Do You Have Experience Repairing Gasoline, Diesel, Hybrid, or Electric Engines?

Do you have experience repairing gasoline, diesel, hybrid, or electric engines? CARDIAGTECH.NET offers the best tools and equipment for any type of engine repair. Discover solutions to improve your repair skills and efficiency. Choose the right tools to excel in engine repair and maintenance.

1. What Types of Engines Do You Have Experience Repairing?

Do you have experience repairing gasoline, diesel, hybrid, or electric engines? A mechanic’s expertise in engine repair can vary significantly depending on the type of engine. Gasoline engines, known for their widespread use in passenger vehicles, require a mechanic to be familiar with fuel injection systems, ignition timing, and valve adjustments. Diesel engines, commonly found in trucks and heavy machinery, demand knowledge of high-pressure fuel systems and turbocharger maintenance. Hybrid engines, which combine an internal combustion engine with an electric motor, necessitate understanding both traditional engine components and electric drive systems. Electric engines, powering fully electric vehicles, require expertise in battery management systems, electric motor controllers, and high-voltage safety procedures.

Understanding the nuances of each engine type is essential for effective diagnosis and repair. The specific tools and techniques required can differ greatly, and a mechanic skilled in one area may not necessarily be proficient in another. For instance, diagnosing a misfire in a gasoline engine involves checking spark plugs, ignition coils, and fuel injectors, while troubleshooting a hybrid engine might require analyzing the interaction between the gasoline engine and electric motor, or testing the high-voltage battery pack.

1.1. Gasoline Engine Repair Expertise

What specific skills and knowledge are required for gasoline engine repair? A gasoline engine mechanic must have a solid understanding of engine components such as pistons, connecting rods, crankshafts, and camshafts. According to a study by the University of Michigan’s Automotive Research Center, a thorough knowledge of fuel injection systems is crucial, as these systems control the precise delivery of fuel into the engine. The mechanic should be proficient in diagnosing and repairing issues related to fuel injectors, fuel pumps, and fuel filters. Ignition systems, including spark plugs, ignition coils, and distributors, also require careful attention. Mechanics must be able to diagnose and resolve issues such as misfires, rough idling, and poor fuel economy. Valve adjustments are another critical aspect of gasoline engine maintenance. Over time, valves can become misaligned, leading to reduced engine performance and potential damage. Mechanics must be able to adjust valve clearances accurately to ensure optimal engine operation.

1.2. Diesel Engine Repair Expertise

What are the unique challenges and skills involved in diesel engine repair? Diesel engines present a different set of challenges and require specialized expertise. According to research from the Diesel Technology Forum, diesel engines rely on high-pressure fuel systems to ignite fuel through compression, rather than spark ignition. Diesel mechanics must be familiar with components such as fuel injectors, high-pressure fuel pumps, and turbochargers. Diagnosing issues in diesel engines often requires specialized tools and techniques. For example, a mechanic might use a diagnostic scanner to monitor fuel pressure, turbocharger boost, and other critical parameters. They must also be able to perform compression tests to assess the condition of the engine’s cylinders. Turbocharger maintenance is another essential aspect of diesel engine repair. Turbochargers increase engine power by forcing more air into the cylinders, but they are also prone to wear and tear. Mechanics must be able to diagnose and repair issues such as turbocharger leaks, bearing failures, and impeller damage.

1.3. Hybrid Engine Repair Expertise

What specific knowledge and skills are needed to repair hybrid engines? Hybrid engines combine the complexities of both gasoline engines and electric motors, demanding a broad range of skills and knowledge from mechanics. According to a study by the National Renewable Energy Laboratory, hybrid vehicles use a combination of an internal combustion engine and an electric motor to improve fuel efficiency. Hybrid mechanics must be proficient in diagnosing and repairing both traditional engine components and electric drive systems. This includes understanding the interaction between the gasoline engine and electric motor, as well as the operation of the high-voltage battery pack. Diagnosing issues in hybrid engines can be particularly challenging. Mechanics must be able to use diagnostic scanners to monitor the performance of both the gasoline engine and the electric motor. They must also be trained in high-voltage safety procedures to avoid electric shock. Battery management systems are another critical area of expertise for hybrid mechanics. These systems control the charging and discharging of the high-voltage battery pack, and any issues with the battery management system can lead to reduced fuel efficiency and potential battery damage.

1.4. Electric Engine Repair Expertise

What are the unique aspects of repairing electric engines and electric vehicles? Electric engines represent a significant departure from traditional internal combustion engines, requiring mechanics to develop new skills and knowledge. According to research from the Electric Power Research Institute, electric vehicles use an electric motor powered by a high-voltage battery pack to drive the wheels. Electric mechanics must be proficient in diagnosing and repairing issues related to battery management systems, electric motor controllers, and high-voltage safety procedures. Battery management systems are a critical area of expertise for electric mechanics. These systems monitor the voltage, current, and temperature of the battery pack, and any issues with the battery management system can lead to reduced range and potential battery damage. Electric motor controllers are another key component of electric vehicles. These controllers regulate the flow of electricity to the electric motor, and any issues with the controller can lead to reduced performance and potential motor damage. High-voltage safety procedures are paramount when working on electric vehicles. Mechanics must be trained in the proper use of safety equipment, such as insulated gloves and safety glasses, to avoid electric shock.

