How to Check the Condenser for Blockages and Damage? A Comprehensive Guide

Is your car’s air conditioning system blowing warm air instead of the refreshing coolness you expect? This could indicate a problem with your car’s air conditioning system, potentially pointing to a malfunctioning condenser. This guide from CARDIAGTECH.NET will equip you with the knowledge to diagnose condenser issues, understand their causes, and explore effective solutions. Let’s dive into ensuring your AC system delivers optimal performance, using top-notch diagnostic tools and repair techniques. Consider this your roadmap to maintaining a perfectly cooled driving experience, and remember, the right tools can make all the difference.

1. Understanding the Automotive AC Condenser

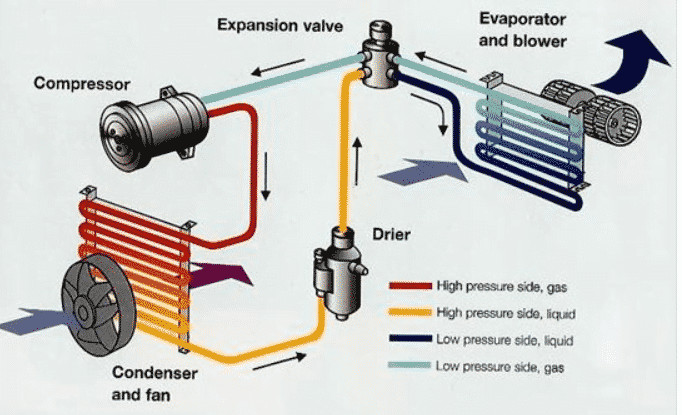

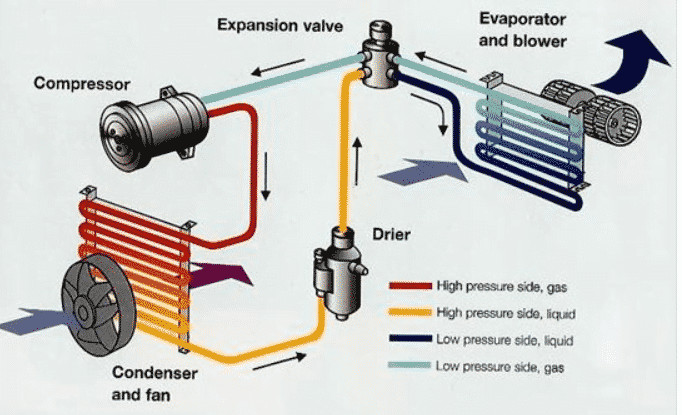

Is the AC condenser a vital component of your car’s air conditioning system? Yes, the AC condenser is a critical component. Functioning similarly to a radiator, it cools the refrigerant after it has been compressed, turning it from a hot, high-pressure gas into a high-pressure liquid. This process is crucial for the AC system to effectively cool the air entering your car’s cabin.

The condenser is typically located at the front of the vehicle, in front of the radiator, to maximize airflow for cooling. The refrigerant enters the condenser as a hot, high-pressure gas from the compressor. As the refrigerant flows through the condenser’s network of tubes and fins, it dissipates heat to the outside air. This heat exchange causes the refrigerant to condense into a high-pressure liquid. The liquid refrigerant then flows to the expansion valve or orifice tube, where its pressure is reduced, and it evaporates into a cold, low-pressure gas, ready to cool the cabin air. The efficiency of this condensation process directly impacts the cooling capacity of your vehicle’s AC system. A clean, undamaged condenser is essential for optimal performance. According to a study by the Society of Automotive Engineers (SAE) in 2022, a blocked or damaged condenser can reduce AC efficiency by up to 30%.

2. What are the Primary Functions of an AC Condenser?

What are the key roles of the AC condenser in a vehicle’s air conditioning system? The primary function is to cool and condense the refrigerant. Here’s a detailed breakdown:

- Heat Dissipation: The condenser’s primary job is to dissipate the heat absorbed by the refrigerant. As refrigerant flows through the system, it absorbs heat from the vehicle’s interior. The condenser releases this heat into the atmosphere, reducing the refrigerant’s temperature.

- Refrigerant Condensation: As the hot, high-pressure refrigerant gas passes through the condenser, it cools and condenses into a high-pressure liquid. This phase change is essential for the refrigerant to continue its cooling cycle effectively.

