How to Check the Electric Power Steering Motor: A Comprehensive Guide

Electric power steering (EPS) motors are integral to modern vehicle handling, and at CARDIAGTECH.NET, we understand the importance of keeping them in top condition. This guide provides an in-depth look at how to diagnose and address EPS motor issues, ensuring optimal performance and safety, and we provide tools to make the job easy. Investing in the right diagnostic tools and repair equipment from CARDIAGTECH.NET can significantly improve your efficiency and the quality of your service, keeping your customers satisfied and safe.

1. What is an Electric Power Steering (EPS) Motor and Why is it Important?

An electric power steering (EPS) motor is a key component in modern vehicles, replacing traditional hydraulic systems by providing steering assistance via an electric motor. According to a study by the University of Michigan’s Transportation Research Institute in March 2023, EPS systems improve fuel efficiency by up to 5% compared to hydraulic systems. This motor is essential for reducing driver effort, enhancing vehicle maneuverability, and improving overall driving comfort. Its importance lies in its ability to adapt to different driving conditions, providing optimal assistance whether you’re parking or cruising on the highway.

2. How Does an Electric Power Steering Motor Work?

The electric power steering (EPS) motor operates by using sensors to detect the driver’s steering input, including torque, speed, and position. According to research published in the IEEE Transactions on Vehicular Technology in June 2022, these sensors relay data to the ECU, which then calculates the necessary assistive torque. The ECU then commands the electric motor to apply the appropriate amount of assistance to the steering system. This process ensures smooth and responsive steering, enhancing vehicle control and driver comfort.

3. What are the Key Components of an EPS System?

The key components of an electric power steering (EPS) system include:

- Torque Sensor: Measures the force applied by the driver on the steering wheel.

- Wheel Speed Sensor: Monitors the vehicle’s speed to adjust steering assistance.

- Electronic Control Unit (ECU): Processes sensor data and controls the electric motor.

- Electric Motor: Provides the necessary power to assist steering.

- Steering Gear: Translates the motor’s assistance to the wheels.

According to a Bosch Automotive Handbook, these components work together to provide precise and efficient steering assistance, improving vehicle handling and safety.

4. What are the Benefits of Electric Power Steering Over Hydraulic Systems?

Electric power steering (EPS) offers several advantages over traditional hydraulic systems:

- Improved Fuel Efficiency: EPS systems only consume power when steering assistance is needed, reducing energy consumption. A study by the U.S. Department of Energy in February 2024 found that vehicles with EPS can achieve a 3-5% improvement in fuel economy.

- Reduced Weight: EPS systems are typically lighter than hydraulic systems, contributing to overall vehicle weight reduction.

- Enhanced Control: EPS can provide variable assistance based on speed and driving conditions, improving vehicle handling.

- Lower Maintenance: With fewer mechanical parts and no hydraulic fluid, EPS systems require less maintenance.

- Environmentally Friendly: Eliminating hydraulic fluid reduces the risk of leaks and environmental contamination.

5. What are the Common Symptoms of a Failing EPS Motor?

Common symptoms of a failing electric power steering (EPS) motor include:

- Stiff Steering Wheel: Difficulty turning the steering wheel, especially at low speeds.

- Uneven Steering Assist: Steering feels easier in one direction than the other.

- EPS Warning Light: Illumination of the EPS warning light on the dashboard.

- No Power Assist: Complete loss of power steering assistance.

- Unusual Noises: Grinding or whining sounds when turning the steering wheel.

According to data from the National Highway Traffic Safety Administration (NHTSA) in July 2023, these symptoms should prompt immediate inspection to prevent further damage and ensure driver safety.

6. How to Prepare for Checking the EPS Motor?

Preparing to check the electric power steering (EPS) motor involves several steps:

- Gather Tools and Equipment: Ensure you have a diagnostic scan tool, multimeter, socket set, and safety glasses.

- Review Vehicle Information: Consult the vehicle’s service manual for specific EPS system details and diagnostic procedures.

