Do You Have Basic Knowledge of Electric Vehicles (EVs)?

Do you have basic knowledge of the structure and operating principles of Electric Vehicles (EVs)? If you’re looking to expand your expertise in the rapidly growing field of EV repair, understanding the fundamentals is crucial, and CARDIAGTECH.NET is here to assist you with the best tools. Grasping these basics will enable you to diagnose issues accurately and ensure efficient repairs using the proper diagnostic tools.

1. Understanding the Fundamental Structure of Electric Vehicles

Electric Vehicles (EVs) represent a significant shift in automotive technology, moving away from traditional internal combustion engines (ICE) to electric motors powered by batteries. Understanding the structure of an EV is essential for effective maintenance and repair.

1.1 What are the Key Components of an Electric Vehicle?

The core components of an EV include the battery pack, electric motor, power electronics controller, onboard charger, and thermal management system. According to a study by the U.S. Department of Energy, these components work together to provide propulsion and manage energy flow within the vehicle.

- Battery Pack: This is the heart of the EV, storing the electrical energy needed to power the motor. Battery packs are typically composed of lithium-ion cells due to their high energy density and long lifespan, according to research from the University of California, Berkeley.

- Electric Motor: Converts electrical energy from the battery pack into mechanical energy to drive the wheels. EVs use various types of motors, including AC induction motors and permanent magnet synchronous motors, each with its own efficiency and performance characteristics.

- Power Electronics Controller: This unit manages the flow of electrical energy from the battery to the motor, controlling the motor’s speed and torque. It also handles regenerative braking, which captures energy during deceleration and returns it to the battery.

- Onboard Charger: Converts AC power from an external charging source into DC power to charge the battery pack. Onboard chargers vary in their charging speed and voltage capabilities, affecting how quickly an EV can be recharged.

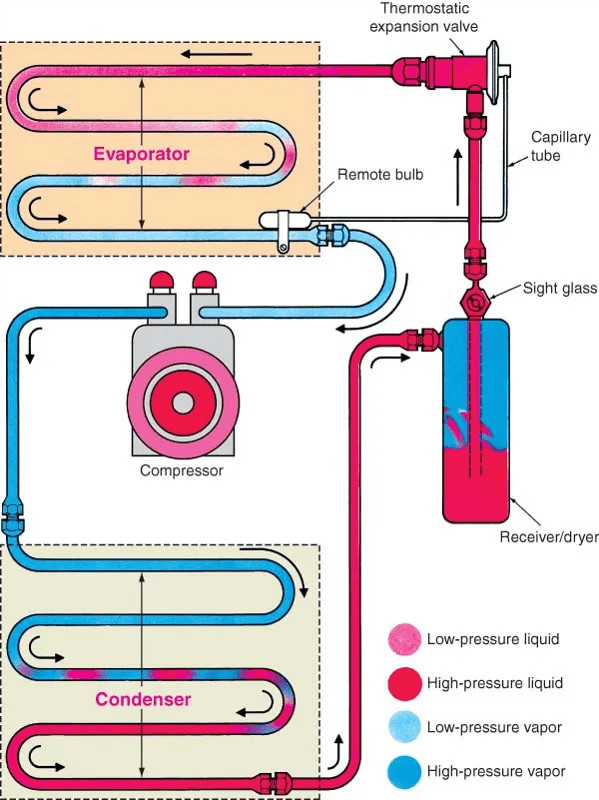

- Thermal Management System: Regulates the temperature of the battery pack, motor, and power electronics to ensure optimal performance and longevity. This system uses liquid cooling or air cooling to dissipate heat and maintain consistent operating temperatures.

1.2 How Does the Battery Pack Work?

The battery pack in an EV is composed of numerous individual battery cells, typically lithium-ion, connected in series and parallel to achieve the desired voltage and capacity. These cells store energy through electrochemical reactions, releasing electrons to power the motor when the vehicle is in operation.

