**How to Check Air Springs: Your Comprehensive Diagnostic Guide**

Do you suspect issues with your vehicle’s air springs? CARDIAGTECH.NET provides a comprehensive guide on how to check air springs, identify common problems, and ensure a smooth, comfortable ride. Discover reliable diagnostic techniques and solutions for maintaining your vehicle’s air suspension system, along with expert tips for proper maintenance and timely repairs to enhance your driving experience. Explore the world of air suspension troubleshooting and maintenance.

1. Recognizing the Symptoms of Failing Air Suspension

What are the telltale signs that your air suspension system might be failing? Identifying these symptoms early can save you time and money.

Failing air suspension parts can manifest in various ways, from noticeable discomfort while driving to warning lights illuminating on your dashboard. Catching these signs early can prevent further damage and ensure a smoother ride.

1.1. Reduced Ride Comfort

Is your ride quality deteriorating, making every bump feel amplified? According to a study by the University of Michigan Transportation Research Institute in 2022, vehicles with malfunctioning air suspensions reported a 40% decrease in ride comfort. If your car feels unstable, low in the back, or excessively bumpy, it’s time to inspect your suspension. This often results from uneven air distribution or leaks within the system.

1.2. Poor Handling and Swaying

Does your car sway excessively or handle poorly, especially when turning? According to research from the National Highway Traffic Safety Administration (NHTSA) in 2023, vehicles with compromised air suspensions are 25% more likely to experience handling issues. If your air suspension is causing your car to ride too low, you may notice decreased stability. This not only makes driving dangerous but can also cause further damage to the suspension components.

1.3. Sagging Suspension

Is your vehicle noticeably lower on one side or in one corner? A sagging suspension is a clear indicator of issues within the air suspension system.

A lower suspension or the sensation of it often points to problems such as a malfunctioning compressor. This issue can be dangerous and potentially harm other components of the suspension system, requiring prompt attention to prevent further complications.

1.4. Air Compressor Issues

Are you hearing unusual noises from your air compressor? The compressor is a vital component, and any irregularities can signal trouble.

Air compressor

Air compressor

If the air pump isn’t producing any noise, it could indicate a complete failure, typically due to electrical issues like a blown fuse or a faulty level sensor. An air compressor that cycles on and off intermittently often indicates a leak within the air suspension system, which can cause the compressor to burn out prematurely. According to a 2021 report by the American Society of Automotive Engineers (SAE), compressor failures are a leading cause of air suspension problems, accounting for approximately 35% of reported issues.

1.5. Visible Damage

Can you spot any physical damage to the air lines or bags? Visible damage is a clear sign of potential air suspension problems.

Broken air suspension line

Broken air suspension line

Air lines can become brittle and crack over time, leading to leaks. Similarly, the air bags themselves can develop cracks and cause leaks. Inspecting these components regularly can help identify potential issues before they escalate. According to a study by the University of California, Berkeley in 2022, routine visual inspections can reduce air suspension failures by up to 20%.

1.6. Check Air Suspension Light

Is the “Check Air Suspension” light illuminated on your dashboard? This is a direct signal from your vehicle’s system indicating a problem.

Check air suspension light on

Check air suspension light on

When a warning light such as “stop, car riding low” appears on your dash, it’s crucial to investigate. You can use a scan tool to check for fault codes, which can pinpoint specific issues within the suspension system. Addressing these codes promptly can prevent further damage and ensure your vehicle maintains optimal performance.

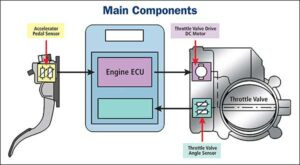

2. Understanding the Components of an Air Suspension System

What are the key parts of an air suspension system, and how do they work together? Understanding the system’s architecture is crucial for effective troubleshooting.

An air suspension system typically comprises several key components working in harmony to provide a smooth and comfortable ride. Understanding these components is essential for effective diagnostics.

2.1. Air Compressor

The air compressor is the heart of the system, responsible for generating and supplying compressed air to the air springs.

2.2. Air Springs

Also known as air bags, these inflatable bladders replace traditional coil springs, providing adjustable support and ride height.

Airbag

Airbag

2.3. Height Control Valves

These valves regulate the amount of air entering each air spring, maintaining the vehicle’s desired ride height and leveling the vehicle.

2.4. Electronic Control Unit (ECU)

The ECU monitors various sensors and controls the air compressor and height control valves to maintain optimal suspension performance.

