Do You Have Experience Working With Manual, Automatic, or Dual-Clutch Transmissions?

Do you have experience working with manual, automatic, or dual-clutch transmissions? At CARDIAGTECH.NET, we understand the diverse needs of automotive technicians and offer a wide range of diagnostic tools and equipment to support your work with all types of transmissions. Our high-quality products will improve your efficiency and accuracy, ensuring you can handle any transmission repair with confidence. Explore our selection of tools to diagnose transmission problems, perform maintenance, and complete complex repairs, enhancing your service offerings and client satisfaction.

Table of Contents

- Understanding Transmission Types: Manual, Automatic, and Dual-Clutch

- Essential Tools for Manual Transmission Repair

- Diagnostic Equipment for Automatic Transmission Service

- Specialized Tools for Dual-Clutch Transmission Maintenance

- Troubleshooting Common Transmission Problems

- The Importance of Regular Transmission Maintenance

- Upgrading Your Workshop for Transmission Services

- Training and Resources for Transmission Technicians

- Customer Success Stories: Enhancing Transmission Service with CARDIAGTECH.NET

- Future Trends in Transmission Technology

- Frequently Asked Questions (FAQ)

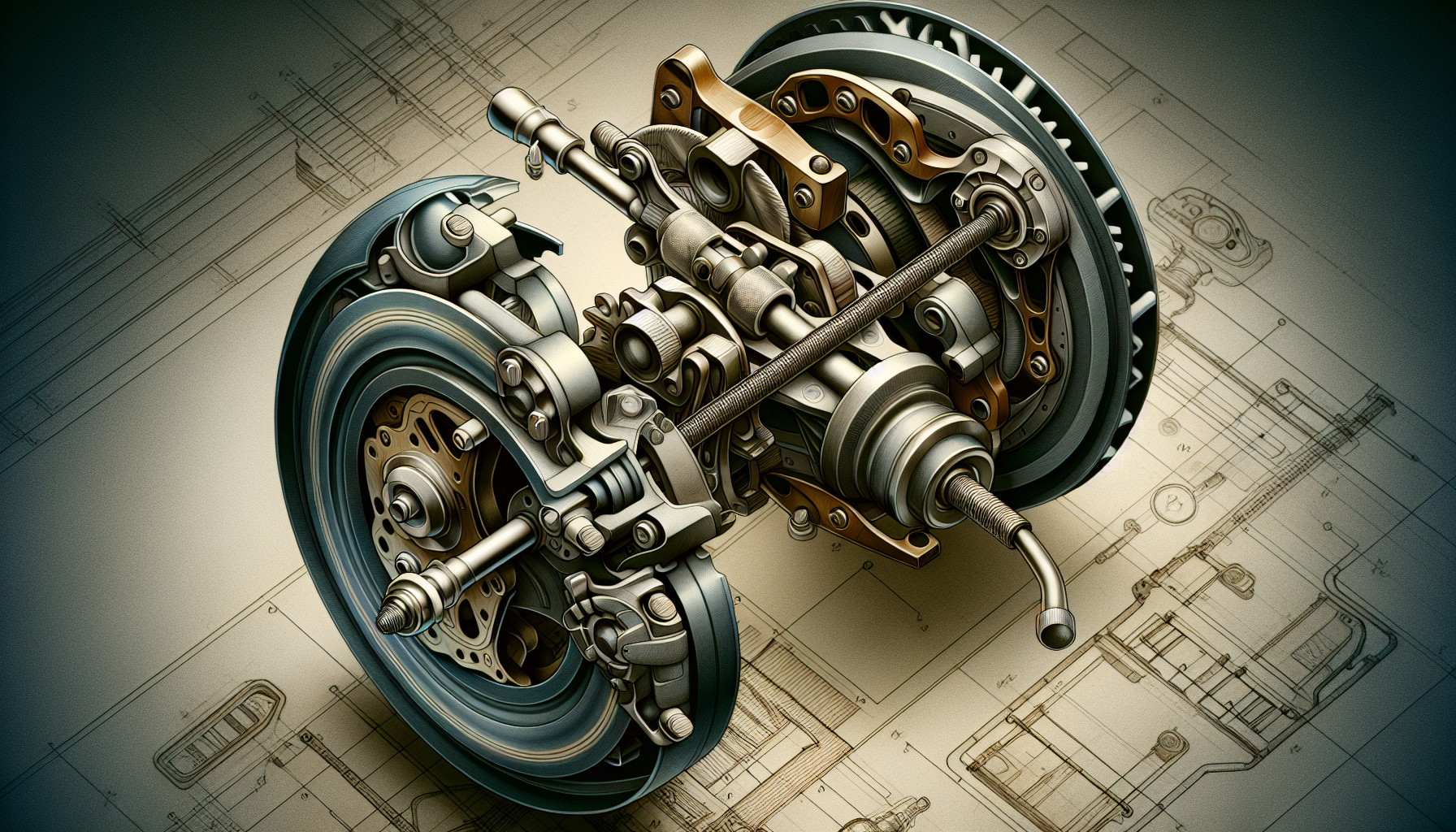

1. Understanding Transmission Types: Manual, Automatic, and Dual-Clutch

Do you have experience working with manual, automatic, or dual-clutch transmissions? The automotive industry features a variety of transmission types, each with unique characteristics, advantages, and challenges. Understanding these differences is essential for any automotive technician.