CARDIAGTECH.NET can provide the tools you need to work on all engine types. Contact us at +1 (641) 206-8880 for more information.

2. What Diagnostic Tools Are Essential for Modern Engine Repair?

What diagnostic tools are essential for modern engine repair, and how do they aid in identifying and resolving engine issues? Modern engine repair relies heavily on advanced diagnostic tools to accurately identify and resolve engine issues. These tools range from basic code readers to sophisticated diagnostic scanners, each playing a crucial role in the repair process. According to a report by the Automotive Service Association, the use of diagnostic tools has significantly improved the efficiency and accuracy of engine repairs. Code readers are essential for retrieving diagnostic trouble codes (DTCs) from the engine control unit (ECU). These codes provide valuable information about potential issues, such as misfires, sensor failures, and emissions problems. Diagnostic scanners offer more advanced capabilities, including live data streaming, component testing, and bi-directional controls. Live data streaming allows mechanics to monitor the real-time performance of various engine components, such as fuel injectors, oxygen sensors, and throttle position sensors. Component testing enables mechanics to activate or deactivate individual components to verify their functionality. Bi-directional controls allow mechanics to send commands to the ECU to perform specific tests, such as cylinder compression tests or fuel injector tests.

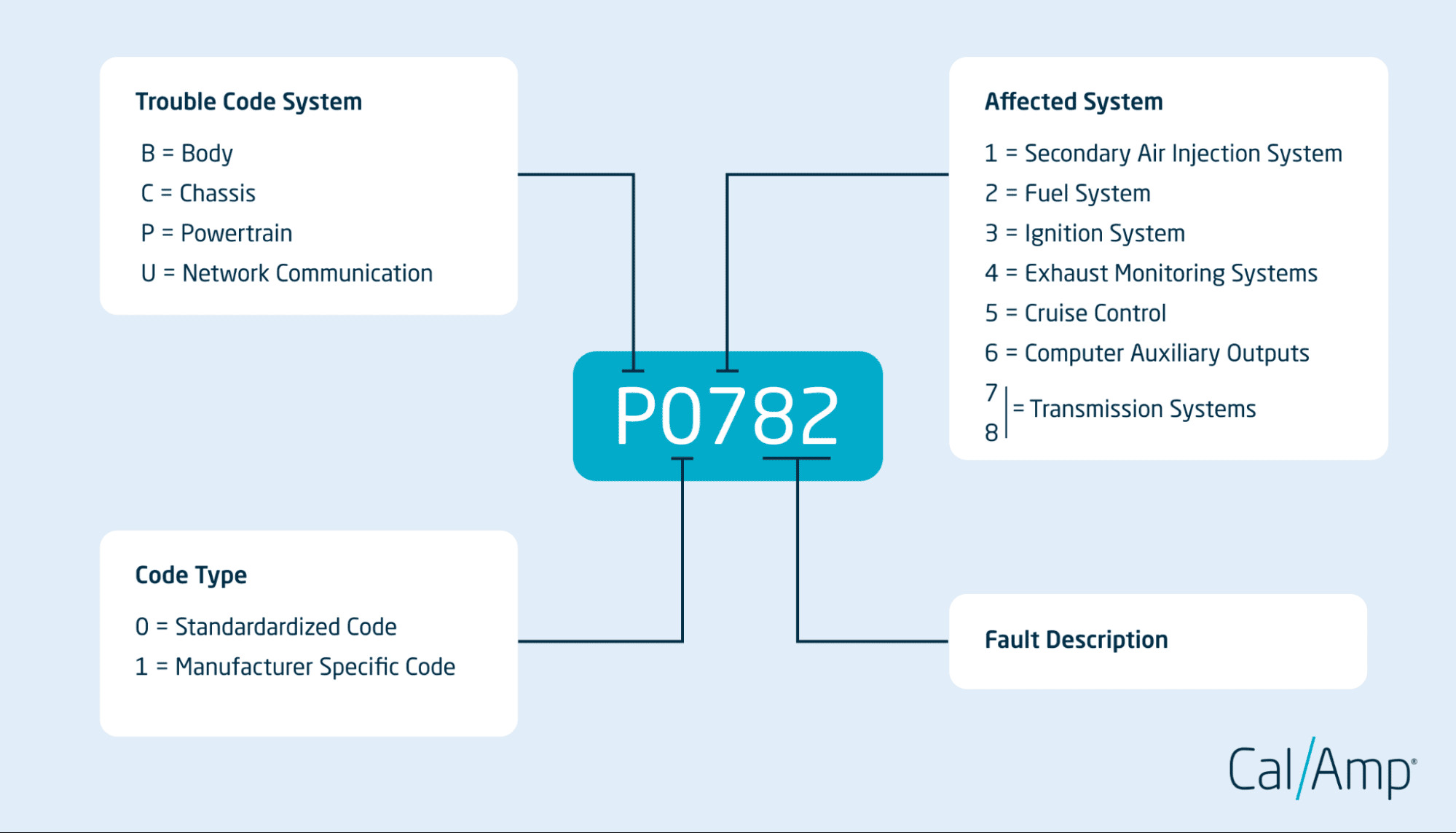

2.1. The Role of Code Readers in Engine Diagnostics

How do code readers assist in diagnosing engine problems? Code readers are indispensable tools for modern engine diagnostics, providing mechanics with a quick and easy way to retrieve diagnostic trouble codes (DTCs) from the engine control unit (ECU). According to a study by the National Institute for Automotive Service Excellence (ASE), DTCs are standardized codes that indicate specific issues within the engine or its related systems. Code readers work by connecting to the vehicle’s diagnostic port, typically located under the dashboard. Once connected, the code reader retrieves any stored DTCs from the ECU and displays them on the screen. These codes can then be used to pinpoint the source of the problem. While code readers provide valuable information, they are not a substitute for thorough diagnostics. Mechanics must still use their knowledge and experience to interpret the codes and perform additional tests to confirm the diagnosis. For example, a DTC indicating a misfire in a specific cylinder might require further investigation to determine the root cause, such as a faulty spark plug, ignition coil, or fuel injector.

2.2. Diagnostic Scanners and Their Advanced Capabilities

What are the advanced capabilities of diagnostic scanners in engine repair? Diagnostic scanners offer a wide range of advanced capabilities that go beyond simple code reading. These tools provide mechanics with real-time data, component testing, and bi-directional controls, allowing for more comprehensive and accurate diagnostics. Live data streaming is one of the most valuable features of diagnostic scanners. This allows mechanics to monitor the real-time performance of various engine components, such as fuel injectors, oxygen sensors, and throttle position sensors. By analyzing this data, mechanics can identify anomalies and pinpoint