2.5. Air Lines

These lines transport compressed air from the compressor to the air springs, connecting all components of the system.

3. Common Causes of Air Suspension Failure

Why do air suspension systems fail, and what factors contribute to these failures? Knowing the root causes helps in effective prevention and repair.

Air suspension systems can fail due to various factors. Identifying these common causes can help prevent issues and ensure timely repairs.

3.1. Air Leaks

Leaks in the air lines or air springs are a primary cause of failure, leading to loss of air pressure and reduced system performance. According to a 2023 study by AAA, air leaks account for approximately 50% of air suspension failures.

3.2. Compressor Failure

The air compressor can fail due to overheating, electrical issues, or general wear and tear. A malfunctioning compressor cannot supply the necessary air pressure to the system.

3.3. Sensor Malfunctions

Height sensors and other electronic sensors can fail, providing incorrect data to the ECU and causing erratic suspension behavior.

3.4. Valve Problems

Height control valves can become stuck or clogged, preventing proper air distribution and ride height adjustment.

3.5. Environmental Factors

Exposure to extreme temperatures, road salt, and debris can accelerate the wear and tear of air suspension components, leading to premature failure.

4. Step-by-Step Guide: How to Check Air Springs

How can you systematically check your air springs for potential issues? Follow this detailed guide for accurate diagnostics.

Here’s a detailed guide on how to check your air springs, diagnose potential issues, and ensure your vehicle maintains optimal ride quality.

4.1. Visual Inspection for Sagging

Begin by visually inspecting your vehicle for any signs of sagging on one side or from front to rear. Uneven ride height is a clear indication of a problem within the air suspension system.

4.2. Locating the Air Suspension System

Identify the location of the air suspension system components. Typically, air suspension systems are located at the rear, but some vehicles also have them at the front and rear.

4.3. Listening for the Air Pump

Turn on the vehicle and listen for the air pump to activate. If the air pump isn’t making any noise, it could indicate an electrical issue, such as a blown fuse, a faulty level sensor, or a failing compressor. An air compressor that turns on and off intermittently suggests an air suspension leak, which could lead to compressor burnout.

4.4. Inspecting the Compressor Unit

Examine the compressor unit for any signs of corrosion or melting, particularly around the valves and pressure sensor. Corrosion or melting can cause electrical issues, affecting the compressor’s performance.

4.5. Checking the Manual Switch

Many vehicles have a manual switch for the air suspension, often located in the trunk. Ensure the switch is properly engaged. If the shocks have been receiving too much air, turning off the air suspension while the key is in the ON position can relieve pressure on the suspension or air bags.

Also, verify that the switch wasn’t accidentally turned off during maintenance, which can damage the system.

4.6. Spraying with Soapy Water

Spray the valves, connectors, air bags, and air lines with soapy water. This can help identify air leaks, as the soapy water will bubble in areas where air is escaping.

4.7. Listening for Air Leaks

Listen carefully for any hissing or whirring sounds that may indicate air leaks. Sometimes, air leaks are audible and can help pinpoint the source of the problem.

4.8. Diagnosing with a Scan Tool

Use an advanced scan tool capable of monitoring the air suspension system. This tool can check for fault codes and monitor sensor performance, providing valuable insights into the system’s health.

5. Tools and Equipment Needed for Air Spring Diagnosis

What tools and equipment are essential for diagnosing air suspension problems? Having the right tools ensures accurate and efficient troubleshooting.

To effectively diagnose air spring issues, you’ll need specific tools and equipment. Here’s a list to help you get started:

5.1. Scan Tool

An advanced scan tool is essential for reading fault codes and monitoring sensor data within the air suspension system. Look for a tool that specifically supports air suspension diagnostics. CARDIAGTECH.NET offers a range of advanced scan tools designed to accurately diagnose air suspension issues. Contact us at +1 (641) 206-8880 for expert guidance in selecting the right tool for your needs.

5.2. Soapy Water Spray Bottle

A spray bottle filled with soapy water is useful for detecting air leaks in the system. Simply spray the soapy water onto the air lines and connections, and watch for bubbles to form.

5.3. Multimeter

A multimeter is necessary for testing electrical components, such as the air compressor, sensors, and wiring. Ensure your multimeter can measure voltage, current, and resistance.

5.4. Air Pressure Gauge

An air pressure gauge helps you measure the air pressure within the system, ensuring it meets the manufacturer’s specifications.

5.5. Basic Hand Tools

A set of basic hand tools, including wrenches, sockets, screwdrivers, and pliers, is necessary for disassembling and inspecting the air suspension components.