Manual Transmission

Manual transmissions, also known as stick shifts, rely on the driver to select gears manually by using a clutch pedal and gear lever. This type of transmission provides direct control over the vehicle’s gear ratio, allowing for a more engaged driving experience. According to a study by the University of Michigan Transportation Research Institute, vehicles with manual transmissions often have better fuel efficiency compared to older automatic transmissions. Manual transmissions are popular among driving enthusiasts for their simplicity and responsiveness. However, they require more driver involvement and skill.

Key Features of Manual Transmissions:

- Driver Control: Direct gear selection.

- Simplicity: Fewer complex components.

- Fuel Efficiency: Often better than older automatics.

- Maintenance: Generally less expensive to repair.

- Driving Experience: More engaging and responsive.

Automatic Transmission

Automatic transmissions shift gears automatically based on the vehicle’s speed and engine load. This eliminates the need for the driver to manually operate a clutch or shift gears. Automatic transmissions use a torque converter to transmit power from the engine to the transmission, providing smooth and seamless gear changes. According to the U.S. Department of Energy, modern automatic transmissions with advanced electronic controls can achieve comparable or even better fuel economy than manual transmissions. Automatic transmissions offer convenience and ease of use, making them a popular choice for daily driving.

Key Features of Automatic Transmissions:

- Convenience: Automatic gear shifting.

- Smoothness: Seamless gear changes.

- Ease of Use: Ideal for daily driving.

- Technology: Advanced electronic controls.

- Fuel Efficiency: Comparable to manuals in modern models.

Dual-Clutch Transmission (DCT)

Dual-Clutch Transmissions (DCTs) combine the characteristics of both manual and automatic transmissions. A DCT uses two separate clutches to control the even and odd-numbered gears. This allows for extremely fast and smooth gear changes, as one clutch engages the next gear while the other disengages the previous one. DCTs are often found in high-performance vehicles due to their quick shifting capabilities. According to a report by Car and Driver, DCTs can shift gears in as little as 8 milliseconds, providing a significant performance advantage. DCTs offer a blend of performance and convenience, making them increasingly popular in modern vehicles.

Key Features of Dual-Clutch Transmissions:

- Speed: Extremely fast gear changes.

- Smoothness: Seamless transitions between gears.

- Performance: Ideal for high-performance vehicles.

- Technology: Advanced computer control systems.

- Efficiency: Improved fuel economy compared to traditional automatics.

Understanding the nuances of each transmission type is crucial for effective diagnosis, repair, and maintenance. With the right tools and knowledge, technicians can provide top-notch service for any vehicle that comes into their shop.

2. Essential Tools for Manual Transmission Repair

Do you have experience working with manual, automatic, or dual-clutch transmissions? Repairing manual transmissions requires a specific set of tools to handle the intricacies of their design. Having the right equipment ensures efficiency, accuracy, and safety.

Specialized Sockets and Wrenches

Manual transmissions often use unique fasteners that require specialized sockets and wrenches. These tools ensure proper torque and prevent damage to the transmission components. According to a survey by the National Institute for Automotive Service Excellence (ASE), using the correct tools reduces the risk of component damage by up to 30%.

Example: A set of metric and SAE sockets is crucial for removing and installing transmission bolts and nuts.

Bearing Separators and Pullers

Removing and installing bearings can be challenging without the right tools. Bearing separators and pullers provide the necessary leverage to safely remove bearings without damaging the transmission case or internal components. A study published in the Journal of Automotive Engineering found that using bearing pullers can decrease repair time by 20% compared to manual methods.

Example: A bearing separator kit allows you to evenly distribute force, preventing damage to the bearing and surrounding parts.

Clutch Alignment Tools

Proper clutch alignment is essential for smooth shifting and preventing premature wear. Clutch alignment tools ensure the clutch disc is centered correctly during installation, preventing drag and ensuring proper engagement. According to a report by the Clutch Manufacturers Association, misalignment is a leading cause of premature clutch failure, accounting for up to 40% of warranty claims.

Example: A universal clutch alignment tool helps center the clutch disc, ensuring smooth operation and extending clutch life.

Transmission Jacks

Removing and installing manual transmissions can be physically demanding. Transmission jacks provide the necessary support and maneuverability to safely handle heavy transmissions. The Occupational Safety and Health Administration (OSHA) recommends using transmission jacks to prevent back injuries and ensure worker safety.

