How to Adjust the Clearance of Drum Brake Shoes: A Comprehensive Guide

At CARDIAGTECH.NET, we understand the importance of properly adjusted drum brakes for your vehicle’s safety and performance, and adjusting the clearance of drum brake shoes is critical for optimal braking. This guide provides a complete overview of how to adjust drum brake shoes, ensuring you achieve optimal braking performance, reduce brake fade, and maintain brake system health. Learn about manual adjustment techniques, self-adjusting mechanisms, and how to identify common brake problems to keep your braking system in top condition, using correct tools and methods to improve overall braking performance.

Table of Contents

- Understanding Drum Brake Systems

- Why Adjusting Drum Brake Shoe Clearance Is Essential

- Identifying the Need for Adjustment

- Tools and Materials Required

- Step-by-Step Guide to Adjusting Drum Brake Shoes

- Manual Adjustment vs. Self-Adjusting Systems

- Troubleshooting Common Issues

- Maintaining Your Drum Brake System

- When to Seek Professional Help

- The Future of Brake Technology

- Understanding Drum Brake Shoe Materials

- Advanced Techniques for Performance Tuning

- Drum Brake Shoe Adjustment and Vehicle Safety

- The Role of CARDIAGTECH.NET in Brake Maintenance

- Frequently Asked Questions (FAQs)

1. Understanding Drum Brake Systems

What are drum brake systems and how do they work?

Drum brake systems use a drum-shaped component that rotates with the wheel, and brake shoes lined with friction material press against the inside of the drum to create friction and slow the vehicle. According to a study by the National Highway Traffic Safety Administration (NHTSA), drum brakes, while less common in newer vehicles, still play a crucial role in the braking systems of many cars on the road. The primary components of a drum brake system include:

- Brake Drum: A cylindrical metal component attached to the wheel hub that rotates with the wheel.

- Brake Shoes: Curved metal pieces lined with friction material that press against the inside of the drum.

- Wheel Cylinder: A hydraulic cylinder that pushes the brake shoes outward when the brake pedal is applied.

- Return Springs: Springs that pull the brake shoes back to their resting position when the brake pedal is released.

- Adjuster Mechanism: A mechanism that allows for adjusting the clearance between the brake shoes and the drum as the friction material wears down.

Drum brakes function through hydraulic pressure. When the driver presses the brake pedal, hydraulic fluid from the master cylinder flows to the wheel cylinder, pushing its pistons outward. These pistons force the brake shoes against the inside of the drum, creating friction that slows the wheel. The return springs then retract the shoes when the brake pedal is released, allowing the wheel to rotate freely again. Proper maintenance and adjustment of these components are essential for ensuring optimal braking performance and safety.

2. Why Adjusting Drum Brake Shoe Clearance Is Essential

Why is adjusting drum brake shoe clearance essential for vehicle safety?

Adjusting drum brake shoe clearance is essential because it ensures optimal braking performance, even wear, and overall safety by maintaining the correct distance between the brake shoes and the drum. According to a report by the University of Michigan Transportation Research Institute, properly adjusted brakes can reduce stopping distances by up to 25%. Here’s why this adjustment is so critical:

- Optimal Braking Performance: Correct clearance ensures the brake shoes engage the drum quickly and efficiently, providing maximum stopping power.

- Even Wear: Proper adjustment helps distribute braking force evenly across the brake shoes, preventing uneven wear and extending their lifespan.

- Safety: Maintaining correct brake shoe clearance is vital for vehicle safety, reducing the risk of brake failure and ensuring reliable stopping power in emergency situations.

- Reduced Brake Fade: Proper adjustment minimizes heat buildup in the brakes, reducing the likelihood of brake fade during prolonged or heavy braking.

- Parking Brake Performance: The parking brake relies on the correct adjustment of the rear drum brakes to function effectively.

When brake shoes wear down over time, the clearance between the shoes and the drum increases. This increased clearance results in a longer pedal travel and reduced braking efficiency. Regular adjustments compensate for this wear, ensuring the brakes remain responsive and effective. CARDIAGTECH.NET emphasizes the importance of this adjustment to maintain vehicle safety and performance.