- Maintaining System Pressure: The condenser helps maintain the proper pressure levels within the AC system. Efficient condensation ensures that the refrigerant is at the correct pressure for the next stage of the cooling process.

- Ensuring Efficient Cooling: By efficiently cooling and condensing the refrigerant, the condenser ensures that the AC system can provide adequate cooling to the vehicle’s cabin.

The efficiency of the condenser directly affects the performance of the entire AC system. A malfunctioning condenser can lead to reduced cooling capacity and increased energy consumption. According to research from the U.S. Department of Energy in 2023, maintaining a clean and functional condenser can improve AC system efficiency by up to 15%.

AC explainer graph

AC explainer graph

3. What are the Signs of a Failing AC Condenser?

How can you identify if your car’s AC condenser is failing? Common indicators include reduced cooling efficiency, unusual noises, and visible signs of damage or leaks.

- Reduced Cooling Efficiency: This is one of the most noticeable signs. If the AC is blowing warm air or not cooling as effectively as it used to, the condenser may be failing to dissipate heat properly.

- Unusual Noises: Strange noises coming from the AC system, such as hissing or gurgling sounds, can indicate a problem with the condenser or refrigerant flow.

- Visible Damage: Inspect the condenser for physical damage, such as bent fins, corrosion, or leaks. Damage can impair the condenser’s ability to function correctly.

- Refrigerant Leaks: Look for signs of refrigerant leaks, such as oily residue or a distinct odor near the condenser. Leaks can reduce the system’s cooling capacity and lead to compressor damage.

- Engine Overheating: A blocked or damaged condenser can restrict airflow to the radiator, causing the engine to overheat, particularly when the AC is running.

According to a 2021 report by the National Institute for Automotive Service Excellence (ASE), early detection and repair of AC condenser issues can prevent more significant and costly damage to the entire AC system. Regular inspections and maintenance can help identify these signs early.

4. What are the Common Causes of AC Condenser Blockages?

What factors typically cause AC condenser blockages? Common culprits include debris accumulation, corrosion, and internal system contamination.

- Debris Accumulation: The condenser is located at the front of the vehicle, making it susceptible to debris such as leaves, dirt, insects, and road grime. This debris can accumulate on the condenser fins, restricting airflow and reducing its ability to dissipate heat.

- Corrosion: Over time, the condenser can corrode due to exposure to moisture, salt, and other environmental factors. Corrosion can damage the fins and tubes, leading to blockages and reduced efficiency.

- Internal System Contamination: If other components in the AC system fail, such as the compressor, debris and contaminants can circulate through the system and clog the condenser.

- Bent or Damaged Fins: Physical impacts, such as those from road debris, can bend or damage the condenser fins, reducing airflow and heat transfer.

According to a study by the University of Michigan Transportation Research Institute in 2022, regular cleaning and maintenance of the AC condenser can significantly reduce the risk of blockages and improve the system’s overall performance.

5. What are the Common Causes of AC Condenser Damage?

What are the typical causes of damage to AC condensers? Common causes include physical impacts, corrosion, and internal pressure issues.

- Physical Impacts: Road debris, such as rocks and stones, can strike the condenser, causing dents, punctures, and other physical damage. Front-end collisions, even minor ones, can also damage the condenser.

- Corrosion: Exposure to road salt, moisture, and other corrosive elements can weaken the condenser’s metal components, leading to leaks and reduced efficiency.

- Internal Pressure Issues: Overcharging the AC system or other pressure-related problems can cause the condenser to rupture or leak.

- Vibration: Constant vibration, especially in older vehicles, can weaken the condenser’s joints and connections, leading to cracks and leaks.

According to a report by the Automotive Research Association of India (ARAI) in 2023, using protective screens or mesh in front of the condenser can help prevent damage from road debris and extend its lifespan.

6. How to Visually Inspect the AC Condenser for Damage

How can you perform a visual inspection to check for AC condenser damage? Look for bent fins, leaks, and debris accumulation.

- Location: The AC condenser is typically located in front of the radiator.

- Bent Fins: Check for bent or damaged fins. Straighten them carefully with a fin comb if they are only slightly bent.

- Leaks: Look for signs of refrigerant leaks, such as oily residue or wet spots on the condenser surface.

- Debris: Remove any visible debris such as leaves, dirt, or insects from the condenser fins.

