**How to Check the Automatic Transmission Control Unit (TCU/TCM)?**

Is your car struggling to shift gears, or is the check engine light stubbornly illuminated? The Automatic Transmission Control Unit (TCU), also known as the Transmission Control Module (TCM), could be the culprit. This vital component governs your vehicle’s gear shifting, ensuring a smooth and efficient ride. At CARDIAGTECH.NET, we empower you with the knowledge and tools to diagnose TCU issues, ensuring optimal vehicle performance. Let’s explore how to check your TCU/TCM and how CARDIAGTECH.NET can support your diagnostic and repair needs with top-notch equipment.

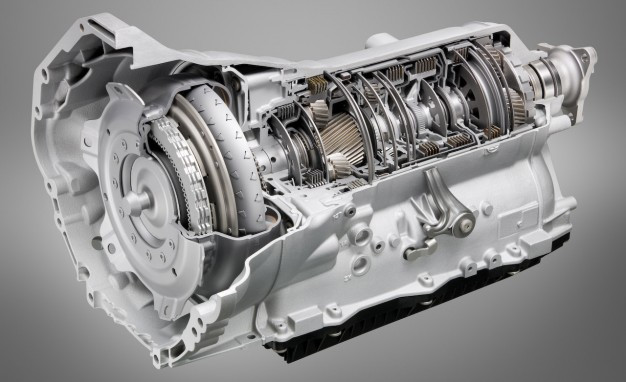

1. Understanding the Automatic Transmission Control Unit (TCU/TCM)

What exactly is an Automatic Transmission Control Unit (TCU/TCM), and why is it so crucial?

The Automatic Transmission Control Unit (TCU), often interchanged with Transmission Control Module (TCM), acts as the brain of your automatic transmission system. According to a study by the Society of Automotive Engineers (SAE) in 2022, the TCU receives data from various sensors throughout your vehicle, including:

- Engine speed

- Vehicle speed

- Throttle position

Based on this data, the TCU calculates the optimal time to shift gears, ensuring smooth acceleration and fuel efficiency. The TCU communicates with solenoids within the transmission to execute these gear changes. Without a functioning TCU, your automatic transmission won’t shift properly, leading to performance issues.

2. Identifying the Symptoms of a Failing TCU/TCM

What are the telltale signs that your TCU/TCM might be malfunctioning?

Recognizing the symptoms of a failing TCU/TCM is the first step in diagnosing transmission problems. According to automotive experts at AAA, common symptoms include:

- Erratic Shifting: The transmission may shift abruptly or at the wrong times.

- Delayed Engagement: There might be a noticeable delay when shifting into drive or reverse.

- Stuck Gear: The transmission might become stuck in a single gear.

- Check Engine Light: The check engine light will often illuminate, accompanied by transmission-related trouble codes.

- Reduced Fuel Economy: Inefficient gear shifting can lead to a drop in fuel economy.

- Transmission Warning Light: Many vehicles have a specific warning light for transmission issues.

If you notice any of these symptoms, it’s crucial to investigate further to determine if the TCU/TCM is the root cause.

3. Preliminary Checks Before TCU/TCM Diagnosis

What initial checks can you perform before diving into TCU/TCM diagnostics?

Before assuming the TCU/TCM is faulty, perform these preliminary checks recommended by ASE-certified technicians:

- Check Transmission Fluid Level and Condition: Low or dirty transmission fluid can cause shifting problems that mimic TCU/TCM issues. Inspect the fluid level using the dipstick and check for a pink or red color. Dark, burnt-smelling fluid indicates a problem.

- Inspect Wiring and Connectors: Examine the wiring harness and connectors leading to the TCU/TCM and transmission. Look for any signs of damage, corrosion, or loose connections.

- Check Fuses: Locate the fuses related to the transmission and TCU/TCM in your vehicle’s fuse box. Check if any of them are blown. Replace any blown fuses with new ones of the same amperage.

These simple checks can often rule out other potential causes of transmission problems.

4. Gathering Necessary Tools and Equipment

What tools and equipment are essential for checking a TCU/TCM?