the source of the problem. For example, a mechanic might use live data streaming to monitor the voltage output of an oxygen sensor to determine if it is functioning correctly. Component testing is another important capability of diagnostic scanners. This allows mechanics to activate or deactivate individual components to verify their functionality. For example, a mechanic might use component testing to activate a fuel injector to check if it is spraying fuel correctly. Bi-directional controls allow mechanics to send commands to the ECU to perform specific tests. For example, a mechanic might use bi-directional controls to perform a cylinder compression test or a fuel injector test.

2.3. Multimeters and Oscilloscopes in Electrical Diagnostics

How are multimeters and oscilloscopes used in electrical diagnostics of engines? Multimeters and oscilloscopes are essential tools for diagnosing electrical issues in modern engines. Multimeters are used to measure voltage, current, and resistance in electrical circuits. Oscilloscopes provide a visual representation of electrical signals, allowing mechanics to analyze waveform patterns and identify anomalies. According to a report by Fluke Corporation, multimeters are used to check the voltage and continuity of circuits, while oscilloscopes are used to analyze the performance of sensors and actuators. Mechanics might use a multimeter to check the voltage at a sensor to determine if it is receiving power. They might also use an oscilloscope to analyze the waveform of a crankshaft position sensor to check for signal irregularities. Both multimeters and oscilloscopes require a solid understanding of electrical theory and circuit analysis. Mechanics must be able to interpret the readings and waveforms to accurately diagnose electrical issues.

CARDIAGTECH.NET provides high-quality diagnostic tools to help you perform effective engine repairs. Contact us at 276 Reock St, City of Orange, NJ 07050, United States.

3. What Are the Common Issues in Gasoline Engines and How Are They Addressed?

What are the common issues in gasoline engines, and what are the methods for addressing them effectively? Gasoline engines, despite their widespread use and relative simplicity, are prone to a variety of issues that can affect their performance and longevity. Common problems include misfires, rough idling, poor fuel economy, and overheating. According to a study by AAA, engine-related issues are among the most frequent causes of vehicle breakdowns. Addressing these issues requires a systematic approach, starting with accurate diagnosis and followed by appropriate repair procedures. Misfires are a common problem in gasoline engines, often caused by faulty spark plugs, ignition coils, or fuel injectors. A misfire occurs when one or more cylinders fail to ignite the air-fuel mixture properly, resulting in reduced power and increased emissions. Diagnosing misfires typically involves using a diagnostic scanner to identify the affected cylinder and then testing the spark plug, ignition coil, and fuel injector. Rough idling can be caused by a variety of factors, including vacuum leaks, dirty throttle bodies, or faulty idle air control valves. Rough idling occurs when the engine struggles to maintain a stable idle speed, resulting in vibrations and poor drivability. Diagnosing rough idling typically involves checking for vacuum leaks, cleaning the throttle body, and testing the idle air control valve.

