How To Check The Airbag System Using Diagnostic Software?

Checking the airbag system using diagnostic software is essential for ensuring vehicle safety and functionality, and CARDIAGTECH.NET provides the necessary tools and expertise to address these concerns effectively. Using diagnostic software, you can promptly identify and resolve issues, ensuring the safety and dependability of your vehicle’s supplementary restraint system. Explore tailored solutions for your car’s diagnostics, safety system checks, and repair requirements. Car Diagnostic BMW

1. Understanding the Airbag System and Its Importance

Why is understanding the airbag system crucial? Because it directly impacts your safety and that of your passengers.

The airbag system, also known as the Supplemental Restraint System (SRS), is designed to deploy in the event of a collision, providing a crucial cushion that protects occupants from serious injuries. According to the National Highway Traffic Safety Administration (NHTSA), airbags saved 50,457 lives from 1987 to 2017. This highlights their critical role in vehicle safety. A properly functioning airbag system is essential for minimizing harm during accidents.

1.1. Key Components of the Airbag System

What are the key components of the airbag system? Understanding these elements is vital for effective diagnostics and repairs.

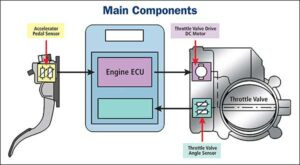

The airbag system consists of several interconnected components:

- Airbag Control Module (ACM) or Airbag Control Unit (ACU): The brain of the system, it monitors sensors and determines when to deploy the airbags.

- Crash Sensors: Located in the front, side, and sometimes rear of the vehicle, these sensors detect sudden deceleration indicative of a collision.

- Airbags: Typically located in the steering wheel, dashboard, seats, and side pillars, these inflatable cushions provide a protective barrier.

- Seatbelt Pretensioners: These tighten the seatbelts during a collision to secure occupants in their seats.

- Occupant Classification System (OCS): This system detects the presence and size of the occupant to adjust airbag deployment force.

- Clock Spring: This allows the steering wheel airbag to function while the steering wheel is turning.

1.2. Why Regular Checks are Essential

Why should you regularly check your airbag system? Regular checks ensure the system is ready to protect you when needed most.

Regular checks are essential for the following reasons:

- Safety Assurance: Ensures the system will function correctly in a collision.

- Early Detection: Identifies potential issues before they become critical.

- Regulatory Compliance: Many jurisdictions require functional safety systems for vehicle registration and inspection.

- Liability Prevention: Protects vehicle owners from liability in case of accidents where a malfunctioning airbag system results in injuries.

1.3. Common Airbag System Problems

What are some common problems that can occur with airbag systems? Knowing these issues helps in quick and accurate diagnostics.

Common airbag system problems include:

- Sensor Malfunctions: Damaged or faulty crash sensors.

- Wiring Issues: Corrosion, damage, or loose connections in the wiring harness.

- Module Failures: Malfunctions in the ACM/ACU due to electrical issues or software glitches.

- Clock Spring Problems: Broken or worn clock springs preventing airbag deployment.

- Seatbelt Pretensioner Issues: Malfunctions in the seatbelt pretensioners preventing them from tightening during a crash.

- Occupant Classification System (OCS) Errors: Incorrect readings from the OCS leading to improper airbag deployment.

These issues can trigger the airbag warning light, indicating the need for immediate inspection and repair. At CARDIAGTECH.NET, we provide diagnostic tools that help pinpoint these problems quickly and accurately, ensuring your airbag system is always ready to protect you. Contact us at +1 (641) 206-8880 for expert advice and solutions tailored to your needs. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

2. Diagnostic Software: An Overview

What is diagnostic software and why is it essential for modern vehicle maintenance? Diagnostic software provides precise insights into your vehicle’s health.

Diagnostic software is a specialized tool that interfaces with a vehicle’s onboard computer system to read and interpret data from various sensors and modules. This software allows technicians and vehicle owners to:

- Read Diagnostic Trouble Codes (DTCs): Identify specific issues within the vehicle’s systems.

