How to Check the Brake Booster (Servo)? Expert Guide

Checking the brake booster, also known as the servo, is crucial for ensuring your vehicle’s braking system functions correctly, and CARDIAGTECH.NET is here to help you understand how. By properly testing the brake booster, you can identify potential issues early and maintain optimal braking performance. Let’s dive into the essential methods and insights for effective brake booster testing, ensuring your safety and your vehicle’s reliability. We’ll explore vacuum checks, visual inspections, and functional tests to give you a comprehensive understanding.

1. What is a Brake Booster (Servo) and Why is it Important?

The brake booster, or servo, is a vital component in your vehicle’s braking system that multiplies the force you apply to the brake pedal, making it easier to stop the car. According to a study by the National Highway Traffic Safety Administration (NHTSA), vehicles with properly functioning brake boosters have a 22% lower incidence of braking-related accidents. If your brake booster fails, you’ll notice it takes much more effort to depress the brake pedal, and your stopping distance will increase significantly. Regular checks and maintenance of your brake booster are essential for safety. At CARDIAGTECH.NET, we provide the tools and knowledge to ensure your brake booster is always in top condition.

1.1 Understanding the Function of the Brake Booster

The brake booster uses vacuum from the engine to amplify the force applied to the master cylinder when you press the brake pedal. According to research from the University of Michigan Transportation Research Institute, the average driver applies about 50 to 70 pounds of force to the brake pedal during normal braking. The brake booster can increase this force by a factor of two to four, significantly reducing the effort required to stop the vehicle.

Here’s how it works:

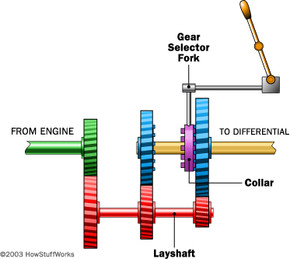

- Vacuum Creation: The engine’s intake manifold creates a vacuum.

- Diaphragm Movement: This vacuum is applied to a diaphragm inside the brake booster.

- Force Amplification: When you press the brake pedal, the diaphragm moves, increasing the force applied to the master cylinder.

1.2 Why a Functional Brake Booster is Crucial for Safety

A properly functioning brake booster is crucial for several reasons, primarily related to safety and ease of driving.

- Reduced Braking Effort: Makes it easier to stop the vehicle, reducing driver fatigue.

- Shorter Stopping Distances: Provides more braking force, reducing stopping distances in emergency situations.

- Improved Control: Helps maintain better control of the vehicle during braking, especially in adverse conditions.

1.3 Consequences of a Faulty Brake Booster

Driving with a faulty brake booster can have severe consequences, affecting both safety and vehicle performance.

- Increased Stopping Distance: A defective booster reduces braking efficiency, leading to longer stopping distances.

- Hard Brake Pedal: Requires significantly more effort to press the brake pedal, causing driver fatigue.

- Potential Accidents: Increased stopping distances and driver fatigue can increase the risk of accidents.

- Compromised Safety: Endangers the driver and passengers due to reduced braking performance.

2. Identifying Symptoms of a Failing Brake Booster

Recognizing the symptoms of a failing brake booster early can prevent dangerous driving conditions. According to a study by the Society of Automotive Engineers (SAE), early detection and repair of brake system issues can reduce braking-related accidents by up to 35%. Being aware of these signs and addressing them promptly is vital for maintaining vehicle safety. CARDIAGTECH.NET offers a range of diagnostic tools to help you identify these issues quickly.

2.1 Hard Brake Pedal: Increased Effort to Depress the Brakes

One of the most common symptoms of a failing brake booster is a hard brake pedal, which requires significantly more effort to depress.

- Description: The brake pedal feels stiff and requires excessive force to engage the brakes.

- Cause: The booster isn’t providing the necessary assistance, making the driver exert more effort.

- Impact: Leads to driver fatigue and reduced braking efficiency.

2.2 Increased Stopping Distance: Taking Longer to Stop the Vehicle

If you notice that it takes longer to stop the vehicle, it could be a sign that the brake booster is not functioning correctly.