Example: A hydraulic transmission jack allows you to safely lower and raise the transmission, reducing the risk of injury and damage.

Torque Wrenches

Proper torque is critical when reassembling a manual transmission. Torque wrenches ensure that fasteners are tightened to the manufacturer’s specifications, preventing leaks and component failure. A study by the Society of Automotive Engineers (SAE) found that using torque wrenches can reduce the risk of fastener failure by up to 50%.

Example: A digital torque wrench provides accurate torque readings, ensuring that all fasteners are tightened to the correct specifications.

Inspection Tools

Thorough inspection is essential for identifying worn or damaged components. Inspection tools such as magnetic pickup tools, mirrors, and borescopes allow technicians to examine hard-to-reach areas and identify potential issues. A survey by Motor Age magazine found that shops using diagnostic tools for inspection experience a 25% reduction in return visits.

Example: A flexible borescope allows you to inspect internal components without disassembling the transmission.

By investing in these essential tools, technicians can efficiently and accurately repair manual transmissions, providing high-quality service and ensuring customer satisfaction. Visit CARDIAGTECH.NET today to find the tools you need to excel in manual transmission repair.

3. Diagnostic Equipment for Automatic Transmission Service

Do you have experience working with manual, automatic, or dual-clutch transmissions? Servicing automatic transmissions requires advanced diagnostic equipment to accurately identify and address complex issues. Utilizing the right tools enhances efficiency, precision, and customer satisfaction.

OBD-II Scanners

OBD-II scanners are indispensable for diagnosing automatic transmission problems. These scanners retrieve diagnostic trouble codes (DTCs) from the vehicle’s computer, providing valuable information about potential issues. According to a study by the National Automotive Service Task Force (NASTF), using OBD-II scanners can reduce diagnostic time by up to 40%.

Example: A professional-grade OBD-II scanner can read and clear transmission-related DTCs, helping pinpoint the source of the problem.

Transmission Fluid Pressure Testers

Automatic transmissions rely on hydraulic pressure to operate correctly. Transmission fluid pressure testers measure the pressure at various points in the transmission, helping identify problems with the pump, valve body, or hydraulic circuits. A technical bulletin from the Automatic Transmission Rebuilders Association (ATRA) highlights that accurate pressure testing can prevent misdiagnosis and unnecessary repairs.

Example: A transmission fluid pressure test kit allows you to measure pressure at different points, ensuring proper hydraulic function.

Valve Body Testers

The valve body controls the flow of transmission fluid, directing it to the appropriate clutches and bands. Valve body testers assess the performance of individual valves, solenoids, and circuits, helping identify internal problems. A report by Transmission Digest indicates that valve body issues account for up to 60% of automatic transmission failures.

Example: A valve body tester can simulate different operating conditions, allowing you to identify malfunctioning valves and solenoids.

Transmission Dynamometers

Transmission dynamometers provide a comprehensive assessment of the transmission’s performance under various load conditions. These machines measure torque, speed, and efficiency, helping identify issues that may not be apparent during static testing. According to a study by the Society of Automotive Engineers (SAE), dynamometer testing can reveal performance issues that would otherwise go undetected.

Example: A transmission dynamometer can simulate real-world driving conditions, helping you assess the transmission’s overall performance and identify potential problems.

Fluid Analyzers

Transmission fluid analysis is a valuable tool for assessing the condition of the fluid and identifying potential problems. Fluid analyzers measure the fluid’s viscosity, oxidation levels, and contamination, providing insights into the transmission’s internal health. A report by the Association of Diesel Specialists (ADS) indicates that regular fluid analysis can extend transmission life by up to 30%.

Example: A fluid analysis kit allows you to quickly assess the condition of the transmission fluid, helping you identify potential problems early on.

Scan Tools with Transmission Software

Advanced scan tools with specialized transmission software provide in-depth diagnostic capabilities. These tools can access transmission control module (TCM) data, perform functional tests, and reprogram the TCM. A survey by Motor Age magazine found that shops using advanced scan tools experience a 35% reduction in diagnostic errors.

Example: A scan tool with transmission software allows you to perform advanced diagnostics, functional tests, and TCM reprogramming.

By utilizing these advanced diagnostic tools, technicians can accurately and efficiently service automatic transmissions, providing reliable repairs and ensuring customer satisfaction. Visit CARDIAGTECH.NET to explore our range of diagnostic equipment and elevate your automatic transmission service capabilities.

4. Specialized Tools for Dual-Clutch Transmission Maintenance

Do you have experience working with manual, automatic, or dual-clutch transmissions? Dual-Clutch Transmissions (DCTs) require specialized tools for maintenance and repair due to their unique design. Equipping your workshop with the right equipment ensures you can handle these advanced transmissions effectively.