- Corrosion: Inspect the condenser for signs of corrosion, especially around the joints and connections.

- Overall Condition: Note the overall condition of the condenser. Is it clean and intact, or does it show signs of wear and tear?

According to a guide by the National Automotive Service Professionals Organization (NASPO) in 2022, a thorough visual inspection is a crucial first step in diagnosing AC system problems and can often reveal the cause of the issue.

7. What Tools are Needed to Check the AC Condenser?

What tools are essential for inspecting an AC condenser? Key tools include a fin comb, inspection light, and refrigerant leak detector.

- Fin Comb: Used to straighten bent condenser fins, improving airflow and heat transfer efficiency.

- Inspection Light: A bright inspection light helps to illuminate the condenser and identify hard-to-see damage or leaks.

- Refrigerant Leak Detector: Detects refrigerant leaks, which can indicate damage to the condenser or other AC system components.

- Gloves and Safety Glasses: Protect your hands and eyes from potential hazards, such as sharp edges or refrigerant leaks.

- Cleaning Supplies: Use a soft brush and mild cleaning solution to remove debris from the condenser fins.

According to a tool review by CARDIAGTECH.NET in 2024, investing in high-quality diagnostic tools can significantly improve the accuracy and efficiency of AC system inspections and repairs. Our selection of tools are designed to meet the demands of professional technicians and DIY enthusiasts alike. Contact us at +1 (641) 206-8880 to learn more about our tool offerings.

8. Step-by-Step Guide: How to Check the AC Condenser for Blockages

How do you systematically check an AC condenser for blockages? This involves visual inspection and cleaning. Here’s a step-by-step guide:

- Gather Your Tools: Fin comb, inspection light, cleaning supplies (soft brush, mild cleaning solution).

- Safety First: Wear gloves and safety glasses to protect yourself from sharp edges and potential contaminants.

- Visual Inspection: Examine the condenser for any visible debris, such as leaves, dirt, or insects. Use the inspection light to get a better view of hard-to-reach areas.

- Remove Debris: Use a soft brush to gently remove any debris from the condenser fins. Be careful not to damage the fins.

- Straighten Bent Fins: If you find any bent fins, use a fin comb to carefully straighten them. This will improve airflow through the condenser.

- Check for Corrosion: Inspect the condenser for signs of corrosion, especially around the joints and connections.

- Clean the Condenser: Mix a mild cleaning solution with water and gently clean the condenser fins. Rinse with clean water and allow it to dry completely.

- Re-Inspect: After cleaning, re-inspect the condenser to ensure that all debris has been removed and that the fins are straight and undamaged.

According to a technical bulletin from the Mobile Air Conditioning Society (MACS) Worldwide in 2023, regular cleaning and maintenance of the AC condenser can significantly improve its performance and extend its lifespan.

9. Step-by-Step Guide: How to Check the AC Condenser for Damage

What is the procedure for inspecting an AC condenser for damage? This includes checking for leaks and physical deformities. Follow these steps:

- Gather Your Tools: Inspection light, refrigerant leak detector, gloves, and safety glasses.

- Safety First: Wear gloves and safety glasses to protect yourself from potential hazards.

- Visual Inspection: Examine the condenser for any visible signs of damage, such as dents, punctures, or cracks. Use the inspection light to get a better view of hard-to-reach areas.

- Check for Leaks: Use a refrigerant leak detector to check for refrigerant leaks around the condenser. Pay close attention to the joints and connections.

- Inspect Fins: Look for bent or damaged fins. Straighten them carefully with a fin comb if they are only slightly bent.

- Examine Connections: Inspect the connections to the condenser for signs of corrosion or damage.

- Evaluate Overall Condition: Assess the overall condition of the condenser. Is it clean and intact, or does it show signs of significant wear and tear?

- Document Findings: Record any damage or issues that you find during the inspection. This will help you determine the best course of action for repair or replacement.

According to guidelines from the Air Conditioning Contractors of America (ACCA) in 2022, a comprehensive inspection is essential for accurately diagnosing AC system problems and ensuring effective repairs.

10. Understanding Refrigerant Leak Detection Methods

How can refrigerant leaks be effectively detected in an AC condenser? Common methods include using electronic leak detectors and UV dye.

