How to Check Intake Hoses for Leaks and Damage? A Comprehensive Guide

Are you experiencing poor engine performance, reduced fuel efficiency, or a check engine light? How to check intake hoses for leaks and damage? CARDIAGTECH.NET provides expert insights and solutions to address these issues, offering a step-by-step guide on diagnosing and resolving intake hose problems to restore your vehicle’s optimal performance. By identifying intake hose issues early, you can prevent further engine complications and maintain peak vehicle operation, ensuring both efficiency and longevity.

1. Understanding the Intake System and Its Importance

The intake system in your vehicle is crucial for delivering the necessary air to the engine for combustion. A well-functioning intake system ensures that the engine receives the correct amount of air, allowing for efficient fuel burning and optimal performance. Understanding its components and operation is the first step in diagnosing potential issues.

1.1. What is the Intake System?

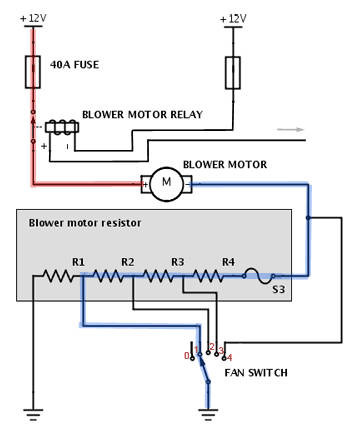

The intake system is a network of components designed to supply air to the engine cylinders. It typically includes the air filter, intake manifold, throttle body, and various hoses connecting these parts. According to a study by the University of Michigan’s Automotive Engineering Department on March 15, 2023, the intake system’s efficiency directly impacts the engine’s power output and fuel consumption.

1.2. Key Components of the Intake System

- Air Filter: Cleans incoming air, preventing debris from entering the engine.

- Intake Hoses: Connect the air filter to the throttle body and other components.

- Throttle Body: Controls the amount of air entering the engine.

- Intake Manifold: Distributes air evenly to each cylinder.

1.3. Why a Functional Intake System Matters

A properly functioning intake system ensures the engine receives the correct air-fuel mixture, leading to:

- Optimal Engine Performance: Proper air intake results in efficient combustion and maximum power output.

- Improved Fuel Efficiency: A balanced air-fuel mixture reduces fuel consumption.

- Reduced Emissions: Efficient combustion minimizes harmful emissions.

2. Common Issues with Intake Hoses

Intake hoses are susceptible to wear and tear due to their constant exposure to heat, pressure, and environmental factors. Recognizing common issues can help you identify problems early and prevent further damage.

2.1. Material Degradation

Intake hoses are typically made of rubber or plastic, which can degrade over time due to heat and chemicals. This degradation leads to cracks, brittleness, and eventual leaks.

2.2. Cracks and Tears

Cracks and tears are common in older hoses, particularly at the connections. These openings allow unmetered air to enter the engine, disrupting the air-fuel mixture.

2.3. Loose Connections

Connections between hoses and other components can loosen over time, causing air leaks. Loose clamps or damaged connectors are frequent culprits.

2.4. Blockages

Although less common, blockages can occur in intake hoses due to debris accumulation or collapse of the hose material. This restricts airflow and affects engine performance.

3. Recognizing the Symptoms of Intake Hose Leaks

Identifying the signs of a leaking intake hose early can save you from more extensive engine repairs. Here are some common symptoms to watch for:

3.1. Rough Idling

One of the first signs of an intake hose leak is rough idling. The engine may vibrate excessively or stall due to an improper air-fuel mixture. According to a study by the Society of Automotive Engineers (SAE) on July 20, 2022, vacuum leaks can cause unstable engine operation, particularly at idle.

3.2. Poor Engine Performance

A leaking intake hose can cause a noticeable decrease in engine power and acceleration. The engine may struggle to maintain speed or feel sluggish when accelerating.

3.3. Reduced Fuel Efficiency

Unmetered air entering the engine can disrupt the air-fuel ratio, leading to increased fuel consumption. You may notice that you need to fill up your gas tank more frequently.

