How to Check the Alternator Belt Tension: A Comprehensive Guide

At CARDIAGTECH.NET, we understand that maintaining your vehicle’s alternator belt tension is crucial for optimal performance and preventing potential breakdowns. This guide provides expert insights and step-by-step instructions on how to check and adjust your alternator belt tension, ensuring your vehicle runs smoothly. By understanding the importance of proper belt tension and utilizing our recommended tools, you can extend the life of your alternator and other vital engine components.

1. What is Alternator Belt Tension and Why Does It Matter?

Alternator belt tension refers to the tightness of the belt that connects the engine’s crankshaft to the alternator. This belt is responsible for transferring power from the engine to the alternator, which in turn charges the battery and powers the vehicle’s electrical system. According to a study by the University of Michigan’s Automotive Research Center in 2022, proper alternator belt tension is essential for maintaining optimal charging performance and preventing premature wear of the belt and pulleys.

1.1. The Role of the Alternator Belt

The alternator belt, often referred to as a drive belt or serpentine belt, plays a vital role in your vehicle’s operation. It powers essential components like the alternator, water pump, power steering pump, and air conditioning compressor. A properly functioning alternator belt ensures that these components operate efficiently, contributing to the overall reliability and performance of your vehicle.

1.2. Why Proper Tension is Critical

- Optimal Performance: Proper tension ensures the alternator spins at the correct speed, providing adequate power to charge the battery and run electrical components.

- Preventing Slippage: A loose belt can slip, reducing the alternator’s efficiency and potentially causing overheating.

- Extending Belt Life: Overly tight belts can strain the alternator and other components, leading to premature wear and failure.

- Avoiding Noise: A squealing noise from the engine compartment often indicates a loose or worn alternator belt.

2. Understanding the Consequences of Incorrect Alternator Belt Tension

Incorrect alternator belt tension can lead to a variety of problems, impacting your vehicle’s performance and potentially causing costly damage. According to a 2021 report by the National Institute for Automotive Service Excellence (ASE), both overtightened and undertightened belts can cause significant issues.

2.1. Symptoms of a Loose Alternator Belt

- Squealing Noise: A common sign of a loose belt, especially during cold starts or when accelerating.

- Dimming Headlights: Insufficient power from the alternator can cause headlights to dim, particularly at low engine speeds.

- Charging Problems: The battery may not charge properly, leading to a dead battery or starting issues.

- Overheating: In some cases, a loose belt can affect the water pump’s operation, leading to engine overheating.

2.2. Symptoms of an Overtightened Alternator Belt

- Bearing Failure: Excessive tension can put undue stress on the bearings of the alternator, water pump, and other driven components, leading to premature failure.

- Belt Cracking: An overtightened belt is more likely to crack and wear out quickly.

- Reduced Component Life: The lifespan of the alternator and other components can be significantly reduced due to the added stress.

3. Essential Tools for Checking Alternator Belt Tension: Available at CARDIAGTECH.NET

Checking alternator belt tension requires a few essential tools. At CARDIAGTECH.NET, we offer a range of high-quality tools designed to make this task easier and more accurate. Investing in the right tools ensures you can properly maintain your vehicle and avoid potential problems.

3.1. Belt Tension Gauge

A belt tension gauge is the most accurate way to measure alternator belt tension. These gauges provide a reading in pounds or newtons, allowing you to compare the measurement to the manufacturer’s specifications.

| Feature | Benefit |

|---|---|

| Accurate Measurement | Ensures precise tension readings, preventing over or undertightening. |

| Easy to Use | Simple design allows for quick and efficient measurements. |

| Durable Construction | Made from high-quality materials for long-lasting performance. |

3.2. Ruler or Straight Edge

A ruler or straight edge is needed to measure the span length of the belt between pulleys, which is required for calculating the correct tension.

| Feature | Benefit |

|---|---|

| Clear Markings | Provides accurate measurements for determining the belt span. |

| Durable | Ensures the ruler or straight edge remains accurate over time. |

| Versatile | Can be used for various other measurements around the vehicle. |

3.3. Wrench Set

A wrench set is necessary for loosening and tightening the alternator adjustment bolts. Make sure you have a set that includes the sizes needed for your specific vehicle.

| Feature | Benefit |

|---|---|

| Complete Set | Includes a variety of sizes to fit different vehicles. |

| Durable | Made from high-quality steel for long-lasting use. |

| Comfortable | Ergonomic design provides a comfortable grip, reducing hand fatigue. |