According to a study by Argonne National Laboratory, the performance of EV batteries is influenced by factors such as temperature, charge rate, and discharge depth. Proper battery management systems (BMS) are crucial for monitoring and controlling these factors to optimize battery life and performance.

1.3 What Role Does the Electric Motor Play?

The electric motor converts electrical energy into mechanical energy, which propels the vehicle. Unlike internal combustion engines, electric motors provide instant torque, resulting in quick acceleration.

Research from the University of Michigan indicates that electric motors are highly efficient, converting over 90% of electrical energy into mechanical energy, compared to around 30-40% for gasoline engines. This efficiency contributes to the overall energy savings and reduced emissions of EVs.

1.4 Understanding the Power Electronics Controller

The power electronics controller, also known as the inverter, manages the flow of electrical energy from the battery to the motor. It converts DC power from the battery into AC power required by the motor, and it also controls the motor’s speed and torque.

According to a report by the Electric Power Research Institute (EPRI), advanced power electronics controllers can improve the efficiency and performance of EVs. These controllers use sophisticated algorithms to optimize energy flow and minimize losses, contributing to extended driving range and improved acceleration.

1.5 Why is Thermal Management Important?

The thermal management system is essential for maintaining the optimal operating temperature of the battery pack, motor, and power electronics. Overheating can degrade battery performance and lifespan, while extremely low temperatures can reduce battery capacity and power output.

Research from the National Renewable Energy Laboratory (NREL) shows that effective thermal management can significantly improve the durability and performance of EV batteries. These systems use liquid cooling or air cooling to dissipate heat and maintain consistent operating temperatures, ensuring reliable operation in diverse climates.

2. Exploring the Operating Principles of Electric Vehicles

Understanding the operating principles of EVs is essential for diagnosing and repairing issues effectively. This involves understanding how the various components interact to provide propulsion and manage energy flow.

2.1 How Does an EV Start and Accelerate?

When the driver presses the accelerator pedal, the power electronics controller signals the battery pack to release electrical energy. This energy flows to the electric motor, which converts it into mechanical energy, driving the wheels and propelling the vehicle forward.

Unlike gasoline engines, electric motors provide instant torque, resulting in quick acceleration. The power electronics controller regulates the flow of energy to the motor, allowing for precise control of speed and torque.

2.2 What is Regenerative Braking?

Regenerative braking is a key feature of EVs that captures energy during deceleration and returns it to the battery pack. When the driver releases the accelerator pedal or applies the brakes, the electric motor acts as a generator, converting kinetic energy into electrical energy.

This electrical energy is then stored in the battery pack, increasing the vehicle’s range and reducing wear on the brake pads. According to a study by the Society of Automotive Engineers (SAE), regenerative braking can improve the energy efficiency of EVs by up to 20%.

2.3 How Does Charging Work?

EVs can be charged using various methods, including Level 1, Level 2, and DC fast charging. Level 1 charging uses a standard household outlet and is the slowest method, while Level 2 charging uses a 240-volt outlet and provides faster charging speeds. DC fast charging is the quickest method, using high-voltage DC power to charge the battery pack in as little as 30 minutes.

The onboard charger converts AC power from the charging source into DC power to charge the battery pack. It also communicates with the charging equipment to monitor battery characteristics such as voltage, current, and temperature.

2.4 Understanding Battery Management Systems (BMS)

The battery management system (BMS) is a critical component of EVs that monitors and controls the battery pack’s performance. It protects the battery from overcharging, over-discharging, and overheating, ensuring optimal performance and longevity.

According to research from the University of Texas at Austin, advanced BMS algorithms can improve the accuracy of state-of-charge estimation and extend battery life. These systems use sophisticated sensors and control strategies to optimize battery performance and prevent damage.

