How to Check the Mechanical Components of the Parking Brake System?

Are you concerned about the effectiveness of your vehicle’s parking brake system? At CARDIAGTECH.NET, we understand the importance of a properly functioning parking brake for the safety and security of your vehicle. In this guide, we’ll cover how to check the mechanical components of the parking brake system, ensuring it performs reliably when needed. Let’s explore the intricacies of parking brake mechanisms, troubleshooting techniques, and component assessments to elevate your expertise in vehicle maintenance. We’ll also touch on common problems, maintenance procedures, and the tools you’ll need, including some available at CARDIAGTECH.NET, to keep your parking brake system in top condition.

1. Understanding the Parking Brake System

What is the parking brake system and why is it important? The parking brake system, also known as the emergency brake, is a crucial safety feature in every vehicle. It’s designed to keep the vehicle stationary when parked, especially on inclines, preventing it from rolling away.

1.1. Definition and Purpose

The parking brake system is an independent braking system that mechanically applies the brakes, typically on the rear wheels. According to a study by the National Highway Traffic Safety Administration (NHTSA) in 2020, a malfunctioning parking brake can lead to vehicle rollaway, causing accidents and injuries. The primary purpose is to hold the vehicle securely in place when parked, providing a reliable alternative to the hydraulic service brakes. It is activated manually, using a lever, pedal, or button, and operates independently from the primary braking system.

1.2. Types of Parking Brake Systems

What are the different types of parking brake systems? There are several types of parking brake systems, each with its unique design and functionality. Understanding these differences is crucial for effective inspection and maintenance.

| Type of Parking Brake | Description | Advantages | Disadvantages |

|---|---|---|---|

| Mechanical Lever/Cable | This is the most common type, using a hand lever or foot pedal connected to the rear brakes via cables. When engaged, the lever pulls the cables, activating the brake shoes or calipers. | Simple design, easy to maintain, cost-effective. | Can stretch or break over time, requiring adjustment or replacement. Susceptible to corrosion. |

| Electric Parking Brake (EPB) | EPB systems use an electric motor to engage the brakes. Activated by a button, the motor tightens the brake cables or directly applies pressure to the brake calipers. According to a report by Bosch in 2022, EPB systems improve safety by providing consistent braking force and can be integrated with other vehicle safety systems. | More precise, integrates with vehicle electronics, reduces driver effort. | More complex, requires specialized tools for maintenance, can be more expensive to repair. |

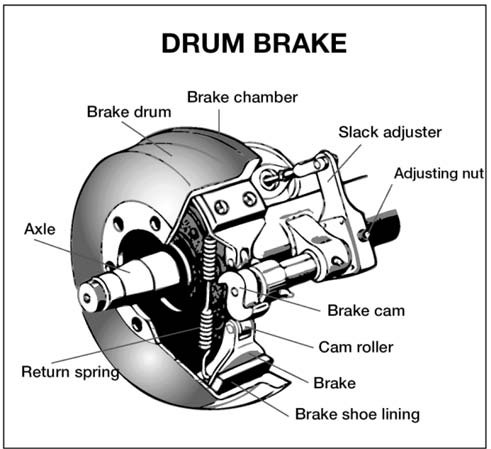

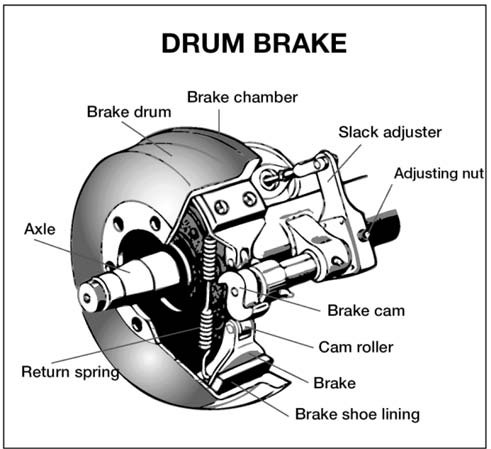

| Drum Brakes | In vehicles with drum brakes, the parking brake typically uses the same brake shoes as the service brakes. When the parking brake is engaged, a mechanical linkage forces the shoes against the drum. A 2018 study by the Society of Automotive Engineers (SAE) found that drum brakes are still common in many vehicles due to their cost-effectiveness and reliability. | Cost-effective, simple design. | Can be less effective in wet conditions, prone to fading with heavy use. |