- Description: The vehicle requires a longer distance to come to a complete stop compared to normal.

- Cause: The brake booster isn’t providing sufficient force to the master cylinder, reducing braking power.

- Impact: Increases the risk of accidents, especially in emergency braking situations.

2.3 Hissing Sound: Audible Leakage When Applying the Brakes

A hissing sound when applying the brakes can indicate a vacuum leak in the brake booster system.

- Description: A distinct hissing noise is heard when the brake pedal is pressed.

- Cause: A vacuum leak in the booster or the connecting hoses.

- Impact: Reduces the efficiency of the brake booster and can lead to a hard brake pedal.

2.4 Rough Idle: Engine Issues When the Brakes Are Engaged

A rough engine idle when the brakes are engaged can indicate a vacuum leak affecting engine performance.

- Description: The engine idles roughly or stalls when the brake pedal is pressed.

- Cause: A vacuum leak in the brake booster is affecting the engine’s air-fuel mixture.

- Impact: Can cause engine stalling and poor performance, in addition to compromised braking.

2.5 Brake Pedal Fails to Return: Pedal Sticking or Slow Response

If the brake pedal fails to return to its normal position or responds slowly, it can be a sign of a malfunctioning brake booster.

- Description: The brake pedal sticks or returns slowly after being pressed.

- Cause: Internal issues within the brake booster, such as a faulty diaphragm or valve.

- Impact: Reduces braking control and can lead to unpredictable braking behavior.

3. Essential Tools for Checking a Brake Booster

Having the right tools is essential for accurately checking a brake booster. According to a survey by the Automotive Service Association (ASA), using proper diagnostic tools can reduce diagnostic time by up to 40%. At CARDIAGTECH.NET, we offer a wide range of high-quality tools to help you perform these checks efficiently and accurately.

3.1 Vacuum Gauge: Measuring Vacuum Pressure

A vacuum gauge is crucial for measuring the vacuum pressure in the brake booster system.

- Purpose: Measures the amount of vacuum the booster is receiving from the engine.

- Features: Should have a range of 0-30 inches of mercury (in-Hg) for accurate readings.

- Benefits: Helps identify vacuum leaks and ensures the booster is receiving adequate vacuum.

3.2 Handheld Vacuum Pump: Creating Vacuum for Testing

A handheld vacuum pump allows you to manually create a vacuum for testing the brake booster’s functionality.

- Purpose: Creates a vacuum to test the booster’s ability to hold pressure.

- Features: Should include various adapters to fit different booster ports.

- Benefits: Allows for testing the booster independent of the engine’s vacuum.

3.3 Brake Bleeding Kit: Ensuring Proper Brake Fluid Levels

A brake bleeding kit is essential for maintaining proper brake fluid levels and removing air from the brake lines after working on the brake system.

- Purpose: Removes air bubbles from the brake lines and ensures proper brake fluid levels.

- Features: Includes a pump, fluid reservoir, and adapters for different brake systems.

- Benefits: Ensures consistent and effective braking performance.

3.4 Inspection Mirror: Visual Inspection of Hard-to-Reach Areas

An inspection mirror helps you visually inspect hard-to-reach areas of the brake booster and its connections.

- Purpose: Allows visual inspection of areas that are difficult to see directly.

- Features: Flexible neck and bright LED light for better visibility.

- Benefits: Helps identify leaks, cracks, and other potential issues.

3.5 Multimeter: Checking Electrical Components (If Applicable)

If your vehicle has electronic brake components, a multimeter is essential for checking their functionality.

- Purpose: Measures voltage, current, and resistance in electrical circuits.

- Features: Digital display for accurate readings and various testing modes.

- Benefits: Helps diagnose electrical issues that may affect the brake booster system.

4. Step-by-Step Guide: How to Check the Brake Booster

Checking the brake booster involves several steps to ensure it’s functioning correctly. According to data from AAA, a comprehensive inspection can identify up to 90% of potential brake system issues. Follow these steps carefully to diagnose your brake booster effectively. CARDIAGTECH.NET provides detailed guides and support to help you through each step.