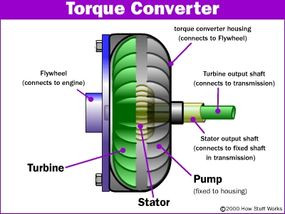

2.5 What is the Role of the Transmission in EVs?

Unlike traditional vehicles with multiple gears, EVs typically have a single-speed transmission. This is because electric motors provide a wide range of torque at any speed, eliminating the need for multiple gears.

The transmission in an EV transfers mechanical power from the electric motor to the wheels. It is designed to be efficient and durable, with minimal maintenance requirements.

3. Advanced Diagnostic Tools for Electric Vehicle Repair

As EVs become more prevalent, the need for advanced diagnostic tools to repair and maintain these vehicles is growing. CARDIAGTECH.NET offers a range of tools tailored to meet the demands of EV servicing.

3.1 Why are Specialized Tools Needed for EV Repair?

EVs operate at high voltages, posing significant safety risks for technicians. Specialized tools such as high-voltage gloves, insulated tools, and safety interlocks are essential for working safely on EVs.

According to the National Fire Protection Association (NFPA), technicians working on EVs should receive specialized training and use appropriate personal protective equipment (PPE) to prevent electrical shock and other hazards.

3.2 What Diagnostic Scanners are Essential for EV Repair?

Diagnostic scanners are crucial for identifying and troubleshooting issues in EVs. These scanners can read diagnostic trouble codes (DTCs) from the vehicle’s computer system and provide valuable information about the nature and location of the problem.

CARDIAGTECH.NET offers a range of advanced diagnostic scanners specifically designed for EVs. These scanners can diagnose issues with the battery pack, motor, power electronics, and other EV-specific components.

3.3 The Importance of Battery Testing Equipment

Battery testing equipment is essential for assessing the health and performance of EV battery packs. These tools can measure battery voltage, capacity, and internal resistance, providing valuable insights into the condition of the battery.

According to a study by the Idaho National Laboratory, regular battery testing can help identify potential issues before they lead to significant problems. This can help extend the life of the battery pack and improve the overall reliability of the EV.

3.4 Thermal Imaging for EV Diagnostics

Thermal imaging cameras can be used to identify hotspots and temperature variations in EV components such as the battery pack, motor, and power electronics. These variations can indicate potential problems such as failing cells, loose connections, or overheating components.

CARDIAGTECH.NET offers high-resolution thermal imaging cameras that can help technicians quickly and accurately diagnose issues in EVs. These cameras provide a non-invasive way to assess the condition of EV components without disassembling the vehicle.

3.5 What Role Does Software Play in EV Diagnostics?

Software plays a crucial role in EV diagnostics, providing access to vehicle data, diagnostic procedures, and repair information. EV manufacturers provide proprietary software for diagnosing and programming their vehicles, and technicians need to have access to these tools to perform effective repairs.

CARDIAGTECH.NET offers a range of software solutions for EV diagnostics, including OEM diagnostic software and aftermarket diagnostic platforms. These tools provide technicians with the information they need to diagnose and repair EVs efficiently.

4. Ensuring Safety While Working on Electric Vehicles

Safety is paramount when working on electric vehicles due to the high voltages involved. Proper training, equipment, and procedures are essential to protect technicians from electrical shock and other hazards.

4.1 Understanding High-Voltage Safety Procedures

High-voltage safety procedures are critical for working on EVs. These procedures include disconnecting the high-voltage battery, verifying that the system is de-energized, and using appropriate personal protective equipment (PPE).

According to OSHA guidelines, technicians working on EVs should receive specialized training in high-voltage safety procedures. This training should cover topics such as lockout/tagout procedures, arc flash hazards, and the proper use of PPE.

4.2 The Importance of Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is essential for protecting technicians from electrical shock and other hazards when working on EVs. This includes high-voltage gloves, insulated tools, safety glasses, and arc flash suits.

CARDIAGTECH.NET offers a range of high-quality PPE specifically designed for EV repair. These products are tested and certified to meet industry standards, ensuring the safety of technicians working on EVs.