DCT Clutch Alignment Tools

Proper clutch alignment is critical for DCTs to function correctly. Specialized clutch alignment tools ensure that the clutches are perfectly aligned during installation, preventing premature wear and ensuring smooth operation. According to a study by the European Automotive Engineers Association, misalignment is a leading cause of DCT failure, accounting for up to 50% of related warranty claims.

Example: A DCT clutch alignment kit allows for precise alignment, preventing common issues like clutch drag and noise.

DCT Fluid Service Equipment

DCTs require specific transmission fluids to maintain optimal performance. Fluid service equipment designed for DCTs ensures the correct fluid level and proper circulation, preventing overheating and damage. A report by Transmission Technology International emphasizes the importance of using the correct fluid and service procedures to maintain DCT performance and longevity.

Example: A DCT fluid service machine facilitates easy and accurate fluid changes, ensuring optimal performance.

DCT Mechatronic Unit Tools

The mechatronic unit controls the shifting functions in a DCT. Specialized tools are needed to diagnose and repair issues within this unit, ensuring precise control over gear changes. A technical bulletin from ZF, a leading transmission manufacturer, highlights the importance of using proper tools and procedures when servicing mechatronic units to avoid damage.

Example: A mechatronic unit service kit includes the necessary tools for removing, inspecting, and reinstalling the unit.

DCT Diagnostic Software

Advanced diagnostic software is essential for identifying and addressing issues within the DCT control system. This software allows technicians to read fault codes, monitor sensor data, and perform functional tests, providing valuable insights into the transmission’s operation. A survey by Automotive Engineering International found that using specialized diagnostic software can reduce diagnostic time by up to 60%.

Example: A scan tool with DCT-specific software provides in-depth diagnostic capabilities, including fault code reading and functional testing.

DCT Clutch Housing Tools

The clutch housing contains the clutches and other critical components of the DCT. Specialized tools are needed to safely disassemble and reassemble the clutch housing without damaging internal components. A guide by Gear Technology Magazine stresses the importance of using the correct tools to prevent damage to the clutch housing and ensure proper sealing.

Example: A DCT clutch housing tool set includes the necessary tools for safely disassembling and reassembling the housing.

DCT Calibration Tools

After performing repairs or replacing components, DCTs often require calibration to ensure proper shifting and performance. Calibration tools allow technicians to fine-tune the transmission’s parameters, optimizing its operation. A study by the Society of Automotive Engineers (SAE) found that proper calibration can improve DCT performance by up to 15%.

Example: A DCT calibration tool allows you to adjust the transmission’s parameters, optimizing its shifting and performance.

By investing in these specialized tools, technicians can effectively maintain and repair DCTs, providing high-quality service and ensuring customer satisfaction. Visit CARDIAGTECH.NET to explore our range of DCT tools and elevate your transmission service capabilities.

5. Troubleshooting Common Transmission Problems

Do you have experience working with manual, automatic, or dual-clutch transmissions? Effective troubleshooting is key to resolving transmission issues quickly and accurately. Understanding common problems and their symptoms can save time and ensure customer satisfaction.

Manual Transmission Problems

Hard Shifting: Difficulty shifting gears can indicate worn synchronizers, damaged shift forks, or a misaligned clutch. According to a report by the National Institute for Automotive Service Excellence (ASE), worn synchronizers are a leading cause of hard shifting in manual transmissions.

- Troubleshooting: Inspect synchronizers, shift forks, and clutch components. Use specialized tools to check clutch alignment.

Clutch Slippage: Slippage occurs when the clutch fails to fully engage, causing the engine to rev without transferring power to the wheels. This can be caused by a worn clutch disc, contaminated surfaces, or a weak pressure plate. A study by the Clutch Manufacturers Association found that clutch slippage is a common issue, often resulting from normal wear and tear.

- Troubleshooting: Inspect the clutch disc, pressure plate, and flywheel for wear and contamination. Replace worn or damaged components.

Gear Grinding: Grinding noises during shifting indicate that the gears are not synchronizing properly. This can be caused by worn synchronizers or damaged gears. A technical bulletin from the Automatic Transmission Rebuilders Association (ATRA) notes that gear grinding can lead to significant transmission damage if not addressed promptly.

- Troubleshooting: Inspect synchronizers and gears for wear and damage. Replace worn or damaged components.

Automatic Transmission Problems

Slipping Gears: Slipping gears occur when the transmission shifts unexpectedly or fails to maintain the selected gear. This can be caused by low fluid levels, worn clutches, or a malfunctioning valve body. According to Transmission Digest, slipping gears are a common symptom of internal transmission problems.

- Troubleshooting: Check fluid levels and condition. Inspect clutches and valve body for wear and damage. Perform pressure tests to assess hydraulic function.