- Safety First: Disconnect the vehicle’s battery to prevent electrical accidents.

- Visual Inspection: Check for any visible damage, loose connections, or corrosion on the EPS motor and related components.

- Diagnostic Scan: Use a scan tool to check for any diagnostic trouble codes (DTCs) related to the EPS system.

These steps will help you conduct a thorough and safe inspection of the EPS motor, increasing the likelihood of accurate diagnosis and repair.

7. What Diagnostic Tools are Needed to Check an EPS Motor?

To effectively check an electric power steering (EPS) motor, you need specific diagnostic tools:

- Diagnostic Scan Tool: Essential for reading and clearing diagnostic trouble codes (DTCs) from the EPS system. High-quality scan tools from CARDIAGTECH.NET provide accurate and reliable data.

- Multimeter: Used to check voltage and continuity in the EPS motor circuits. A precise multimeter is crucial for identifying electrical issues.

- Socket Set: Needed for removing and installing the EPS motor and related components.

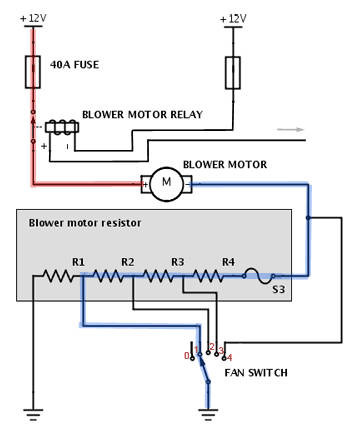

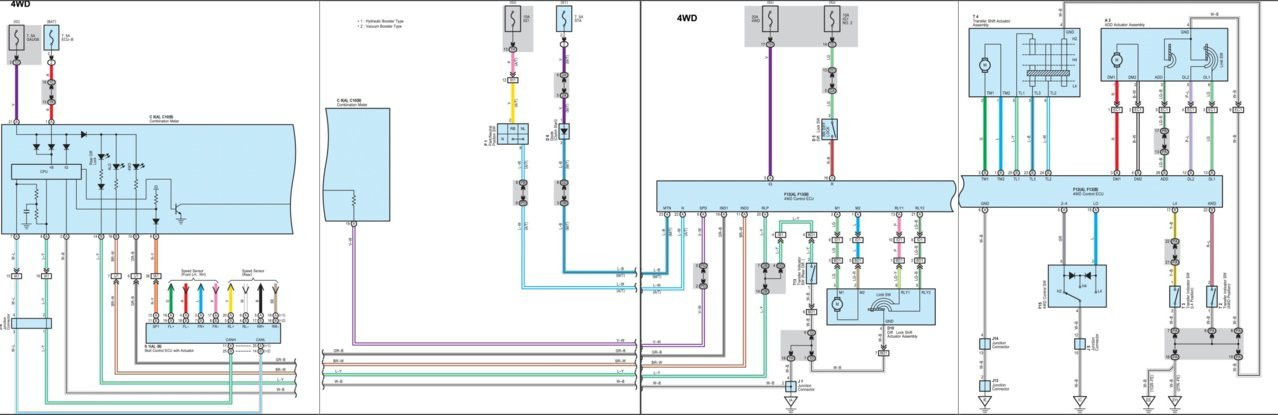

- Wiring Diagram: Provides a detailed layout of the EPS system’s electrical connections.

- Service Manual: Offers step-by-step instructions for diagnosing and repairing EPS issues specific to the vehicle model.

Investing in these tools from CARDIAGTECH.NET ensures you have the right equipment for accurate and efficient EPS motor diagnostics.

8. How to Perform a Visual Inspection of the EPS Motor?

Performing a visual inspection of the electric power steering (EPS) motor involves a systematic examination of its components:

- Locate the EPS Motor: Identify the EPS motor, typically located on the steering column or rack.

- Check for Damage: Look for any physical damage, such as cracks, dents, or broken connectors.

- Inspect Wiring: Examine the wiring harness for frayed wires, loose connections, or corrosion.