4.3 How to Properly Disconnect the High-Voltage Battery

Disconnecting the high-voltage battery is a critical step in EV repair. This involves following a specific procedure to de-energize the system and prevent electrical shock.

The procedure typically involves using a diagnostic scanner to verify that the high-voltage system is disabled, removing the service plug or disconnect switch, and waiting a specified amount of time for the capacitors to discharge. Technicians should always follow the manufacturer’s recommended procedure for disconnecting the high-voltage battery.

4.4 What are the Risks of Arc Flash?

Arc flash is a dangerous electrical phenomenon that can occur when working on high-voltage systems. It involves a sudden release of electrical energy that can cause severe burns, blindness, and even death.

According to the IEEE, arc flash hazards can be mitigated by using appropriate PPE, following safe work practices, and using arc flash protection devices. Technicians working on EVs should be aware of the risks of arc flash and take appropriate precautions to protect themselves.

4.5 The Role of Regular Safety Training

Regular safety training is essential for keeping technicians up-to-date on the latest safety procedures and best practices for working on EVs. This training should cover topics such as high-voltage safety, arc flash hazards, and the proper use of PPE.

CARDIAGTECH.NET offers comprehensive safety training programs for EV repair. These programs are designed to provide technicians with the knowledge and skills they need to work safely on EVs.

5. Tips for Maintaining Electric Vehicles

Proper maintenance is essential for keeping EVs running smoothly and reliably. Regular inspections, fluid checks, and battery maintenance can help extend the life of the vehicle and prevent costly repairs.

5.1 The Importance of Regular Inspections

Regular inspections are crucial for identifying potential issues before they lead to significant problems. This includes checking the tires, brakes, suspension, and other critical components.

According to a study by Consumer Reports, regular maintenance can help improve the reliability and longevity of EVs. Inspections should be performed at least once a year, or more frequently if the vehicle is driven in harsh conditions.

5.2 What Fluids Need to be Checked in EVs?

While EVs don’t require oil changes like gasoline vehicles, they still have fluids that need to be checked and maintained. This includes brake fluid, coolant, and transmission fluid.

Brake fluid should be checked regularly and replaced as needed to ensure proper braking performance. Coolant is essential for maintaining the optimal operating temperature of the battery pack and other components. Transmission fluid should be checked and replaced according to the manufacturer’s recommendations.

5.3 How to Properly Maintain the Battery Pack

The battery pack is the most expensive component of an EV, so proper maintenance is essential for extending its life. This includes avoiding extreme temperatures, minimizing fast charging, and maintaining a consistent state of charge.

According to research from the University of California, Irvine, maintaining a state of charge between 20% and 80% can help maximize battery life. Fast charging should be minimized, as it can generate heat and degrade battery performance.

5.4 The Role of Software Updates in EV Maintenance

Software updates are an important part of EV maintenance. These updates can improve vehicle performance, add new features, and fix bugs.

EV manufacturers regularly release software updates that can be installed over the air or at a service center. Technicians should ensure that the vehicle’s software is up-to-date to maintain optimal performance.

5.5 Why Tire Maintenance is Critical for EVs

Tire maintenance is critical for EVs because tire pressure and wear can significantly impact the vehicle’s range and efficiency. EVs are heavier than gasoline vehicles due to the weight of the battery pack, which can increase tire wear.

Regular tire rotations, balancing, and alignment are essential for maximizing tire life and maintaining optimal performance. Technicians should also ensure that the tires are inflated to the proper pressure, as underinflated tires can reduce range and efficiency.

6. Future Trends in Electric Vehicle Technology

Electric vehicle technology is constantly evolving, with new innovations emerging all the time. Understanding these trends can help technicians prepare for the future and stay ahead of the curve.