3.1. Diagnosing and Resolving Misfires

What are the steps to diagnose and resolve misfires in gasoline engines? Diagnosing and resolving misfires in gasoline engines requires a systematic approach to identify the root cause of the problem. Misfires can be caused by a variety of factors, including faulty spark plugs, ignition coils, fuel injectors, or even compression issues. According to a guide by the National Institute for Automotive Service Excellence (ASE), the first step in diagnosing a misfire is to use a diagnostic scanner to retrieve diagnostic trouble codes (DTCs) from the engine control unit (ECU). These codes will indicate which cylinder is misfiring. Once the affected cylinder has been identified, the next step is to inspect the spark plug, ignition coil, and fuel injector. The spark plug should be inspected for signs of wear, damage, or fouling. The ignition coil should be tested for proper resistance and output voltage. The fuel injector should be tested for proper spray pattern and flow rate. If the spark plug, ignition coil, and fuel injector appear to be in good condition, the next step is to perform a compression test on the affected cylinder. A compression test will reveal whether the cylinder has adequate compression to support combustion. If the compression is low, it could indicate a problem with the valves, piston rings, or cylinder head.

3.2. Addressing Rough Idling and Vacuum Leaks

How do you identify and fix rough idling and vacuum leaks in gasoline engines? Addressing rough idling and vacuum leaks in gasoline engines requires a systematic approach to identify and repair the source of the problem. Rough idling can be caused by a variety of factors, including vacuum leaks, dirty throttle bodies, or faulty idle air control valves. According to a report by the Automotive Service Association, vacuum leaks are a common cause of rough idling. Vacuum leaks occur when air enters the engine through unintended pathways, disrupting the air-fuel mixture and causing the engine to run poorly. Identifying vacuum leaks typically involves using a smoke machine to introduce smoke into the intake manifold. The smoke will then escape through any vacuum leaks, making them easy to spot. Once a vacuum leak has been identified, it should be repaired by replacing the damaged hose or gasket. A dirty throttle body can also cause rough idling. The throttle body controls the amount of air entering the engine, and if it becomes dirty or clogged, it can disrupt the airflow and cause the engine to idle roughly. Cleaning the throttle body typically involves using a throttle body cleaner to remove any deposits or debris.

3.3. Improving Fuel Economy in Gasoline Engines

What are the strategies for improving fuel economy in gasoline engines? Improving fuel economy in gasoline engines involves addressing factors that affect the engine’s efficiency, such as air-fuel mixture, ignition timing, and overall engine condition. According to the Environmental Protection Agency (EPA), regular maintenance and proper driving habits can significantly improve fuel economy. One of the most effective ways to improve fuel economy is to ensure that the engine is properly tuned. This includes checking and adjusting the air-fuel mixture, ignition timing, and valve clearances. A properly tuned engine will run more efficiently and consume less fuel. Replacing worn spark plugs can also improve fuel economy. Worn spark plugs can cause misfires, which reduce engine efficiency and increase fuel consumption. Replacing worn spark plugs with new ones can restore the engine’s efficiency and improve fuel economy. Keeping the tires properly inflated can also improve fuel economy. Underinflated tires create more rolling resistance, which reduces fuel economy. Checking and maintaining the proper tire pressure can improve fuel economy by as much as 3%.

To get the best performance from your gasoline engines, trust CARDIAGTECH.NET for your diagnostic and repair needs. Call us at +1 (641) 206-8880.

4. What Are the Key Maintenance Procedures for Diesel Engines?

What are the key maintenance procedures for diesel engines, and why are they crucial for longevity and performance? Diesel engines require specific maintenance procedures to ensure their longevity and optimal performance. These procedures include regular oil changes, fuel filter replacements, and cooling system maintenance. According to a study by the Diesel Technology Forum, proper maintenance can significantly extend the life of a diesel engine and prevent costly repairs. Oil changes are essential for diesel engines because diesel oil tends to become contaminated more quickly than gasoline oil. Diesel oil contains additives to neutralize acids and suspend soot particles, but these additives deplete over time. Regular oil changes help to remove contaminants and ensure that the engine is properly lubricated. Fuel filter replacements are also crucial for diesel engines. Diesel fuel can contain contaminants that can clog the fuel filter and reduce engine performance. Replacing the fuel filter regularly helps to ensure that the engine receives a clean supply of fuel.

4.1. The Importance of Regular Oil Changes in Diesel Engines

Why are regular oil changes particularly important for diesel engines? Regular oil changes are particularly important for diesel engines due to the unique characteristics of diesel combustion and the resulting contaminants that accumulate in the oil. According to a guide by Mobil, diesel engines produce more soot and other combustion byproducts than gasoline engines, which can quickly degrade the oil’s lubricating properties. Diesel oil contains additives designed to neutralize acids and suspend soot particles, but these additives deplete over time. As the oil degrades, it becomes less effective at protecting the engine’s components from wear and tear. Regular oil changes help to remove these contaminants and replenish the oil’s additives, ensuring that the engine is properly lubricated and protected. The frequency of oil changes depends on several factors, including the engine’s operating conditions, the type of oil used, and the manufacturer’s recommendations. However, as a general rule, diesel engines should have their oil changed more frequently than gasoline engines.