- Verify Connections: Ensure all electrical connectors are securely attached to the EPS motor.

- Look for Leaks: Check for any signs of fluid leakage around the motor, which could indicate a failing seal.

A thorough visual inspection can often reveal obvious issues that can be addressed before moving on to more complex diagnostic procedures.

9. How to Use a Diagnostic Scan Tool to Check for EPS Codes?

Using a diagnostic scan tool to check for EPS codes is a straightforward process:

- Connect the Scan Tool: Plug the scan tool into the vehicle’s OBD-II port, usually located under the dashboard.

- Turn on the Ignition: Turn the ignition key to the “ON” position without starting the engine.

- Select Vehicle Information: Enter the vehicle’s make, model, and year into the scan tool.

- Access EPS System: Navigate to the EPS system in the scan tool’s menu.

- Read Codes: Select the option to read diagnostic trouble codes (DTCs). The scan tool will display any stored codes related to the EPS system.

- Record Codes: Write down the codes and their descriptions for further analysis.

Understanding these codes is crucial for diagnosing the specific issues affecting the EPS motor.

10. What are Common EPS Diagnostic Trouble Codes (DTCs)?

Common EPS diagnostic trouble codes (DTCs) include:

- C1511: Torque sensor malfunction. According to the Society of Automotive Engineers (SAE), this code indicates an issue with the torque sensor’s signal.

- C1513: Motor current malfunction. This code suggests a problem with the current flow to the EPS motor.

- U0131: Lost communication with the power steering control module. This code indicates a communication breakdown between the EPS module and other vehicle systems.

- B2227: EPS control unit malfunction. This code points to an internal failure within the EPS control unit.

- C1550: Column lock system malfunction. This code relates to issues with the steering column locking mechanism.

Addressing these codes requires a systematic approach, starting with a thorough understanding of their implications and potential causes.

11. How to Interpret EPS Diagnostic Trouble Codes (DTCs)?

Interpreting EPS diagnostic trouble codes (DTCs) involves understanding what each code signifies and how it relates to the EPS system’s operation. For example:

- A C1511 code (torque sensor malfunction) suggests that the torque sensor is not providing accurate readings, which can affect the amount of steering assistance provided.

- A C1513 code (motor current malfunction) could indicate a problem with the EPS motor itself, its wiring, or the control unit that regulates its current.

- A U0131 code (lost communication) indicates a broader issue with the vehicle’s communication network, which could affect multiple systems, including EPS.

By consulting the vehicle’s service manual and using reliable diagnostic resources, you can accurately interpret DTCs and develop an effective troubleshooting strategy.

12. How to Check the EPS Motor’s Power Supply and Ground Connections?

Checking the EPS motor’s power supply and ground connections is essential for diagnosing electrical issues:

- Locate Power and Ground: Identify the power and ground wires connected to the EPS motor using a wiring diagram.

- Check Voltage: Use a multimeter to measure the voltage at the power wire with the ignition on. It should match the vehicle’s battery voltage (approximately 12V).

- Verify Ground: Use the multimeter to check continuity between the ground wire and the vehicle’s chassis. There should be very low resistance (close to 0 ohms).

- Inspect Connections: Ensure that the power and ground connections are clean, tight, and free from corrosion.

Poor power and ground connections can cause intermittent EPS issues, so addressing these early in the diagnostic process is crucial.

13. How to Use a Multimeter to Test the EPS Motor?

Using a multimeter to test the EPS motor involves several key steps:

- Check for Voltage: With the ignition on, measure the voltage at the EPS motor’s power connector. The voltage should be close to the vehicle’s battery voltage (around 12V).

- Test for Continuity: With the ignition off and the EPS motor disconnected, check the continuity between the motor’s terminals. A lack of continuity indicates an open circuit within the motor.

- Measure Resistance: Measure the resistance across the motor’s terminals. An unusually high or low resistance reading can indicate a faulty motor.