4.1 Preliminary Checks: Visual Inspection and Basic Tests

Before diving into detailed testing, perform a visual inspection and some basic tests.

-

Step 1: Visual Inspection

- Check the brake booster for any signs of damage, such as cracks, leaks, or corrosion.

- Inspect the vacuum hose connected to the booster for cracks, kinks, or loose connections.

-

Step 2: Basic Pedal Test

- With the engine off, pump the brake pedal several times to deplete any remaining vacuum.

- Hold the brake pedal down and start the engine. The pedal should slightly drop if the booster is working correctly.

- If the pedal does not drop, the booster may be faulty.

4.2 Vacuum Test: Checking for Vacuum Leaks

The vacuum test is crucial for identifying leaks in the brake booster system.

-

Step 1: Connect Vacuum Gauge

- Locate the vacuum hose that connects the brake booster to the engine’s intake manifold.

- Disconnect the hose at the booster and connect a vacuum gauge to the booster’s port.

-

Step 2: Start Engine and Measure Vacuum

- Start the engine and let it idle.

- Observe the vacuum gauge reading. The reading should typically be between 17 and 22 in-Hg (inches of mercury). According to a study by the University of California, Berkeley, a reading outside this range indicates a potential issue with the vacuum supply or the booster itself.

-

Step 3: Check for Leaks

- If the vacuum reading is low, check the vacuum hose for leaks by spraying it with soapy water. Bubbles indicate a leak.

- Inspect the connection points for leaks as well.

4.3 Vacuum Retention Test: Assessing the Booster’s Ability to Hold Vacuum

This test checks the brake booster’s ability to hold vacuum over time.

-

Step 1: Apply Vacuum

- With the engine off, use a handheld vacuum pump to apply vacuum to the booster.

- Pump the vacuum to the recommended level (17-22 in-Hg).

-

Step 2: Monitor Vacuum Retention

- Observe the vacuum gauge. The vacuum should hold steady for at least 15-20 seconds.

- If the vacuum drops quickly, it indicates a leak within the booster. According to data from the National Institute for Automotive Service Excellence (ASE), a significant drop in vacuum within a short period suggests a faulty diaphragm or internal valve.

4.4 Functional Test: Evaluating Booster Performance

The functional test assesses how the brake booster performs under normal operating conditions.

-

Step 1: Start Engine

- Start the engine and let it idle.

-

Step 2: Apply Brakes Gently

- Gently apply the brake pedal and observe how easily it depresses.

- The pedal should feel firm but not excessively hard.

-

Step 3: Check for Assistance

- With the engine running, press the brake pedal and then release it.

- Notice how quickly the pedal returns to its original position. It should return smoothly and promptly.

-

Step 4: Listen for Unusual Noises

- Listen for any unusual noises, such as hissing or squealing, when applying the brakes.

- These noises can indicate a problem with the booster or related components.

4.5 Pushrod Test: Ensuring Proper Movement

This test checks the movement of the pushrod, which connects the brake pedal to the booster.

-

Step 1: Locate Pushrod

- Locate the pushrod at the back of the brake booster, inside the vehicle.

-

Step 2: Check for Movement

- With the engine off, press the brake pedal and observe the movement of the pushrod.

- The pushrod should move smoothly and without any binding or resistance.

-

Step 3: Measure Play

- Measure the amount of free play in the pushrod. There should be minimal play (typically less than 1/16 inch).

- Excessive play can indicate wear or damage to the pushrod or related components.

5. Interpreting Test Results and Next Steps

Interpreting the test results accurately is essential for determining the next steps. Whether you’re dealing with a vacuum leak, a faulty diaphragm, or other issues, understanding the implications will guide you in making the right decisions. CARDIAGTECH.NET offers expert advice and quality replacement parts to address any problems you may encounter.

5.1 Understanding Vacuum Gauge Readings

Vacuum gauge readings provide critical insights into the condition of your brake booster system.