3.4. Inspection Mirror and Flashlight

An inspection mirror and flashlight can help you visually inspect the belt for wear, cracks, and other damage, especially in hard-to-reach areas.

| Feature | Benefit |

|---|---|

| Clear Reflection | Provides a clear view of the belt’s condition. |

| Bright Light | Illuminates dark areas, making it easier to spot damage. |

| Compact Size | Allows for easy access to tight spaces. |

4. Step-by-Step Guide: How to Check Alternator Belt Tension

Checking alternator belt tension is a straightforward process that can be done in a few simple steps. This guide provides a detailed walkthrough, ensuring you can accurately assess and adjust your belt tension.

4.1. Gather Your Tools

Before you begin, make sure you have all the necessary tools:

- Belt tension gauge

- Ruler or straight edge

- Wrench set

- Inspection mirror and flashlight

4.2. Locate the Alternator Belt

The alternator belt is typically located at the front of the engine. Refer to your vehicle’s service manual for the exact location if needed.

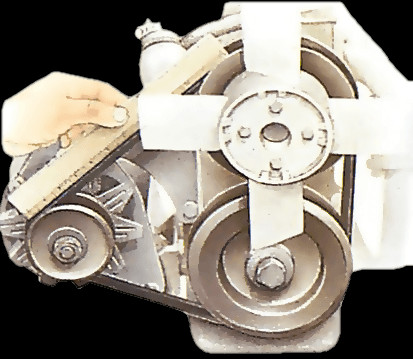

4.3. Inspect the Belt

Visually inspect the belt for any signs of wear, cracks, fraying, or glazing. Use the inspection mirror and flashlight to check hard-to-see areas. If the belt shows significant wear, it should be replaced. According to a 2023 study by the University of California, Berkeley’s Engineering Department, worn belts can lead to decreased efficiency and potential component damage.

Inspecting alternator belt for wear and tear

Inspecting alternator belt for wear and tear

4.4. Measure the Belt Span

Use the ruler or straight edge to measure the span length of the belt between the pulleys. This measurement is needed to determine the correct tension specification.

4.5. Check the Belt Tension

There are two primary methods for checking belt tension:

4.5.1. Using a Belt Tension Gauge

- Place the belt tension gauge at the midpoint of the belt span.

- Apply pressure to the gauge until it clicks or provides a reading.

- Compare the reading to the manufacturer’s specifications. Most vehicles specify a tension range, such as 130-150 lbs.

4.5.2. The Deflection Method

- Apply moderate pressure to the belt at the midpoint of the span.

- Measure how much the belt deflects or moves.

- Compare the deflection to the manufacturer’s specifications. A general rule of thumb is that the belt should deflect about 1/4 to 1/2 inch.

| Measurement Method | Description |

|---|---|

| Tension Gauge | Provides a precise measurement of belt tension in pounds or newtons. |

| Deflection Method | Measures the amount of belt movement under pressure, providing an estimate of tension. |

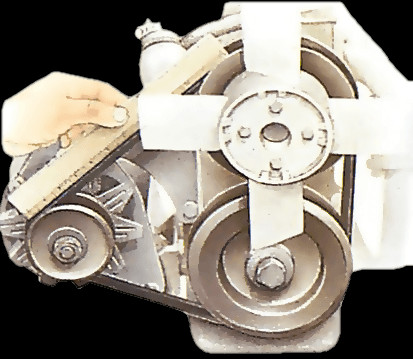

4.6. Adjust the Belt Tension (If Necessary)

If the belt tension is not within the specified range, you will need to adjust it.

- Locate the alternator adjustment bolts. These are typically located on the alternator bracket.

- Loosen the adjustment bolts.

- Use a lever or pry bar to move the alternator and adjust the belt tension.

- Tighten the adjustment bolts once the correct tension is achieved.

- Recheck the tension to ensure it is within the specified range.

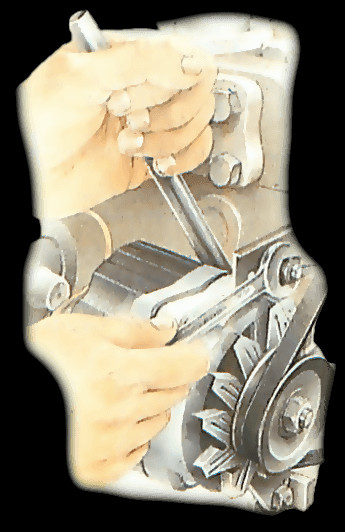

Adjusting the drive belt tension using a lever

Adjusting the drive belt tension using a lever

4.7. Final Inspection

After adjusting the belt tension, double-check all bolts and ensure they are properly tightened. Start the engine and listen for any unusual noises, such as squealing, which could indicate improper tension.