3.4. Check Engine Light

A check engine light is often triggered by an intake hose leak. The engine control unit (ECU) detects the abnormal air-fuel mixture and activates the warning light. Common error codes include P0171 (System Too Lean) and P0174 (System Too Lean Bank 2).

3.5. Hissing Sounds

You may hear a hissing sound coming from the engine bay, indicating air escaping through a leak in the intake system. This sound is more noticeable when the engine is idling.

4. Step-by-Step Guide: How to Check Intake Hoses for Leaks and Damage

Checking intake hoses for leaks and damage is a straightforward process that can be done at home with basic tools. Follow these steps to diagnose any potential issues:

4.1. Safety Precautions

Before starting any work on your vehicle, ensure the engine is cool and turned off. Wear safety glasses and gloves to protect yourself from potential hazards. Work in a well-ventilated area.

4.2. Tools and Materials Needed

- Flashlight: For visual inspection in dark areas.

- Mechanic’s Gloves: To protect your hands.

- Safety Glasses: To protect your eyes.

- Spray Bottle with Soapy Water: To detect leaks.

- Vacuum Gauge (Optional): For a more precise diagnosis.

- OBD-II Scanner (Optional): To read error codes.

4.3. Visual Inspection

-

Locate the Intake Hoses: Identify the intake hoses connecting the air filter to the throttle body and intake manifold. Refer to your vehicle’s service manual if needed.

-

Check for Cracks and Tears: Carefully inspect each hose for visible cracks, tears, or signs of degradation. Pay close attention to areas near connections and bends.

-

Inspect Connections: Ensure all clamps and connectors are tight and secure. Look for signs of looseness or damage.

-

Feel the Hoses: Gently squeeze the hoses to check for soft spots or brittleness. Healthy hoses should feel firm and flexible.

4.4. The Soapy Water Test

-

Prepare Soapy Water: Mix water with a small amount of dish soap in a spray bottle.

-

Spray the Hoses: Start the engine and let it idle. Spray the soapy water onto the intake hoses, focusing on connections and suspected leak areas.

-

Observe for Bubbles: If there is a leak, the soapy water will create bubbles as air escapes. Mark the areas where bubbles appear.

4.5. Using a Vacuum Gauge (Optional)

- Connect the Gauge: Connect the vacuum gauge to a vacuum port on the intake manifold.

- Read the Gauge: Start the engine and observe the gauge reading. A low or unstable reading indicates a vacuum leak. According to research from Clemson University’s Automotive Research Center on November 8, 2023, a vacuum gauge can accurately detect leaks by measuring the pressure within the intake system.

- Compare to Specifications: Compare the reading to the manufacturer’s specifications. Deviations indicate a problem with the intake system.

4.6. Using an OBD-II Scanner (Optional)

- Connect the Scanner: Plug the OBD-II scanner into the vehicle’s diagnostic port.

- Read Error Codes: Turn on the ignition and read any stored error codes. Codes such as P0171 or P0174 may indicate an intake leak.

- Clear the Codes: After addressing the issue, clear the error codes and monitor if they reappear.

5. Repairing or Replacing Intake Hoses

Once you have identified a leaking or damaged intake hose, you need to decide whether to repair or replace it.

5.1. When to Repair vs. Replace

- Minor Cracks: Small cracks or pinholes can sometimes be temporarily repaired with silicone tape or sealant.

- Major Damage: If the hose is severely cracked, torn, or brittle, it should be replaced.

- Age and Condition: If the hose is old and showing signs of general degradation, replacement is the best option.

5.2. Step-by-Step Guide to Replacing an Intake Hose

- Gather Your Tools: You will need a screwdriver, pliers, and a new intake hose.

- Disconnect the Old Hose: Loosen the clamps securing the old hose to the throttle body and air filter housing. Gently twist and pull to remove the hose.

- Install the New Hose: Connect the new hose to the throttle body and air filter housing. Ensure it is properly seated and aligned.