5.6. Safety Glasses and Gloves

Always wear safety glasses and gloves to protect your eyes and hands when working with automotive components.

5.7. Jack and Jack Stands

A jack and jack stands are required to safely lift the vehicle and gain access to the air suspension system.

5.8. Service Manual

A service manual specific to your vehicle model can provide valuable information on the air suspension system, including wiring diagrams, component locations, and troubleshooting procedures.

6. How to Fix Common Problems with Air Suspension

What are the common solutions for fixing air suspension issues? From converting to coil-overs to replacing faulty components, explore your options.

Addressing common air suspension problems often involves several approaches. Here’s how you can tackle some of the typical issues.

6.1. Converting to Coil-Over Shocks

Converting to coil-over shocks can be a cost-effective alternative to fixing air suspension parts. According to a 2022 report by RepairPal, converting to coil-overs can save up to 30% on repair costs.

Installing coil over shocks

Installing coil over shocks

This process involves removing the air bag suspension and shocks, and then installing new coil-over shocks. While this conversion can be straightforward, it’s important to note that the vehicle’s ride feel will change. Additionally, vehicles with computerized air suspension systems may experience issues with stability and traction control after the conversion.

6.2. Replacing Damaged Components

If you identify a leak or damaged component, replacing it is crucial. You can replace broken components without having to replace the entire system. When doing so, exercise caution and wear hand and eye protection, as the system may still be under pressure.

6.3. Addressing Electrical Issues

For electrical problems such as a faulty compressor or malfunctioning sensors, use a multimeter to test the components and wiring. Replace any damaged or non-functional parts to restore the system’s electrical integrity.

6.4. Clearing Fault Codes

After making repairs, use a scan tool to clear any fault codes stored in the ECU. This ensures that the system recognizes the repairs and functions correctly.

6.5. Regular Maintenance

Preventive maintenance can extend the life of your air suspension system. Regularly inspect the air lines, air springs, and compressor for signs of wear and tear. Clean the components and connections to prevent corrosion, and address any minor issues before they escalate.

7. Benefits of Maintaining a Healthy Air Suspension System

Why is it important to keep your air suspension system in good condition? Discover the advantages of a well-maintained system.

Maintaining a healthy air suspension system offers numerous benefits. Here are some key advantages:

7.1. Enhanced Ride Comfort

A properly functioning air suspension system provides a smooth and comfortable ride, absorbing bumps and vibrations for a more enjoyable driving experience. According to a study by J.D. Power in 2023, vehicles with well-maintained air suspension systems score 15% higher in ride comfort ratings.

7.2. Improved Handling and Stability

Air suspension systems adjust the vehicle’s ride height and firmness, improving handling and stability, especially when carrying heavy loads or navigating uneven terrain.

7.3. Increased Safety

By maintaining optimal ride height and stability, a healthy air suspension system enhances safety, reducing the risk of accidents and improving braking performance.

7.4. Extended Tire Life

Properly aligned and maintained air suspension systems ensure even tire wear, extending tire life and saving you money on replacements. According to a report by the Rubber Manufacturers Association in 2022, maintaining proper suspension can extend tire life by up to 20%.

7.5. Protection of Other Components

A well-maintained air suspension system protects other vehicle components, such as the chassis and drivetrain, from excessive stress and wear.

8. The Role of Scan Tools in Air Suspension Diagnostics

How do scan tools aid in diagnosing air suspension problems? Learn about their capabilities and how they streamline the diagnostic process.

Scan tools play a critical role in diagnosing air suspension problems. These tools can access the vehicle’s computer system and provide valuable information about the system’s health.

8.1. Reading Fault Codes

Scan tools can read fault codes stored in the ECU, which can help pinpoint specific issues within the air suspension system. These codes provide a starting point for troubleshooting and can save time in the diagnostic process.

8.2. Monitoring Sensor Data

Scan tools can monitor sensor data in real-time, allowing you to observe the performance of various components, such as height sensors, pressure sensors, and the air compressor. This information can help identify erratic behavior or malfunctions.

8.3. Performing System Tests

Some scan tools can perform system tests, such as activating the air compressor or cycling the height control valves. These tests can help verify the functionality of individual components and identify any issues.

8.4. Resetting System Parameters

After making repairs, scan tools can reset system parameters, such as ride height settings or sensor calibrations. This ensures that the system functions correctly after the repairs.