| Disc Brakes | For vehicles with disc brakes, the parking brake may use a separate, smaller drum brake inside the rotor hat or integrate directly with the caliper. Integrated systems use a mechanical mechanism to apply pressure to the brake pads. According to a 2021 article in “Car and Driver,” disc brakes offer better stopping power and heat dissipation compared to drum brakes, making them ideal for performance vehicles. | Better stopping power, improved heat dissipation. | More complex, can be more expensive to maintain. |

| Integrated Caliper | This type integrates the parking brake mechanism directly into the brake caliper. When activated, a screw or lever system applies pressure to the brake pads, clamping the rotor. ZF’s 2023 Automotive Technology Report highlights that integrated caliper systems are becoming increasingly popular due to their compact design and ease of integration with electronic control systems. | Compact design, integrates seamlessly with the braking system. | Can be more complex to repair, requiring specialized knowledge. |

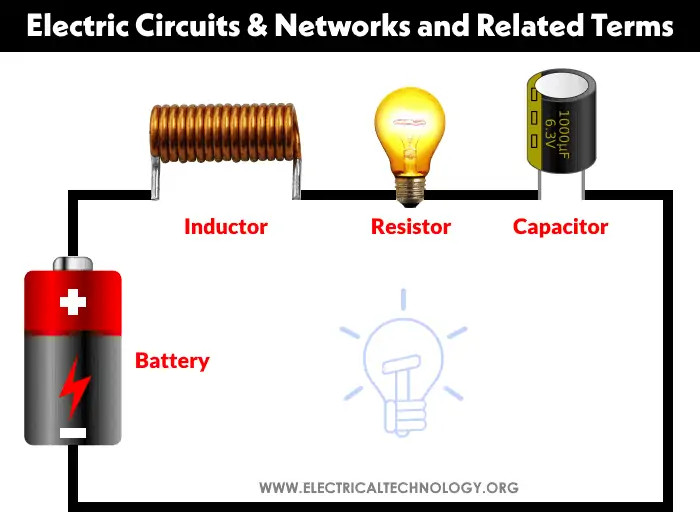

1.3. Common Mechanical Components

What are the key mechanical components of the parking brake system? Familiarizing yourself with these parts will assist you when assessing the parking brake.

- Cables: Connect the parking brake lever or pedal to the rear brakes.

- Lever or Pedal: The activation point for the parking brake system.

- Equalizer Bar: Balances the tension between the left and right brake cables.

- Brake Shoes or Pads: The friction materials that press against the drums or rotors.

- Springs: Return the brake components to their original position when the parking brake is released.

- Linkages: Mechanical connections that transfer force from the cables to the brakes.

- Actuators: Mechanisms that apply the brakes, such as cams or levers within the brake drum or caliper.

2. Identifying the Intent of Searching for Mechanical Component Checks

What are users hoping to achieve when searching for information on checking mechanical components? When users search for information on checking the mechanical components of the parking brake system, they typically have one of five primary intentions.

- Troubleshooting a Malfunctioning Parking Brake: Users often search when they notice their parking brake is not holding the vehicle properly, making noise, or is difficult to engage or release. They want to diagnose the cause of the problem.

- Performing Routine Maintenance: Some users search for this information as part of their regular vehicle maintenance routine to ensure the parking brake system remains in good working condition, preventing future issues.

- Preparing for a Vehicle Inspection: Vehicle owners often need to inspect their parking brake system to pass safety inspections. They seek detailed instructions on what to check and how to ensure compliance.

- DIY Repair: Many users prefer to fix their vehicles themselves to save money on labor costs. They search for guides and instructions to perform the necessary checks and repairs on the parking brake system.