6.1 What are Solid-State Batteries?

Solid-state batteries are a promising technology that could revolutionize the EV industry. These batteries use a solid electrolyte instead of a liquid electrolyte, which can improve energy density, safety, and charging speed.

According to research from the Massachusetts Institute of Technology (MIT), solid-state batteries could offer up to 50% more energy density than lithium-ion batteries. They are also less flammable and can charge faster, making them an ideal choice for future EVs.

6.2 The Rise of Wireless Charging

Wireless charging is another emerging technology that could make EV ownership more convenient. Wireless charging systems use electromagnetic fields to transfer energy from a charging pad to the vehicle’s battery pack, eliminating the need for cables.

According to a report by Navigant Research, wireless charging could become a mainstream technology in the coming years. It offers a convenient way to charge EVs at home, at work, or in public spaces.

6.3 How Will Artificial Intelligence (AI) Impact EVs?

Artificial intelligence (AI) is playing an increasingly important role in EVs, enabling advanced features such as autonomous driving, predictive maintenance, and personalized driving experiences.

AI algorithms can analyze data from the vehicle’s sensors to optimize energy consumption, improve safety, and enhance performance. According to a study by McKinsey, AI could unlock significant value in the EV industry by improving efficiency and reducing costs.

6.4 What is the Future of Battery Recycling?

Battery recycling is becoming increasingly important as the number of EVs on the road grows. Recycling batteries can recover valuable materials such as lithium, cobalt, and nickel, reducing the environmental impact of battery production.

According to a report by the International Energy Agency (IEA), battery recycling could play a key role in meeting the growing demand for battery materials. New technologies are being developed to improve the efficiency and cost-effectiveness of battery recycling.

6.5 The Growing Importance of Cybersecurity in EVs

Cybersecurity is becoming increasingly important in EVs as vehicles become more connected and reliant on software. EVs are vulnerable to cyberattacks that could compromise vehicle safety, security, and privacy.

According to a report by the National Highway Traffic Safety Administration (NHTSA), automakers need to take steps to protect EVs from cyber threats. This includes implementing robust cybersecurity measures, conducting regular security testing, and providing software updates to address vulnerabilities.

Do you want to enhance your skills and equip your repair shop with the best tools for servicing electric vehicles? At CARDIAGTECH.NET, we offer a comprehensive range of diagnostic tools and equipment designed to meet the evolving needs of EV technology. Contact us today at +1 (641) 206-8880 or visit our location at 276 Reock St, City of Orange, NJ 07050, United States, to discover how we can help you stay ahead in the EV repair industry.

7. Electric Vehicle Terminology

Navigating the world of electric vehicles comes with its own set of terminology. Familiarizing yourself with these terms will enhance your understanding and communication within the EV landscape.

7.1 Common Acronyms and Terms

- BEV: Battery Electric Vehicle, referring to vehicles powered solely by batteries.

- PHEV: Plug-in Hybrid Electric Vehicle, combining a battery-powered electric motor with an internal combustion engine.

- EVSE: Electric Vehicle Supply Equipment, the charging equipment used to charge EVs.

- SOC: State of Charge, indicating the current charge level of the battery.

- SOH: State of Health, reflecting the overall condition and performance of the battery.

- Regenerative Braking: The process of capturing energy during deceleration to recharge the battery.

- DC Fast Charging: High-speed charging using direct current, allowing for rapid battery replenishment.

- Onboard Charger: The charger within the EV that converts AC power to DC for battery charging.

- Inverter: Converts DC power from the battery to AC power for the electric motor.

- BMS (Battery Management System): A system that monitors and manages the performance and safety of the battery.

7.2 Technical Specifications

- Voltage (V): The electrical potential difference, crucial for understanding the power levels in EV systems.

- Current (A): The flow of electrical charge, essential for assessing the performance and load on electrical components.

- Capacity (kWh): The amount of energy the battery can store, determining the vehicle’s range.

- Power (kW): The rate at which energy is transferred, indicating the motor’s output and charging speed.