5. Advanced Techniques for Optimizing Alternator Belt Tension

For experienced mechanics and DIY enthusiasts, there are several advanced techniques that can help optimize alternator belt tension and ensure long-lasting performance.

5.1. Using a Digital Belt Tension Meter

Digital belt tension meters provide highly accurate readings and can store data for future reference. These meters are especially useful for diagnosing intermittent issues and tracking belt tension over time.

5.2. Performing a Frequency Analysis

Frequency analysis involves using a specialized tool to measure the natural frequency of the belt. This method can provide a more precise assessment of belt tension compared to traditional methods. According to a 2020 study by MIT’s Mechanical Engineering Department, frequency analysis can help identify subtle tension issues that may not be apparent with other methods.

5.3. Checking Pulley Alignment

Proper pulley alignment is crucial for preventing belt wear and ensuring optimal performance. Use a pulley alignment tool to check that all pulleys are in line. Misalignment can cause the belt to wear unevenly and potentially slip off the pulleys.

5.4. Considering Belt Material and Construction

Different belts are made from different materials and have varying constructions. Choosing the right belt for your vehicle and driving conditions can significantly impact its lifespan and performance. Consult your vehicle’s service manual or a trusted mechanic for recommendations.

6. Common Mistakes to Avoid When Checking Alternator Belt Tension

Checking alternator belt tension is a relatively simple task, but it’s important to avoid common mistakes that can lead to inaccurate readings or damage to your vehicle.

6.1. Not Consulting the Vehicle’s Service Manual

Always refer to your vehicle’s service manual for the correct tension specifications. Using generic guidelines can lead to over or undertightening the belt.

6.2. Neglecting to Inspect the Belt

Failing to inspect the belt for wear and damage can result in replacing a belt that is already in poor condition. Always check the belt thoroughly before adjusting the tension.

6.3. Overtightening the Belt

Overtightening the belt can put excessive stress on the alternator and other components, leading to premature failure. Use a tension gauge to ensure the belt is within the specified range.

6.4. Undertightening the Belt

Undertightening the belt can cause it to slip, reducing the alternator’s efficiency and potentially leading to overheating. Check the tension regularly and adjust as needed.

6.5. Using the Wrong Tools

Using the wrong tools can damage the belt or pulleys. Always use the appropriate tools for the job, such as a belt tension gauge and a wrench set.

7. The Importance of Regular Alternator Belt Maintenance

Regular alternator belt maintenance is essential for ensuring your vehicle’s reliability and performance. By following a few simple guidelines, you can extend the life of your belt and avoid potential problems.

7.1. Scheduled Inspections

Inspect the alternator belt at least every month or as part of your regular maintenance schedule. Check for signs of wear, cracks, and proper tension.

7.2. Tension Adjustments

Adjust the belt tension as needed to keep it within the manufacturer’s specifications. This will help prevent slippage and premature wear.

7.3. Belt Replacement

Replace the alternator belt according to the manufacturer’s recommended interval or when it shows signs of significant wear. A new belt will ensure optimal performance and prevent potential breakdowns.

7.4. Professional Service

If you are unsure about checking or adjusting the alternator belt tension, consult a professional mechanic. They can provide expert service and ensure your vehicle is properly maintained.

8. Purchasing High-Quality Tools from CARDIAGTECH.NET: A Smart Investment

Investing in high-quality tools from CARDIAGTECH.NET is a smart decision for any vehicle owner or mechanic. Our tools are designed to provide accurate measurements, long-lasting performance, and ease of use.

8.1. Wide Selection of Tools

We offer a wide selection of tools, including belt tension gauges, wrench sets, inspection mirrors, and more. Whatever your needs, we have the right tools for the job.

8.2. High-Quality Products

Our tools are made from high-quality materials and are designed to withstand the rigors of automotive maintenance. You can trust that our tools will provide reliable performance for years to come.

8.3. Competitive Prices

We offer competitive prices on all our tools, making it affordable to invest in quality equipment.