3. Identifying the Need for Adjustment

What are the signs that drum brakes need adjustment?

Signs that drum brakes need adjustment include increased brake pedal travel, reduced braking efficiency, a soft or spongy brake pedal, and unusual noises such as squealing or grinding. A study by the AAA Foundation for Traffic Safety found that poorly maintained brakes contribute to approximately 5% of all vehicle crashes. Here are common indicators that your drum brakes may require adjustment:

- Increased Brake Pedal Travel: If you notice that you need to press the brake pedal further down than usual to achieve the same level of braking, it could be a sign that the brake shoes are too far from the drum.

- Reduced Braking Efficiency: If your vehicle takes longer to stop or doesn’t stop as quickly as it used to, the brake shoes may not be making sufficient contact with the drum.

- Soft or Spongy Brake Pedal: A soft or spongy feel in the brake pedal can indicate excessive clearance between the brake shoes and the drum, leading to reduced braking performance.

- Unusual Noises: Squealing, grinding, or clicking noises coming from the brakes can indicate that the brake shoes are rubbing against the drum due to improper adjustment or worn components.

- Parking Brake Issues: If the parking brake requires excessive travel or doesn’t hold the vehicle securely, it may be related to the adjustment of the rear drum brakes.

- Uneven Braking: If the vehicle pulls to one side when braking, it could indicate that one or more drum brakes are not adjusted properly, leading to uneven braking force.

If you observe any of these symptoms, it’s essential to inspect and adjust your drum brakes promptly. Ignoring these signs can lead to further damage to the brake system and compromise your safety. Regular inspections and timely adjustments are crucial for maintaining optimal braking performance.

4. Tools and Materials Required

What tools and materials are needed to adjust drum brakes?

To adjust drum brakes, you will need a jack, jack stands, a lug wrench, a brake adjusting tool, a screwdriver, a hammer, and gloves. According to a survey by the National Institute for Automotive Service Excellence (ASE), having the right tools can reduce repair time by up to 30%. Here is a detailed list of the necessary tools and materials:

| Tool/Material | Description |

|---|---|

| Jack | Used to lift the vehicle safely. |

| Jack Stands | Used to support the vehicle once it is lifted. |

| Lug Wrench | Used to remove the lug nuts from the wheels. |

| Brake Adjusting Tool | A specialized tool designed to turn the star wheel adjuster inside the drum brake assembly. |

| Screwdriver | Used to help manipulate the adjuster and remove the rubber plug covering the adjustment access hole. |

| Hammer | Used to gently tap the brake drum if it is stuck or difficult to remove. |

| Gloves | To protect your hands from dirt, grease, and brake dust. |

| Wheel Chocks | To prevent the vehicle from rolling while it is being lifted. |

| Safety Glasses | To protect your eyes from debris and brake dust. |

| Brake Cleaner | To clean brake components and remove contaminants. |

| Penetrating Oil | To help loosen any stuck or corroded parts. |

| Torque Wrench | To tighten the lug nuts to the manufacturer’s specified torque. |

| Service Manual | Provides detailed instructions and specifications for your vehicle’s brake system. |

Having these tools and materials on hand will help you perform the adjustment safely and effectively. Always prioritize safety by using jack stands to support the vehicle and wearing safety glasses and gloves to protect yourself from potential hazards. CARDIAGTECH.NET offers a range of high-quality brake tools and equipment to ensure you have everything you need for the job. Contact us at +1 (641) 206-8880 for expert advice and assistance in selecting the right tools for your specific needs.

5. Step-by-Step Guide to Adjusting Drum Brake Shoes

How do you adjust drum brake shoes, step-by-step?

Adjusting drum brake shoes involves lifting the vehicle, removing the wheel, locating the adjuster, tightening the shoes until they drag slightly, and then backing off the adjuster until the wheel spins freely. A study by the Society of Automotive Engineers (SAE) found that following a systematic procedure can improve the accuracy and effectiveness of brake adjustments. Here’s a detailed step-by-step guide:

- Prepare the Vehicle:

- Park the vehicle on a level surface and engage the parking brake.