- Monitor System Parameters: Observe real-time data from sensors and modules.

- Perform System Tests: Activate components to verify their functionality.

- Reset Systems: Clear DTCs and reset system settings after repairs.

According to a report by Grand View Research, the automotive diagnostic scan tools market is expected to reach $8.24 billion by 2027, growing at a CAGR of 6.1% from 2020 to 2027. This growth is driven by the increasing complexity of vehicle systems and the need for accurate diagnostics.

2.1. Types of Diagnostic Software

What are the different types of diagnostic software available? Understanding the types helps you choose the right tool for your needs.

There are several types of diagnostic software, each designed for specific purposes:

- OEM (Original Equipment Manufacturer) Software: Developed by the vehicle manufacturer, this software provides the most comprehensive diagnostic capabilities for their vehicles. Examples include TechStream for Toyota, ISTA for BMW, and GDS2 for GM.

- Aftermarket Software: Developed by third-party companies, this software offers broader compatibility across multiple vehicle brands. Examples include Autel, Launch, and Bosch diagnostic tools.

- Mobile Apps: Designed for smartphones and tablets, these apps connect to the vehicle via Bluetooth or Wi-Fi and offer basic diagnostic functions. Examples include Torque Pro and OBD Auto Doctor.

2.2. Key Features to Look For

What key features should you look for in diagnostic software? Choosing software with the right features enhances diagnostic accuracy and efficiency.

When selecting diagnostic software, consider the following features:

- Compatibility: Ensure the software supports the vehicle makes and models you work with.

- Functionality: Look for features such as DTC reading and clearing, live data streaming, bi-directional control, and system resets.

- User Interface: Choose software with an intuitive and easy-to-navigate interface.

- Update Frequency: Regular updates are crucial to support new vehicle models and diagnostic protocols.

- Customer Support: Reliable customer support can be invaluable when troubleshooting issues.

2.3. Benefits of Using Diagnostic Software

What are the benefits of using diagnostic software for airbag system checks? Using diagnostic software offers numerous advantages for vehicle maintenance.

Using diagnostic software provides several benefits:

- Accuracy: Pinpoints the exact problem, reducing guesswork and unnecessary repairs.

- Efficiency: Speeds up the diagnostic process, saving time and labor costs.

- Comprehensive Data: Provides detailed information about the vehicle’s systems.

- Cost Savings: Prevents costly repairs by addressing issues early.

- Improved Safety: Ensures safety systems like airbags function correctly.

By utilizing diagnostic software from CARDIAGTECH.NET, you can ensure your airbag system is in optimal condition, providing safety and peace of mind. Contact us today at +1 (641) 206-8880 to learn more about our diagnostic solutions and how they can benefit you. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

3. Step-by-Step Guide: Checking the Airbag System with Diagnostic Software

How do you check the airbag system using diagnostic software? Follow this step-by-step guide for effective diagnostics.

Checking the airbag system involves a systematic approach to ensure accurate diagnostics and effective repairs. Here’s a detailed guide:

3.1. Preparation

What preparations are necessary before starting the diagnostic process? Proper preparation ensures a smooth and efficient process.

- Gather Your Tools: Ensure you have the diagnostic software, a compatible scan tool, and a fully charged laptop or tablet.

- Locate the OBD-II Port: The OBD-II (On-Board Diagnostics II) port is typically located under the dashboard on the driver’s side.

- Turn on the Ignition: Turn the ignition to the “ON” position without starting the engine.

- Connect the Scan Tool: Plug the scan tool into the OBD-II port.

3.2. Connecting to the Vehicle’s Computer

How do you connect the diagnostic software to the vehicle’s computer? A stable connection is crucial for accurate data retrieval.

- Launch the Diagnostic Software: Open the diagnostic software on your laptop or tablet.

- Select Vehicle Information: Enter the vehicle’s make, model, and year.