- Understanding the System: Some users simply want to understand how the parking brake system works, its components, and how to identify potential problems. This knowledge helps them make informed decisions about maintenance and repairs.

3. Essential Tools and Equipment

What tools and equipment are required to check the mechanical components of the parking brake system? Having the right tools will make the inspection and maintenance easier. You can find many of these tools at CARDIAGTECH.NET.

3.1. Basic Hand Tools

- Wrench Set: For loosening and tightening bolts and nuts.

- Socket Set: Provides versatility for various fastener sizes.

- Screwdrivers: Both Phillips head and flathead screwdrivers are necessary.

- Pliers: For gripping and manipulating small parts.

- Hammer: For tapping components into place.

3.2. Specialty Tools

- Brake Spring Pliers: Used for removing and installing brake springs.

- Brake Spoon: Helps in adjusting brake shoes.

- Cable Tension Meter: Measures the tension in the parking brake cables.

- Wheel Chocks: Secures the vehicle during inspection and maintenance.

3.3. Diagnostic Equipment

- Multimeter: Tests electrical continuity and voltage in EPB systems.

- OBD-II Scanner: Reads diagnostic trouble codes (DTCs) in vehicles with EPB systems. According to a 2023 report by the Auto Care Association, using an OBD-II scanner can significantly reduce diagnostic time and improve accuracy.

3.4. Safety Gear

- Gloves: Protects hands from dirt, grease, and sharp edges.

- Safety Glasses: Prevents debris from entering the eyes.

- Jack Stands: Supports the vehicle safely after lifting.

4. Step-by-Step Guide to Checking Mechanical Components

How do you thoroughly inspect the mechanical components of the parking brake system? Follow these steps to conduct a comprehensive check of the parking brake system’s mechanical components.

4.1. Preparation

- Gather Tools and Equipment: Ensure you have all necessary tools and safety gear.

- Secure the Vehicle: Park the vehicle on a level surface, engage the parking brake, and use wheel chocks to prevent movement.

- Lift the Vehicle: Use a jack to lift the vehicle and secure it with jack stands. Never work under a vehicle supported only by a jack.

4.2. Visual Inspection

- Inspect Cables: Check the parking brake cables for signs of damage, such as fraying, corrosion, or kinks.

- Examine Linkages: Look for bent, broken, or missing linkages. Ensure all connections are secure.

- Check Springs: Verify that all springs are intact and properly positioned.

- Inspect Brake Shoes or Pads: Check the thickness of the brake shoes or pads. Replace if they are worn below the recommended minimum.

- Examine Brake Drums or Rotors: Look for cracks, excessive rust, or scoring on the brake drums or rotors.

4.3. Cable Inspection and Adjustment

- Check Cable Tension: Use a cable tension meter to measure the tension in the parking brake cables. Compare the reading to the manufacturer’s specifications.

- Adjust Cable Tension: If the tension is incorrect, adjust the cable using the adjuster nut or mechanism. Refer to the vehicle’s service manual for the correct procedure. According to a 2022 study by ASE, proper cable tension is critical for the parking brake to function effectively.

- Lubricate Cables: Apply lubricant to the cables to prevent corrosion and ensure smooth operation.

4.4. Lever or Pedal Inspection

- Check for Smooth Operation: Ensure the parking brake lever or pedal moves smoothly without binding or excessive resistance.

- Inspect the Latch Mechanism: Verify that the latch mechanism engages securely and releases properly.

- Adjust Lever or Pedal Travel: If necessary, adjust the lever or pedal travel to ensure proper engagement.

4.5. Brake Component Inspection (Drum Brakes)

- Remove Brake Drum: Carefully remove the brake drum to access the internal components.

- Inspect Brake Shoes: Check the brake shoes for wear, cracks, or contamination.

Brake shoe wear

Brake shoe wear - Examine Springs and Linkages: Inspect the springs, linkages, and adjusters for damage or wear.

- Clean and Lubricate: Clean the brake components and apply brake grease to the appropriate contact points.

- Reassemble: Reassemble the brake drum, ensuring all parts are correctly positioned.