- Energy Density (Wh/kg): The amount of energy stored per unit of mass, impacting the vehicle’s weight and range.

- Charging Time: The duration required to fully charge the battery, varying with charging level and battery capacity.

- Range: The distance an EV can travel on a single charge, influenced by battery capacity and driving conditions.

- Efficiency (miles/kWh): The distance an EV can travel per unit of energy, reflecting the vehicle’s energy usage.

- Thermal Management: The system that regulates the temperature of the battery and other components to ensure optimal performance and longevity.

- Regenerative Braking Efficiency: The percentage of kinetic energy recovered during braking and converted back into electrical energy.

8. How to Choose the Right Diagnostic Tools for Your Shop

Selecting the appropriate diagnostic tools for your EV repair shop is crucial for providing efficient and accurate service.

8.1 Assess Your Shop’s Needs

- Types of EVs: Determine which EV models you’ll be servicing to ensure tool compatibility.

- Service Volume: Evaluate the number of EVs you anticipate servicing to select tools with adequate capacity.

- Budget: Set a realistic budget, balancing cost with the features and capabilities you need.

- Technician Skill Level: Choose tools that match your technicians’ expertise, with user-friendly interfaces and comprehensive support.

8.2 Key Features to Look For

- Comprehensive Diagnostics: Tools should offer in-depth diagnostics for battery packs, motors, and power electronics.

- Software Updates: Ensure the tool receives regular software updates to support the latest EV models and diagnostic procedures.

- User-Friendly Interface: Opt for tools with intuitive interfaces and clear instructions for efficient operation.

- Data Logging: Tools should be capable of logging data for detailed analysis and troubleshooting.

- Remote Support: Look for tools with remote support features for expert assistance when needed.

8.3 Types of Diagnostic Tools

- Diagnostic Scanners: Essential for reading and clearing diagnostic trouble codes (DTCs) and accessing vehicle data.

- Battery Testers: Tools for evaluating battery health, capacity, and performance.

- Thermal Imaging Cameras: Used to identify hotspots and temperature variations in EV components.

- High-Voltage Probes: Specialized probes for safely measuring voltage in high-voltage systems.

- Insulation Testers: Tools for verifying the integrity of insulation in high-voltage components.

8.4 Top Brands and Models

- Snap-on: Offers a range of high-end diagnostic tools for EVs, known for their comprehensive features and reliability.

- Bosch: Provides a variety of diagnostic solutions, including scanners and battery testers, with a focus on user-friendliness.

- Autel: Specializes in advanced diagnostic tools for EVs, with features like remote diagnostics and cloud-based data analysis.

- Fluke: Known for its high-quality multimeters and thermal imaging cameras, essential for EV diagnostics and safety.

8.5 Training and Support

- Training Programs: Invest in training programs for your technicians to ensure they can effectively use the diagnostic tools.

- Technical Support: Choose tools with reliable technical support from the manufacturer for troubleshooting and assistance.

- Online Resources: Utilize online forums, videos, and knowledge bases to stay updated on best practices and tips for EV diagnostics.

- Community Engagement: Participate in industry communities to share knowledge and learn from other professionals in the field.

9. How Electric Vehicle Technology is Transforming the Automotive Industry

The rise of electric vehicles is transforming the automotive industry, bringing significant changes in manufacturing, infrastructure, and skills requirements.

9.1 Changes in Manufacturing

- New Components: EV manufacturing requires new components such as battery packs, electric motors, and power electronics, leading to new supply chains and manufacturing processes.

- Automation: EV manufacturing often involves more automation to handle battery assembly and integration, improving efficiency and reducing costs.

- Lightweight Materials: The use of lightweight materials such as aluminum and carbon fiber is increasing to improve EV range and performance.

- Software Integration: Software integration is becoming more critical as EVs rely on complex software systems for vehicle control, energy management, and connectivity.

