly repairs. These symptoms can vary, but often include:

- Warning Lights: Illumination of the AdBlue or check engine light on the dashboard.

- Limp Mode: Reduced engine power and speed, triggered by the system to limit emissions.

- Message Display: “Incorrect DEF Fluid Detected,” “Check AdBlue System,” or similar messages on the dashboard display.

- Increased DEF Consumption: Noticeably higher usage of DEF than usual.

- DEF Leaks: Visible leaks around the DEF tank, pump, or injector.

- Engine Performance Issues: Rough idling or decreased fuel efficiency.

- Failed Emissions Test: Inability to pass emissions testing due to high NOx levels.

These symptoms indicate potential issues within the AdBlue system, requiring prompt diagnosis and repair. Regular monitoring and timely intervention are crucial for maintaining the health and efficiency of your Mercedes Sprinter.

3. Diagnostic Trouble Codes (DTCs) Related to AdBlue Issues

Diagnostic Trouble Codes (DTCs) provide valuable insights into the specific problems within the AdBlue system. Here are some common DTCs associated with Mercedes Sprinter AdBlue malfunctions:

| DTC Code | Description | Potential Issue |

|---|---|---|

| P203F | Reductant Level Too Low | Low DEF level, faulty level sensor |

| P204F | Reductant System Performance | DEF injector issues, clogged lines |

| P207F | Reductant Quality Performance | Incorrect DEF fluid, contaminated DEF |

| P20E8 | Reductant Injection Valve Circuit Low | Faulty DEF injector, wiring issues |

| P20EE | SCR NOx Catalyst Efficiency Below Threshold | Catalyst failure, NOx sensor malfunction |

| U010E | Lost Communication With Reductant Control Module | Wiring issues, faulty control module |

| P13DF00 | AdBlue System Malfunction | General system fault, requiring further investigation |

| P229F62 | NOx Sensor Circuit Range/Performance – Bank 1 | Faulty NOx sensor, wiring issues |

These codes, when read using a diagnostic scanner like those available at CARDIAGTECH.NET, help pinpoint the exact component or system area causing the problem. Accurate identification is the first step towards effective repair.

4. Step-by-Step Diagnostic Process for AdBlue Malfunctions

Diagnosing AdBlue system malfunctions requires a systematic approach to accurately identify the root cause. Here’s a step-by-step diagnostic process:

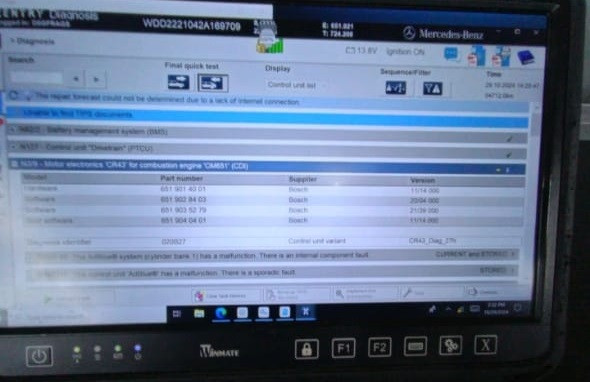

- Initial Scan: Use a diagnostic scanner to read and record all DTCs present in the system. This provides a baseline understanding of the issues.

- Visual Inspection: Check the DEF tank for adequate fluid levels and signs of contamination. Inspect the DEF lines, pump, and injector for leaks or damage.

- DEF Quality Test: Verify the quality of the DEF fluid using a refractometer. The ideal urea concentration should be between 32.5% and 37.5%.

- Component Testing: Test the DEF pump, injector, and sensors using a multimeter or specialized testing equipment. Ensure they are functioning within specified parameters.

- Wiring Inspection: Check the wiring harness and connectors for any signs of damage, corrosion, or loose connections. Use a wiring diagram to verify continuity and proper voltage.

- NOx Sensor Evaluation: Evaluate the performance of the NOx sensors using live data from the diagnostic scanner. Compare readings to known good values.