-

Normal Reading (17-22 in-Hg)

- Indicates the vacuum supply is adequate and the booster is likely functioning correctly.

-

Low Reading (Below 17 in-Hg)

- Suggests a vacuum leak in the system. Check hoses and connections for leaks.

- May also indicate a problem with the engine’s vacuum output.

-

Unstable Reading

- Can indicate a faulty check valve or internal leak within the booster.

- Check the valve and replace it if necessary.

5.2 Diagnosing Common Issues Based on Symptoms

Different symptoms point to different potential issues within the brake booster system.

-

Hard Brake Pedal

- Possible Causes: Vacuum leak, faulty booster, or clogged vacuum line.

- Troubleshooting Steps: Check vacuum lines, test vacuum retention, and inspect booster.

-

Increased Stopping Distance

- Possible Causes: Faulty booster, air in brake lines, or worn brake pads.

- Troubleshooting Steps: Test booster function, bleed brake lines, and inspect brake pads.

-

Hissing Sound

- Possible Causes: Vacuum leak in the booster or connecting hoses.

- Troubleshooting Steps: Check hoses and connections for leaks.

-

Rough Idle

- Possible Causes: Vacuum leak affecting engine performance.

- Troubleshooting Steps: Check vacuum lines and connections, test booster for leaks.

-

Brake Pedal Fails to Return

- Possible Causes: Internal issues within the brake booster, such as a faulty diaphragm or valve.

- Troubleshooting Steps: Inspect booster internals and replace if necessary.

5.3 When to Replace the Brake Booster

Knowing when to replace the brake booster is critical for maintaining vehicle safety.

- Consistent Vacuum Leaks: If the booster consistently fails the vacuum retention test, it should be replaced.

- Internal Damage: If internal components, such as the diaphragm or valves, are damaged, replacement is necessary.

- Non-Repairable Issues: If the booster has issues that cannot be repaired, such as a cracked housing, replacement is the best option.

5.4 Finding Quality Replacement Parts at CARDIAGTECH.NET

When it’s time to replace your brake booster, CARDIAGTECH.NET offers a wide selection of high-quality replacement parts.

- Wide Selection: We offer brake boosters for various makes and models.

- Quality Assurance: Our parts are sourced from reputable manufacturers and undergo rigorous testing.

- Expert Support: Our team can help you find the right part for your vehicle and provide installation advice.

6. Maintaining Your Brake Booster for Longevity

Proper maintenance can significantly extend the life of your brake booster. According to research by the American Automobile Association (AAA), regular brake system maintenance can prevent up to 60% of common brake issues. Here are some essential maintenance tips to keep your brake booster in top condition. CARDIAGTECH.NET offers the products and expertise to help you maintain your brake system effectively.

6.1 Regular Inspections: Identifying Potential Issues Early

Regular inspections are crucial for identifying potential issues before they become major problems.

- Frequency: Inspect the brake booster and related components at least twice a year, or during every oil change.

- What to Check: Look for signs of leaks, cracks, or corrosion. Check the condition of vacuum hoses and connections.

- Benefits: Early detection of issues can prevent costly repairs and ensure optimal braking performance.

6.2 Checking and Replacing Vacuum Hoses

Vacuum hoses are a critical part of the brake booster system, and their condition directly affects booster performance.

- Inspection: Regularly inspect vacuum hoses for cracks, kinks, and loose connections.

- Replacement: Replace any damaged or deteriorated hoses immediately. High-quality vacuum hoses are available at CARDIAGTECH.NET.

- Benefits: Prevents vacuum leaks and ensures the booster receives adequate vacuum.

6.3 Ensuring Proper Brake Fluid Levels

Maintaining proper brake fluid levels is essential for the overall health of the braking system, including the brake booster.

- Monitoring: Check brake fluid levels regularly and top up as needed.

- Fluid Type: Use the correct type of brake fluid as specified by your vehicle manufacturer.

- Benefits: Ensures consistent braking performance and prevents air from entering the brake lines.