9.2 Infrastructure Development

- Charging Infrastructure: The growth of EVs requires significant investment in charging infrastructure, including home chargers, public charging stations, and DC fast charging corridors.

- Grid Upgrades: The increased demand for electricity from EVs requires upgrades to the electrical grid to ensure reliable power supply and prevent overloads.

- Smart Charging: Smart charging technologies are being developed to optimize energy usage and reduce the impact of EV charging on the grid.

- Renewable Energy: Integrating renewable energy sources such as solar and wind power with EV charging can further reduce the environmental impact of EVs.

9.3 New Skills Requirements

- High-Voltage Training: Technicians need specialized training in high-voltage safety procedures and EV diagnostics to work safely and effectively on EVs.

- Software Expertise: Expertise in software diagnostics, programming, and cybersecurity is becoming more important as EVs rely on complex software systems.

- Battery Management: Knowledge of battery technology, management systems, and recycling is essential for maintaining and servicing EV battery packs.

- Electrical Engineering: A strong understanding of electrical engineering principles is needed to diagnose and repair EV electrical systems.

- Thermal Management: Expertise in thermal management systems is important for maintaining the optimal operating temperature of EV components.

9.4 Economic Impact

- Job Creation: The EV industry is creating new jobs in manufacturing, research and development, charging infrastructure, and maintenance services.

- Investment Opportunities: The growth of EVs is attracting significant investment in new technologies, startups, and infrastructure projects.

- Reduced Fuel Costs: EVs can significantly reduce fuel costs for consumers, leading to savings and increased disposable income.

- Environmental Benefits: EVs can reduce greenhouse gas emissions and air pollution, contributing to a cleaner and healthier environment.

9.5 Government Policies and Incentives

- Tax Credits: Governments are offering tax credits and rebates to encourage the adoption of EVs.

- Emission Standards: Stricter emission standards are driving automakers to invest in EVs and reduce their reliance on gasoline vehicles.

- Charging Infrastructure Support: Governments are providing funding and incentives to support the development of charging infrastructure.

- Research and Development: Governments are investing in research and development to advance EV technology and reduce costs.

10. FAQ: Electric Vehicle Basics

Here are some frequently asked questions to help you better understand the basics of electric vehicles:

10.1 What is an electric vehicle (EV)?

An electric vehicle (EV) is a vehicle powered by an electric motor rather than an internal combustion engine. It uses a large battery pack to store electricity, which powers the motor.

10.2 How do EVs differ from gasoline cars?

EVs differ from gasoline cars in several ways:

- Power Source: EVs use electricity, while gasoline cars use gasoline.

- Emissions: EVs produce zero tailpipe emissions, while gasoline cars produce emissions.

- Maintenance: EVs typically require less maintenance than gasoline cars, as they have fewer moving parts.

- Fueling: EVs are charged using electricity, while gasoline cars are fueled at gas stations.

10.3 What are the different types of EVs?

There are three main types of EVs:

- Battery Electric Vehicles (BEVs): These vehicles are powered solely by batteries and have no gasoline engine.

- Plug-in Hybrid Electric Vehicles (PHEVs): These vehicles combine a battery-powered electric motor with a gasoline engine and can be plugged in to charge the battery.

- Hybrid Electric Vehicles (HEVs): These vehicles combine a gasoline engine with an electric motor but cannot be plugged in to charge the battery.

10.4 How do you charge an EV?

EVs can be charged using different charging levels:

- Level 1 Charging: Uses a standard household outlet (120V) and is the slowest charging method.

- Level 2 Charging: Uses a 240V outlet and is faster than Level 1 charging.

- DC Fast Charging: Uses high-voltage DC power and is the fastest charging method.

10.5 How long does it take to charge an EV?

The charging time for an EV depends on the battery size, charging level, and charging equipment. Level 1 charging can take several hours to fully charge an EV, while DC fast charging can charge an