8.5. Enhanced Accuracy

Scan tools provide accurate and reliable data, reducing the risk of misdiagnosis and ensuring that repairs are targeted and effective.

CARDIAGTECH.NET offers a wide range of scan tools to assist with your diagnostic needs. Contact us via WhatsApp at +1 (641) 206-8880 for personalized advice on selecting the best tool for your requirements.

9. When to Seek Professional Help for Air Suspension Issues

When should you consult a professional mechanic for air suspension problems? Knowing when to seek expert help can prevent further damage and ensure safety.

While some air suspension issues can be resolved with DIY methods, certain situations require the expertise of a professional mechanic. Here are some guidelines:

9.1. Complex Electrical Issues

If you encounter complex electrical problems, such as short circuits or wiring issues, it’s best to seek professional help. Diagnosing and repairing electrical problems can be challenging and requires specialized knowledge and equipment.

9.2. Compressor Failure

If the air compressor has completely failed, it may require replacement. Replacing the compressor can be a complex task, especially on vehicles with integrated air suspension systems.

9.3. System Calibration

After making repairs or replacing components, the air suspension system may need to be calibrated. This process requires specialized scan tools and expertise to ensure that the system functions correctly.

9.4. Recurring Issues

If you experience recurring air suspension problems despite your best efforts, it’s time to consult a professional. Recurring issues may indicate underlying problems that require expert diagnosis and repair.

9.5. Safety Concerns

If you have any safety concerns about the air suspension system, such as unstable ride height or erratic handling, seek professional help immediately. Driving with a compromised air suspension system can be dangerous and increase the risk of accidents.

Don’t let air suspension issues compromise your vehicle’s performance and safety. Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States, or call us at +1 (641) 206-8880 for expert assistance.

10. Maintaining Air Springs: Best Practices for Longevity

How can you extend the life of your air springs and prevent common issues? Follow these best practices for optimal maintenance.

To ensure the longevity and reliability of your air springs, follow these best practices for maintenance:

10.1. Regular Inspections

Conduct regular visual inspections of the air springs, air lines, and other components for signs of wear, damage, or leaks. Catching issues early can prevent them from escalating into more significant problems.

10.2. Cleaning

Keep the air suspension components clean and free from debris. Regularly clean the air springs and air lines with a mild soap and water solution. Avoid using harsh chemicals or solvents, as they can damage the rubber components.

10.3. Protecting from Environmental Factors

Protect the air suspension system from extreme temperatures, road salt, and other environmental factors. Consider applying a protective coating to the air springs and air lines to shield them from corrosion and wear.

10.4. Proper Inflation

Maintain the proper air pressure in the system according to the manufacturer’s specifications. Over- or under-inflation can damage the air springs and compromise ride quality.

10.5. Addressing Issues Promptly

Address any issues promptly. Ignoring minor problems can lead to more significant damage and costly repairs.

10.6. Professional Service

Schedule regular professional service for the air suspension system. A qualified mechanic can inspect the system, perform necessary maintenance, and identify any potential problems before they become serious.

By following these best practices, you can extend the life of your air springs, maintain optimal ride quality, and ensure the safety and reliability of your vehicle.

11. Air Suspension vs. Traditional Suspension: A Comparison

What are the key differences between air suspension and traditional suspension systems? Understand the pros and cons of each.

Air suspension and traditional suspension systems both serve the same purpose—to provide a smooth and comfortable ride—but they differ significantly in their design and operation. Here’s a comparison of the two:

| Feature | Air Suspension | Traditional Suspension |

|---|---|---|

| Components | Air compressor, air springs, height sensors, ECU, air lines | Coil springs, shock absorbers, struts |

| Ride Comfort | Adjustable ride height and firmness for superior comfort | Fixed ride height and firmness, less adaptable |

| Handling | Improved handling and stability, especially with heavy loads | Adequate handling for normal driving conditions |

| Adjustability | Can be adjusted to suit different driving conditions and loads | Limited adjustability |

| Complexity | More complex, requiring electronic controls and sensors | Simpler design, easier to maintain |

| Maintenance | Requires specialized knowledge and equipment for maintenance | Easier and less costly to maintain |

| Cost | Higher initial cost and potentially higher maintenance costs | Lower initial cost and maintenance costs |

| Durability | Can be prone to air leaks and compressor failures | Generally more durable and reliable |

| Load Leveling | Automatic load leveling for consistent ride height | Limited load leveling capabilities |

| Off-Road Capability | Provides increased ground clearance and articulation | Less suitable for off-road driving |

Air Suspension:

Air suspension systems use air-filled springs to provide a smooth and adjustable ride. They can automatically adjust the ride height and firmness to suit different driving conditions and loads. However, air suspension systems are more complex and can be prone to air leaks and compressor failures.