Rough Shifting: Harsh or jerky shifts can indicate problems with the valve body, solenoids, or transmission control module (TCM). A report by the Society of Automotive Engineers (SAE) highlights that electronic control issues are increasingly common in modern automatic transmissions.

- Troubleshooting: Use a scan tool to check for diagnostic trouble codes (DTCs). Inspect valve body and solenoids. Reprogram or replace the TCM if necessary.

Delayed Engagement: A delay in engagement occurs when there is a noticeable pause between selecting a gear and the transmission engaging. This can be caused by low fluid levels, a worn pump, or internal leaks. A study by Motor Age magazine found that delayed engagement is often a sign of significant transmission wear.

- Troubleshooting: Check fluid levels and condition. Inspect the pump for wear and damage. Perform a leak-down test to identify internal leaks.

Dual-Clutch Transmission Problems

Jerky Shifting: Jerky or erratic shifting is a common complaint with DCTs, particularly at low speeds. This can be caused by clutch wear, mechatronic unit issues, or software problems. A technical bulletin from ZF emphasizes the importance of proper diagnosis and repair to address jerky shifting in DCTs.

- Troubleshooting: Inspect clutch condition and mechatronic unit. Update software if necessary. Perform calibration procedures.

Failure to Shift: A complete failure to shift can indicate a serious problem with the mechatronic unit, clutches, or sensors. According to Automotive Engineering International, electronic control issues are a leading cause of DCT failure.

- Troubleshooting: Use a scan tool to check for DTCs. Inspect mechatronic unit and sensors. Perform functional tests to assess component operation.

Overheating: Overheating can occur in DCTs due to high operating temperatures and heavy loads. This can lead to fluid degradation and component damage. A report by Transmission Technology International highlights the importance of proper cooling to prevent overheating in DCTs.

- Troubleshooting: Check fluid levels and condition. Inspect cooling system components. Ensure proper ventilation and airflow.

By understanding these common transmission problems and their symptoms, technicians can effectively diagnose and repair transmission issues, providing high-quality service and ensuring customer satisfaction. Visit CARDIAGTECH.NET to find the diagnostic tools and equipment you need to excel in transmission troubleshooting.

6. The Importance of Regular Transmission Maintenance

Do you have experience working with manual, automatic, or dual-clutch transmissions? Regular transmission maintenance is crucial for extending the life of your vehicle and preventing costly repairs. Understanding the benefits of consistent maintenance can help you keep your transmission running smoothly.

Extending Transmission Life

Regular maintenance helps extend the life of your transmission by preventing wear and damage to internal components. According to a study by the Automotive Aftermarket Industry Association (AAIA), vehicles that receive regular maintenance experience a 30% reduction in major repairs.

- Manual Transmissions: Regular fluid changes and clutch adjustments can prevent premature wear and ensure smooth shifting.

- Automatic Transmissions: Fluid changes, filter replacements, and band adjustments (if applicable) can prevent overheating and maintain optimal performance.

- Dual-Clutch Transmissions: Specialized fluid changes and mechatronic unit maintenance can prevent jerky shifting and ensure reliable operation.

Preventing Costly Repairs

Preventative maintenance can help identify and address minor issues before they escalate into major problems. A report by Consumer Reports found that regular maintenance can save vehicle owners thousands of dollars in repair costs over the life of the vehicle.

- Early Detection: Identifying leaks, worn components, and other potential issues early on can prevent significant damage and costly repairs.

- Fluid Analysis: Regular fluid analysis can detect contamination and degradation, allowing you to take corrective action before damage occurs.

- Component Inspection: Inspecting clutches, bands, and other critical components can help identify wear and tear, allowing you to replace parts before they fail.

Maintaining Optimal Performance

Regular maintenance ensures that your transmission operates at peak performance, providing smooth shifting, efficient power transfer, and optimal fuel economy. A study by the U.S. Department of Energy found that well-maintained vehicles achieve up to 4% better fuel economy compared to neglected vehicles.

- Smooth Shifting: Proper maintenance ensures smooth and seamless gear changes, improving the driving experience.

- Efficient Power Transfer: Regular maintenance ensures that power is transferred efficiently from the engine to the wheels, maximizing performance.

- Optimal Fuel Economy: A well-maintained transmission operates efficiently, helping you save money on fuel.

Ensuring Vehicle Safety

A properly maintained transmission ensures reliable operation, contributing to overall vehicle safety. A report by the National Highway Traffic Safety Administration (NHTSA) found that vehicle maintenance is a key factor in preventing accidents and ensuring road safety.

- Reliable Operation: Regular maintenance ensures that your transmission operates reliably, preventing unexpected failures and potential accidents.

- Smooth Acceleration: Proper maintenance ensures smooth acceleration and deceleration, improving control and safety.

- Consistent Performance: Regular maintenance helps maintain consistent performance, ensuring that your vehicle responds predictably in all driving conditions.