4.2. Fuel Filter Replacements and Fuel System Maintenance

How often should fuel filters be replaced in diesel engines, and what other fuel system maintenance is necessary? Fuel filter replacements are a critical part of diesel engine maintenance, as diesel fuel can contain contaminants that can clog the filter and reduce engine performance. According to a report by Fleet Owner magazine, clogged fuel filters can lead to reduced power, poor fuel economy, and even engine damage. The frequency of fuel filter replacements depends on several factors, including the quality of the fuel, the engine’s operating conditions, and the manufacturer’s recommendations. However, as a general rule, diesel engines should have their fuel filters replaced every 10,000 to 20,000 miles. In addition to fuel filter replacements, other fuel system maintenance procedures are also necessary to ensure the proper operation of diesel engines. These procedures include checking the fuel lines for leaks, inspecting the fuel injectors for proper spray pattern, and cleaning the fuel tank to remove any sediment or debris.

4.3. Cooling System Maintenance in Diesel Engines

What are the key aspects of cooling system maintenance in diesel engines? Cooling system maintenance is essential for diesel engines, as these engines generate a significant amount of heat. According to a guide by Cummins, proper cooling system maintenance can prevent overheating, extend engine life, and improve fuel economy. Key aspects of cooling system maintenance include checking the coolant level regularly, inspecting the hoses and belts for wear and tear, and flushing the cooling system periodically to remove any sediment or debris. The coolant level should be checked regularly to ensure that the engine has adequate coolant to prevent overheating. The hoses and belts should be inspected for signs of wear, such as cracks or fraying. Worn hoses and belts should be replaced to prevent leaks or failures. The cooling system should be flushed periodically to remove any sediment or debris that can accumulate over time. This helps to maintain the cooling system’s efficiency and prevent overheating.

CARDIAGTECH.NET can help you maintain your diesel engines with our comprehensive range of tools and equipment. Contact us at 276 Reock St, City of Orange, NJ 07050, United States.

5. What Are the Safety Precautions When Working on Hybrid and Electric Vehicles?

What are the necessary safety precautions when working on hybrid and electric vehicles due to their high-voltage systems? Working on hybrid and electric vehicles requires strict adherence to safety precautions due to their high-voltage systems. These vehicles operate at voltages significantly higher than traditional gasoline-powered cars, posing a risk of electric shock if proper procedures are not followed. According to the National Fire Protection Association (NFPA), hybrid and electric vehicles can have voltages ranging from 200 to 800 volts DC, which can be lethal. Safety precautions include wearing appropriate personal protective equipment (PPE), de-energizing the high-voltage system before starting work, and using insulated tools. PPE includes insulated gloves, safety glasses, and non-conductive footwear. Insulated gloves are rated for specific voltage levels and should be inspected for damage before each use. Safety glasses protect the eyes from potential arc flashes or explosions. Non-conductive footwear prevents electrical current from passing through the body to the ground.

5.1. Personal Protective Equipment (PPE) for Hybrid/EV Work

What specific personal protective equipment is required when working on hybrid and electric vehicles? Personal protective equipment (PPE) is essential when working on hybrid and electric vehicles to protect against the hazards of high-voltage systems. According to a guide by the Occupational Safety and Health Administration (OSHA), PPE should include insulated gloves, safety glasses, and non-conductive footwear. Insulated gloves are the most critical piece of PPE for hybrid/EV work. These gloves are designed to protect against electric shock by providing a barrier between the technician and the high-voltage components. The gloves must be rated for the specific voltage levels of the vehicle being worked on and should be inspected for damage before each use. Safety glasses are also essential to protect the eyes from potential arc flashes or explosions. Arc flashes can occur when high-voltage electricity jumps across a gap, creating a bright flash of light and intense heat. Non-conductive footwear prevents electrical current from passing through the body to the ground. This type of footwear is typically made of rubber or other non-conductive materials.

5.2. De-Energizing High-Voltage Systems Safely

What is the proper procedure for de-energizing the high-voltage system in hybrid and electric vehicles? De-energizing the high-voltage system is a critical step before starting any work on hybrid and electric vehicles. This process involves disconnecting the high-voltage battery pack and ensuring that all high-voltage components are no longer energized. According to a guide by the Society of Automotive Engineers (SAE), the de-energizing procedure should be performed according to the vehicle manufacturer’s instructions. The first step is to disconnect the negative terminal of the 12-volt battery. This will prevent the vehicle from accidentally starting up during the repair process. Next, locate the high-voltage disconnect switch, which is typically located under the hood or in the passenger compartment. Follow the manufacturer’s instructions to disconnect the high-voltage battery pack. After disconnecting the high-voltage battery pack, wait for the specified amount of time to allow the capacitors in the system to discharge. This can take anywhere from 5 minutes to 30 minutes, depending on the vehicle.