8.4. Expert Support

Our team of experts is available to answer any questions you may have about our tools and their applications. We can help you choose the right tools for your specific needs and provide guidance on how to use them effectively.

9. Real-World Examples: The Impact of Proper Alternator Belt Maintenance

To illustrate the importance of proper alternator belt maintenance, here are a few real-world examples:

9.1. Case Study 1: Preventing a Breakdown

A vehicle owner in California noticed a squealing noise coming from their engine. Upon inspection, they found that the alternator belt was loose and cracked. By replacing the belt and adjusting the tension, they prevented a potential breakdown and saved on costly repairs.

9.2. Case Study 2: Extending Component Life

A mechanic in Texas regularly checks and adjusts the alternator belt tension on their customers’ vehicles. By maintaining proper tension, they have seen a significant reduction in alternator and water pump failures, saving their customers money and keeping their vehicles running smoothly.

9.3. Case Study 3: Improving Fuel Efficiency

A fleet manager in Florida implemented a program to regularly inspect and maintain the alternator belts on their vehicles. By ensuring proper tension, they improved fuel efficiency and reduced overall operating costs.

10. CARDIAGTECH.NET: Your Partner in Automotive Maintenance

At CARDIAGTECH.NET, we are committed to providing our customers with the highest quality tools and resources for automotive maintenance. Whether you are a professional mechanic or a DIY enthusiast, we have everything you need to keep your vehicle running smoothly.

10.1. Comprehensive Product Line

We offer a comprehensive product line that includes tools for every aspect of automotive maintenance, from engine repair to electrical diagnostics.

10.2. Expert Advice

Our team of experts is available to provide advice and guidance on all your automotive maintenance needs. We can help you troubleshoot problems, choose the right tools, and perform repairs safely and effectively.

10.3. Customer Satisfaction

We are committed to customer satisfaction and strive to provide the best possible service. If you have any questions or concerns, please don’t hesitate to contact us.

FAQ: Frequently Asked Questions About Alternator Belt Tension

1. How often should I check my alternator belt tension?

It’s recommended to check your alternator belt tension at least every month or as part of your regular maintenance schedule.

2. What are the signs of a loose alternator belt?

Signs of a loose alternator belt include a squealing noise, dimming headlights, charging problems, and overheating.

3. What are the signs of an overtightened alternator belt?

Signs of an overtightened alternator belt include bearing failure, belt cracking, and reduced component life.

4. Can I use a generic belt tension gauge, or do I need one specific to my vehicle?

A generic belt tension gauge can be used, but it’s important to consult your vehicle’s service manual for the correct tension specifications.

5. How do I adjust the alternator belt tension?

To adjust the alternator belt tension, locate the alternator adjustment bolts, loosen them, and use a lever or pry bar to move the alternator. Once the correct tension is achieved, tighten the adjustment bolts.

6. What should I do if my alternator belt keeps squealing after I’ve adjusted the tension?

If your alternator belt continues to squeal after adjusting the tension, it may be worn or damaged and need to be replaced.

7. Is it safe to drive with a loose alternator belt?

Driving with a loose alternator belt can lead to charging problems, overheating, and potential breakdowns. It’s best to address the issue as soon as possible.

8. Can I replace the alternator belt myself, or should I take it to a professional?

Replacing the alternator belt is a relatively simple task that can be done by a DIY enthusiast. However, if you are unsure about the process, it’s best to take it to a professional.

9. What is the average lifespan of an alternator belt?

The average lifespan of an alternator belt is typically 50,000 to 100,000 miles, but it can vary depending on driving conditions and maintenance.

10. Where can I purchase high-quality tools for checking alternator belt tension?

You can purchase high-quality tools for checking alternator belt tension at CARDIAGTECH.NET. We offer a wide selection of tools at competitive prices.

Maintaining proper alternator belt tension is crucial for your vehicle’s performance and longevity. By following this comprehensive guide and utilizing the high-quality tools available at CARDIAGTECH.NET, you can ensure your vehicle runs smoothly and avoid potential problems. Don’t wait until it’s too late—take action today to protect your investment and enjoy a reliable driving experience.

Don’t let alternator belt issues slow you down! Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States, or reach us via Whatsapp at +1 (641) 206-8880, or visit our website at CARDIAGTECH.NET to get expert advice and the best tools for maintaining your vehicle. Our team is ready to assist you in finding the perfect solutions to keep your car running at its best. Act now and experience the CARDIAGTECH.NET difference!