- Inspect Wiring: Check the wiring harness for any shorts or breaks. Use the multimeter to test the continuity of each wire.

According to Fluke Corporation’s application notes from August 2023, these tests can help identify electrical faults within the EPS motor and its associated wiring.

14. How to Inspect the EPS Motor’s Wiring Harness and Connectors?

Inspecting the EPS motor’s wiring harness and connectors involves a detailed examination of the electrical connections:

-

Visual Inspection: Look for any signs of damage, such as frayed wires, cracked insulation, or bent connector pins.

alt: Damaged wiring harness of an electric power steering motor showing frayed wires and cracked insulation.

-

Check Connections: Ensure that all connectors are securely attached to the EPS motor and other components.

-

Test for Continuity: Use a multimeter to check the continuity of each wire in the harness. A lack of continuity indicates a break in the wire.

-

Inspect for Corrosion: Look for any signs of corrosion on the connector pins. Clean the pins with a wire brush or contact cleaner if necessary.

-

Perform Voltage Drop Test: With the circuit energized, measure the voltage drop across each connector. A high voltage drop indicates a poor connection.

Addressing wiring and connector issues can resolve many EPS problems and prevent future failures.

15. How to Test the EPS Torque Sensor?

Testing the EPS torque sensor involves several steps to ensure it is providing accurate readings:

- Locate the Torque Sensor: Identify the torque sensor, typically located on the steering column.

- Check Voltage: Use a multimeter to measure the voltage at the torque sensor’s power and signal wires with the ignition on.

- Monitor Signal: Use a scan tool to monitor the torque sensor’s output signal while turning the steering wheel. The signal should change smoothly and proportionally with the steering input.

- Compare Readings: Compare the sensor’s readings to the manufacturer’s specifications. Inaccurate readings indicate a faulty sensor.

- Calibrate Sensor: If necessary, use a scan tool to recalibrate the torque sensor.

A faulty torque sensor can cause uneven steering assist and other EPS issues, so accurate testing is crucial.

16. How to Diagnose a Lack of Power Assist in the EPS System?

Diagnosing a lack of power assist in the EPS system requires a systematic approach:

- Check for DTCs: Use a scan tool to check for any diagnostic trouble codes (DTCs) related to the EPS system.

- Inspect Power Supply: Verify that the EPS motor is receiving adequate power. Check the voltage at the motor’s power connector with the ignition on.

- Test Torque Sensor: Ensure that the torque sensor is functioning properly. Monitor its output signal while turning the steering wheel.

- Check Motor Function: Use a scan tool to command the EPS motor to operate. If the motor does not respond, it may be faulty.

- Inspect Wiring: Look for any damage or corrosion in the EPS system’s wiring harness.

By systematically checking these components, you can identify the cause of the lack of power assist and implement the appropriate repair.

17. How to Diagnose Uneven Steering Assist (Easier to Turn in One Direction)?

Diagnosing uneven steering assist involves checking several components:

-

Check Wheel Alignment: Ensure that the vehicle’s wheels are properly aligned. Misalignment can cause uneven steering feel.

alt: Technician checking the wheel alignment of a vehicle using specialized equipment to ensure proper steering.

-

Inspect Torque Sensor: Test the torque sensor to ensure it is providing accurate readings. A faulty torque sensor can cause uneven steering assist.

-

Check Steering Gear: Inspect the steering gear for any signs of damage or wear. A worn steering gear can cause uneven steering feel.

-

Test EPS Motor: Use a scan tool to command the EPS motor to operate in both directions. If the motor operates unevenly, it may be faulty.

-

Inspect Wiring: Look for any damage or corrosion in the EPS system’s wiring harness.

Addressing these issues can restore balanced steering and improve vehicle handling.

18. How to Troubleshoot Unusual Noises Coming from the EPS System?

Troubleshooting unusual noises from the EPS system requires careful inspection:

- Identify the Noise: Determine the type of noise (grinding, whining, clicking) and when it occurs (turning, driving straight).