5.3. Using Insulated Tools and Equipment

Why is it important to use insulated tools and equipment when working on hybrid and electric vehicles? Using insulated tools and equipment is essential when working on hybrid and electric vehicles to prevent electric shock. Insulated tools are designed to provide a barrier between the technician and the high-voltage components, reducing the risk of electrical current passing through the body. According to a guide by the Electric Vehicle Safety Training Consortium, insulated tools should be used for all work on high-voltage systems. Insulated tools are typically marked with a voltage rating, indicating the maximum voltage they are designed to withstand. It is important to use tools that are rated for the specific voltage levels of the vehicle being worked on. Before using insulated tools, they should be inspected for damage, such as cracks or cuts in the insulation. Damaged tools should be replaced immediately. In addition to insulated tools, other specialized equipment is also required for hybrid/EV work, such as high-voltage test meters and insulation testers.

CARDIAGTECH.NET offers a range of insulated tools and equipment to ensure your safety when working on hybrid and electric vehicles. Contact us at +1 (641) 206-8880.

6. How Do You Diagnose Battery Issues in Hybrid and Electric Vehicles?

What are the methods for diagnosing battery issues in hybrid and electric vehicles, and how can you ensure accurate results? Diagnosing battery issues in hybrid and electric vehicles requires specialized tools and knowledge due to the complexity of high-voltage battery systems. Common battery problems include reduced range, decreased performance, and complete battery failure. According to a report by the National Renewable Energy Laboratory (NREL), battery-related issues are among the most common problems in hybrid and electric vehicles. Diagnosing these issues requires a systematic approach, starting with a visual inspection of the battery pack and followed by advanced diagnostic tests. A visual inspection can reveal obvious signs of damage, such as leaks, corrosion, or swelling. However, many battery issues are not visible to the naked eye and require advanced diagnostic tests to identify. These tests include voltage testing, capacity testing, and internal resistance testing.

6.1. Voltage Testing and Balancing Procedures

How do you perform voltage testing and balancing procedures on hybrid and electric vehicle batteries? Voltage testing and balancing are essential procedures for diagnosing and maintaining hybrid and electric vehicle batteries. Voltage testing involves measuring the voltage of individual battery modules to identify any cells that are significantly lower or higher than the others. According to a guide by the Electric Power Research Institute (EPRI), voltage imbalances can indicate underlying problems with the battery pack. The voltage of each battery module should be measured using a high-voltage multimeter. The readings should be compared to the manufacturer’s specifications to identify any modules that are out of range. Balancing procedures involve adjusting the voltage of individual battery modules to ensure that they are all at the same level. This helps to improve the battery pack’s overall performance and longevity. Balancing can be performed using specialized battery balancing equipment.

6.2. Capacity Testing for Battery Health Assessment

What is capacity testing, and how does it help assess the health of hybrid and electric vehicle batteries? Capacity testing is a critical method for assessing the overall health and performance of hybrid and electric vehicle batteries. Capacity testing involves measuring the amount of energy that the battery can store and deliver. According to a report by the Idaho National Laboratory (INL), a battery’s capacity decreases over time due to aging and degradation. The capacity of a battery is typically measured in amp-hours (Ah). A battery with a higher capacity can store and deliver more energy than a battery with a lower capacity. Capacity testing is performed using specialized battery testing equipment. The battery is fully charged and then discharged at a constant rate until it reaches a specified voltage level. The amount of energy that the battery delivers during the discharge is measured and compared to the manufacturer’s specifications.

6.3. Identifying Internal Resistance Issues in Batteries

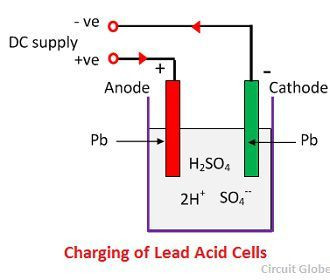

How can internal resistance issues be identified and addressed in hybrid and electric vehicle batteries? Internal resistance is a measure of the opposition to the flow of electricity within a battery. According to a guide by the Argonne National Laboratory (ANL), high internal resistance can reduce a battery’s performance and lifespan. Internal resistance can be caused by a variety of factors, including corrosion, degradation of the electrodes, and electrolyte depletion. High internal resistance can lead to reduced power output, increased heat generation, and decreased charging efficiency. Internal resistance can be measured using specialized battery testing equipment. The equipment applies a load to the battery and measures the voltage drop. The voltage drop is then used to calculate the internal resistance. Addressing internal resistance issues typically involves replacing the affected battery modules or cells. In some cases, it may be possible to reduce internal resistance by cleaning the battery terminals and connections.