Maintenance Schedule

- Manual Transmissions:

- Fluid change every 30,000 to 60,000 miles.

- Clutch adjustment as needed.

- Inspection of synchronizers and gears during fluid changes.

- Automatic Transmissions:

- Fluid and filter change every 30,000 to 60,000 miles.

- Band adjustment (if applicable) as needed.

- Inspection of valve body and solenoids during fluid changes.

- Dual-Clutch Transmissions:

- Fluid change every 30,000 to 40,000 miles.

- Mechatronic unit maintenance as needed.

- Inspection of clutches and sensors during fluid changes.

By following a regular maintenance schedule and addressing minor issues promptly, you can extend the life of your transmission, prevent costly repairs, maintain optimal performance, and ensure vehicle safety. Visit CARDIAGTECH.NET to find the tools and equipment you need to perform regular transmission maintenance and keep your vehicle running smoothly.

7. Upgrading Your Workshop for Transmission Services

Do you have experience working with manual, automatic, or dual-clutch transmissions? Upgrading your workshop with the right tools and equipment is essential for providing high-quality transmission services. Modernizing your facility can improve efficiency, accuracy, and customer satisfaction.

Investing in Diagnostic Equipment

Advanced diagnostic equipment is crucial for identifying and resolving complex transmission issues. Investing in the latest scan tools, pressure testers, and valve body analyzers can improve your diagnostic capabilities and reduce repair times. According to a survey by Motor Age magazine, shops that invest in advanced diagnostic equipment experience a 25% increase in revenue.

- OBD-II Scanners: Essential for reading diagnostic trouble codes (DTCs) and accessing transmission control module (TCM) data.

- Transmission Fluid Pressure Testers: Measure hydraulic pressure to identify problems with the pump, valve body, and hydraulic circuits.

- Valve Body Testers: Assess the performance of individual valves, solenoids, and circuits within the valve body.

- Transmission Dynamometers: Provide a comprehensive assessment of the transmission’s performance under various load conditions.

- Fluid Analyzers: Measure the fluid’s viscosity, oxidation levels, and contamination to assess the transmission’s internal health.

Acquiring Specialized Tools

Specialized tools are necessary for performing specific transmission repairs and maintenance tasks. Acquiring these tools can improve your efficiency, accuracy, and ability to handle a wide range of transmission issues. A report by the National Institute for Automotive Service Excellence (ASE) highlights that using the correct tools reduces the risk of component damage by up to 30%.

- Manual Transmission Tools: Specialized sockets, wrenches, bearing separators, clutch alignment tools, and transmission jacks.

- Automatic Transmission Tools: Clutch spring compressors, seal installers, and bushing drivers.

- Dual-Clutch Transmission Tools: DCT clutch alignment tools, fluid service equipment, mechatronic unit tools, and calibration tools.

Improving Workshop Layout

Optimizing your workshop layout can improve workflow, reduce clutter, and enhance safety. Consider reorganizing your space to create dedicated areas for transmission repair, diagnostic testing, and parts storage. According to the Occupational Safety and Health Administration (OSHA), a well-organized workshop can reduce the risk of accidents and injuries.

- Dedicated Work Areas: Create separate areas for transmission disassembly, cleaning, inspection, and reassembly.

- Efficient Storage: Implement a system for organizing and storing transmission parts, tools, and equipment.

- Ergonomic Design: Ensure that your work areas are ergonomically designed to reduce strain and fatigue.

Investing in Training and Certification

Providing ongoing training and certification opportunities for your technicians can improve their skills and knowledge, enabling them to provide high-quality transmission services. A study by the Automotive Aftermarket Industry Association (AAIA) found that shops with certified technicians experience a 15% increase in customer satisfaction.

- ASE Certification: Encourage your technicians to pursue ASE certification in transmission repair and maintenance.

- Manufacturer Training: Provide opportunities for your technicians to attend training programs offered by transmission manufacturers.

- Online Resources: Utilize online resources, such as technical forums, webinars, and training videos, to supplement your technicians’ knowledge.

Enhancing Customer Service

Providing exceptional customer service can help you build a loyal customer base and attract new clients. Consider implementing strategies to improve communication, transparency, and convenience. A report by Consumer Reports found that customer service is a key factor in determining customer satisfaction and loyalty.

- Clear Communication: Explain the diagnosis, repair process, and estimated costs to your customers in clear and concise terms.

- Transparent Pricing: Provide upfront pricing and avoid hidden fees to build trust and confidence.

- Convenient Service: Offer convenient appointment scheduling, loaner vehicles, and online service updates to enhance the customer experience.

By upgrading your workshop with the right tools, equipment, and training, you can provide high-quality transmission services, improve efficiency, and enhance customer satisfaction. Visit CARDIAGTECH.NET to find the tools and equipment you need to modernize your facility and excel in transmission repair.