4.6. Brake Component Inspection (Disc Brakes)

- Inspect Brake Pads: Check the brake pads for wear and damage.

- Examine Caliper Mechanism: Inspect the caliper mechanism for corrosion or binding.

- Check Rotor Condition: Verify the rotor is free from cracks, excessive rust, or scoring.

- Lubricate Sliding Surfaces: Apply brake lubricant to the sliding surfaces of the caliper and brake pads.

- Reassemble: Reassemble the brake components, ensuring proper alignment.

4.7. Testing the Parking Brake

- Engage the Parking Brake: Engage the parking brake fully.

- Attempt to Move the Vehicle: Try to move the vehicle forward and backward to ensure the parking brake is holding securely.

- Test on an Incline: If possible, test the parking brake on a moderate incline to verify its holding ability.

- Release the Parking Brake: Ensure the parking brake releases completely and the wheels are free to rotate.

5. Addressing Common Issues

What are the typical problems encountered with parking brake systems and how can you fix them? Knowing how to troubleshoot common issues can save time and effort.

5.1. Parking Brake Not Holding

- Worn Brake Shoes or Pads: Replace worn brake shoes or pads.

- Stretched or Damaged Cables: Adjust or replace the parking brake cables.

- Incorrect Cable Tension: Adjust the cable tension to the manufacturer’s specifications.

- Contaminated Brake Surfaces: Clean the brake drums or rotors and replace contaminated brake shoes or pads.

5.2. Parking Brake Sticking or Binding

- Corroded Cables: Lubricate or replace corroded cables.

- Binding Linkages: Clean and lubricate the linkages.

- Seized Caliper Mechanism: Rebuild or replace the caliper.

5.3. Parking Brake Lever or Pedal Too Loose or Too Tight

- Incorrect Cable Adjustment: Adjust the cable tension to the proper specification.

- Damaged Adjuster Mechanism: Replace the adjuster mechanism.

5.4. Electronic Parking Brake (EPB) Malfunctions

- Faulty Actuator Motor: Replace the actuator motor.

- Wiring Issues: Inspect and repair any damaged wiring or connections.

- Control Module Problems: Diagnose and reprogram or replace the control module. According to a 2020 report by AAA, electrical issues are a common cause of EPB malfunctions.

6. The Role of Anti-lock Braking Systems (ABS)

How does ABS affect the parking brake system? While ABS primarily enhances the service brakes, it can indirectly influence the parking brake system’s effectiveness.

6.1. ABS and Brake Performance

ABS prevents wheel lockup during hard braking, improving vehicle control. However, ABS does not directly affect the mechanical operation of the parking brake. A 2023 study by the Insurance Institute for Highway Safety (IIHS) found that vehicles with ABS have a lower incidence of accidents due to improved braking performance.

6.2. Integrated Systems

In some modern vehicles, the ABS and EPB systems are integrated. If the ABS system detects a fault, it may affect the EPB, and vice versa. Regular maintenance and diagnostic checks are essential to ensure both systems function correctly.

6.3. Diagnostic Considerations

When diagnosing parking brake issues, it’s essential to check for ABS-related fault codes. A malfunctioning ABS system can sometimes trigger false alarms or interfere with the operation of the EPB.

7. Safety Tips and Precautions

What safety measures should you take when working on the parking brake system? Always prioritize safety when inspecting and maintaining the parking brake system.

7.1. General Safety Guidelines

- Wear Safety Gear: Always wear gloves and safety glasses to protect yourself.

- Secure the Vehicle: Ensure the vehicle is properly supported with jack stands before working underneath.

- Disconnect the Battery: Disconnect the negative battery terminal to prevent electrical shorts.

- Work in a Well-Ventilated Area: If using cleaning solvents or lubricants, work in a well-ventilated area.

7.2. Specific Precautions

- Avoid Open Flames: Keep open flames away from brake components, especially when using flammable solvents.

- Proper Disposal: Dispose of used brake fluid and contaminated materials properly.

- Torque Specifications: Always tighten fasteners to the manufacturer’s specified torque to ensure proper function and prevent damage.