CARDIAGTECH.NET offers the tools and equipment you need to diagnose and maintain hybrid and electric vehicle batteries. Contact us at 276 Reock St, City of Orange, NJ 07050, United States.

7. What Is the Future of Engine Repair with Emerging Technologies?

What is the future of engine repair, considering the impact of emerging technologies and evolving vehicle designs? The future of engine repair is being shaped by emerging technologies and evolving vehicle designs. As vehicles become more complex and rely increasingly on electronic systems, mechanics will need to adapt their skills and knowledge to stay ahead of the curve. According to a report by Deloitte, the automotive industry is undergoing a period of rapid transformation, driven by trends such as electrification, autonomous driving, and connected car technologies. These trends will have a profound impact on the way engines are designed, manufactured, and repaired. Mechanics will need to be proficient in diagnosing and repairing issues related to electric motors, battery management systems, and advanced driver-assistance systems (ADAS). They will also need to be comfortable working with data and software, as these will play an increasingly important role in engine diagnostics and repair.

7.1. The Impact of Electric Vehicles on Engine Repair

How will the rise of electric vehicles change the landscape of engine repair? The rise of electric vehicles (EVs) is poised to significantly alter the landscape of engine repair, shifting the focus from traditional internal combustion engines (ICEs) to electric motors, battery systems, and power electronics. According to a forecast by Bloomberg New Energy Finance, EVs are expected to account for a majority of new car sales by 2040. This transition will lead to a decline in the demand for traditional engine repair services and an increase in the demand for EV-related repair services. Mechanics will need to acquire new skills and knowledge to work on EVs, including expertise in high-voltage systems, battery management, and electric motor diagnostics. They will also need to invest in specialized tools and equipment, such as insulated tools, high-voltage test meters, and battery testing equipment.

7.2. The Role of Artificial Intelligence (AI) in Diagnostics

How can artificial intelligence (AI) enhance engine diagnostics and repair processes? Artificial intelligence (AI) is emerging as a powerful tool for enhancing engine diagnostics and repair processes. AI can analyze vast amounts of data from vehicle sensors, diagnostic tools, and repair databases to identify patterns and anomalies that would be difficult for humans to detect. According to a report by McKinsey, AI can improve the accuracy and efficiency of engine diagnostics, reducing downtime and repair costs. AI-powered diagnostic systems can provide mechanics with step-by-step guidance on how to diagnose and repair complex engine problems. They can also predict potential engine failures before they occur, allowing for proactive maintenance and preventing costly breakdowns.

7.3. The Importance of Continuous Learning for Mechanics

Why is continuous learning essential for mechanics in the face of technological advancements in the automotive industry? Continuous learning is becoming increasingly essential for mechanics in the face of rapid technological advancements in the automotive industry. As vehicles become more complex and rely increasingly on electronic systems, mechanics must stay up-to-date with the latest technologies and repair techniques. According to a study by the National Automobile Dealers Association (NADA), mechanics who invest in continuous learning are more likely to be successful and earn higher salaries. Continuous learning can take many forms, including attending training courses, reading technical publications, and participating in online forums. Mechanics can also pursue certifications from organizations such as the National Institute for Automotive Service Excellence (ASE) to demonstrate their expertise.

Stay ahead of the curve with CARDIAGTECH.NET’s advanced tools and training resources. Call us today at +1 (641) 206-8880.

8. What Are the Benefits of Using High-Quality Repair Tools?

What are the advantages of using high-quality repair tools over cheaper alternatives in terms of efficiency, safety, and durability? Using high-quality repair tools offers significant advantages over cheaper alternatives in terms of efficiency, safety, and durability. High-quality tools are designed to perform their intended function accurately and reliably, reducing the risk of errors and rework. According to a report by Consumer Reports, high-quality tools are more likely to last longer and provide better value for money in the long run. Efficiency is improved with high-quality tools because they are designed to fit properly and work smoothly. This reduces the amount of time and effort required to complete a repair. Safety is enhanced with high-quality tools because they are less likely to break or fail during use, reducing the risk of injury. Durability is a key advantage of high-quality tools. These tools are typically made from stronger materials and are designed to withstand the rigors of daily use.

8.1. Improving Efficiency with Precision Tools

How do precision tools contribute to greater efficiency in engine repair? Precision tools play a critical role in improving efficiency in engine repair by ensuring accuracy, reducing errors, and minimizing rework. According to a guide by Snap-on, precision tools are designed to meet exacting standards and provide consistent performance. Accurate measurements are essential for many engine repair tasks, such as setting valve clearances, adjusting fuel injectors, and torquing bolts. Precision tools, such as micrometers, dial indicators, and torque wrenches, allow mechanics to make these measurements with confidence. Reducing errors is another key benefit of precision tools. When tools fit properly and work smoothly, there is less chance of damaging components or making mistakes. Minimizing rework is a direct result of using precision tools. By ensuring accuracy and reducing errors, mechanics can complete repairs correctly the first time, saving time and money.