- Place wheel chocks behind the rear wheels to prevent rolling.

- Loosen the lug nuts on the wheel you will be working on.

- Lift the Vehicle:

- Use a jack to lift the vehicle and place jack stands securely under the frame.

- Ensure the vehicle is stable before proceeding.

- Remove the Wheel:

- Fully unscrew the lug nuts and remove the wheel.

- Locate the Adjuster Access Hole:

- On the backing plate of the drum brake assembly, locate the small oval or rectangular hole. This hole is usually covered with a rubber plug.

- Remove the Rubber Plug:

- Use a screwdriver or pick to carefully remove the rubber plug from the access hole.

- Insert the Brake Adjusting Tool:

- Insert the brake adjusting tool into the access hole. You may need a flashlight to see the star wheel adjuster.

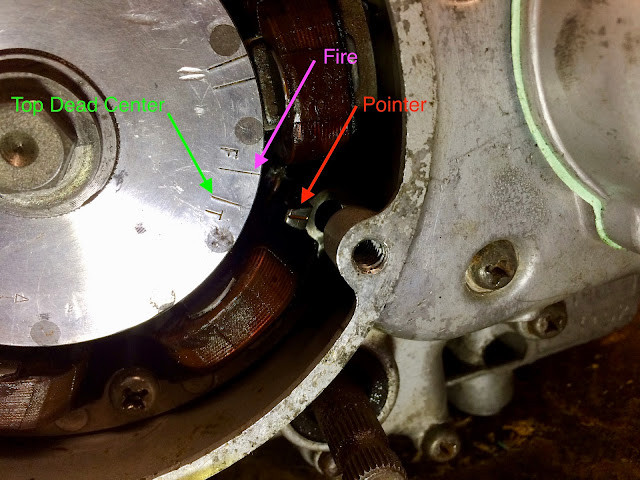

- Adjust the Star Wheel:

- Use the brake adjusting tool to turn the star wheel. Depending on the design, you may need to move the tool up or down to engage the star wheel teeth.

- Turn the star wheel in small increments to expand the brake shoes outward towards the drum. The goal is to tighten the shoes until they make slight contact with the drum.

- Check for Drag:

- After each adjustment, try to spin the brake drum by hand. You should feel a slight drag as the shoes make contact with the drum.

- Back Off the Adjuster:

- Once you feel a slight drag, back off the adjuster by a few clicks (usually 2-3 clicks) until the drum spins freely with minimal drag. This ensures the shoes are close enough to provide effective braking but not so tight that they cause excessive wear or heat.

- Repeat on the Other Side:

- Repeat the adjustment process on the other side of the vehicle to ensure balanced braking.

- Replace the Rubber Plug:

- Once the adjustment is complete, replace the rubber plug in the access hole to prevent dirt and debris from entering the brake assembly.

- Reinstall the Wheel:

- Mount the wheel back onto the hub and tighten the lug nuts by hand.

- Lower the Vehicle:

- Remove the jack stands and lower the vehicle to the ground.

- Torque the Lug Nuts:

- Use a torque wrench to tighten the lug nuts to the manufacturer’s specified torque. This is crucial for ensuring the wheel is securely attached to the vehicle.

- Test the Brakes:

- Before driving the vehicle, pump the brake pedal several times to ensure the brakes are functioning properly.

- Perform a test drive in a safe area to verify that the brakes are responsive and effective.

Following these steps carefully will help you adjust your drum brakes properly and maintain optimal braking performance. If you encounter any difficulties or are unsure about any part of the process, consult a professional mechanic. CARDIAGTECH.NET offers expert advice and support to help you with all your brake maintenance needs. Reach out to us at 276 Reock St, City of Orange, NJ 07050, United States, or call +1 (641) 206-8880 for assistance.

6. Manual Adjustment vs. Self-Adjusting Systems

What are the differences between manual and self-adjusting drum brake systems?