- Establish Connection: Follow the software prompts to establish a connection with the vehicle’s computer. This may involve selecting the correct communication protocol.

3.3. Reading Diagnostic Trouble Codes (DTCs)

How do you read Diagnostic Trouble Codes (DTCs) from the airbag system? DTCs provide vital clues about system malfunctions.

- Navigate to the Airbag System: In the diagnostic software, navigate to the section for the airbag system, often labeled as SRS (Supplemental Restraint System) or Airbag.

- Read DTCs: Select the option to read diagnostic trouble codes. The software will display any stored DTCs related to the airbag system.

- Record the Codes: Write down each DTC and its description for further analysis.

3.4. Interpreting the Codes

How do you interpret the Diagnostic Trouble Codes (DTCs)? Understanding the codes is essential for identifying the problem.

- Consult the Vehicle’s Service Manual: Refer to the vehicle’s service manual or online resources to understand the meaning of each DTC.

- Identify Faulty Components: Determine which components or circuits are associated with each DTC.

- Prioritize Codes: Address the most critical codes first, as they may be causing more significant issues.

3.5. Performing System Tests

How do you perform system tests using diagnostic software? System tests verify the functionality of individual components.

- Access System Tests: In the diagnostic software, navigate to the system tests section for the airbag system.

- Select Tests: Choose the appropriate tests for the components associated with the DTCs. Common tests include sensor checks, airbag deployment simulations, and wiring harness tests.

- Run Tests: Follow the software prompts to run each test. Observe the results and note any failures or anomalies.

3.6. Clearing the Codes

When and how should you clear the Diagnostic Trouble Codes (DTCs)? Clearing codes should only be done after verifying the repairs.

- Verify Repairs: Ensure that all identified issues have been properly repaired or replaced.

- Clear DTCs: In the diagnostic software, select the option to clear diagnostic trouble codes.

- Verify Clearance: Confirm that all DTCs have been cleared and that the airbag warning light is off.

- Test Drive: Perform a test drive to ensure that the airbag system functions correctly and that no new DTCs appear.

By following these steps and using the right diagnostic tools from CARDIAGTECH.NET, you can effectively check and maintain your airbag system. For expert assistance and to purchase reliable diagnostic software, contact us at +1 (641) 206-8880. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

4. Common DTCs and Their Meanings

What are some common Diagnostic Trouble Codes (DTCs) related to the airbag system? Knowing these codes helps in quick and accurate diagnostics.

Understanding common DTCs is crucial for diagnosing airbag system issues quickly and accurately. Here are some of the most frequent DTCs and their meanings:

4.1. B0001 – Driver Airbag Deployment Control

What does DTC B0001 indicate? It often points to issues within the driver’s airbag circuit.

- Description: Driver Airbag Deployment Control

- Meaning: This code indicates a fault in the driver’s airbag circuit, which may include the airbag module, wiring, or clock spring.

- Possible Causes:

- Faulty airbag module

- Damaged wiring harness

- Defective clock spring

- Poor connection

4.2. B0002 – Passenger Airbag Deployment Control

What does DTC B0002 indicate? It signifies problems in the passenger airbag circuit.

- Description: Passenger Airbag Deployment Control

- Meaning: This code indicates a fault in the passenger’s airbag circuit, similar to the driver’s side.

- Possible Causes:

- Faulty airbag module

- Damaged wiring harness

- Poor connection

- Defective passenger seat sensor

4.3. B0051 – Side Airbag Deployment Control (Left)

What does DTC B0051 indicate? It points to malfunctions in the left side airbag system.

- Description: Side Airbag Deployment Control (Left)

- Meaning: This code indicates a fault in the left side airbag circuit, which is typically located in the seat or side panel.

- Possible Causes:

- Faulty side airbag module

- Damaged wiring harness

- Poor connection

- Defective impact sensor

4.4. B0052 – Side Airbag Deployment Control (Right)

What does DTC B0052 indicate? It indicates issues with the right side airbag system.