- Inspect Steering Gear: Check the steering gear for any signs of wear or damage. Grinding noises may indicate a worn steering gear.

- Test EPS Motor: Listen to the EPS motor while it is operating. Whining noises may indicate a faulty motor.

- Check Steering Column: Inspect the steering column for any loose components or worn bearings. Clicking noises may indicate a problem with the steering column.

- Inspect Wiring: Look for any loose or damaged wiring that may be causing electrical interference.

Accurately identifying the source of the noise is the first step toward resolving the issue and restoring quiet operation.

19. How to Recalibrate the EPS Torque Sensor?

Recalibrating the EPS torque sensor is necessary after replacement or when steering issues arise:

- Connect Scan Tool: Plug a diagnostic scan tool into the vehicle’s OBD-II port.

- Access EPS System: Navigate to the EPS system in the scan tool’s menu.

- Select Calibration Function: Choose the option to recalibrate the torque sensor.

- Follow Instructions: Follow the scan tool’s instructions for the calibration procedure. This typically involves turning the steering wheel to specific positions.

- Verify Calibration: After calibration, verify that the torque sensor is providing accurate readings.

Proper calibration ensures that the EPS system provides the correct amount of steering assist, improving vehicle handling and driver comfort.

20. What are the Safety Precautions to Take When Working on the EPS System?

When working on the EPS system, it is essential to take the following safety precautions:

- Disconnect Battery: Disconnect the vehicle’s battery to prevent electrical shocks and accidental activation of the EPS motor.

- Wear Safety Glasses: Wear safety glasses to protect your eyes from debris and chemicals.

- Use Proper Tools: Use the correct tools for the job to prevent damage to the EPS system and injury to yourself.

- Consult Service Manual: Refer to the vehicle’s service manual for specific safety procedures and warnings.

- Work in a Safe Area: Work in a well-lit and ventilated area.

Following these precautions will help ensure a safe and successful repair of the EPS system.

21. When Should You Replace the EPS Motor?

You should consider replacing the EPS motor under the following conditions:

- Motor Failure: The EPS motor is completely non-functional.

- Internal Damage: There is internal damage to the motor, such as burnt windings or broken components.

- Excessive Wear: The motor shows signs of excessive wear, such as worn brushes or bearings.

- Persistent Issues: The EPS system continues to malfunction despite troubleshooting and repairs.

- Diagnostic Codes: Specific diagnostic trouble codes (DTCs) indicate a motor failure.

Replacing a faulty EPS motor ensures reliable steering assistance and improves vehicle safety.

22. What are the Steps for Replacing the EPS Motor?

Replacing the EPS motor involves several steps:

- Disconnect Battery: Disconnect the vehicle’s battery to prevent electrical shocks.

- Remove Components: Remove any components that are blocking access to the EPS motor, such as trim panels or other parts.

- Disconnect Wiring: Disconnect the electrical connectors from the EPS motor.

- Remove Mounting Bolts: Remove the bolts that secure the EPS motor to the steering column or rack.

- Install New Motor: Install the new EPS motor, ensuring it is properly aligned and secured.

- Reconnect Wiring: Reconnect the electrical connectors to the EPS motor.

- Reinstall Components: Reinstall any components that were removed to access the EPS motor.

- Reconnect Battery: Reconnect the vehicle’s battery.

- Calibrate System: Calibrate the EPS system using a diagnostic scan tool.

Following these steps ensures a successful replacement of the EPS motor and restores proper steering function.

23. What are the Best Practices for Maintaining the EPS System?

Best practices for maintaining the EPS system include:

- Regular Inspections: Periodically inspect the EPS system for any signs of damage or wear.

- Check Wiring: Inspect the wiring harness for frayed wires, loose connections, or corrosion.

- Monitor Performance: Pay attention to the steering feel and listen for any unusual noises.

- Keep Components Clean: Keep the EPS motor and related components clean and free from debris.

- Address Issues Promptly: Address any EPS issues promptly to prevent further damage and ensure driver safety.