Manual drum brake systems require periodic manual adjustments, while self-adjusting systems automatically compensate for brake shoe wear, although they may still require occasional manual intervention. According to research by the American Society of Mechanical Engineers (ASME), self-adjusting systems reduce the need for frequent maintenance but are not entirely maintenance-free. Here are the key differences between the two types of systems:

| Feature | Manual Adjustment | Self-Adjusting |

|---|---|---|

| Adjustment Method | Requires manual adjustment using a brake adjusting tool. | Automatically adjusts the brake shoes as they wear. |

| Frequency | Needs to be adjusted periodically (e.g., every 12,000 miles or during routine maintenance). | Typically requires less frequent adjustment, but should still be inspected regularly. |

| Complexity | Simpler design, easier to understand and maintain. | More complex design with additional components for automatic adjustment. |

| Reliability | Reliable if adjusted properly and regularly. | Can be more reliable in maintaining consistent brake performance, but prone to failure if neglected. |

| Cost | Lower initial cost. | Higher initial cost due to the more complex design. |

| Maintenance | Requires more hands-on maintenance and attention. | Less frequent maintenance, but still needs periodic inspection. |

| Adjustment Process | Involves manually turning the star wheel adjuster to set the correct brake shoe clearance. | Relies on a mechanism that automatically adjusts the shoes when the parking brake is engaged or when the brakes are applied in reverse. |

Manual adjustment systems require a technician or vehicle owner to manually turn the star wheel adjuster to maintain the correct clearance between the brake shoes and the drum. This process needs to be repeated periodically as the brake shoes wear down.

Self-adjusting systems, on the other hand, use a mechanism that automatically adjusts the brake shoes as they wear. In many self-adjusting systems, the adjustment occurs when the parking brake is engaged or when the brakes are applied while driving in reverse. The adjuster mechanism senses the increased clearance and automatically tightens the brake shoes to maintain optimal performance. Despite their convenience, self-adjusting systems should still be inspected regularly to ensure they are functioning correctly.

7. Troubleshooting Common Issues

What are common problems encountered while adjusting drum brakes and how can they be resolved?

Common issues include stuck adjusters, corroded parts, and difficulty removing the brake drum, often resolved by using penetrating oil, cleaning components, and gently tapping the drum. A survey by the Automotive Aftermarket Industry Association (AAIA) indicates that addressing these issues promptly can prevent more significant brake problems. Here are some troubleshooting tips for common issues:

| Issue | Possible Cause(s) | Solution(s) |

|---|---|---|

| Stuck Adjuster | Corrosion, dirt, or debris preventing the star wheel from turning. | Apply penetrating oil to the adjuster mechanism and use a brake adjusting tool to gently free it up. Clean the adjuster with brake cleaner. |

| Corroded Parts | Rust and corrosion buildup on brake components. | Use a wire brush or sandpaper to remove corrosion from the brake shoes, drum, and backing plate. Apply a thin layer of brake grease to prevent future corrosion. |

| Difficulty Removing Drum | Rust or corrosion bonding the drum to the hub. | Apply penetrating oil to the center of the drum and around the hub. Gently tap the drum with a hammer to loosen it. Use a drum puller if necessary. |

| Uneven Brake Wear | Uneven adjustment, worn components, or contaminated brake shoes. | Inspect brake shoes for wear and contamination. Replace worn or contaminated shoes. Adjust the brakes evenly on both sides. |

| Squealing Brakes | Worn brake shoes, contaminated surfaces, or improperly adjusted brakes. | Inspect brake shoes for wear and contamination. Clean the brake drum and shoes with brake cleaner. Adjust the brakes properly. |

| Soft Brake Pedal | Air in the brake lines, leaking wheel cylinder, or improperly adjusted brakes. | Bleed the brake lines to remove air. Inspect the wheel cylinder for leaks and replace if necessary. Adjust the brakes properly. |

| Parking Brake Issues | Stretched or broken parking brake cable, or improperly adjusted drum brakes. | Inspect the parking brake cable for damage and replace if necessary. Adjust the drum brakes properly, as the parking brake relies on this adjustment. |

When encountering these issues, it’s important to proceed with caution and address each problem systematically. Always use appropriate safety measures, such as wearing gloves and safety glasses, and consult a professional if you are unsure about any part of the troubleshooting process. Regular maintenance and inspection of your drum brakes can help prevent many of these problems from occurring.