- System Reset and Adaptation: After addressing the identified issues, perform an AdBlue system reset and adaptation using the diagnostic scanner to ensure proper operation.

By following these steps, you can effectively diagnose and address AdBlue system malfunctions in your Mercedes Sprinter. CARDIAGTECH.NET offers a wide range of diagnostic tools to support each stage of this process.

5. Component Testing: DEF Injector, Pump, and Sensors

Testing individual components of the AdBlue system is crucial for accurate diagnosis. Here’s how to test the DEF injector, pump, and sensors:

-

DEF Injector:

- Visual Inspection: Check for any physical damage or signs of clogging.

- Resistance Test: Use a multimeter to measure the resistance of the injector solenoid. Compare the reading to the manufacturer’s specifications.

- Activation Test: Use a diagnostic scanner to activate the injector and listen for a clicking sound, indicating proper operation.

- Flow Test: Disconnect the injector from the exhaust system and use a specialized tool to measure the DEF flow rate.

-

DEF Pump:

- Voltage Test: Verify that the pump is receiving the correct voltage using a multimeter.

- Amperage Test: Measure the current draw of the pump using an ammeter. Compare the reading to the manufacturer’s specifications.

- Pressure Test: Use a pressure gauge to measure the DEF pressure at the injector.

-

DEF Level Sensor:

- Resistance Test: Measure the resistance of the sensor at different fluid levels. The resistance should change proportionally to the fluid level.

- Voltage Test: Verify that the sensor is sending the correct voltage signal to the ECU.

-

DEF Temperature Sensor:

- Resistance Test: Measure the resistance of the sensor at different temperatures. The resistance should change according to the temperature.

- Voltage Test: Verify that the sensor is sending the correct voltage signal to the ECU.

Accurate component testing ensures that you replace only the faulty parts, saving time and money. CARDIAGTECH.NET provides the tools and resources necessary for comprehensive component testing.

6. Advanced Troubleshooting: NOx Sensors and Wiring

Advanced troubleshooting involves checking the NOx sensors and wiring, which are vital for the AdBlue system’s efficiency.

-

NOx Sensor Testing:

- Visual Inspection: Look for any physical damage.

- Live Data Analysis: Use a diagnostic scanner to monitor NOx sensor readings in real-time. Compare upstream and downstream sensor values.

- Sensor Function Test: Perform a sensor function test using the diagnostic scanner to verify proper operation.

- Wiring and Connections: Inspect wiring and connectors for damage.

-

Wiring Inspection:

- Continuity Test: Use a multimeter to check for continuity in the wiring harness.

- Voltage Drop Test: Measure the voltage drop across the wiring to identify any excessive resistance.

- Short Circuit Test: Check for short circuits to ground or other components.

Addressing issues with NOx sensors and wiring ensures the AdBlue system operates correctly and reduces emissions effectively.

7. AdBlue System Reset and Adaptation Procedures

After repairing or replacing components in the AdBlue system, performing a reset and adaptation is essential for proper function. Here’s how:

- Clear DTCs: Use a diagnostic scanner to clear all stored DTCs related to the AdBlue system.

- AdBlue System Reset: Access the AdBlue system control module using the diagnostic scanner and initiate a system reset. This procedure clears any learned values and prepares the system for adaptation.

- NOx Sensor Adaptation: Perform a NOx sensor adaptation procedure using the diagnostic scanner. This allows the ECU to learn the characteristics of the new or repaired NOx sensors.

- DEF Injector Calibration: Calibrate the DEF injector using the diagnostic scanner to ensure accurate DEF dosing.

- System Verification: After completing the reset and adaptation procedures, perform a system verification test to ensure that all components are functioning correctly.

These steps ensure the AdBlue system operates efficiently and meets emission standards. CARDIAGTECH.NET’s diagnostic tools simplify these processes.