8. Maintenance Best Practices

What maintenance procedures should you follow to keep your parking brake system in optimal condition? Regular maintenance is key to extending the life and reliability of the parking brake system.

8.1. Regular Inspections

- Monthly Checks: Perform a visual inspection of the parking brake system monthly.

- Annual Service: Have the parking brake system professionally serviced annually.

8.2. Lubrication

- Cable Lubrication: Lubricate the parking brake cables every six months to prevent corrosion and ensure smooth operation.

- Component Lubrication: Apply brake grease to the appropriate contact points during brake service.

8.3. Adjustments

- Cable Adjustment: Adjust the parking brake cable tension as needed to maintain proper engagement.

- Brake Shoe Adjustment: Adjust the brake shoes periodically to compensate for wear.

8.4. Replacement Intervals

- Brake Shoes or Pads: Replace brake shoes or pads when they are worn below the recommended minimum thickness.

- Cables: Replace parking brake cables if they are frayed, corroded, or stretched.

- Springs: Replace any broken or weakened springs.

9. The Advantages of Purchasing Tools from CARDIAGTECH.NET

Why should you purchase your automotive tools from CARDIAGTECH.NET? When it comes to maintaining and repairing your vehicle’s parking brake system, having the right tools is essential. CARDIAGTECH.NET offers a wide range of high-quality tools and equipment designed to meet the needs of both professional mechanics and DIY enthusiasts. Here’s why CARDIAGTECH.NET should be your go-to source for automotive tools:

9.1. High-Quality Products

CARDIAGTECH.NET is committed to providing customers with top-of-the-line tools that are durable, reliable, and accurate. Our products are sourced from reputable manufacturers and undergo rigorous testing to ensure they meet the highest standards of quality. Whether you need a basic wrench set or a specialized diagnostic scanner, you can trust that CARDIAGTECH.NET offers products that will perform flawlessly.

9.2. Wide Selection

We understand that every automotive job is unique, which is why we offer an extensive selection of tools and equipment to cater to a variety of needs. From hand tools and power tools to diagnostic equipment and specialty items, CARDIAGTECH.NET has everything you need to tackle any parking brake system repair or maintenance task. Our comprehensive inventory ensures you can find the exact tool you need without having to shop around.

9.3. Competitive Pricing

At CARDIAGTECH.NET, we believe that high-quality tools should be accessible to everyone. That’s why we offer competitive pricing on all our products, ensuring you get the best value for your money. Our affordable prices, combined with frequent promotions and discounts, make it easier for you to invest in the tools you need without breaking the bank.

9.4. Expert Support

Navigating the world of automotive tools can be overwhelming, especially for those who are new to DIY repairs. That’s why CARDIAGTECH.NET provides expert support to help you make informed decisions. Our knowledgeable staff can answer your questions, offer product recommendations, and guide you through the selection process. We’re committed to ensuring you have the support you need to choose the right tools for your specific needs.

9.5. Convenient Shopping Experience

CARDIAGTECH.NET offers a seamless and convenient online shopping experience. Our user-friendly website allows you to easily browse our product catalog, compare different tools, and place your order with just a few clicks. We also provide detailed product descriptions, customer reviews, and how-to guides to help you make the right choice. With CARDIAGTECH.NET, you can shop for automotive tools from the comfort of your own home and have them delivered right to your doorstep.

9.6. Fast and Reliable Shipping

We understand that when you need a tool, you need it fast. That’s why CARDIAGTECH.NET offers fast and reliable shipping on all orders. We partner with trusted shipping providers to ensure your tools arrive on time and in perfect condition. Our efficient order processing and shipping system means you can get the tools you need quickly, allowing you to get back to work on your vehicle without delay.

9.7. Customer Satisfaction Guarantee

At CARDIAGTECH.NET, customer satisfaction is our top priority. We stand behind the quality of our products and are committed to ensuring you are completely satisfied with your purchase. If you’re not happy with your order for any reason, simply contact us, and we’ll do everything we can to make it right. Our customer satisfaction guarantee ensures you can shop with confidence, knowing that we’re always here to support you.