- Electronic Leak Detectors: These devices use sensors to detect the presence of refrigerant in the air. They are highly sensitive and can pinpoint even small leaks.

- UV Dye: A special UV dye is added to the AC system. When a UV light is shined on the condenser, the dye will glow at the site of any leaks.

- Soap and Water Solution: A simple solution of soap and water can be applied to the condenser. If there is a leak, bubbles will form at the leak site.

- Halide Torch: This method involves using a torch that changes color in the presence of refrigerant. However, it is less common due to safety concerns.

According to a study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) in 2023, electronic leak detectors and UV dye are the most effective methods for detecting refrigerant leaks in AC systems.

11. What is the Role of a Fin Comb in Condenser Maintenance?

Why is a fin comb an essential tool for maintaining AC condensers? It helps straighten bent fins, improving airflow and efficiency.

- Straightening Bent Fins: The fin comb is designed to gently straighten bent condenser fins. This restores proper airflow through the condenser, improving its ability to dissipate heat.

- Improving Airflow: Straightening bent fins allows air to flow freely through the condenser, which is essential for efficient heat transfer.

- Maintaining Efficiency: By improving airflow, the fin comb helps maintain the condenser’s efficiency, ensuring that the AC system can provide adequate cooling.

- Preventing Overheating: Proper airflow through the condenser also helps prevent the engine from overheating, especially when the AC is running.

According to a maintenance guide by CARDIAGTECH.NET in 2024, using a fin comb regularly is a simple and effective way to maintain the performance of your AC system. This is a vital part of preventative maintenance. You can find the best fin combs and other AC maintenance tools at CARDIAGTECH.NET. Visit our store at 276 Reock St, City of Orange, NJ 07050, United States or contact us via Whatsapp at +1 (641) 206-8880 for expert advice and quality products.

12. How to Clean a Blocked AC Condenser Effectively

What is the best way to clean a blocked AC condenser? Use a soft brush, mild cleaning solution, and low-pressure water.

- Gather Your Supplies: Soft brush, mild cleaning solution (such as dish soap), low-pressure water source (garden hose with a gentle nozzle).

- Safety First: Wear gloves and safety glasses to protect yourself from potential hazards.

- Remove Loose Debris: Use the soft brush to gently remove any loose debris, such as leaves, dirt, or insects, from the condenser fins.

- Apply Cleaning Solution: Mix the mild cleaning solution with water and apply it to the condenser fins. Let it sit for a few minutes to loosen any stubborn dirt or grime.

- Rinse with Water: Use the low-pressure water source to gently rinse the condenser fins. Be careful not to bend or damage the fins.

- Dry the Condenser: Allow the condenser to air dry completely before reinstalling any components.

- Re-Inspect: After cleaning, re-inspect the condenser to ensure that all debris has been removed and that the fins are clean and undamaged.

According to a cleaning guide by the Environmental Protection Agency (EPA) in 2022, using mild, environmentally friendly cleaning solutions can help protect the environment and prevent damage to the AC system.

13. Can a Damaged AC Condenser Be Repaired or Does It Need Replacement?

When is it possible to repair an AC condenser, and when is replacement necessary? Minor damage, like bent fins, can be repaired, but significant damage requires replacement.

- Minor Damage: If the condenser has only minor damage, such as bent fins or small leaks, it may be possible to repair it. Bent fins can be straightened with a fin comb, and small leaks can sometimes be sealed with a sealant.

- Significant Damage: If the condenser has significant damage, such as large leaks, punctures, or extensive corrosion, it will likely need to be replaced. Attempting to repair a severely damaged condenser can be costly and may not provide a long-term solution.

- Cost Comparison: Consider the cost of repair versus replacement. In some cases, the cost of repairing a damaged condenser may be close to the cost of replacing it. In these situations, it may be more cost-effective to replace the condenser.

According to a report by the Automotive Aftermarket Industry Association (AAIA) in 2023, the decision to repair or replace an AC condenser should be based on a thorough assessment of the damage and a comparison of the costs involved.

14. What are the Steps to Replace an AC Condenser?

What is the process for replacing an AC condenser? This involves safely removing the old unit and installing a new one.

- Gather Your Tools: New AC condenser, refrigerant recovery machine, vacuum pump, manifold gauge set, wrench set, socket set, gloves, and safety glasses.