- Description: Side Airbag Deployment Control (Right)

- Meaning: This code indicates a fault in the right side airbag circuit.

- Possible Causes:

- Faulty side airbag module

- Damaged wiring harness

- Poor connection

- Defective impact sensor

4.5. B0081 – Seatbelt Pretensioner Deployment Control (Driver)

What does DTC B0081 indicate? It suggests a problem with the driver’s seatbelt pretensioner.

- Description: Seatbelt Pretensioner Deployment Control (Driver)

- Meaning: This code indicates a fault in the driver’s seatbelt pretensioner circuit, which is designed to tighten the seatbelt during a collision.

- Possible Causes:

- Faulty seatbelt pretensioner

- Damaged wiring harness

- Poor connection

- Defective sensor

4.6. B0082 – Seatbelt Pretensioner Deployment Control (Passenger)

What does DTC B0082 indicate? It signifies malfunctions in the passenger’s seatbelt pretensioner.

- Description: Seatbelt Pretensioner Deployment Control (Passenger)

- Meaning: This code indicates a fault in the passenger’s seatbelt pretensioner circuit.

- Possible Causes:

- Faulty seatbelt pretensioner

- Damaged wiring harness

- Poor connection

- Defective sensor

4.7. B1000 – ECU Hardware Failure

What does DTC B1000 indicate? It suggests a failure within the Airbag Control Module (ACM) itself.

- Description: ECU Hardware Failure

- Meaning: This code indicates a hardware failure within the Airbag Control Module (ACM) or Airbag Control Unit (ACU).

- Possible Causes:

- Faulty ACM/ACU

- Internal circuit failure

- Power supply issues

4.8. B1001 – ECU Software Failure

What does DTC B1001 indicate? It points to software issues within the Airbag Control Module (ACM).

- Description: ECU Software Failure

- Meaning: This code indicates a software failure within the Airbag Control Module (ACM) or Airbag Control Unit (ACU).

- Possible Causes:

- Corrupted software

- Incompatible software version

- Software glitches

Understanding these common DTCs can significantly speed up the diagnostic process and help you address airbag system issues more effectively. At CARDIAGTECH.NET, we offer advanced diagnostic tools and software that provide detailed code descriptions and troubleshooting guidance. Contact us today at +1 (641) 206-8880 for expert advice and solutions tailored to your needs. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

5. Advanced Diagnostic Techniques

What are some advanced diagnostic techniques for airbag systems? These techniques offer deeper insights into complex issues.

Beyond basic DTC reading and interpretation, advanced diagnostic techniques can help you tackle more complex airbag system problems. These techniques require specialized tools and expertise, but they can provide valuable insights:

5.1. Live Data Streaming

How can live data streaming help diagnose airbag system issues? Real-time data provides valuable insights into sensor behavior.

- Functionality: Live data streaming allows you to monitor real-time data from various sensors and modules within the airbag system.

- Benefits:

- Identify Intermittent Issues: Detect problems that may not trigger a DTC but still affect system performance.

- Verify Sensor Readings: Confirm that sensors are providing accurate data.

- Monitor System Response: Observe how the system responds to changes in vehicle conditions.

5.2. Bi-Directional Control

What is bi-directional control and how does it aid in airbag system diagnostics? This feature allows you to actively test components.

- Functionality: Bi-directional control allows you to send commands to the vehicle’s computer to activate specific components within the airbag system.

- Benefits:

- Actuate Components: Test the functionality of airbags, seatbelt pretensioners, and other components.

- Isolate Faults: Determine whether a problem is caused by a faulty component or a wiring issue.

- Verify Repairs: Confirm that repaired components are functioning correctly.

5.3. Oscilloscope Testing

How does oscilloscope testing aid in diagnosing airbag system problems? It provides a visual representation of electrical signals.

- Functionality: An oscilloscope is an electronic test instrument that displays electrical signals as a waveform, allowing you to analyze their voltage, frequency, and shape.