8. Preventive Maintenance for a Healthy AdBlue System

Preventive maintenance is key to keeping your Mercedes Sprinter’s AdBlue system in top condition. Here are some essential tips:

- Use High-Quality DEF: Always use DEF that meets the ISO 22241 standard. This ensures the correct urea concentration and minimizes the risk of contamination.

- Regular DEF Level Checks: Monitor the DEF level regularly and refill as needed. Avoid running the tank completely dry, as this can damage the pump.

- Inspect DEF Tank and Lines: Periodically inspect the DEF tank, lines, and connections for leaks or damage.

- Check DEF Injector: Inspect the DEF injector for signs of clogging or corrosion. Clean or replace as necessary.

- Monitor NOx Sensors: Keep an eye on NOx sensor readings using a diagnostic scanner. Replace faulty sensors promptly.

- Regular System Scans: Perform regular system scans using a diagnostic scanner to identify any potential issues before they escalate.

- Follow Service Intervals: Adhere to the manufacturer’s recommended service intervals for the AdBlue system.

By following these preventive maintenance tips, you can extend the life of your AdBlue system and avoid costly repairs.

9. The Role of High-Quality Diagnostic Tools from CARDIAGTECH.NET

High-quality diagnostic tools are essential for effectively diagnosing and repairing AdBlue system malfunctions. CARDIAGTECH.NET offers a range of tools designed to meet the needs of automotive professionals and DIY enthusiasts:

- Diagnostic Scanners: Our advanced diagnostic scanners can read and clear DTCs, display live data, perform component testing, and execute system resets and adaptations.

- DEF System Testers: These specialized tools allow you to test the DEF pump, injector, and sensors to ensure they are functioning within specified parameters.

- NOx Sensor Analyzers: Our NOx sensor analyzers provide accurate readings of NOx levels, helping you identify faulty sensors and ensure proper system operation.

- Multimeters and Electrical Testers: These versatile tools are essential for testing wiring continuity, voltage, and resistance.

- Refractometers: Use a refractometer to verify the quality of the DEF fluid and ensure the correct urea concentration.

Investing in high-quality diagnostic tools from CARDIAGTECH.NET empowers you to accurately diagnose and repair AdBlue system issues, saving time and money. Contact us at +1 (641) 206-8880 or visit our website CARDIAGTECH.NET for more information. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

10. Case Studies: Real-World AdBlue System Repairs

Examining real-world case studies can provide valuable insights into common AdBlue system issues and their solutions:

Case Study 1: DEF Injector Clogging

- Vehicle: 2016 Mercedes Sprinter

- Symptoms: Check engine light, P204F code, reduced engine power

- Diagnosis: Using a diagnostic scanner from CARDIAGTECH.NET, the technician identified a clogged DEF injector.

- Solution: The DEF injector was removed and cleaned. After reinstallation, the system was reset and calibrated. The vehicle’s performance was restored.

Case Study 2: Faulty NOx Sensor

- Vehicle: 2018 Mercedes Sprinter

- Symptoms: Check engine light, P229F62 code, failed emissions test

- Diagnosis: A NOx sensor analyzer from CARDIAGTECH.NET revealed that the downstream NOx sensor was faulty.

- Solution: The faulty NOx sensor was replaced, and the system was adapted using the diagnostic scanner. The vehicle passed the emissions test.

Case Study 3: DEF Pump Failure

- Vehicle: 2014 Mercedes Sprinter

- Symptoms: AdBlue warning light, U010E code, limp mode

- Diagnosis: Testing with a multimeter showed that the DEF pump was not receiving power.

- Solution: The DEF pump was replaced, and the system was reset. The vehicle returned to normal operation.

These case studies demonstrate the importance of accurate diagnosis and the effectiveness of using high-quality diagnostic tools from CARDIAGTECH.NET to resolve AdBlue system issues.

11. Cost-Effective Solutions for AdBlue System Issues

Addressing AdBlue system issues promptly and effectively can save you money in the long run. Here are some cost-effective solutions:

- Accurate Diagnosis: Use high-quality diagnostic tools to accurately identify the root cause of the problem, avoiding unnecessary parts replacements.