8. Maintaining Your Drum Brake System

What maintenance practices ensure the longevity and reliability of drum brake systems?

Regular cleaning, lubrication of moving parts, and periodic inspection for wear and damage ensure the longevity and reliability of drum brake systems. According to a maintenance guide by the National Automotive Technicians Education Foundation (NATEF), consistent maintenance can significantly extend the life of brake components. Here are key maintenance practices:

- Regular Cleaning: Clean the brake components periodically to remove brake dust, dirt, and debris. Use brake cleaner to clean the brake shoes, drum, and backing plate.

- Lubrication: Lubricate the moving parts of the brake system, such as the star wheel adjuster and the contact points between the brake shoes and the backing plate. Use a high-temperature brake grease specifically designed for brake systems.

- Inspection for Wear and Damage: Inspect the brake shoes for wear, cracks, and contamination. Check the brake drum for scoring, cracks, and excessive wear. Replace any worn or damaged components promptly.

- Check and Adjust the Brakes: Regularly check and adjust the drum brakes to maintain proper clearance between the brake shoes and the drum. This ensures optimal braking performance and prevents uneven wear.

- Inspect the Wheel Cylinder: Inspect the wheel cylinder for leaks. Leaks can compromise the hydraulic pressure in the brake system and reduce braking efficiency.

- Replace Return Springs: Replace the return springs periodically, as they can weaken over time and affect the brake shoe retraction.

- Check Parking Brake Cable: Inspect the parking brake cable for stretching, fraying, and damage. Adjust or replace the cable as needed to ensure proper parking brake function.

- Flush Brake Fluid: Flush the brake fluid every two years or as recommended by the vehicle manufacturer. Brake fluid can absorb moisture over time, which can lead to corrosion and reduced braking performance.

Following these maintenance practices will help keep your drum brake system in good condition and ensure reliable braking performance. Regular maintenance not only extends the life of your brake components but also enhances your safety on the road.

9. When to Seek Professional Help

When is it necessary to seek professional help for drum brake adjustments?

Seek professional help when you lack experience, encounter significant resistance, or notice persistent brake issues after adjustment. According to a consumer report by J.D. Power, professional brake services ensure accuracy and safety. Here are situations where professional assistance is recommended:

- Lack of Experience: If you are not familiar with drum brake systems or lack the necessary tools and equipment, it’s best to seek professional help.

- Significant Resistance: If you encounter significant resistance while trying to adjust the brakes or remove the brake drum, don’t force it. Seek professional assistance to avoid damaging the brake components.

- Persistent Brake Issues: If you continue to experience brake issues, such as soft pedal, squealing noises, or uneven braking, even after adjusting the brakes, it could indicate a more serious problem that requires professional diagnosis and repair.

- Brake Fluid Leaks: If you notice brake fluid leaks around the wheel cylinder or brake lines, seek professional help immediately. Brake fluid leaks can compromise the hydraulic pressure in the brake system and lead to brake failure.

- Worn or Damaged Components: If you find that the brake shoes, drum, or other brake components are excessively worn or damaged, it’s best to have them replaced by a professional.

- ABS Issues: If your vehicle has an Anti-lock Braking System (ABS) and you are experiencing issues with the brakes, such as the ABS light staying on, seek professional help. ABS systems require specialized diagnostic tools and expertise.

Attempting to repair or adjust brakes without the proper knowledge and tools can be dangerous and may lead to further damage. Professionals have the expertise and equipment to diagnose and repair brake problems accurately and safely. CARDIAGTECH.NET recommends seeking professional help when in doubt to ensure your safety and the proper functioning of your vehicle’s braking system. You can reach our experts at 276 Reock St, City of Orange, NJ 07050, United States, or call +1 (641) 206-8880 for reliable service and support.

10. The Future of Brake Technology

What are the latest advancements and future trends in brake technology?