- Benefits:

- Analyze Signal Integrity: Detect issues such as signal noise, voltage drops, and intermittent connections.

- Diagnose Sensor Problems: Evaluate the output signals from crash sensors and other components.

- Identify Wiring Issues: Locate shorts, opens, and high-resistance connections in the wiring harness.

5.4. Inertial Sensor Calibration

How is inertial sensor calibration important for modern airbag systems? Proper calibration ensures accurate crash detection.

- Functionality: Inertial sensors, such as accelerometers and gyroscopes, are used in advanced airbag systems to detect vehicle motion and impact forces.

- Benefits:

- Ensure Accurate Crash Detection: Calibrating these sensors ensures that the airbag system can accurately detect a collision and deploy the airbags at the appropriate time.

- Compensate for Sensor Drift: Over time, inertial sensors can drift out of calibration, leading to inaccurate readings. Calibration corrects these errors.

- Optimize System Performance: Proper calibration optimizes the overall performance of the airbag system, improving its ability to protect occupants in a crash.

5.5. Network Communication Analysis

How does analyzing network communication help in diagnosing airbag system issues? It uncovers communication problems between modules.

- Functionality: Modern vehicles use communication networks such as CAN (Controller Area Network) and LIN (Local Interconnect Network) to allow various modules to communicate with each other.

- Benefits:

- Identify Communication Issues: Detect problems such as lost messages, corrupted data, and network errors.

- Diagnose Module Problems: Determine whether a module is failing to communicate properly.

- Troubleshoot Wiring Issues: Locate problems in the network wiring harness.

By mastering these advanced diagnostic techniques and utilizing high-quality tools from CARDIAGTECH.NET, you can effectively diagnose and repair even the most challenging airbag system problems. Contact us today at +1 (641) 206-8880 for expert advice and to explore our range of diagnostic solutions. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

Diagnostic software interface on a scanner, displaying vehicle system information

6. Safety Precautions When Working With Airbag Systems

Why are safety precautions crucial when working with airbag systems? Airbag systems can be dangerous if mishandled.

Working with airbag systems requires strict adherence to safety precautions to prevent accidental deployment and potential injuries. Airbags contain explosive components that can cause serious harm if mishandled.

6.1. Disconnecting the Battery

Why should you always disconnect the battery before working on the airbag system? This prevents accidental airbag deployment.

- Purpose: Disconnecting the battery ensures that the airbag system is de-energized, preventing accidental deployment during diagnostics or repairs.

- Procedure:

- Turn off the ignition.

- Locate the battery in the engine compartment or trunk.

- Disconnect the negative (-) terminal first, followed by the positive (+) terminal.

- Wait at least 10 minutes before proceeding with any work on the airbag system to allow any residual electrical charge to dissipate.

6.2. Avoiding Static Electricity

Why is it important to avoid static electricity when handling airbag components? Static can trigger airbag deployment.

- Purpose: Static electricity can trigger the deployment of airbags, even when the system is de-energized.

- Precautions:

- Ground yourself by touching a grounded metal object before handling any airbag components.

- Wear an anti-static wrist strap to continuously discharge any static electricity.

- Work in a static-free environment, such as a workshop with anti-static flooring.

6.3. Handling Airbag Modules Carefully

How should you handle airbag modules to prevent accidental deployment? Careful handling is essential to avoid damage.

- Purpose: Airbag modules contain explosive materials and sensitive components that can be damaged if mishandled.

- Guidelines:

- Always carry airbag modules with the airbag cover facing away from your body.

- Avoid dropping or jarring airbag modules.

- Store airbag modules in a cool, dry place away from direct sunlight and heat.

- Never attempt to disassemble or repair an airbag module.

6.4. Proper Disposal of Deployed Airbags

How should you dispose of deployed airbags safely? Proper disposal prevents environmental hazards.