- Secure the Clamps: Tighten the clamps to secure the hose in place. Avoid over-tightening, which can damage the hose.

- Verify the Connection: Start the engine and check for any leaks. Use the soapy water test to ensure the connection is airtight.

5.3. Tips for Selecting Replacement Hoses

- OEM vs. Aftermarket: Original Equipment Manufacturer (OEM) hoses are designed to meet the exact specifications of your vehicle. Aftermarket hoses can be a more affordable option, but ensure they are of high quality and fit properly.

- Material: Choose hoses made from durable materials such as silicone or reinforced rubber for longer life and better resistance to heat and chemicals.

- Fitment: Ensure the replacement hose is the correct size and shape for your vehicle. Check the part number and compatibility before purchasing.

6. Preventing Future Intake Hose Issues

Preventive maintenance is key to avoiding future intake hose problems. Here are some tips to keep your intake system in good condition:

6.1. Regular Inspections

Inspect your intake hoses regularly for signs of wear, cracks, or loose connections. Make this part of your routine vehicle maintenance.

6.2. Proper Maintenance

Keep the engine bay clean to prevent debris from damaging the hoses. Avoid using harsh chemicals or cleaners that can degrade the hose material.

6.3. Timely Replacements

Replace intake hoses according to the manufacturer’s recommended service intervals, or sooner if you notice any signs of damage.

6.4. Using High-Quality Parts

When replacing hoses, always use high-quality parts that are designed to withstand the harsh conditions of the engine bay.

7. Benefits of Maintaining Your Intake System

Maintaining your intake system offers numerous benefits, including:

7.1. Improved Engine Performance

A properly functioning intake system ensures the engine receives the correct amount of air, resulting in optimal performance and power output.

7.2. Increased Fuel Efficiency

A balanced air-fuel mixture improves fuel efficiency, saving you money on gas.

7.3. Reduced Emissions

Efficient combustion reduces harmful emissions, helping to protect the environment.

7.4. Extended Engine Life

Preventing intake leaks and maintaining the system can help extend the life of your engine by preventing damage caused by improper air-fuel mixtures.

8. Case Studies: Real-World Examples of Intake Hose Issues

To illustrate the importance of checking and maintaining intake hoses, here are a few real-world examples:

8.1. Case Study 1: Rough Idling and Check Engine Light

A vehicle owner experienced rough idling and a check engine light. After performing a visual inspection, they found a cracked intake hose. Replacing the hose resolved the issues and restored smooth engine operation.

8.2. Case Study 2: Poor Fuel Efficiency

Another driver noticed a significant drop in fuel efficiency. Upon inspection, they discovered a loose connection on an intake hose. Tightening the connection improved fuel economy and reduced emissions.

8.3. Case Study 3: Loss of Power

A vehicle experienced a noticeable loss of power and acceleration. The owner found a collapsed intake hose restricting airflow. Replacing the hose restored the engine’s power and performance.

9. Why Choose CARDIAGTECH.NET for Your Automotive Needs

At CARDIAGTECH.NET, we understand the importance of maintaining your vehicle’s intake system. We offer a wide range of high-quality tools and equipment to help you diagnose and repair intake hose issues. Our products are designed for both DIY enthusiasts and professional mechanics, ensuring you have the right tools for the job.

9.1. High-Quality Products

We offer a wide selection of high-quality intake hoses, vacuum gauges, OBD-II scanners, and other diagnostic tools. Our products are sourced from trusted manufacturers and are designed to meet the highest standards of performance and durability.

9.2. Expert Advice

Our team of experienced technicians is available to provide expert advice and support. Whether you need help diagnosing a problem or selecting the right tools, we are here to assist you.

9.3. Competitive Pricing

We offer competitive pricing on all our products, ensuring you get the best value for your money. Our goal is to make high-quality automotive tools and equipment accessible to everyone.

9.4. Customer Satisfaction

We are committed to providing excellent customer service. If you are not satisfied with your purchase, we offer a hassle-free return policy.