Regular maintenance helps prolong the life of the EPS system and ensures reliable steering performance.

24. How Does Temperature Affect the Performance of the EPS Motor?

Temperature can significantly affect the performance of the EPS motor:

- High Temperatures: High temperatures can cause the EPS motor to overheat, reducing its efficiency and potentially causing it to shut down.

- Low Temperatures: Low temperatures can increase the viscosity of the grease inside the motor, making it harder to turn and reducing its performance.

- Extreme Conditions: Extreme temperature fluctuations can cause components to expand and contract, leading to wear and damage.

According to a study by the University of Alaska Fairbanks in January 2024, maintaining the EPS system within its optimal temperature range is crucial for reliable performance.

25. What is the Role of the EPS Control Module (ECU)?

The EPS control module (ECU) plays a central role in the EPS system:

- Data Processing: It processes data from various sensors, including the torque sensor and wheel speed sensor.

- Motor Control: It controls the operation of the EPS motor, adjusting the amount of steering assist based on driving conditions.

- Fault Detection: It monitors the EPS system for faults and stores diagnostic trouble codes (DTCs).

- Communication: It communicates with other vehicle systems, such as the engine control unit (ECU) and anti-lock braking system (ABS).

The EPS control module (ECU) is essential for providing precise and reliable steering assistance.

26. How to Update the EPS Control Module (ECU) Software?

Updating the EPS control module (ECU) software can improve performance and address known issues:

- Connect Scan Tool: Plug a diagnostic scan tool into the vehicle’s OBD-II port.

- Access EPS System: Navigate to the EPS system in the scan tool’s menu.

- Select Software Update: Choose the option to update the ECU software.

- Follow Instructions: Follow the scan tool’s instructions for the update procedure. This typically involves downloading the latest software from the manufacturer’s website.

- Verify Update: After the update, verify that the EPS system is functioning properly.

Regular software updates can enhance the performance and reliability of the EPS system.

27. Can Aftermarket Modifications Affect the EPS System?

Yes, aftermarket modifications can affect the EPS system:

- Suspension Modifications: Lowering or lifting the vehicle can change the steering geometry and affect the EPS system’s performance.

- Wheel and Tire Modifications: Installing larger or wider wheels and tires can increase the load on the EPS motor and affect its operation.

- Performance Tuning: Modifying the engine or transmission can affect the vehicle’s speed and torque, which can impact the EPS system.

It is essential to ensure that any aftermarket modifications are compatible with the EPS system and do not compromise its performance or safety.

28. How Does Vehicle Speed Affect the EPS Motor?

Vehicle speed significantly affects the EPS motor:

- Low Speeds: At low speeds, the EPS motor provides maximum assistance to make steering easier for parking and maneuvering.

- High Speeds: At high speeds, the EPS motor reduces assistance to improve stability and prevent oversteering.

- Variable Assistance: The EPS system adjusts the amount of assistance based on vehicle speed to provide optimal steering feel and control.

This variable assistance ensures that the driver has the appropriate level of steering control in all driving conditions.

29. What is the Relationship Between EPS and Vehicle Stability Control (VSC)?

The EPS and Vehicle Stability Control (VSC) systems work together to enhance vehicle safety:

- Corrective Steering: The VSC system can use the EPS system to provide corrective steering inputs to help the driver maintain control during a skid or loss of traction.

- Enhanced Stability: By integrating with the EPS system, the VSC system can provide more precise and effective control, improving overall vehicle stability.

- Integrated Control: The EPS and VSC systems share data and work together to optimize vehicle handling and safety.

This integration of systems enhances vehicle stability and helps prevent accidents.

30. How to Find a Reputable EPS Repair Shop?

Finding a reputable EPS repair shop involves several steps:

- Check for Certification: Look for shops that are certified by organizations such as the National Institute for Automotive Service Excellence (ASE).

- Read Reviews: Read online reviews to get an idea of the shop’s reputation and quality of work.