- Regulations: Deployed airbags are considered hazardous waste and must be disposed of according to local, state, and federal regulations.

- Procedure:

- Contact a certified hazardous waste disposal facility for guidance.

- Follow their instructions for packaging and labeling the deployed airbag.

- Transport the airbag to the disposal facility in a secure container.

- Obtain a certificate of disposal for your records.

6.5. Using Proper Tools and Equipment

Why is it important to use proper tools when working with airbag systems? Using the right tools minimizes the risk of damage.

- Importance: Using the correct tools and equipment ensures that you can perform diagnostic and repair tasks safely and effectively.

- Recommendations:

- Use specialized airbag diagnostic tools and scan tools recommended by the vehicle manufacturer.

- Use torque wrenches to tighten airbag module mounting bolts to the specified torque values.

- Use insulated tools to prevent electrical shorts.

- Wear safety glasses and gloves to protect yourself from debris and chemicals.

By following these safety precautions and using high-quality tools from CARDIAGTECH.NET, you can minimize the risks associated with working on airbag systems and ensure the safety of yourself and others. Contact us today at +1 (641) 206-8880 for expert advice and to explore our range of diagnostic solutions. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

7. Choosing the Right Diagnostic Software for Your Needs

How do you choose the right diagnostic software for your specific needs? Consider compatibility, features, and budget.

Selecting the appropriate diagnostic software is critical for effectively diagnosing and repairing airbag systems. The right software can save you time, money, and frustration by providing accurate and comprehensive diagnostic capabilities.

7.1. Compatibility with Vehicle Makes and Models

Why is compatibility important when choosing diagnostic software? Ensuring compatibility prevents errors and ensures full functionality.

- Importance: The diagnostic software must be compatible with the specific makes and models of vehicles you work on.

- Considerations:

- Vehicle Coverage: Check the software’s vehicle coverage list to ensure it supports the vehicles you service most frequently.

- Diagnostic Protocols: Ensure the software supports the diagnostic protocols used by your vehicles, such as CAN, K-Line, and J1850.

- OEM vs. Aftermarket: Decide whether you need OEM software for in-depth diagnostics on specific brands or aftermarket software for broader coverage.

7.2. Key Features and Functionality

What key features and functionalities should you look for in diagnostic software? These features enhance diagnostic accuracy and efficiency.

- Essential Features:

- DTC Reading and Clearing: Ability to read and clear diagnostic trouble codes.

- Live Data Streaming: Real-time data monitoring for sensors and modules.

- Bi-Directional Control: Ability to activate components for testing.

- System Tests: Pre-programmed tests for specific systems and components.

- Wiring Diagrams: Access to wiring diagrams for troubleshooting electrical issues.

- Technical Bulletins: Access to technical service bulletins (TSBs) and repair information.

7.3. User Interface and Ease of Use

Why is the user interface important when choosing diagnostic software? An intuitive interface improves efficiency and reduces errors.

- Considerations:

- Intuitive Layout: The software should have an intuitive layout and easy-to-navigate menus.

- Clear Data Presentation: Data should be presented in a clear and organized manner.

- Customization Options: The ability to customize the software to your preferences can improve efficiency.

- Training and Support: Look for software that comes with comprehensive training materials and reliable customer support.

7.4. Update Frequency and Support

Why are regular updates and reliable support important for diagnostic software? Updates ensure compatibility with new vehicles and features.

- Importance: Regular updates and reliable support are essential for keeping your diagnostic software up-to-date and functioning correctly.

- Considerations:

- Update Frequency: Check how often the software is updated with new vehicle coverage, features, and bug fixes.

- Subscription Costs: Be aware of any subscription costs associated with updates and support.

- Support Channels: Look for software that offers multiple support channels, such as phone, email, and online forums.

- Response Time: Check the vendor’s reputation for providing timely and helpful support.

7.5. Budget Considerations

How should you consider your budget when choosing diagnostic software? Balance features with cost to find the best value.