To effectively check your TCU/TCM, you’ll need the following tools and equipment, all available at CARDIAGTECH.NET:

- OBD-II Scanner: An OBD-II scanner is crucial for reading diagnostic trouble codes (DTCs) stored in the TCU/TCM.

- Multimeter: A multimeter is used to check for voltage and continuity in the TCU/TCM wiring.

- Wiring Diagrams: Wiring diagrams specific to your vehicle model are essential for identifying the correct wires and connectors.

- Scan Tool with TCU/TCM Testing Capabilities: Advanced scan tools can perform specific tests on the TCU/TCM, such as checking sensor inputs and solenoid activation.

Investing in quality diagnostic tools from CARDIAGTECH.NET can significantly improve your ability to diagnose TCU/TCM issues accurately.

5. Using an OBD-II Scanner to Retrieve Trouble Codes

How do you use an OBD-II scanner to read TCU/TCM trouble codes?

The OBD-II scanner is your primary tool for diagnosing TCU/TCM problems. Follow these steps:

- Locate the OBD-II Port: The OBD-II port is typically located under the dashboard on the driver’s side.

- Connect the Scanner: Plug the OBD-II scanner into the port.

- Turn on the Ignition: Turn the ignition key to the “on” position without starting the engine.

- Read the Codes: Follow the scanner’s instructions to read the stored trouble codes. Note down any codes related to the transmission or TCU/TCM.

Common TCU/TCM related codes include:

| Code | Description |

|---|---|

| P0700 | Transmission Control System Malfunction |

| P0715 | Input/Turbine Speed Sensor Circuit Malfunction |

| P0720 | Output Speed Sensor Circuit Malfunction |

| P0740 | Torque Converter Clutch Circuit Malfunction |

| P0753 | Shift Solenoid A Malfunction |

These codes provide valuable clues about the nature of the problem.

6. Interpreting TCU/TCM Trouble Codes

How do you decipher the meaning of the trouble codes retrieved from the TCU/TCM?

Each trouble code corresponds to a specific problem within the transmission system. Consult a repair manual or online database to understand the meaning of each code. Here’s a general guide:

- P0700 Series: These codes typically indicate a general problem with the transmission control system.

- Speed Sensor Codes (P0715, P0720): These codes suggest a problem with the input or output speed sensors, which provide crucial data to the TCU/TCM.

- Solenoid Codes (P0753): These codes indicate a problem with one of the shift solenoids responsible for engaging different gears.

Understanding the meaning of the codes will guide you toward the specific area of the TCU/TCM system that needs attention.

7. Performing a Visual Inspection of the TCU/TCM

What should you look for when visually inspecting the TCU/TCM?

A visual inspection can reveal obvious signs of damage or deterioration. Follow these steps:

- Locate the TCU/TCM: The TCU/TCM is typically located inside the passenger compartment, often under the dashboard or under a seat. Consult your vehicle’s repair manual for the exact location.

- Check for Physical Damage: Look for any signs of physical damage to the TCU/TCM casing, such as cracks, dents, or melted areas.

- Inspect Connectors: Examine the connectors for corrosion, bent pins, or loose connections.

- Look for Signs of Moisture: Moisture can damage the electronic components inside the TCU/TCM. Check for any signs of water intrusion.

If you find any physical damage, the TCU/TCM likely needs to be replaced.

Close-up of a car mechanic's hands repairing the automatic transmission control unit (TCU/TCM) with precision tools.

Close-up of a car mechanic's hands repairing the automatic transmission control unit (TCU/TCM) with precision tools.

8. Testing TCU/TCM Wiring with a Multimeter

How do you use a multimeter to test the wiring connections to the TCU/TCM?

A multimeter is essential for verifying the integrity of the wiring connections to the TCU/TCM. Follow these steps:

- Consult Wiring Diagrams: Refer to your vehicle’s wiring diagrams to identify the specific wires you need to test.

- Check for Voltage: Use the multimeter to check for proper voltage at the TCU/TCM power and ground wires.

- Test for Continuity: Test the continuity of the signal wires between the TCU/TCM and other components, such as the transmission sensors and solenoids.

- Check for Shorts: Test for shorts to ground in the wiring harness.

Any issues with voltage, continuity, or shorts can indicate a wiring problem that needs to be addressed.