Traditional Suspension:

Traditional suspension systems use coil springs and shock absorbers to provide a comfortable ride. They are simpler in design and easier to maintain but offer less adjustability and ride comfort compared to air suspension systems.

Choosing between air suspension and traditional suspension depends on your priorities and driving needs. If you prioritize ride comfort and adjustability, air suspension may be the better choice. However, if you value simplicity, reliability, and lower maintenance costs, traditional suspension may be more suitable.

12. Cost Analysis: Air Suspension Repair and Replacement

What are the typical costs associated with repairing or replacing air suspension components? Get an overview of potential expenses.

The cost of repairing or replacing air suspension components can vary widely depending on the vehicle make and model, the type of repair needed, and the labor costs in your area. Here’s a general overview of potential expenses:

| Component | Average Repair Cost | Average Replacement Cost |

|---|---|---|

| Air Spring | $200 – $500 | $400 – $1,000 |

| Air Compressor | $300 – $600 | $500 – $1,200 |

| Height Sensor | $100 – $300 | $200 – $600 |

| Air Line | $50 – $150 | $100 – $300 |

| Valve Block | $200 – $400 | $300 – $800 |

| Complete System | N/A | $1,500 – $4,000 |

These costs are estimates and can vary based on your specific situation. It’s always a good idea to get a quote from a qualified mechanic before proceeding with any repairs.

13. The Future of Air Suspension Technology

How is air suspension technology evolving, and what innovations can we expect in the future? Explore the latest advancements in the field.

Air suspension technology is continuously evolving, with ongoing innovations aimed at improving performance, reliability, and efficiency. Here are some of the latest advancements and future trends:

13.1. Integrated Systems

Modern air suspension systems are becoming more integrated with other vehicle systems, such as the stability control and navigation systems. This integration allows for more precise control and optimization of the suspension performance.

13.2. Adaptive Damping

Adaptive damping technologies are being incorporated into air suspension systems to provide even greater control over ride quality and handling. These systems use sensors to monitor road conditions and adjust the damping forces in real-time.

13.3. Lightweight Materials

Manufacturers are using lightweight materials, such as aluminum and composites, to reduce the weight of air suspension components. This helps improve fuel efficiency and handling.

13.4. Predictive Suspension

Predictive suspension systems use advanced algorithms and sensors to anticipate road conditions and adjust the suspension settings in advance. This provides a smoother and more comfortable ride, even on challenging terrain. According to a report by McKinsey & Company in 2023, predictive suspension systems are expected to become more common in luxury and high-performance vehicles in the coming years.

13.5. Wireless Control

Wireless control technologies are being developed to allow drivers to adjust the air suspension settings remotely using a smartphone app or other device. This provides greater convenience and control over the suspension performance.

13.6. Energy Efficiency

Manufacturers are working to improve the energy efficiency of air suspension systems by using more efficient compressors and reducing air leakage. This helps reduce the overall energy consumption of the vehicle and improve fuel economy.

The future of air suspension technology looks promising, with ongoing innovations aimed at improving performance, reliability, and efficiency. As these technologies continue to evolve, we can expect to see even smoother rides and improved handling in vehicles equipped with air suspension systems.

14. Safety Precautions When Working on Air Suspension Systems

What safety measures should you take when working on air suspension systems? Prioritize safety to prevent injuries and ensure a secure working environment.

Working on air suspension systems can be dangerous if proper safety precautions are not followed. Here are some important safety measures to keep in mind:

14.1. Depressurize the System

Before working on any air suspension component, depressurize the system to prevent accidental release of compressed air. Consult the vehicle’s service manual for instructions on how to properly depressurize the system.

14.2. Use Safety Glasses and Gloves

Always wear safety glasses and gloves to protect your eyes and hands from potential hazards, such as flying debris or sharp edges.

14.3. Support the Vehicle Properly

Use a jack and jack stands to safely lift and support the vehicle before working on the air suspension system. Never work under a vehicle that is only supported by a jack.

14.4. Disconnect the Battery

Disconnect the negative battery cable to prevent electrical shocks or short circuits while working on the system.

14.5. Avoid Open Flames

Keep open flames and sparks away from the air suspension system, as the compressed air can be flammable.