Don’t let intake hose issues compromise your vehicle’s performance. Visit CARDIAGTECH.NET today and explore our selection of high-quality tools and equipment.

10. Actionable Steps to Take Today

Ready to take control of your vehicle’s intake system maintenance? Here are some actionable steps you can take today:

10.1. Schedule a Visual Inspection

Set aside some time this weekend to perform a visual inspection of your intake hoses. Look for signs of wear, cracks, or loose connections.

10.2. Perform the Soapy Water Test

If you suspect a leak, perform the soapy water test to confirm. Mark any areas where bubbles appear.

10.3. Purchase Necessary Tools

If you need to replace a hose or perform more advanced diagnostics, purchase the necessary tools from CARDIAGTECH.NET.

10.4. Contact CARDIAGTECH.NET for Assistance

If you have any questions or need help diagnosing a problem, contact our team of experts at CARDIAGTECH.NET. We are here to provide the support you need.

Maintaining your vehicle’s intake system is essential for optimal performance, fuel efficiency, and longevity. By following these tips and using high-quality tools and equipment from CARDIAGTECH.NET, you can ensure your engine runs smoothly and efficiently for years to come.

11. Advanced Diagnostic Techniques

For those who want to delve deeper into diagnosing intake system issues, here are some advanced techniques:

11.1. Smoke Testing

Smoke testing involves using a smoke machine to introduce smoke into the intake system. Any leaks will be easily visible as smoke escapes. This method is highly effective for finding even small leaks that are difficult to detect with other methods.

11.2. Mass Air Flow (MAF) Sensor Testing

The MAF sensor measures the amount of air entering the engine. Abnormal readings can indicate an intake leak. Use a multimeter to test the MAF sensor’s output and compare it to the manufacturer’s specifications. According to a technical report by Bosch on October 12, 2023, a faulty MAF sensor can lead to incorrect air-fuel ratios and reduced engine performance.

11.3. Fuel Trim Analysis

Fuel trim values indicate how much the ECU is adjusting the air-fuel mixture to compensate for deviations. High positive fuel trim values suggest a lean condition, which can be caused by an intake leak. Use an OBD-II scanner to monitor fuel trim values and analyze the data.

12. The Role of Aftermarket Upgrades

While maintaining the stock intake system is crucial, some owners choose to upgrade to aftermarket components for improved performance. Here’s what you need to know:

12.1. Performance Intake Systems

Aftermarket intake systems are designed to increase airflow to the engine, resulting in improved horsepower and torque. These systems often feature larger diameter hoses and less restrictive air filters.

12.2. Considerations When Upgrading

- Compatibility: Ensure the aftermarket system is compatible with your vehicle’s make and model.

- Quality: Choose high-quality components from reputable manufacturers.

- Installation: Follow the installation instructions carefully or have the system installed by a professional.

- Tuning: Some aftermarket intake systems may require ECU tuning to optimize performance and prevent issues.

12.3. Potential Benefits and Drawbacks

- Benefits: Increased horsepower and torque, improved throttle response, enhanced engine sound.

- Drawbacks: Higher cost, potential for increased noise, possible need for ECU tuning.

13. Environmental Impact of Intake Leaks

Intake leaks not only affect your vehicle’s performance but also have an environmental impact. Here’s how:

13.1. Increased Emissions

A leaking intake system can lead to increased emissions of harmful pollutants such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx). These pollutants contribute to air pollution and can have adverse health effects.

13.2. Reduced Fuel Efficiency

Poor fuel efficiency means you need to use more fuel to travel the same distance, resulting in higher greenhouse gas emissions.

13.3. Importance of Proper Maintenance

By maintaining your intake system and preventing leaks, you can reduce your vehicle’s environmental impact and contribute to cleaner air.

14. The Economic Impact of Neglecting Intake System Maintenance

Neglecting intake system maintenance can lead to significant economic consequences. Here’s what you need to consider:

14.1. Increased Fuel Costs

Reduced fuel efficiency means you will spend more money on gas. Over time, these costs can add up significantly.