Latest advancements include electronic braking systems (EBS), regenerative braking, and advanced materials for brake components, enhancing safety and efficiency. A report by McKinsey & Company highlights that technological advancements are rapidly transforming the automotive industry, including braking systems. Here are some notable trends:

- Electronic Braking Systems (EBS): EBS integrates the vehicle’s braking system with electronic control units (ECUs), providing enhanced control and stability. EBS can automatically adjust braking force to each wheel, improving stopping distances and preventing skidding.

- Regenerative Braking: Regenerative braking systems, commonly used in hybrid and electric vehicles, capture the kinetic energy produced during braking and convert it into electrical energy, which is then stored in the vehicle’s battery. This improves energy efficiency and extends the driving range.

- Advanced Materials: Manufacturers are using advanced materials, such as carbon ceramics and lightweight alloys, to produce brake components that are lighter, stronger, and more resistant to wear and heat. These materials improve braking performance and extend the lifespan of brake components.

- Brake-by-Wire Technology: Brake-by-wire systems replace the traditional mechanical linkage between the brake pedal and the brake calipers with electronic sensors and actuators. This technology provides more precise control over braking force and allows for integration with advanced driver-assistance systems (ADAS).

- Artificial Intelligence (AI) Integration: AI is being used to analyze data from various sensors in the vehicle to predict braking needs and optimize braking performance. AI-powered braking systems can adapt to different driving conditions and driver behaviors, improving safety and comfort.

- Smart Brake Assist: Smart brake assist systems use sensors to detect potential collisions and automatically apply the brakes to mitigate or prevent accidents. These systems can significantly reduce the risk of rear-end collisions and improve overall safety.

These advancements in brake technology are aimed at improving safety, efficiency, and performance. As technology continues to evolve, we can expect to see even more innovative braking systems that enhance the driving experience and reduce the risk of accidents. CARDIAGTECH.NET is committed to staying at the forefront of these technological advancements, providing our customers with the latest and most reliable brake solutions.

11. Understanding Drum Brake Shoe Materials

What materials are commonly used in drum brake shoes and how do they affect performance?

Common materials include organic, semi-metallic, and ceramic compounds, each offering different levels of friction, heat resistance, and durability. According to a study by the Brake Manufacturers Council (BMC), the choice of brake shoe material significantly impacts braking performance and safety. Here’s an overview of the common materials used:

| Material | Composition | Characteristics | Advantages | Disadvantages | Common Applications |

|---|---|---|---|---|---|

| Organic | Made from organic fibers, such as cellulose, and held together by a resin binder. | Softer material, produces less noise, and is gentler on the brake drum. | Quiet operation, low cost, and minimal wear on the brake drum. | Lower friction coefficient, shorter lifespan, and not suitable for heavy-duty applications. | Older vehicles and light-duty applications. |

| Semi-Metallic | Contains a mix of metallic fibers (e.g., steel, iron, copper) and organic materials. | Offers a good balance between friction, heat resistance, and durability. | Higher friction coefficient than organic shoes, better heat dissipation, and longer lifespan. | Can be noisier than organic shoes, and may cause more wear on the brake drum. | Most passenger vehicles and light trucks. |

| Ceramic | Made from ceramic fibers, bonding agents, and small amounts of metallic fibers. | Provides excellent friction, heat resistance, and durability. Produces very little brake dust and noise. | Excellent stopping power, low noise, minimal brake dust, and long lifespan. | Higher cost than organic and semi-metallic shoes, and may not perform as well in cold weather. | High-performance vehicles, luxury cars, and vehicles with ABS. |

| Non-Asbestos Organic (NAO) | Uses organic materials without asbestos. | Offers a compromise between performance and environmental concerns. | Environmentally friendly, provides adequate stopping power, and reduces wear on the brake drum. | May not perform as well as semi-metallic or ceramic shoes in demanding conditions. | Modern passenger vehicles. |

The choice of brake shoe material depends on the specific needs and performance requirements of the vehicle. Organic shoes are suitable for older vehicles and light-duty applications where noise and drum wear are primary concerns. Semi-metallic shoes provide a good balance of performance and durability for most passenger vehicles. Ceramic shoes are ideal for high-performance vehicles and those with ABS, offering excellent stopping power and minimal noise and dust. CARDIAGTECH.NET offers a variety of brake shoe materials to meet the diverse needs of our customers. Contact us at +1 (641) 206-8880 for expert advice on selecting the right brake shoes for your vehicle.