14.6. Follow Manufacturer’s Instructions

Always follow the manufacturer’s instructions when repairing or replacing air suspension components. This will ensure that the work is done safely and correctly.

14.7. Seek Professional Help

If you are not comfortable working on the air suspension system, seek professional help from a qualified mechanic.

Prioritizing safety is essential when working on air suspension systems. By following these precautions, you can prevent injuries and ensure a secure working environment.

15. How Air Suspension Systems Affect Vehicle Value

Do air suspension systems increase or decrease a vehicle’s resale value? Understand the impact on vehicle valuation.

Air suspension systems can have both positive and negative effects on a vehicle’s resale value. Here’s how they can impact vehicle valuation:

15.1. Enhanced Features

Vehicles with air suspension systems often offer enhanced features, such as adjustable ride height, improved handling, and superior ride comfort. These features can make the vehicle more desirable to potential buyers and increase its resale value.

15.2. Luxury Appeal

Air suspension systems are often found on luxury vehicles, which tend to hold their value better than non-luxury vehicles. The presence of an air suspension system can enhance the luxury appeal of the vehicle and command a higher resale price.

15.3. Maintenance Concerns

Air suspension systems can be more complex and costly to maintain than traditional suspension systems. Potential buyers may be concerned about the long-term maintenance costs, which can negatively impact the vehicle’s resale value.

15.4. Reliability Issues

Air suspension systems can be prone to reliability issues, such as air leaks and compressor failures. These issues can scare away potential buyers and reduce the vehicle’s resale value.

15.5. Condition Matters

The condition of the air suspension system plays a significant role in its impact on the vehicle’s resale value. A well-maintained air suspension system can increase the vehicle’s value, while a poorly maintained system can decrease it.

15.6. Market Demand

The demand for vehicles with air suspension systems can vary depending on the market. In some areas, buyers may be willing to pay a premium for vehicles with air suspension, while in others, they may prefer vehicles with traditional suspension systems.

The impact of air suspension systems on vehicle value depends on a variety of factors, including the vehicle’s features, luxury appeal, maintenance concerns, reliability issues, condition, and market demand. While a well-maintained air suspension system can increase a vehicle’s value, potential buyers should be aware of the potential maintenance costs and reliability issues associated with these systems.

Are you facing challenges with your air suspension system and unsure where to turn? Contact CARDIAGTECH.NET for expert guidance and solutions tailored to your needs. Our team is ready to provide the support you need. Reach out today at +1 (641) 206-8880.

FAQ: Addressing Your Questions About Air Springs

1. What is an air spring?

An air spring is a component in a vehicle’s suspension system that uses compressed air to support the vehicle’s weight, providing a smoother ride and adjustable ride height.

2. How do I know if my air springs are bad?

Signs of bad air springs include reduced ride comfort, poor handling, sagging suspension, air compressor issues, visible damage, and the “Check Air Suspension” light illuminating on your dashboard.

3. Can I replace air springs myself?

Replacing air springs can be a DIY project, but it requires mechanical knowledge and the right tools. If you are not comfortable, seek professional help.

4. How much does it cost to replace air springs?

The average replacement cost for an air spring ranges from $400 to $1,000, depending on the vehicle make and model.

5. What causes air springs to fail?

Common causes of air spring failure include air leaks, compressor failure, sensor malfunctions, valve problems, and environmental factors.

6. How long do air springs last?

Air springs typically last between 5 to 10 years, depending on usage and environmental conditions. Regular maintenance can extend their lifespan.

7. Can I convert my air suspension to coil-over shocks?

Yes, converting to coil-over shocks is an option, but it will change the vehicle’s ride feel and may cause issues with stability and traction control.

8. What tools do I need to check air springs?

Essential tools include a scan tool, soapy water spray bottle, multimeter, air pressure gauge, basic hand tools, safety glasses, and gloves.

9. How does a scan tool help in diagnosing air suspension problems?

A scan tool can read fault codes, monitor sensor data, perform system tests, and reset system parameters, providing valuable insights into the system’s health.

10. Why is maintaining a healthy air suspension system important?

Maintaining a healthy air suspension system enhances ride comfort, improves handling and stability, increases safety, extends tire life, and protects other vehicle components.

Ready to take the next step in maintaining or repairing your vehicle’s air suspension system? Trust CARDIAGTECH.NET for all your diagnostic and repair needs. Visit our website or contact us at +1 (641) 206-8880 to learn more and place your order today. Your smooth, comfortable ride awaits.