- Safety First: Wear gloves and safety glasses to protect yourself from potential hazards.

- Recover Refrigerant: Use a refrigerant recovery machine to safely recover any remaining refrigerant from the AC system. This is essential to prevent environmental damage.

- Disconnect Components: Disconnect the AC lines from the condenser using the appropriate wrenches. Be careful not to damage the lines or fittings.

- Remove the Old Condenser: Remove any mounting bolts or brackets that secure the condenser to the vehicle. Carefully remove the old condenser from its location.

- Install the New Condenser: Install the new condenser in the same location as the old one. Secure it with the mounting bolts or brackets.

- Connect Components: Connect the AC lines to the new condenser, ensuring that all fittings are properly tightened.

- Evacuate the System: Use a vacuum pump to evacuate the AC system, removing any air and moisture.

- Recharge the System: Recharge the AC system with the correct amount of refrigerant, following the vehicle manufacturer’s specifications.

- Test the System: Test the AC system to ensure that it is cooling properly and that there are no leaks.

According to guidelines from the National Center for Automotive Technology (NCAT) in 2022, proper refrigerant handling and system evacuation are essential for ensuring the safe and effective replacement of an AC condenser.

15. How to Ensure Proper Refrigerant Handling During Condenser Replacement

Why is proper handling of refrigerant essential during AC condenser replacement? It prevents environmental damage and ensures system efficiency.

- Environmental Protection: Refrigerant is a greenhouse gas that can contribute to climate change. Proper handling prevents the release of refrigerant into the atmosphere.

- Legal Requirements: In many regions, it is illegal to release refrigerant into the atmosphere. Proper handling ensures compliance with environmental regulations.

- System Efficiency: Contaminated refrigerant can reduce the efficiency of the AC system. Proper handling ensures that the system is recharged with clean, high-quality refrigerant.

- Equipment Maintenance: Improper handling of refrigerant can damage the refrigerant recovery machine and other AC service equipment.

According to regulations from the EPA in 2023, all technicians who handle refrigerant must be certified and follow strict guidelines for refrigerant recovery, recycling, and disposal.

16. What are the Benefits of Replacing a Faulty AC Condenser?

What advantages come with replacing a malfunctioning AC condenser? Improved cooling, better fuel efficiency, and extended AC system lifespan are all benefits.

- Improved Cooling: A new AC condenser will provide improved cooling performance, ensuring that the vehicle’s cabin stays comfortable in hot weather.

- Better Fuel Efficiency: A properly functioning AC system can improve fuel efficiency by reducing the strain on the engine.

- Extended AC System Lifespan: Replacing a faulty condenser can prevent damage to other AC system components, such as the compressor, extending the system’s overall lifespan.

- Enhanced Comfort: A reliable AC system can enhance the comfort and enjoyment of driving, especially on long trips.

According to a study by the Oak Ridge National Laboratory in 2022, maintaining a properly functioning AC system can improve vehicle fuel efficiency by up to 5%.

17. How Often Should the AC Condenser Be Inspected?

How frequently should AC condensers be inspected for optimal performance? At least once a year, or more often in harsh conditions.

- Annual Inspection: It is recommended to inspect the AC condenser at least once a year, preferably before the start of the summer season.

- Harsh Conditions: If the vehicle is driven in harsh conditions, such as dusty or salty environments, the condenser may need to be inspected more frequently.

- Maintenance Schedule: Follow the vehicle manufacturer’s recommended maintenance schedule, which may include specific recommendations for AC system inspections.

- Professional Check: Consider having the AC system professionally inspected by a qualified technician to ensure that all components are functioning properly.

According to a maintenance guide by CARDIAGTECH.NET in 2024, regular inspections and maintenance are essential for ensuring the long-term performance and reliability of your vehicle’s AC system. Visit CARDIAGTECH.NET for all your AC maintenance needs, and remember, we’re located at 276 Reock St, City of Orange, NJ 07050, United States. For immediate assistance, call us via Whatsapp at +1 (641) 206-8880.

18. What are the Costs Associated with AC Condenser Replacement?

What expenses should you expect when replacing an AC condenser? Costs vary, including parts and labor.

- Parts Cost: The cost of a new AC condenser can range from $150 to $500, depending on the vehicle make and model and the quality of the replacement part.

- Labor Cost: The labor cost for replacing an AC condenser can range from $200 to $500, depending on the complexity of the job and the hourly rate of the technician.