8.2. Ensuring Safety with Reliable Equipment

How does reliable equipment contribute to a safer working environment for mechanics? Reliable equipment is essential for ensuring a safer working environment for mechanics. According to a guide by the National Safety Council, reliable equipment is less likely to break or fail during use, reducing the risk of injury. Reliable equipment includes items such as jacks, lifts, and safety stands. These items are designed to support vehicles safely and securely while mechanics are working underneath them. Using reliable equipment helps to prevent accidents and injuries, such as vehicle rollovers or falls.

8.3. Long-Term Cost Savings with Durable Tools

What are the long-term cost savings associated with investing in durable repair tools? Investing in durable repair tools can lead to significant long-term cost savings. While durable tools may cost more upfront, they are designed to last longer and withstand the rigors of daily use. According to a report by the Equipment Leasing and Finance Association, durable tools can reduce the need for frequent replacements, saving money over time. In addition to reducing replacement costs, durable tools can also improve efficiency and reduce downtime. Durable tools are less likely to break or fail during use, which means that mechanics can complete repairs more quickly and with less interruption.

Invest in your future with CARDIAGTECH.NET’s durable and reliable repair tools. Contact us at 276 Reock St, City of Orange, NJ 07050, United States.

9. How to Stay Updated with the Latest Engine Repair Techniques?

What are the best strategies for staying updated with the latest engine repair techniques and advancements in the automotive industry? Staying updated with the latest engine repair techniques and advancements in the automotive industry is crucial for mechanics to remain competitive and provide high-quality service. The automotive industry is constantly evolving, with new technologies and repair methods emerging all the time. According to a report by the TechForce Foundation, mechanics who stay up-to-date with the latest advancements are more likely to be successful and earn higher salaries. Strategies for staying updated include attending training courses, reading technical publications, participating in online forums, and pursuing certifications.

9.1. Attending Industry Training Courses and Workshops

What are the benefits of attending industry training courses and workshops for engine repair? Attending industry training courses and workshops offers numerous benefits for engine repair professionals. These courses provide hands-on experience, expert instruction, and the opportunity to network with other professionals in the field. According to a guide by the Automotive Management Institute (AMI), training courses can improve mechanics’ skills, knowledge, and earning potential. Hands-on experience is a key benefit of training courses. Mechanics can practice new repair techniques under the guidance of experienced instructors. Expert instruction is another valuable aspect of training courses. Instructors can provide insights and tips that are not available elsewhere. Networking opportunities are also important. Training courses provide a chance to meet other mechanics and share ideas and experiences.

9.2. Subscribing to Technical Publications and Online Resources

How can technical publications and online resources help mechanics stay informed about engine repair advancements? Subscribing to technical publications and utilizing online resources can be an effective way for mechanics to stay informed about engine repair advancements. According to a guide by the Society of Automotive Engineers (SAE), technical publications provide in-depth information on new technologies and repair methods. Technical publications include magazines, journals, and manuals. These resources often feature articles written by industry experts and provide detailed explanations of complex concepts. Online resources, such as websites, forums, and blogs, can also be valuable sources of information. These resources often feature up-to-date news and information on the latest advancements.

9.3. Pursuing Certifications to Demonstrate Expertise

What are the advantages of pursuing certifications, such as ASE certifications, for engine repair technicians? Pursuing certifications, such as ASE (National Institute for Automotive Service Excellence) certifications, offers numerous advantages for engine repair technicians. According to a guide by ASE, certifications demonstrate expertise, improve credibility, and increase earning potential. Demonstrating expertise is a key benefit of certifications. Certifications show that a technician has met certain standards of knowledge and skill. Improving credibility is another advantage of certifications. Certifications can help to build trust with customers and employers. Increasing earning potential is also a significant benefit. Certified technicians are often able to command higher salaries than non-certified technicians.

Keep your skills sharp with CARDIAGTECH.NET’s resources and training opportunities. Call us at +1 (641) 206-8880.

10. What Are Common Mistakes to Avoid During Engine Repair?

What are the common mistakes to avoid during engine repair to ensure quality and prevent future issues? Avoiding common mistakes during engine repair is crucial for ensuring quality and preventing future issues. Mistakes can lead to reduced performance, increased downtime, and even engine damage. According to a guide by the Automotive Service Association (ASA), common mistakes include improper diagnosis, using incorrect parts, and neglecting safety precautions. Improper diagnosis is a frequent mistake. Mechanics may misdiagnose the problem, leading to unnecessary repairs and continued issues. Using incorrect parts is another common mistake. Parts must be compatible with the vehicle and meet the manufacturer’s specifications.

10.1. Avoiding Improper Diagnosis Through Thorough Inspection

How can improper diagnosis be avoided through thorough inspection and diagnostic procedures? Improper diagnosis can be avoided through thorough inspection and diagnostic procedures. According to a guide by the National Institute for Automotive Service Excellence (ASE), a thorough inspection involves a visual examination of the engine and its components. This includes checking for leaks, damage,