12. Advanced Techniques for Performance Tuning

What advanced techniques can be used to fine-tune drum brakes for enhanced performance?

Advanced techniques include matching brake shoe materials to driving conditions, optimizing spring tension, and using precision measuring tools for accurate adjustments. According to performance tuning experts at the SEMA Garage, these techniques can significantly improve braking performance. Here are some advanced methods:

- Matching Brake Shoe Materials to Driving Conditions: Select brake shoe materials that are best suited for your specific driving conditions. For example, if you frequently drive in demanding conditions or tow heavy loads, consider using semi-metallic or ceramic shoes for improved heat resistance and stopping power.

- Optimizing Spring Tension: The return springs play a crucial role in brake shoe retraction. Using higher-tension springs can improve brake response and prevent brake drag. However, be careful not to use springs that are too strong, as this can lead to premature wear of the brake shoes.

- Precision Measuring Tools: Use precision measuring tools, such as dial indicators and micrometers, to accurately measure the brake drum diameter and brake shoe thickness. This information can help you determine the optimal clearance between the brake shoes and the drum and ensure even wear.

- Brake Shoe Arcing: Brake shoe arcing involves grinding the brake shoes to match the curvature of the brake drum. This ensures maximum contact between the shoes and the drum, improving braking performance.

- Adjustable Proportioning Valves: Adjustable proportioning valves allow you to fine-tune the balance of braking force between the front and rear brakes. This can be particularly useful for vehicles with modified suspension systems or different tire sizes.

- Performance Brake Drums: Consider upgrading to performance brake drums made from high-quality materials with improved heat dissipation characteristics. These drums can help reduce brake fade and improve overall braking performance.

- Cryogenic Treatment: Cryogenic treatment involves cooling brake components to extremely low temperatures to improve their strength and durability. This process can enhance the performance and lifespan of brake drums and shoes.

These advanced techniques require a thorough understanding of brake systems and should be performed by experienced professionals. When done correctly, they can significantly improve the performance and reliability of your drum brakes. CARDIAGTECH.NET offers expert advice and high-quality brake components to help you achieve optimal braking performance. Contact us at 276 Reock St, City of Orange, NJ 07050, United States, or call +1 (641) 206-8880 for more information.

13. Drum Brake Shoe Adjustment and Vehicle Safety

How does proper drum brake shoe adjustment contribute to overall vehicle safety?

Proper adjustment ensures consistent braking force, reduces stopping distances, and prevents brake failure, crucial for avoiding accidents and maintaining vehicle control. A study by the National Safety Council (NSC) emphasizes that well-maintained brakes are essential for preventing collisions. Here’s how proper adjustment enhances safety:

- Consistent Braking Force: Properly adjusted brakes ensure that each wheel receives the correct amount of braking force. This prevents uneven braking, which can cause the vehicle to pull to one side or lose control during braking.

- Reduced Stopping Distances: Correct brake shoe clearance allows the brakes to engage quickly and efficiently, reducing stopping distances. Shorter stopping distances can be critical in avoiding accidents, especially in emergency situations.

- Prevention of Brake Failure: Regular adjustment and maintenance can prevent brake failure by ensuring that the brake components are in good condition and functioning properly. Brake failure can have catastrophic consequences, so it’s essential to maintain your brakes diligently.

- Improved Stability: Proper brake adjustment contributes to overall vehicle stability by ensuring that the brakes respond predictably and consistently. This is particularly important in adverse weather conditions, such as rain, snow, or ice.

- Enhanced ABS Performance: For vehicles equipped with ABS, proper brake adjustment is essential for optimal ABS performance. ABS relies on accurate brake engagement to prevent wheel lockup and maintain steering control during braking.

- Parking Brake Effectiveness: The parking brake relies on the correct adjustment of the rear drum brakes to function effectively. A properly adjusted parking brake will securely hold the vehicle in place, preventing it from rolling on inclines.