- Ask for Recommendations: Ask friends, family, or colleagues for recommendations.

- Verify Experience: Ensure that the shop has experience working on EPS systems, especially for your vehicle’s make and model.

- Inquire About Warranty: Ask about the shop’s warranty policy for EPS repairs.

Choosing a reputable repair shop ensures that your EPS system is properly diagnosed and repaired.

31. How Much Does it Cost to Repair or Replace an EPS Motor?

The cost to repair or replace an EPS motor can vary depending on several factors:

- Vehicle Make and Model: The cost of parts and labor can vary depending on the vehicle’s make and model.

- Type of Repair: Minor repairs, such as wiring or connector issues, may be less expensive than replacing the entire motor.

- Parts Availability: The availability and cost of replacement parts can affect the overall cost.

- Labor Rates: Labor rates vary depending on the repair shop’s location and expertise.

According to estimates from RepairPal in September 2023, the average cost to replace an EPS motor ranges from $800 to $1500, including parts and labor.

32. What is the Lifespan of an EPS Motor?

The lifespan of an EPS motor can vary depending on several factors:

- Driving Conditions: Harsh driving conditions, such as frequent off-roading or extreme temperatures, can shorten the lifespan of the motor.

- Maintenance: Regular maintenance, such as inspecting and cleaning the EPS system, can help prolong its lifespan.

- Component Quality: The quality of the EPS motor and related components can affect its durability.

- Vehicle Usage: High mileage vehicles may experience more wear and tear on the EPS system.

On average, an EPS motor can last between 100,000 and 150,000 miles.

33. What are the Latest Advancements in EPS Technology?

The latest advancements in EPS technology include:

- Brushless Motors: Brushless EPS motors offer improved efficiency, reliability, and lifespan compared to traditional brushed motors.

- Torque Overlay: Torque overlay technology allows the EPS system to provide additional steering assist in specific situations, such as during emergency maneuvers.

- Advanced Control Algorithms: Advanced control algorithms improve the precision and responsiveness of the EPS system, providing a more natural and intuitive steering feel.

- Integration with ADAS: Integration with Advanced Driver Assistance Systems (ADAS) allows the EPS system to work in conjunction with features such as lane keep assist and automatic emergency steering.

These advancements are enhancing the performance, safety, and functionality of EPS systems.

34. How to Choose the Right Replacement EPS Motor?

Choosing the right replacement EPS motor involves several considerations:

- Compatibility: Ensure that the replacement motor is compatible with your vehicle’s make, model, and year.

- Quality: Choose a high-quality replacement motor from a reputable manufacturer.

- Warranty: Look for a replacement motor that comes with a warranty.

- Specifications: Verify that the replacement motor meets or exceeds the original equipment manufacturer (OEM) specifications.

- Reviews: Read online reviews to get an idea of the replacement motor’s performance and reliability.

Selecting the right replacement EPS motor ensures proper fit, function, and durability.

35. What are the Environmental Benefits of EPS Systems?

EPS systems offer several environmental benefits:

- Reduced Fuel Consumption: EPS systems consume less energy than traditional hydraulic systems, reducing fuel consumption and emissions.

- No Hydraulic Fluid: EPS systems do not use hydraulic fluid, eliminating the risk of leaks and environmental contamination.

- Lighter Weight: EPS systems are typically lighter than hydraulic systems, contributing to overall vehicle weight reduction and improved fuel efficiency.

- Recyclable Components: Many of the components in EPS systems are recyclable, reducing waste and promoting sustainability.

These environmental benefits make EPS systems a more eco-friendly choice than hydraulic systems.

36. How Do Self-Steering Systems Utilize EPS Technology?

Self-steering systems rely heavily on EPS technology:

- Precise Control: EPS systems provide the precise steering control necessary for self-steering systems to operate accurately.

- Automated Steering: Self-steering systems use the EPS motor to automatically steer the vehicle, following pre-programmed routes or responding to sensor inputs.