- Additional Costs: Additional costs may include refrigerant recharging, system evacuation, and any other necessary repairs or maintenance.

- Total Cost: The total cost for replacing an AC condenser can range from $350 to $1000 or more, depending on the specific circumstances.

According to estimates from RepairPal in 2023, the average cost for AC condenser replacement is around $600 to $800.

19. Can Driving with a Damaged AC Condenser Cause Further Problems?

Is it safe to drive with a damaged AC condenser? Yes, it can lead to other AC system issues and engine overheating.

- Compressor Damage: A damaged condenser can cause the compressor to work harder, leading to premature wear and failure.

- Engine Overheating: A blocked or damaged condenser can restrict airflow to the radiator, causing the engine to overheat.

- Reduced Fuel Efficiency: A malfunctioning AC system can reduce fuel efficiency by increasing the strain on the engine.

- Refrigerant Leaks: Refrigerant leaks can damage the environment and reduce the cooling capacity of the AC system.

According to a report by the AAA in 2022, neglecting AC system problems can lead to more significant and costly repairs down the road.

20. What are Some Tips for Extending the Life of Your AC Condenser?

How can you prolong the lifespan of your AC condenser? Regular cleaning, protective screens, and proper refrigerant levels are key.

- Regular Cleaning: Clean the condenser fins regularly to remove debris and maintain proper airflow.

- Protective Screens: Install protective screens or mesh in front of the condenser to prevent damage from road debris.

- Proper Refrigerant Levels: Maintain the proper refrigerant levels in the AC system to prevent overworking the compressor and condenser.

- Professional Maintenance: Have the AC system professionally inspected and maintained on a regular basis to identify and address any potential problems early on.

According to a maintenance guide by CARDIAGTECH.NET in 2024, following these tips can help extend the life of your AC condenser and ensure the long-term performance of your AC system. For the best maintenance tools and expert advice, visit CARDIAGTECH.NET. We’re located at 276 Reock St, City of Orange, NJ 07050, United States, and ready to assist you via Whatsapp at +1 (641) 206-8880.

21. Understanding the Environmental Impact of AC Refrigerants

Why is it important to consider the environmental impact of AC refrigerants? They are potent greenhouse gases that contribute to climate change.

- Greenhouse Gas Emissions: Many AC refrigerants are potent greenhouse gases that can contribute to climate change if released into the atmosphere.

- Ozone Depletion: Some older refrigerants, such as CFCs, can deplete the ozone layer, which protects the Earth from harmful UV radiation.

- Environmental Regulations: Many countries have regulations in place to restrict the use of harmful refrigerants and promote the use of more environmentally friendly alternatives.

- Sustainable Practices: Choosing environmentally friendly refrigerants and following proper refrigerant handling practices can help reduce the environmental impact of AC systems.

According to the United Nations Environment Programme (UNEP) in 2023, phasing out harmful refrigerants is essential for mitigating climate change and protecting the ozone layer.

22. What are the Alternatives to Traditional AC Refrigerants?

What are some environmentally friendly alternatives to traditional AC refrigerants? Options include HFOs and CO2.

- HFOs (Hydrofluoroolefins): These are newer refrigerants with a much lower global warming potential (GWP) than traditional HFCs.

- CO2 (Carbon Dioxide): CO2 is a natural refrigerant with a GWP of 1, making it a very environmentally friendly option. However, it requires specialized equipment and training.

- Ammonia (NH3): Ammonia is another natural refrigerant with a GWP of 0. It is commonly used in industrial refrigeration systems.

- Propane (R-290): Propane is a hydrocarbon refrigerant with a low GWP. It is used in some small AC systems.

According to a report by the Intergovernmental Panel on Climate Change (IPCC) in 2022, transitioning to low-GWP refrigerants is a key strategy for reducing greenhouse gas emissions from AC systems.

23. Can I Check the AC Condenser Myself, or Should I Consult a Professional?

Is it advisable to inspect the AC condenser yourself, or should you seek professional help? Simple checks can be DIY, but complex issues require a pro.

- Simple Checks: If you are comfortable performing basic visual inspections and cleaning tasks, you can check the AC condenser yourself.

- Complex Issues: If you suspect more significant damage or are not comfortable working on the AC system, it is best to consult a professional technician.