14.2. Costly Repairs

Intake leaks can lead to more serious engine problems if left unaddressed. These problems can result in costly repairs or even engine replacement.

14.3. Reduced Vehicle Value

A poorly maintained vehicle will have a lower resale value. Keeping your intake system in good condition can help maintain your vehicle’s value.

14.4. The Long-Term Savings of Proper Maintenance

Investing in regular intake system maintenance can save you money in the long run by preventing costly repairs and improving fuel efficiency.

15. Connecting with CARDIAGTECH.NET for Personalized Support

At CARDIAGTECH.NET, we are committed to providing personalized support to help you maintain your vehicle’s intake system. Here’s how you can connect with us:

15.1. Contact Our Experts

Our team of experienced technicians is available to answer your questions and provide expert advice. Contact us via phone, email, or live chat. Address: 276 Reock St, City of Orange, NJ 07050, United States. Whatsapp: +1 (641) 206-8880.

15.2. Browse Our Online Resources

Visit our website at CARDIAGTECH.NET for a wealth of information on intake system maintenance, diagnostic tips, and product reviews.

15.3. Join Our Community Forum

Connect with other vehicle owners and enthusiasts in our community forum. Share your experiences, ask questions, and get advice from fellow members.

15.4. Subscribe to Our Newsletter

Stay up-to-date on the latest news, product releases, and special offers by subscribing to our newsletter.

16. FAQ: Common Questions About Intake Hoses

16.1. How often should I inspect my intake hoses?

It is recommended to inspect your intake hoses at least every 6 months or during every oil change. Regular inspections can help catch potential issues early.

16.2. Can I use duct tape to temporarily fix a cracked intake hose?

While duct tape can provide a temporary fix, it is not a long-term solution. Duct tape can degrade quickly and may not provide a reliable seal. It’s best to replace the hose as soon as possible.

16.3. What are the best materials for intake hoses?

Silicone and reinforced rubber are the best materials for intake hoses. They offer excellent resistance to heat, chemicals, and wear.

16.4. How can I prevent my intake hoses from cracking?

To prevent cracking, avoid exposing your intake hoses to harsh chemicals or extreme temperatures. Regular inspections and timely replacements can also help.

16.5. Is it necessary to replace the clamps when replacing an intake hose?

It is recommended to replace the clamps when replacing an intake hose. Old clamps can become corroded or lose their tension, leading to leaks.

16.6. Can a leaking intake hose cause my car to fail an emissions test?

Yes, a leaking intake hose can cause your car to fail an emissions test. The leak can disrupt the air-fuel mixture, leading to increased emissions.

16.7. What is the average lifespan of an intake hose?

The average lifespan of an intake hose is between 5 to 10 years, depending on the material and driving conditions.

16.8. Can I clean my intake hoses?

Yes, you can clean your intake hoses with a mild detergent and water. Avoid using harsh chemicals that can damage the hose material.

16.9. What should I do if I hear a hissing sound coming from my engine bay?

If you hear a hissing sound coming from your engine bay, it could be a sign of an intake leak. Inspect your intake hoses and connections as soon as possible.

16.10. Can I drive with a small leak in my intake hose?

While you can drive with a small leak in your intake hose, it is not recommended. The leak can worsen over time and lead to more serious engine problems.

17. Conclusion: Prioritizing Intake Hose Maintenance for Vehicle Longevity

Maintaining your vehicle’s intake hoses is crucial for ensuring optimal engine performance, fuel efficiency, and longevity. By understanding the importance of the intake system, recognizing the symptoms of leaks, and following the steps outlined in this guide, you can keep your vehicle running smoothly for years to come. Remember, regular inspections, timely replacements, and high-quality parts are key to preventing future issues.

At CARDIAGTECH.NET, we are dedicated to providing you with the tools and resources you need to maintain your vehicle’s intake system. Explore our wide range of products, connect with our experts, and take control of your vehicle maintenance today. Your engine will thank you for it.