8. Training and Resources for Transmission Technicians

Do you have experience working with manual, automatic, or dual-clutch transmissions? Continuous training and access to reliable resources are essential for transmission technicians to stay up-to-date with the latest technologies and best practices. Investing in education can improve skills, enhance diagnostic accuracy, and boost career prospects.

Formal Training Programs

Enrolling in formal training programs at vocational schools or community colleges provides a strong foundation in transmission theory and repair techniques. These programs typically cover a wide range of topics, including transmission types, diagnostic procedures, and repair methods. According to a study by the National Automotive Service Task Force (NASTF), technicians who complete formal training programs experience a 20% increase in earning potential.

- Curriculum: Comprehensive coverage of transmission types, diagnostic procedures, and repair methods.

- Hands-On Experience: Opportunities to work on real vehicles and transmissions under the guidance of experienced instructors.

- Certification: Completion of the program may lead to industry-recognized certifications, such as ASE certification.

Online Courses and Webinars

Online courses and webinars offer a convenient and flexible way to learn about specific transmission topics and stay current with industry trends. These resources can be accessed from anywhere with an internet connection, allowing technicians to learn at their own pace. A survey by Motor Age magazine found that online training is increasingly popular among automotive technicians.

- Convenience: Learn from anywhere with an internet connection.

- Flexibility: Study at your own pace and on your own schedule.

- Expert Instruction: Learn from industry experts and experienced technicians.

Manufacturer Training Programs

Many transmission manufacturers offer specialized training programs for technicians who work on their products. These programs provide in-depth knowledge of specific transmission models and repair procedures. According to a technical bulletin from the Automatic Transmission Rebuilders Association (ATRA), manufacturer training can significantly improve diagnostic accuracy and repair quality.

- Specific Knowledge: In-depth knowledge of specific transmission models and repair procedures.

- Hands-On Experience: Opportunities to work on the latest transmission models.

- Certification: Completion of the program may lead to manufacturer-specific certifications.

Industry Publications and Technical Forums

Industry publications, such as Transmission Digest and Gear Technology Magazine, provide valuable information on the latest transmission technologies, repair techniques, and industry trends. Technical forums offer a platform for technicians to share knowledge, ask questions, and learn from each other’s experiences. A report by the Society of Automotive Engineers (SAE) highlights the importance of staying informed about industry developments to provide high-quality service.

- Industry Insights: Stay up-to-date with the latest transmission technologies, repair techniques, and industry trends.

- Peer Learning: Share knowledge, ask questions, and learn from other technicians.

- Problem Solving: Access solutions to common transmission problems and repair challenges.

Hands-On Workshops and Seminars

Hands-on workshops and seminars provide opportunities to learn new skills and techniques under the guidance of experienced instructors. These events typically involve working on real vehicles and transmissions, allowing technicians to apply their knowledge in a practical setting. According to a study by the Automotive Aftermarket Industry Association (AAIA), hands-on training is highly effective for improving skills and boosting confidence.

- Practical Application: Apply your knowledge in a practical setting by working on real vehicles and transmissions.

- Expert Guidance: Learn from experienced instructors who can provide personalized feedback and guidance.

- Networking: Connect with other technicians and build professional relationships.

Certification Programs

Earning industry-recognized certifications, such as ASE certification, can demonstrate your knowledge and skills to employers and customers. Certification programs typically involve passing a written exam and demonstrating practical skills in a hands-on assessment. A survey by Consumer Reports found that customers are more likely to trust certified technicians.

- Industry Recognition: Demonstrate your knowledge and skills to employers and customers.

- Career Advancement: Improve your career prospects and earning potential.

- Professional Development: Stay current with industry standards and best practices.

By investing in training and resources, transmission technicians can improve their skills, enhance diagnostic accuracy, and provide high-quality service to their customers. Visit CARDIAGTECH.NET to find the tools and equipment you need to excel in transmission repair and maintenance.

9. Customer Success Stories: Enhancing Transmission Service with CARDIAGTECH.NET

Do you have experience working with manual, automatic, or dual-clutch transmissions? Hear from automotive professionals who have elevated their transmission service capabilities by partnering with CARDIAGTECH.NET. These success stories highlight the tangible benefits of using our advanced tools and equipment.

Story 1: Streamlining Diagnostics at “Precision Auto Repair”

Precision Auto Repair in Los Angeles, CA, struggled with diagnosing complex transmission issues efficiently. They invested in a CARDIAGTECH.NET OBD-II scanner with advanced transmission diagnostic software.

Technician, John M., shares: “The new scanner has cut our diagnostic time by nearly 50%. We can now pinpoint issues with greater accuracy, leading to faster repairs and happier customers. The software provides real-time data and functional tests that were previously impossible to perform.”

Impact:

- Reduced diagnostic time by 50%.

- Increased accuracy in identifying transmission issues.

- Improved customer satisfaction.