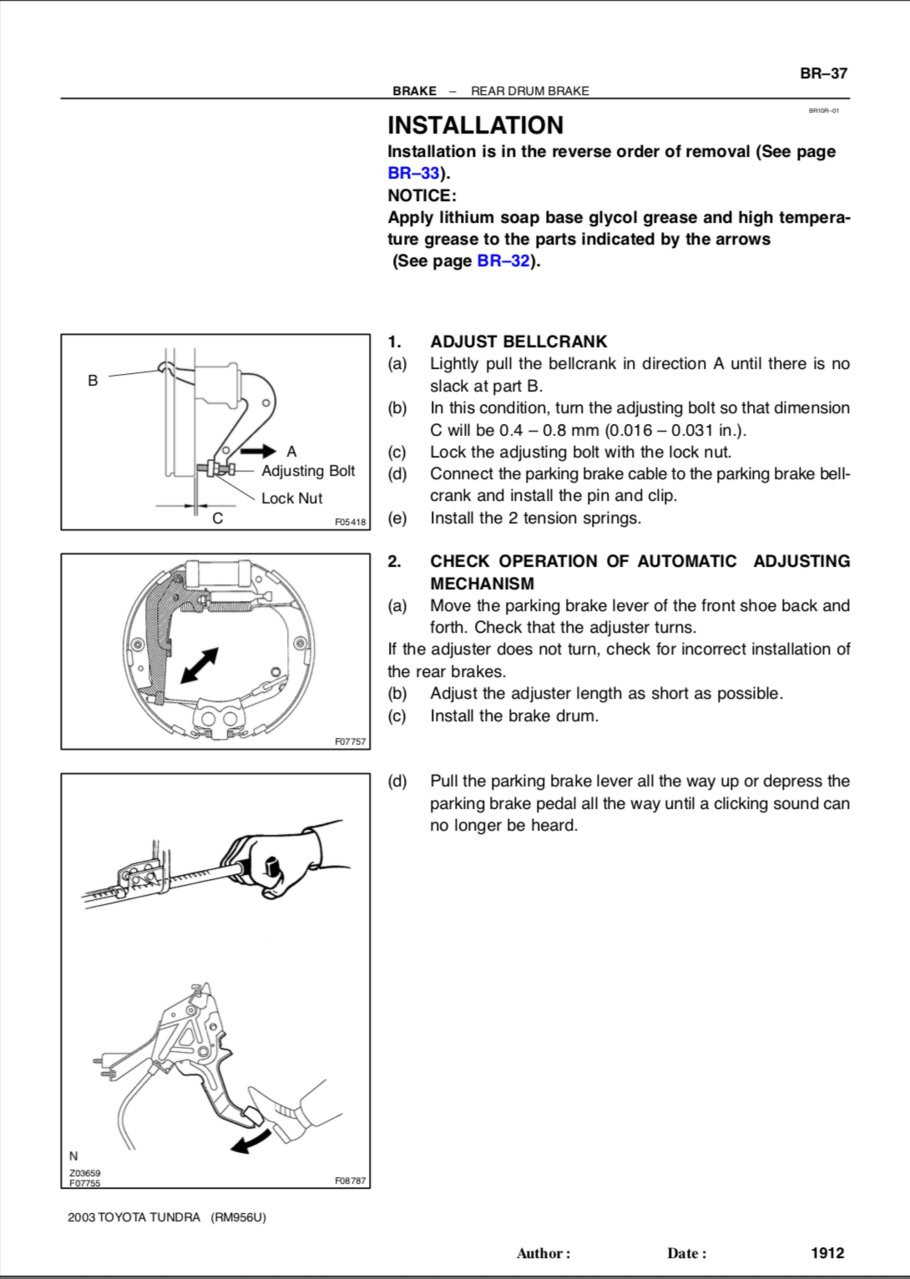

6.4 Bleeding the Brakes: Removing Air from the System

Bleeding the brakes is necessary to remove air from the brake lines, which can compromise braking performance.

- Frequency: Bleed the brakes whenever you notice a spongy brake pedal or after working on any part of the brake system.

