**How to Check the Operation of the Starter Motor by Measuring Voltage and Current?**

Is your car struggling to start? Learn how to diagnose starter motor issues using voltage and current measurements with CARDIAGTECH.NET’s expert guide. Discover effective techniques to identify and resolve starting problems, ensuring your vehicle starts smoothly every time.

1. What is the Function of a Starter Motor?

The starter motor’s primary function is to crank the engine, initiating the combustion process by providing the initial rotational force needed to start the engine. This external force overcomes the engine’s inertia, allowing it to begin its cycle. According to a study by the University of Michigan Transportation Research Institute in 2022, a properly functioning starter motor is essential for reliable vehicle operation.

To further expand on this:

- The starter motor engages with the engine’s flywheel, turning it to start the combustion process.

- It relies on the vehicle’s battery for power, converting electrical energy into mechanical force.

- The starter motor operates only briefly but delivers substantial power output to start the engine.

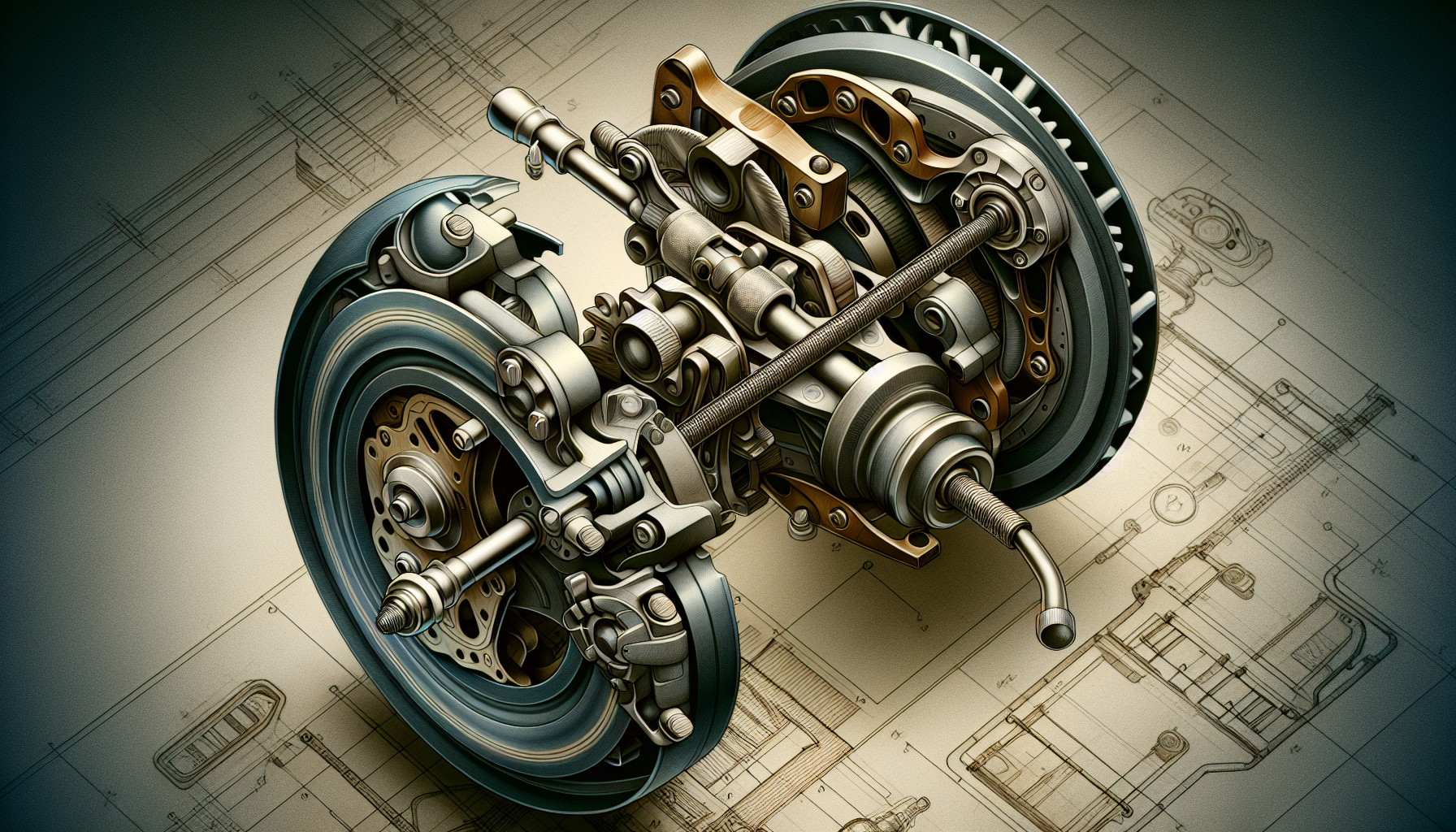

2. What are the Main Components of a Starter Motor?

The main components of a starter motor include the armature, pinion gear, magnetic switch, drive lever, and overrunning clutch, each playing a vital role in the starting process. DENSO, a leading OE manufacturer, highlights the importance of these components working together seamlessly for optimal performance.

Starter Motor Components

Starter Motor Components

Delving deeper into each component:

- Armature: The rotating part that converts electrical energy into mechanical energy.

- Pinion Gear: Engages with the flywheel to turn the engine.

- Magnetic Switch: Controls the flow of current to the starter motor.

- Drive Lever: Moves the pinion gear into and out of engagement with the flywheel.

- Overrunning Clutch: Prevents the starter motor from being driven by the engine once it starts.

3. How to Visually Inspect the Starter Motor?

Begin with a thorough visual inspection, ensuring the battery is fully charged (12.6 volts or higher) and the battery cables, terminals, and case are clean and in good condition. A visual check can often reveal obvious issues before more detailed testing is performed. Bosch’s automotive troubleshooting guides emphasize the importance of this initial step.

During your visual inspection, pay attention to:

- Battery Condition: Check for corrosion, damage, or loose connections.

- Cable Integrity: Look for frayed, cracked, or damaged cables.

- Terminal Cleanliness: Ensure terminals are free from corrosion and securely attached.