- Factors to Consider:

- Initial Cost: Compare the initial purchase price of different software options.

- Subscription Fees: Factor in any ongoing subscription fees for updates and support.

- Return on Investment (ROI): Consider how the software will help you save time and money in the long run by improving diagnostic accuracy and efficiency.

- Free Trials: Take advantage of free trials to test the software before making a purchase.

By carefully considering these factors, you can choose the right diagnostic software for your needs and maximize the effectiveness of your airbag system diagnostics and repairs. At CARDIAGTECH.NET, we offer a range of diagnostic solutions to suit various needs and budgets. Contact us today at +1 (641) 206-8880 for expert advice and to explore our range of diagnostic software. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

8. Maintaining Your Airbag System

How do you maintain your airbag system to ensure its proper function? Regular inspections and prompt repairs are key.

Proper maintenance of your airbag system is essential for ensuring its reliability and effectiveness in the event of a collision. Regular inspections and prompt repairs can help you identify and address potential issues before they become critical.

8.1. Regular Visual Inspections

Why are regular visual inspections important for airbag system maintenance? Visual checks can identify obvious damage.

- Purpose: Regular visual inspections can help you identify obvious signs of damage or wear in the airbag system.

- What to Look For:

- Airbag Warning Light: Check the instrument panel for the airbag warning light. If it is illuminated, it indicates a problem with the system.

- Airbag Covers: Inspect the airbag covers on the steering wheel, dashboard, seats, and side pillars for any signs of damage, such as cracks, tears, or discoloration.

- Wiring Harness: Check the wiring harness for any signs of damage, such as frayed wires, loose connections, or corrosion.

- Seatbelt Pretensioners: Inspect the seatbelt pretensioners for any signs of damage or malfunction.

8.2. Keeping the System Clean and Dry

Why is it important to keep the airbag system clean and dry? Moisture and contaminants can damage components.

- Purpose: Keeping the airbag system clean and dry helps prevent corrosion and damage to sensitive components.

- Precautions:

- Avoid Spills: Avoid spilling liquids on or near airbag components.

- Clean Regularly: Clean airbag covers and surrounding areas with a mild detergent and a soft cloth.

- Protect from Moisture: Protect the system from moisture by addressing any leaks or water intrusion promptly.

8.3. Professional Inspections and Diagnostics

Why should you have your airbag system professionally inspected? Professionals can identify issues that are not visible.

- Benefits:

- Comprehensive Diagnostics: Professional technicians have the tools and expertise to perform comprehensive diagnostics of the airbag system.

- Accurate Identification of Problems: They can accurately identify problems that may not be visible during a visual inspection.

- Expert Repairs: They can perform expert repairs and ensure that the system is functioning correctly.

8.4. Addressing Airbag Warning Lights Promptly

Why is it important to address airbag warning lights promptly? Ignoring the warning light can compromise safety.

- Importance: The airbag warning light is an indication that there is a problem with the system that needs to be addressed.

- Steps to Take:

- Schedule a Diagnostic: Schedule a diagnostic appointment with a qualified technician as soon as possible.

- Avoid DIY Repairs: Avoid attempting DIY repairs unless you have the necessary tools, expertise, and safety training.

- Follow Professional Advice: Follow the advice of the technician and have any necessary repairs performed promptly.

8.5. Keeping Records of Maintenance and Repairs

Why is it important to keep records of airbag system maintenance? Records provide a history of system health.

- Benefits:

- Track System Performance: Records can help you track the performance of the airbag system over time.

- Identify Recurring Issues: They can help you identify any recurring issues that need to be addressed.

- Provide Documentation: They can provide documentation for warranty claims or insurance purposes.

By following these maintenance tips and utilizing the diagnostic solutions offered by CARDIAGTECH.NET, you can ensure that your airbag system is always ready to protect you and your passengers. Contact us today at +1 (641) 206-8880 for expert advice and to explore our range of diagnostic tools and software. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

9. The Future of Airbag System Diagnostics

What does the future hold for airbag system diagnostics? Expect more advanced technology and integration.