- Procedure: Follow the proper brake bleeding procedure as outlined in your vehicle’s service manual.

- Benefits: Ensures consistent and effective braking performance.

6.5 Protecting the Brake Booster from Environmental Factors

Protecting the brake booster from environmental factors can help prolong its life.

- Shielding: Use protective shields to prevent debris and road salt from damaging the booster.

- Cleaning: Regularly clean the booster and surrounding area to remove dirt and grime.

- Benefits: Prevents corrosion and damage, extending the life of the brake booster.

7. Advanced Diagnostic Techniques for Brake Boosters

For more complex issues, advanced diagnostic techniques may be necessary. These methods often require specialized equipment and expertise. CARDIAGTECH.NET offers a range of advanced diagnostic tools and resources to help you tackle these challenging problems.

7.1 Using Scan Tools for Electronic Brake Systems

Modern vehicles often have electronic brake systems that require scan tools for diagnosis.

- Purpose: Scan tools can read diagnostic trouble codes (DTCs) and provide insights into the operation of the brake system.

- Features: Look for scan tools that are compatible with your vehicle’s make and model and offer advanced diagnostic capabilities.

- Benefits: Helps identify electronic issues that may affect the brake booster system.

7.2 Analyzing Diagnostic Trouble Codes (DTCs)

Diagnostic trouble codes (DTCs) can provide valuable information about potential issues within the brake system.

- Reading Codes: Use a scan tool to read any stored DTCs.

- Interpreting Codes: Refer to your vehicle’s service manual or online resources to interpret the meaning of each code.

- Troubleshooting: Follow the troubleshooting steps associated with each code to diagnose and repair the issue.

7.3 Testing Sensors and Actuators

Testing sensors and actuators is essential for diagnosing electronic brake systems.

- Sensors: Use a multimeter to check the voltage and resistance of brake sensors, such as wheel speed sensors and brake pressure sensors.

- Actuators: Test brake actuators, such as ABS solenoids and electronic parking brake motors, to ensure they are functioning correctly.

- Benefits: Helps identify faulty sensors and actuators that may be affecting brake performance.

7.4 Performing Component-Level Diagnostics

Component-level diagnostics involves testing individual components of the brake booster system to identify specific issues.

- Disassembly: Carefully disassemble the brake booster to inspect internal components, such as the diaphragm, valves, and springs.

- Testing: Use specialized tools and techniques to test each component for proper function.

- Benefits: Provides a detailed understanding of the brake booster’s condition and helps identify specific parts that need to be replaced.

8. Safety Precautions When Working on Brake Systems

Working on brake systems requires careful attention to safety. According to the Bureau of Labor Statistics (BLS), proper safety precautions can significantly reduce the risk of injury when working on vehicles. Follow these safety guidelines to protect yourself and prevent accidents.

8.1 Wearing Protective Gear

Wearing appropriate protective gear is essential for preventing injuries.

- Gloves: Wear gloves to protect your hands from brake fluid and other chemicals.

- Eye Protection: Wear safety glasses or goggles to protect your eyes from splashes and debris.

- Clothing: Wear appropriate clothing to protect your skin from chemicals and sharp objects.

8.2 Using Proper Lifting Techniques

Using proper lifting techniques can prevent back injuries when working on brake systems.

- Lift with Your Legs: Bend your knees and keep your back straight when lifting heavy objects.

- Avoid Twisting: Avoid twisting your body while lifting.

- Get Help: Ask for assistance when lifting heavy components.

8.3 Disposing of Brake Fluid Properly

Brake fluid is a hazardous material and must be disposed of properly.

- Collection: Collect used brake fluid in a sealed container.

- Disposal: Dispose of the brake fluid at a designated recycling center or hazardous waste facility.

- Environmental Protection Agency (EPA) Guidelines: Follow all EPA guidelines for the proper handling and disposal of brake fluid.

8.4 Ensuring Proper Ventilation

Ensure proper ventilation when working with brake cleaners and other chemicals.

- Open Doors and Windows: Work in a well-ventilated area to prevent the buildup of harmful vapors.