- Integration with Sensors: Self-steering systems integrate with sensors such as cameras and radar to detect lane markings, obstacles, and other vehicles.

- Enhanced Safety: By providing precise and automated steering control, self-steering systems can enhance vehicle safety and prevent accidents.

EPS technology is essential for enabling self-steering capabilities in modern vehicles.

37. What Future Innovations Can We Expect in EPS Technology?

Future innovations in EPS technology may include:

- Artificial Intelligence (AI): AI-powered EPS systems could learn from driver behavior and adapt to individual driving styles.

- Haptic Feedback: Haptic feedback technology could provide drivers with more intuitive and informative steering feedback.

- Wireless Control: Wireless EPS systems could eliminate the need for physical connections, reducing weight and complexity.

- Energy Harvesting: Energy harvesting technology could capture energy from the vehicle’s motion and use it to power the EPS system.

These innovations promise to further enhance the performance, safety, and efficiency of EPS systems.

38. Why Should You Choose CARDIAGTECH.NET for Your EPS Diagnostic Needs?

Choosing CARDIAGTECH.NET for your EPS diagnostic needs offers several advantages:

- High-Quality Tools: CARDIAGTECH.NET provides a wide range of high-quality diagnostic tools specifically designed for EPS systems.

- Expert Support: Our team of experts can provide technical support and guidance to help you diagnose and repair EPS issues.

- Competitive Prices: CARDIAGTECH.NET offers competitive prices on all of our diagnostic tools and equipment.

- Comprehensive Solutions: We provide comprehensive solutions for all your EPS diagnostic needs, from scan tools to wiring diagrams.

- Customer Satisfaction: At CARDIAGTECH.NET, we are committed to customer satisfaction and strive to provide the best possible service.

Investing in diagnostic tools and repair equipment from CARDIAGTECH.NET can significantly improve your efficiency and the quality of your service, keeping your customers satisfied and safe.

Don’t let EPS issues slow you down. Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States, or via Whatsapp at +1 (641) 206-8880, or visit our website at CARDIAGTECH.NET for expert advice and top-quality diagnostic tools. Solve your challenges and elevate your service today.

FAQ: Electric Power Steering (EPS) Motor

- What is the main function of an electric power steering (EPS) motor?

The primary function of an electric power steering (EPS) motor is to provide steering assistance to the driver by reducing the effort required to turn the steering wheel, enhancing maneuverability and control. - How can I tell if my EPS motor is failing?

Signs of a failing EPS motor include a stiff steering wheel, uneven steering assist, the EPS warning light illuminating, a complete loss of power assist, and unusual noises when turning the steering wheel. - What tools do I need to check the EPS motor?

To check the EPS motor, you’ll need a diagnostic scan tool, a multimeter, a socket set, a wiring diagram, and a service manual. - Can I repair an EPS motor myself, or should I take it to a professional?

While some basic checks can be done yourself, diagnosing and repairing EPS systems often requires specialized tools and expertise, so it’s best to consult a professional. - What does a C1511 diagnostic trouble code indicate for EPS systems?

A C1511 code indicates a malfunction with the torque sensor in the EPS system, which can affect the amount of steering assistance provided. - How often should I inspect my EPS system?

You should inspect your EPS system regularly, ideally during routine vehicle maintenance checks, or whenever you notice any unusual steering behavior. - What safety precautions should I take when working on the EPS system?

Always disconnect the vehicle’s battery, wear safety glasses, use proper tools, and refer to the vehicle’s service manual for specific safety procedures. - How does vehicle speed affect the performance of the EPS motor?

At low speeds, the EPS motor provides maximum assistance, while at high speeds, it reduces assistance to improve stability and prevent oversteering. - What is the average lifespan of an EPS motor?

On average, an EPS motor can last between 100,000 and 150,000 miles, depending on driving conditions and maintenance. - What are some of the latest advancements in EPS technology?

Latest advancements include brushless motors, torque overlay, advanced control algorithms, and integration with Advanced Driver Assistance Systems (ADAS), enhancing performance and safety.