The field of airbag system diagnostics is continually evolving, driven by advancements in technology and the increasing complexity of vehicle safety systems. Here are some of the trends and developments that are shaping the future of airbag system diagnostics:

9.1. Integration with ADAS (Advanced Driver Assistance Systems)

How will airbag systems integrate with ADAS in the future? This integration will enhance overall safety.

- Trend: Airbag systems are becoming increasingly integrated with ADAS, such as automatic emergency braking, lane departure warning, and adaptive cruise control.

- Impact on Diagnostics: Diagnostic tools will need to be able to analyze data from both the airbag system and ADAS to identify potential safety issues.

- Benefits: This integration will enable more proactive safety measures, such as pre-tensioning seatbelts and adjusting airbag deployment parameters based on the severity of the impending collision.

9.2. Use of Artificial Intelligence (AI) and Machine Learning (ML)

How will AI and machine learning enhance airbag system diagnostics? AI can predict failures and improve accuracy.

- Trend: AI and ML are being used to analyze data from airbag systems and predict potential failures before they occur.

- Impact on Diagnostics: Diagnostic tools will be able to use AI and ML algorithms to identify patterns and anomalies in the data, providing technicians with valuable insights into the health of the airbag system.

- Benefits: This will enable more proactive maintenance and repairs, reducing the risk of airbag system failures.

9.3. Remote Diagnostics and Over-the-Air Updates

How will remote diagnostics and over-the-air updates transform airbag system maintenance? This will allow for faster and more convenient service.

- Trend: Remote diagnostics and over-the-air updates are becoming increasingly common in the automotive industry.

- Impact on Diagnostics: Technicians will be able to remotely diagnose airbag system issues and perform software updates without having to physically access the vehicle.

- Benefits: This will save time and money for both technicians and vehicle owners and will enable more convenient and efficient maintenance.

9.4. Enhanced Sensor Technology

How will advancements in sensor technology improve airbag system performance? More accurate sensors will enhance safety.

- Trend: Advancements in sensor technology are leading to the development of more accurate and reliable crash sensors.

- Impact on Diagnostics: Diagnostic tools will need to be able to analyze data from these advanced sensors and verify their calibration.

- Benefits: This will improve the performance of airbag systems and reduce the risk of false deployments or failures to deploy.

9.5. Cybersecurity Measures

Why are cybersecurity measures becoming more important for airbag systems? Protecting against hacking is crucial for safety.

- Trend: As vehicle systems become more connected, cybersecurity is becoming an increasingly important concern.

- Impact on Diagnostics: Diagnostic tools will need to incorporate cybersecurity measures to protect against hacking and unauthorized access to the airbag system.

- Benefits: This will ensure the integrity and reliability of the airbag system and prevent malicious actors from compromising vehicle safety.

By staying abreast of these trends and developments, you can ensure that you are well-prepared to diagnose and maintain airbag systems in the future. CARDIAGTECH.NET is committed to providing our customers with the latest diagnostic solutions and support to help them stay ahead of the curve. Contact us today at +1 (641) 206-8880 for expert advice and to explore our range of diagnostic tools and software. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

10. FAQ: Checking the Airbag System

What are some frequently asked questions about checking the airbag system? Here are answers to common queries.

10.1. How Often Should I Check My Airbag System?

How often should you inspect your airbag system? Regular checks ensure optimal performance.

- It is recommended to check your airbag system at least once a year or whenever the airbag warning light illuminates on your dashboard. Regular inspections can help identify potential issues early and prevent costly repairs.

10.2. Can I Check the Airbag System Myself, or Do I Need a Professional?

Can you check the airbag system yourself? While some checks are possible, professional diagnostics are often necessary.

- While you can perform visual inspections of the airbag system, it is generally recommended to have a professional technician perform a comprehensive diagnostic check using specialized tools and software.