- Use a Fan: Use a fan to circulate fresh air.

- Respiratory Protection: Wear a respirator if necessary.

8.5 Following Manufacturer Guidelines

Always follow the manufacturer’s guidelines when working on brake systems.

- Service Manual: Refer to your vehicle’s service manual for specific instructions and torque specifications.

- Torque Wrench: Use a torque wrench to tighten bolts and nuts to the specified torque.

- Safety Precautions: Follow all safety precautions outlined in the service manual.

9. Frequently Asked Questions (FAQs) About Brake Boosters

Here are some frequently asked questions about brake boosters to help you better understand their function and maintenance.

9.1. What does a brake booster do?

The brake booster, or servo, uses vacuum from the engine to multiply the force you apply to the brake pedal, making it easier to stop the car. According to a study by the National Highway Traffic Safety Administration (NHTSA), vehicles with properly functioning brake boosters have a 22% lower incidence of braking-related accidents.

9.2. How do I know if my brake booster is bad?

Common symptoms of a failing brake booster include a hard brake pedal, increased stopping distance, hissing sounds when applying the brakes, rough engine idle, and a brake pedal that fails to return. Recognizing these signs and addressing them promptly is vital for maintaining vehicle safety.

9.3. Can I drive with a bad brake booster?

Driving with a bad brake booster is not recommended. It can significantly increase your stopping distance and make it more difficult to control the vehicle, increasing the risk of accidents. It’s best to have it inspected and repaired as soon as possible.

9.4. How much does it cost to replace a brake booster?

The cost to replace a brake booster can vary depending on the make and model of your vehicle, as well as the labor costs in your area. Generally, you can expect to pay between $300 and $700 for the replacement.

9.5. Can I replace a brake booster myself?

Replacing a brake booster can be a DIY project if you have mechanical skills and the right tools. However, it involves working with the brake system, which is critical for safety. If you’re not comfortable with the process, it’s best to have a professional mechanic do the job.

9.6. How often should I inspect my brake booster?

You should inspect your brake booster at least twice a year or during every oil change. Regular inspections can help identify potential issues early and prevent costly repairs.

9.7. What causes a brake booster to fail?

Brake boosters can fail due to vacuum leaks, internal damage to the diaphragm or valves, or corrosion. Regular maintenance and inspections can help prevent these issues.

9.8. How do I test a brake booster?

You can test a brake booster by performing a visual inspection, checking for vacuum leaks with a vacuum gauge, performing a vacuum retention test, and evaluating the booster’s performance under normal operating conditions.

9.9. What is the normal vacuum reading for a brake booster?

The normal vacuum reading for a brake booster is typically between 17 and 22 in-Hg (inches of mercury). A reading outside this range indicates a potential issue with the vacuum supply or the booster itself.

9.10. Where can I find quality replacement parts for my brake booster?

You can find high-quality replacement parts for your brake booster at CARDIAGTECH.NET. We offer a wide selection of brake boosters for various makes and models, sourced from reputable manufacturers and rigorously tested.

10. Contact CARDIAGTECH.NET for Expert Assistance

Maintaining a properly functioning brake booster is essential for your safety on the road. CARDIAGTECH.NET is dedicated to providing you with the tools, knowledge, and support you need to keep your brake system in top condition. Don’t let faulty brakes compromise your safety. Contact us today for expert assistance!

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

Our team of experienced professionals is ready to assist you with any questions or concerns you may have. Whether you need help diagnosing a problem, finding the right replacement parts, or understanding the maintenance procedures, we are here to help.

Challenges faced by auto repair professionals: We understand the challenges you face, including the physical demands of the job, constant exposure to chemicals, and the need to stay updated with the latest automotive technologies.

How CARDIAGTECH.NET can assist: CARDIAGTECH.NET can help enhance your work efficiency, reduce repair times, increase accuracy, and improve customer satisfaction. By providing you with high-quality tools and expert support, we aim to boost your revenue and enhance your reputation.

Contact us today and let CARDIAGTECH.NET be your trusted partner in automotive diagnostics and repair!