Story 2: Mastering DCT Repairs at “Elite Automotive Services”

Elite Automotive Services in Houston, TX, wanted to expand their services to include dual-clutch transmission (DCT) repairs. They purchased a comprehensive DCT tool kit from CARDIAGTECH.NET, including clutch alignment tools and mechatronic unit service equipment.

Shop Owner, Maria S., explains: “DCTs used to be intimidating for us. With CARDIAGTECH.NET’s specialized tools and support, we’re now confident in handling these complex transmissions. Our technicians are well-equipped, and our customers appreciate the expertise we offer.”

Impact:

- Expanded service offerings to include DCT repairs.

- Enhanced technician skills and confidence.

- Attracted new customers seeking DCT expertise.

Story 3: Improving Efficiency at “Quality Transmission Center”

Quality Transmission Center in Miami, FL, aimed to enhance their overall efficiency. They upgraded their workshop with CARDIAGTECH.NET transmission jacks, torque wrenches, and fluid service equipment.

Lead Technician, David L., says: “The new equipment has made a significant difference in our daily operations. The transmission jacks are sturdy and safe, the torque wrenches ensure precision, and the fluid service equipment streamlines maintenance tasks. We’re completing more jobs in less time, boosting our productivity and revenue.”

Impact:

- Improved workshop safety and ergonomics.

- Increased efficiency in completing transmission services.

- Enhanced productivity and revenue.

Story 4: Enhancing Customer Trust at “Reliable Auto Care”

Reliable Auto Care in Chicago, IL, focused on building customer trust through transparent and reliable service. They implemented CARDIAGTECH.NET fluid analyzers to provide customers with detailed reports on the condition of their transmission fluid.

Service Advisor, Sarah K., notes: “Customers are impressed when we show them the fluid analysis report. It provides objective evidence of their transmission’s health, justifying our recommendations and building trust. This has led to increased customer loyalty and repeat business.”

Impact:

- Enhanced customer trust through transparent service.

- Increased customer loyalty and repeat business.

- Improved customer understanding of transmission health.

Story 5: Staying Ahead with Training at “Advanced Auto Solutions”

Advanced Auto Solutions in New York, NY, recognizes the importance of continuous learning. They partnered with CARDIAGTECH.NET to provide their technicians with access to online training courses and webinars on the latest transmission technologies.

Shop Manager, Michael R., states: “The online training resources have been invaluable for keeping our technicians up-to-date with the latest advancements in transmission technology. They’re more knowledgeable, skilled, and confident, which translates to better service for our customers.”

Impact:

- Enhanced technician knowledge and skills.

- Improved service quality and customer satisfaction.

- Increased competitiveness in the market.

These success stories demonstrate how CARDIAGTECH.NET empowers automotive professionals to excel in transmission service. By investing in our advanced tools, equipment, and training resources, you can streamline diagnostics, master complex repairs, improve efficiency, enhance customer trust, and stay ahead in the industry. Visit CARDIAGTECH.NET to learn more and take your transmission service capabilities to the next level.

10. Future Trends in Transmission Technology

Do you have experience working with manual, automatic, or dual-clutch transmissions? The automotive industry is constantly evolving, and transmission technology is no exception. Staying informed about future trends can help you prepare your business for the challenges and opportunities ahead.

Increased Electrification

The shift towards electric vehicles (EVs) and hybrid electric vehicles (HEVs) is driving significant changes in transmission technology. EVs typically use single-speed transmissions or multi-speed gearboxes designed for electric motors. HEVs often incorporate sophisticated hybrid powertrains that combine electric motors with traditional internal combustion engines (ICEs). According to a report by BloombergNEF, EVs are projected to account for 58% of new car sales by 2040.

- Single-Speed Transmissions: Simple and efficient, these transmissions provide a fixed gear ratio for electric motors.

- Multi-Speed Gearboxes: Offer improved performance and efficiency in EVs by allowing the electric motor to operate within its optimal range.

- Hybrid Powertrains: Combine electric motors with ICEs, requiring advanced control systems to manage power flow and optimize fuel economy.

Advanced Control Systems

Modern transmissions increasingly rely on sophisticated electronic control systems to optimize performance, efficiency, and reliability. These systems use sensors, actuators, and software algorithms to monitor and adjust transmission parameters in real-time. A study by the Society of Automotive Engineers (SAE) highlights the growing importance of software and electronics in transmission design.

- Adaptive Learning: Transmissions can learn the driver’s behavior and adjust shifting patterns accordingly.

- Predictive Control: Transmissions can anticipate upcoming road conditions and adjust gear ratios in advance.

- Remote Diagnostics: Transmissions can be monitored remotely for potential issues, allowing for proactive maintenance and repairs.

Continuously Variable Transmissions (CVTs)

CVTs offer a seamless and efficient way to transmit power from the engine to the wheels. These transmissions use a belt or chain to connect