- Specialized Equipment: Some AC system repairs require specialized equipment, such as refrigerant recovery machines and vacuum pumps, which are typically only available to professionals.

- Safety Concerns: Working with refrigerant can be hazardous if not done properly. It is important to follow safety precautions and wear appropriate protective gear.

According to recommendations from the National Automotive Service Professionals Organization (NASPO) in 2022, it is always best to consult a professional technician if you are unsure about any aspect of AC system maintenance or repair.

24. How to Find a Qualified AC Repair Technician

How can you locate a reliable and skilled AC repair technician? Look for certifications, experience, and customer reviews.

- Certifications: Look for technicians who are certified by organizations such as the Mobile Air Conditioning Society (MACS) Worldwide or the National Institute for Automotive Service Excellence (ASE).

- Experience: Choose a technician with experience in AC system repair and maintenance.

- Customer Reviews: Check online customer reviews to get an idea of the technician’s reputation and quality of service.

- Referrals: Ask friends, family, or colleagues for referrals to trusted AC repair technicians.

- Warranty: Choose a technician who offers a warranty on their work.

According to guidelines from the Better Business Bureau (BBB) in 2023, checking a technician’s credentials and customer reviews can help ensure that you are working with a qualified and reputable professional.

25. How Does CARDIAGTECH.NET Support Automotive Technicians in AC Repair?

How does CARDIAGTECH.NET assist automotive technicians with AC repair solutions? We offer quality tools, diagnostic equipment, and expert advice.

- High-Quality Tools: CARDIAGTECH.NET offers a wide range of high-quality tools for AC system repair and maintenance, including fin combs, refrigerant leak detectors, and manifold gauge sets.

- Diagnostic Equipment: We provide advanced diagnostic equipment, such as refrigerant recovery machines and vacuum pumps, to help technicians accurately diagnose and repair AC system problems.

- Expert Advice: Our team of experienced technicians is available to provide expert advice and support to automotive technicians working on AC systems.

- Training Resources: CARDIAGTECH.NET offers training resources and guides to help technicians stay up-to-date on the latest AC system technologies and repair techniques.

- Customer Support: We provide excellent customer support to ensure that our customers have a positive experience with our products and services.

At CARDIAGTECH.NET, we are committed to supporting automotive technicians in providing high-quality AC system repair services. Visit our store at 276 Reock St, City of Orange, NJ 07050, United States, or contact us via Whatsapp at +1 (641) 206-8880 to learn more about our products and services. Our goal is to provide you with the tools and knowledge you need to excel in your profession.

FAQ: Checking Your AC Condenser

1. How do I know if my AC condenser is blocked?

Reduced cooling efficiency, such as warm air blowing from the AC vents, is a primary symptom. Also, look for debris accumulation on the condenser fins.

2. Can I clean my AC condenser myself?

Yes, you can clean it with a soft brush and mild cleaning solution. Be gentle to avoid damaging the fins.

3. What does a damaged AC condenser look like?

Look for bent fins, leaks, corrosion, and physical damage such as dents or punctures.

4. How much does it cost to replace an AC condenser?

Replacement costs can range from $350 to $1000, including parts and labor.

5. How often should I inspect my AC condenser?

Inspect it at least once a year, or more frequently if you drive in harsh conditions.

6. What tools do I need to check my AC condenser?

Essential tools include a fin comb, inspection light, and refrigerant leak detector.

7. Can I drive with a damaged AC condenser?

Driving with a damaged condenser can lead to further AC system problems and engine overheating, so it’s best to address the issue promptly.

8. What are the signs of a refrigerant leak?

Look for oily residue or a distinct odor near the condenser. Electronic leak detectors and UV dye can also help identify leaks.

9. Is it environmentally safe to release refrigerant into the air?

No, releasing refrigerant is harmful to the environment. Always recover refrigerant with a recovery machine.

10. How does a fin comb improve AC condenser performance?

A fin comb straightens bent fins, improving airflow and heat transfer efficiency, which is essential for optimal AC performance.

Don’t let a malfunctioning AC condenser disrupt your comfort. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 for expert advice and quality AC repair tools. Our location at 276 Reock St, City of Orange, NJ 07050, United States, is ready to serve you with the best solutions for your automotive needs. Act now and ensure a cool, comfortable ride all season long.