- Component Cleaning: In some cases, cleaning components like the DEF injector can resolve the issue without requiring replacement.

- DIY Repairs: If you have the skills and tools, performing repairs yourself can save on labor costs.

- Preventive Maintenance: Regular preventive maintenance can prevent costly breakdowns and extend the life of the AdBlue system.

- Quality Parts: When replacement is necessary, use high-quality OEM or aftermarket parts to ensure reliability and longevity.

- System Reset and Adaptation: Properly resetting and adapting the system after repairs can prevent further issues and optimize performance.

By implementing these cost-effective solutions, you can minimize the financial impact of AdBlue system issues while maintaining the performance and efficiency of your Mercedes Sprinter.

12. Expert Tips for Maintaining Your Mercedes Sprinter’s AdBlue System

Maintaining your Mercedes Sprinter’s AdBlue system requires attention to detail and adherence to best practices. Here are some expert tips:

- Use Genuine or Equivalent DEF: Always use DEF that meets the ISO 22241 standard to avoid contamination and ensure proper system function.

- Store DEF Properly: Store DEF in a cool, dry place away from direct sunlight to prevent degradation.

- Avoid Contamination: Use clean funnels and containers when filling the DEF tank to prevent contamination.

- Regular Inspections: Inspect the DEF tank, lines, and connections regularly for leaks or damage.

- Monitor DEF Consumption: Keep track of DEF consumption to identify any potential issues early.

- Perform System Resets: After any repairs or component replacements, perform a system reset and adaptation using a diagnostic scanner.

- Stay Updated: Stay informed about the latest AdBlue system technologies and best practices by attending training courses and reading industry publications.

By following these expert tips, you can ensure the longevity and optimal performance of your Mercedes Sprinter’s AdBlue system.

13. AdBlue System FAQs: Addressing Common Questions

Here are some frequently asked questions about AdBlue systems:

- What is AdBlue? AdBlue is a Diesel Exhaust Fluid (DEF) used in Selective Catalytic Reduction (SCR) systems to reduce nitrogen oxide (NOx) emissions.

- How does the AdBlue system work? The AdBlue system injects DEF into the exhaust stream, where it reacts with NOx in the catalytic converter, converting it into nitrogen and water.

- What happens if the AdBlue level is low? A low AdBlue level can trigger a warning light and eventually cause the vehicle to enter limp mode.

- Can I use any DEF in my Mercedes Sprinter? No, always use DEF that meets the ISO 22241 standard to ensure proper system function and avoid damage.

- How often should I refill the AdBlue tank? Refill frequency depends on driving conditions and DEF consumption. Check the level regularly and refill as needed.

- What are the symptoms of an AdBlue system malfunction? Common symptoms include warning lights, limp mode, increased DEF consumption, and failed emissions tests.

- How do I diagnose an AdBlue system problem? Use a diagnostic scanner to read DTCs, perform component testing, and analyze live data.

- Can I reset the AdBlue system myself? Yes, with the right diagnostic tools, you can reset and adapt the AdBlue system after repairs.

- What are the common causes of AdBlue system failure? Common causes include faulty DEF injectors, pumps, sensors, and NOx sensors, as well as contaminated DEF and wiring issues.

- Where can I find reliable diagnostic tools for AdBlue systems? CARDIAGTECH.NET offers a wide range of high-quality diagnostic tools for diagnosing and repairing AdBlue system issues.

Addressing these common questions can help you better understand and maintain your Mercedes Sprinter’s AdBlue system.

If you’re facing challenges with your Mercedes Sprinter AdBlue system, don’t hesitate to reach out for expert assistance. Contact CARDIAGTECH.NET at +1 (641) 206-8880 or visit our website CARDIAGTECH.NET for top-quality diagnostic tools and support. We’re located at 276 Reock St, City of Orange, NJ 07050, United States. Let us help you keep your Sprinter running smoothly and efficiently.