Maintaining your drum brakes in good condition is a crucial aspect of vehicle safety. Regular inspections, adjustments, and timely repairs can help prevent accidents and ensure that your vehicle is safe to drive. CARDIAGTECH.NET is committed to providing high-quality brake components and expert advice to help you maintain your vehicle’s braking system. Contact us at +1 (641) 206-8880 for all your brake maintenance needs.

14. The Role of CARDIAGTECH.NET in Brake Maintenance

How does CARDIAGTECH.NET support vehicle owners and technicians in maintaining drum brake systems?

CARDIAGTECH.NET offers high-quality brake components, diagnostic tools, and expert advice, empowering vehicle owners and technicians to maintain drum brake systems effectively. We provide:

- Wide Range of Brake Components: CARDIAGTECH.NET offers a comprehensive selection of brake shoes, drums, wheel cylinders, return springs, and other brake components from leading manufacturers. Our high-quality components ensure reliable performance and durability.

- Diagnostic Tools: We provide advanced diagnostic tools that can help technicians accurately diagnose brake problems and perform adjustments efficiently. Our tools include brake adjusting tools, drum micrometers, and brake pressure testers.

- Expert Advice and Support: Our team of experienced technicians and automotive experts is available to provide advice and support to vehicle owners and technicians. We can help you troubleshoot brake problems, select the right components, and perform adjustments correctly.

- Training Resources: CARDIAGTECH.NET offers training resources, such as instructional videos and technical articles, to help you learn about drum brake systems and maintenance procedures. Our resources are designed to empower you to perform brake maintenance with confidence.

- Convenient Online Ordering: Our user-friendly website allows you to easily browse our selection of brake components and diagnostic tools and place orders online. We offer fast shipping and secure payment options for your convenience.

- Customer Satisfaction Guarantee: We stand behind the quality of our products and services. If you are not satisfied with your purchase, we offer a customer satisfaction guarantee to ensure that you are completely happy with your experience.

CARDIAGTECH.NET is dedicated to providing the best possible support for vehicle owners and technicians in maintaining drum brake systems. Our commitment to quality, expertise, and customer satisfaction makes us a trusted partner in the automotive industry. Contact us today at 276 Reock St, City of Orange, NJ 07050, United States, or call +1 (641) 206-8880 to learn more about our products and services. Let us help you keep your vehicle’s braking system in top condition.

15. Frequently Asked Questions (FAQs)

What are some frequently asked questions about adjusting drum brake shoes?

Here are some frequently asked questions (FAQs) about adjusting drum brake shoes:

Q1: How often should I adjust my drum brakes?

A1: Drum brakes should be inspected and adjusted every 12,000 to 15,000 miles, or during routine maintenance, to ensure optimal braking performance and prevent uneven wear.

Q2: Can I adjust my drum brakes myself, or should I take it to a professional?

A2: If you have experience with brake systems and have the necessary tools, you can adjust your drum brakes yourself. However, if you are not comfortable with the process or lack the tools, it’s best to take it to a professional.

Q3: What happens if I don’t adjust my drum brakes?

A3: If you don’t adjust your drum brakes, the brake shoes can wear unevenly, leading to reduced braking efficiency, increased stopping distances, and potential brake failure.

Q4: How do I know if my self-adjusting drum brakes are working properly?

A4: You can check if your self-adjusting drum brakes are working properly by observing the brake pedal travel. If the pedal travel is excessive or the brakes feel soft, the self-adjusting mechanism may not be functioning correctly, and you should have it inspected by a professional.

Q5: What are the signs of worn brake shoes?

A5: Signs of worn brake shoes include reduced braking efficiency, increased stopping distances, squealing noises, and a soft or spongy brake pedal.

Q6: Can I replace just the brake shoes, or do I need to replace the drum as well?

A6: You can often replace just the brake shoes if the drum is in good condition. However, if the drum is scored, cracked, or excessively worn, it should be replaced along with the brake shoes.

Q7: How do I clean my drum brakes?

A7: To clean your drum brakes, use brake cleaner to remove brake dust, dirt