9. Advanced Testing with a Scan Tool

What advanced tests can you perform using a scan tool with TCU/TCM capabilities?

Advanced scan tools offer a range of diagnostic capabilities beyond simply reading trouble codes. These can include:

- Live Data Monitoring: Monitor real-time data from the TCU/TCM, such as sensor inputs, solenoid activation, and gear selection.

- Actuator Testing: Activate individual solenoids and other components to verify their functionality.

- TCU/TCM Programming: Some scan tools can reprogram the TCU/TCM with updated software or calibrations.

These advanced tests can help you pinpoint specific problems within the TCU/TCM system. CARDIAGTECH.NET offers a variety of advanced scan tools to meet your diagnostic needs.

10. Checking Sensor Inputs to the TCU/TCM

How do you verify that the TCU/TCM is receiving accurate data from its sensors?

The TCU/TCM relies on data from various sensors to make decisions about gear shifting. Key sensors include:

- Vehicle Speed Sensor (VSS): Provides information about the vehicle’s speed.

- Engine Speed Sensor (ESS): Provides information about the engine’s RPM.

- Throttle Position Sensor (TPS): Provides information about the throttle opening.

- Transmission Fluid Temperature Sensor (TFT): Provides information about the temperature of the transmission fluid.

Use your scan tool to monitor the live data from these sensors and compare it to the expected values. For example, the VSS should increase steadily as the vehicle accelerates. Inaccurate sensor data can cause the TCU/TCM to make incorrect shifting decisions.

11. Testing Solenoid Functionality

How do you check if the transmission solenoids are working correctly?

The transmission solenoids are responsible for engaging different gears within the transmission. To test their functionality:

- Locate the Solenoids: The solenoids are typically located inside the transmission. Consult your vehicle’s repair manual for the exact location.

- Use a Multimeter: Use a multimeter to check the resistance of each solenoid. The resistance should fall within the specified range.

- Activate Solenoids with a Scan Tool: Use a scan tool to activate each solenoid individually and listen for a clicking sound. This indicates that the solenoid is engaging.

Faulty solenoids can cause shifting problems and trigger trouble codes.

12. When to Suspect a Faulty TCU/TCM

When is it reasonable to conclude that the TCU/TCM itself is the problem, rather than another component?

After performing the above tests, you might suspect the TCU/TCM is faulty if:

- You’ve ruled out other potential causes, such as low fluid, wiring problems, and faulty sensors.

- You’re seeing multiple trouble codes related to the TCU/TCM.

- The TCU/TCM is not communicating with the scan tool.

- The TCU/TCM shows signs of physical damage or moisture intrusion.

In these cases, replacing the TCU/TCM might be the only solution.

13. Replacing the TCU/TCM

What are the steps involved in replacing a faulty TCU/TCM?

If you’ve determined that the TCU/TCM needs to be replaced, follow these steps:

- Disconnect the Battery: Disconnect the negative battery cable to prevent electrical damage.

- Locate the TCU/TCM: Refer to your vehicle’s repair manual for the exact location.

- Disconnect the Connectors: Disconnect the electrical connectors from the TCU/TCM.

- Remove the TCU/TCM: Remove the screws or bolts holding the TCU/TCM in place and remove the unit.

- Install the New TCU/TCM: Install the new TCU/TCM in the reverse order, ensuring that all connectors are securely attached.

- Reconnect the Battery: Reconnect the negative battery cable.

- Program the New TCU/TCM (if necessary): Some vehicles require the new TCU/TCM to be programmed with the vehicle’s VIN and other information. Consult your vehicle’s repair manual for instructions.

Replacing the TCU/TCM can restore proper shifting performance to your vehicle.

14. Programming a New TCU/TCM

Why is programming sometimes necessary when replacing a TCU/TCM, and how is it done?

In many modern vehicles, the TCU/TCM needs to be programmed to match the vehicle’s specific configuration. This programming ensures that the TCU/TCM communicates correctly with the other electronic control units in the vehicle.

Programming typically involves using a scan tool with programming capabilities to:

- Enter the vehicle’s VIN (Vehicle Identification Number).