9.8. Building Trust and Credibility

CARDIAGTECH.NET is dedicated to building long-term relationships with our customers based on trust and credibility. We believe in transparency, honesty, and integrity in all our business dealings. Our commitment to providing accurate information, reliable products, and exceptional customer service has earned us a reputation as a trusted source for automotive tools. When you shop with CARDIAGTECH.NET, you can be confident that you’re working with a company that puts your needs first.

By choosing CARDIAGTECH.NET for your automotive tool needs, you’re investing in quality, reliability, and peace of mind. Whether you’re a professional mechanic or a DIY enthusiast, we have the tools and expertise to help you succeed.

10. How CARDIAGTECH.NET Can Help You

How can CARDIAGTECH.NET assist you with your parking brake system maintenance and repair needs? CARDIAGTECH.NET offers a range of products and services to support your automotive maintenance efforts.

10.1. Tool Selection

CARDIAGTECH.NET provides a curated selection of high-quality tools specifically designed for brake system maintenance. Our knowledgeable staff can assist you in choosing the right tools for your specific needs.

10.2. Diagnostic Equipment

We offer advanced diagnostic equipment, including OBD-II scanners and multimeters, to help you troubleshoot complex parking brake system issues.

10.3. Parts and Components

CARDIAGTECH.NET supplies a wide range of replacement parts, including brake shoes, pads, cables, and springs, ensuring you have everything you need to complete your repairs.

10.4. Technical Support

Our team of experienced technicians can provide technical support and guidance, helping you diagnose and resolve any issues you encounter during your maintenance or repair efforts.

FAQ: Checking Mechanical Components of the Parking Brake System

1. What is the main function of the parking brake system?

The primary function of the parking brake system is to hold the vehicle securely in place when parked, especially on inclines. According to a 2019 report by the National Safety Council, a properly functioning parking brake can prevent vehicle rollaway accidents.

2. How often should I inspect my parking brake system?

It is recommended to inspect your parking brake system at least once a month and have it professionally serviced annually.

3. What are the signs of a failing parking brake cable?

Signs of a failing parking brake cable include excessive slack, difficulty engaging the parking brake, and the parking brake not holding the vehicle securely.

4. Can I adjust the parking brake cable myself?

Yes, you can adjust the parking brake cable yourself using basic hand tools. Refer to your vehicle’s service manual for the correct procedure.

5. What is the recommended minimum thickness for brake shoes and pads?

The recommended minimum thickness for brake shoes and pads varies by vehicle. Consult your vehicle’s service manual for specific recommendations. Typically, brake pads should be replaced when they are less than 1/4 inch thick.

6. How do I lubricate the parking brake cables?

To lubricate the parking brake cables, use a cable lubricant and apply it to the cable through the cable housing. Ensure the lubricant penetrates the entire length of the cable.

7. What is an equalizer bar and what does it do?

An equalizer bar balances the tension between the left and right brake cables, ensuring even braking force on both sides of the vehicle.

8. How do I know if my vehicle has an Electronic Parking Brake (EPB)?

Vehicles with an EPB typically have a button or switch on the dashboard instead of a traditional lever or pedal.

9. What should I do if my EPB malfunctions?

If your EPB malfunctions, have it diagnosed by a qualified technician. EPB systems often require specialized diagnostic equipment.

10. Can a faulty ABS system affect the parking brake?

In some modern vehicles with integrated systems, a faulty ABS system can interfere with the operation of the EPB. It is essential to check for ABS-related fault codes when diagnosing parking brake issues.

By following this comprehensive guide, you can effectively check the mechanical components of your parking brake system, ensuring its reliability and safety. Remember, regular maintenance and prompt repairs are essential for maintaining a safe and dependable vehicle. For all your automotive tool needs, visit CARDIAGTECH.NET, where quality meets affordability. Contact us today for expert advice and support at 276 Reock St, City of Orange, NJ 07050, United States. Call us at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET. We are here to help you keep your vehicle running smoothly and safely.