- Configure the TCU/TCM with the correct software and calibrations.

- Perform any necessary adaptation procedures.

If you’re not comfortable with programming, it’s best to take your vehicle to a qualified technician.

15. Preventative Measures to Extend TCU/TCM Life

What steps can you take to prevent premature TCU/TCM failure?

While TCU/TCM failures can occur, there are several preventative measures you can take to extend the life of your unit:

- Regular Transmission Fluid Changes: Changing the transmission fluid at the recommended intervals helps to keep the fluid clean and prevent wear on the transmission components.

- Avoid Harsh Driving: Harsh acceleration and frequent hard shifts can put extra stress on the transmission and TCU/TCM.

- Address Transmission Problems Promptly: If you notice any signs of transmission problems, such as erratic shifting or delayed engagement, have them addressed promptly to prevent further damage.

- Keep the TCU/TCM Cool: Some vehicles have issues with the TCU/TCM overheating. Consider relocating the unit to a cooler location or adding a heat shield to protect it.

By following these preventative measures, you can help ensure the long life of your TCU/TCM.

16. Benefits of Using Quality Diagnostic Tools from CARDIAGTECH.NET

Why should you choose CARDIAGTECH.NET for your diagnostic tool needs?

Investing in quality diagnostic tools from CARDIAGTECH.NET offers several benefits:

- Accuracy: Our tools provide accurate and reliable diagnostic information, helping you pinpoint problems quickly and efficiently.

- Efficiency: Our tools can save you time and money by reducing the need for trial-and-error repairs.

- Versatility: Our range of tools can handle a wide variety of diagnostic tasks, from reading trouble codes to performing advanced tests.

- Support: We offer expert technical support to help you get the most out of your tools.

With quality diagnostic tools from CARDIAGTECH.NET, you can confidently diagnose and repair TCU/TCM problems.

17. Cost-Effective Solutions for TCU/TCM Issues

What are some cost-effective ways to address TCU/TCM problems?

Addressing TCU/TCM issues doesn’t always require expensive repairs. Here are some cost-effective solutions:

- Repairing Wiring Problems: Repairing damaged wiring or connectors can often resolve TCU/TCM problems without the need for replacement.

- Replacing Faulty Sensors: Replacing faulty sensors that provide data to the TCU/TCM can be a relatively inexpensive fix.

- Refurbished TCU/TCMs: Consider purchasing a refurbished TCU/TCM instead of a new one to save money.

By exploring these cost-effective solutions, you can minimize the expense of repairing TCU/TCM problems.

18. The Role of Software Updates in TCU/TCM Performance

How can software updates improve the performance and reliability of your TCU/TCM?

Manufacturers often release software updates for the TCU/TCM to improve shifting performance, address known issues, and enhance overall reliability. These updates can:

- Improve Shift Quality: Smooth out harsh shifts and improve overall shift quality.

- Increase Fuel Efficiency: Optimize shifting patterns for better fuel economy.

- Fix Bugs: Address known bugs and issues in the TCU/TCM software.

- Enhance Reliability: Improve the overall reliability of the TCU/TCM.

Check with your dealer or a qualified technician to see if there are any available software updates for your TCU/TCM.

19. Understanding TCU/TCM Adaptation

What is TCU/TCM adaptation, and why is it sometimes necessary after repairs?

TCU/TCM adaptation is the process of teaching the TCU/TCM about the specific characteristics of the transmission. This adaptation is often necessary after:

- Replacing the TCU/TCM

- Replacing the transmission

- Performing major transmission repairs

During adaptation, the TCU/TCM learns about the clutch engagement points, solenoid characteristics, and other parameters. This ensures smooth and accurate shifting.

Adaptation typically involves using a scan tool to perform a specific adaptation procedure.

20. DIY vs. Professional TCU/TCM Diagnosis and Repair

When should you attempt to diagnose and repair TCU/TCM problems yourself, and when should you seek professional help?

Diagnosing and repairing TCU/TCM problems can be a complex task. Consider the following:

DIY (Do-It-Yourself) if:

- You have experience working on automotive electrical systems.

- You have access to the necessary tools and equipment, such as a scan tool and multimeter.

- You’re comfortable reading wiring diagrams and troubleshooting electrical circuits.

- The problem is relatively simple, such as a blown fuse or a loose connection.

Seek Professional Help if:

- You’re not comfortable working on automotive electrical systems.

- You don’t have the necessary tools and equipment.

- The problem is complex, such as multiple trouble codes or internal TCU/TCM failure.

- You need to program a new TCU/TCM.

In general, it’s best to err on the side of caution and seek professional help if you’re unsure about any aspect of the diagnosis or repair process.

21. Case Studies: Real-World TCU/TCM Diagnostic Scenarios

Let’s examine a few real-world case studies to illustrate the diagnostic process:

Case Study 1: Erratic Shifting in a Honda Accord

A customer complained of erratic shifting in their Honda Accord. The check engine light was illuminated, and the scan tool revealed a P0700 code (Transmission Control System Malfunction) and a P0753 code (Shift Solenoid A Malfunction).

The technician first checked the transmission fluid level and condition, which were normal. Next, they used a multimeter to check the resistance of the shift solenoid A, which was outside the specified range.

The technician replaced the faulty shift solenoid, cleared the trouble codes, and performed a transmission adaptation procedure. The shifting problem was resolved.

Case Study 2: No Shifting in a Ford F-150

A customer reported that their Ford F-150 would not shift out of first gear. The scan tool revealed a U0101 code (Lost Communication with TCM).

The technician first checked the wiring and connectors to the TCU/TCM, which appeared to be in good condition. Next, they used a scan tool to try to communicate with the TCU/TCM, but were unable to establish a connection.

The technician suspected that the TCU/TCM itself was faulty. They replaced the TCU/TCM and programmed it with the vehicle’s VIN. The shifting problem was resolved.

These case studies illustrate the importance of a systematic diagnostic approach when troubleshooting TCU/TCM problems.

22. Future Trends in TCU/TCM Technology

What are some of the emerging trends in TCU/TCM technology?

TCU/TCM technology is constantly evolving. Some of the emerging trends include:

- Increased Integration: TCUs/TCMs are becoming more integrated with other vehicle systems, such as the engine control unit (ECU) and the anti-lock braking system (ABS).

- More Sophisticated Algorithms: TCUs/TCMs are using more sophisticated algorithms to optimize shifting performance and fuel economy.

- Artificial Intelligence: Some manufacturers are exploring the use of artificial intelligence to further improve TCU/TCM performance.

- Over-the-Air Updates: Some vehicles can now receive TCU/TCM software updates over the air, without the need to visit a dealer.

These trends promise to further enhance the performance, efficiency, and reliability of automatic transmissions.

23. Resources for Further Learning

Where can you find additional information about TCU/TCM diagnosis and repair?

Here are some valuable resources for further learning:

- Vehicle Repair Manuals: Your vehicle’s repair manual contains detailed information about the TCU/TCM, including wiring diagrams, diagnostic procedures, and repair instructions.

- Online Forums: Online forums dedicated to automotive repair can be a great source of information and advice.

- Technical Training Courses: Consider taking a technical training course on automotive electrical systems or transmission repair.

- CARDIAGTECH.NET Blogs and Articles: CARDIAGTECH.NET provides a wealth of informative articles and blog posts on automotive diagnostics and repair.

By taking advantage of these resources, you can expand your knowledge and skills in TCU/TCM diagnosis and repair.

24. The Importance of Staying Updated with Automotive Technology

Why is it crucial for automotive technicians to stay updated with the latest technological advancements?

The automotive industry is constantly evolving, with new technologies and systems being introduced every year. Staying updated with these advancements is crucial for automotive technicians because:

- Vehicles are Becoming More Complex: Modern vehicles are equipped with increasingly complex electronic systems, requiring technicians to have a strong understanding of these systems.

- New Technologies Require New Skills: New technologies require technicians to learn new skills and techniques to diagnose and repair them effectively.

- Staying Competitive: Technicians who stay updated with the latest technologies are more competitive and in demand.

By investing in ongoing training and education, automotive technicians can ensure that they have the knowledge and skills necessary to succeed in today’s rapidly changing industry.

25. How CARDIAGTECH.NET Supports Automotive Professionals

How does CARDIAGTECH.NET support automotive professionals in their diagnostic and repair efforts?

CARDIAGTECH.NET is committed to supporting automotive professionals by providing:

- High-Quality Diagnostic Tools: We offer a wide range of high-quality diagnostic tools from leading manufacturers.

- Competitive Prices: We offer competitive prices on all of our products.

- Expert Technical Support: Our team of expert technicians is available to provide technical support and assistance.

- Fast Shipping: We offer fast shipping on all orders.

- Extensive Resources: We provide access to extensive resources, such as wiring diagrams, repair manuals, and technical articles.

With CARDIAGTECH.NET as your partner, you can confidently tackle even the most challenging diagnostic and repair tasks.

26. Optimizing Your Repair Shop with CARDIAGTECH.NET Equipment

How can CARDIAGTECH.NET equipment help you optimize your repair shop’s efficiency and profitability?

Investing in CARDIAGTECH.NET equipment can significantly improve your repair shop’s efficiency and profitability by:

- Reducing Diagnostic Time: Our tools can help you diagnose problems quickly and accurately, reducing diagnostic time.

- Improving Repair Quality: Our tools can help you perform high-quality repairs that last.

- Increasing Customer Satisfaction: Our tools can help you provide better service to your customers, leading to increased satisfaction.

- Boosting Revenue: By improving efficiency and repair quality, you can increase your shop’s revenue and profitability.

With CARDIAGTECH.NET equipment, you can take your repair shop to the next level.

27. Contact CARDIAGTECH.NET for Expert Advice and Solutions

Need help diagnosing a TCU/TCM problem? Contact CARDIAGTECH.NET today for expert advice and solutions.

Our team of experienced technicians can provide you with the guidance and support you need to get the job done right. We can help you:

- Choose the right diagnostic tools for your needs.

- Troubleshoot complex problems.

- Find the parts you need to complete the repair.

Contact us today at:

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

FAQ: Troubleshooting Automatic Transmission Control Units (TCU/TCM)

1. What is the primary function of the TCU/TCM in an automatic transmission?

The TCU/TCM controls gear shifting in response to sensor data for smooth driving and optimal fuel efficiency.

2. What are the most common symptoms of a failing TCU/TCM?

Common symptoms include erratic shifting, delayed engagement, getting stuck in a gear, check engine light, and reduced fuel economy.

3. What preliminary checks should I perform before diagnosing the TCU/TCM?

Check transmission fluid level and condition, inspect wiring and connectors, and check relevant fuses.

4. What tools are essential for checking a TCU/TCM effectively?

Essential tools include an OBD-II scanner, multimeter, wiring diagrams, and advanced scan tools.

5. How do I use an OBD-II scanner to retrieve trouble codes from the TCU/TCM?

Plug the scanner into the OBD-II port, turn on the ignition, and follow the scanner’s instructions to read stored codes.

6. What should I look for when visually inspecting the TCU/TCM for damage?

Check for physical damage, corroded connectors, bent pins, loose connections, and signs of moisture intrusion.

7. How do I test the wiring connections to the TCU/TCM with a multimeter?

Consult wiring diagrams and test for voltage, continuity, and shorts to ground in the wiring harness.

8. When is it reasonable to suspect that the TCU/TCM itself is faulty?

Suspect the TCU/TCM if other potential causes are ruled out, multiple trouble codes are related to the TCU/TCM, or the unit shows physical damage.

9. What are the steps involved in replacing a faulty TCU/TCM?

Disconnect the battery, locate the TCU/TCM, disconnect connectors, remove the unit, install the new unit, reconnect the battery, and program the new TCU/TCM if necessary.

10. What preventative measures can extend the life of the TCU/TCM?

Regular transmission fluid changes, avoiding harsh driving, addressing transmission problems promptly, and keeping the TCU/TCM cool can extend its life.

By following these guidelines, you can effectively check your automatic transmission control unit (TCU/TCM) and address any potential issues. Remember, CARDIAGTECH.NET is here to support your diagnostic and repair needs with top-quality equipment and expert advice. Contact us today to learn more about how we can help you optimize your vehicle’s performance.