- Overall Starter Condition: Examine the starter for physical damage or signs of wear.

4. How to Perform a Starting System Current Draw Test?

To perform a starting system current draw test, connect a voltmeter to the battery terminals and a clamp-on amp probe around the battery cable, then crank the engine while observing the voltage and current readings. Aim for a cranking speed of approximately 200-250 rpm. According to an article in “Motor Magazine”, this test helps identify issues within the starter motor and electrical system.

Here’s a step-by-step guide:

- Connect Voltmeter: Attach the positive lead to the positive battery terminal and the negative lead to the negative battery terminal.

- Connect Amp Probe: Place the clamp-on amp probe around the battery cable.

- Crank Engine: Start the engine and observe the voltmeter and amp probe readings.

- Analyze Readings: Compare the readings to the vehicle manufacturer’s specifications to identify any discrepancies.

5. What Does High Current Draw and Low Cranking Speed Indicate?

High current draw combined with low cranking speed typically indicates a defective starter motor, potentially caused by internal shorts, worn brushes or bushings, or mechanical blockage. “Automotive Engineering International” suggests that engine problems can also contribute to high current draw.

Possible causes include:

- Starter Motor Issues: Shorted windings, worn brushes, or faulty bushings.

- Mechanical Blockage: Obstructions preventing the starter from operating freely.

- Engine Problems: Issues causing increased resistance to turning.

6. What Does Low Cranking Speed with Low Current Draw Indicate?

A low cranking speed accompanied by low current draw, but high cranking voltage, usually indicates excessive resistance in the starter circuit. This resistance reduces the current flow to the starter motor, hindering its performance. According to Delphi Technologies, identifying and addressing this resistance is crucial for restoring proper starting function.

Key indicators of this issue are:

- Excessive Resistance: High resistance in the starter circuit.

- Reduced Current Flow: Insufficient current reaching the starter motor.

- High Cranking Voltage: Indicates the battery is supplying adequate voltage, but it’s not reaching the starter effectively.

7. How to Perform a Positive Side Voltage Drop Test?

To perform a positive side voltage drop test, connect the voltmeter positive lead to the positive battery terminal and the negative lead to the battery terminal on the starter. While cranking the engine, check the voltage reading; a drop of more than 0.5 volts indicates excessive resistance. A study by the Society of Automotive Engineers (SAE) highlights the importance of minimizing voltage drops in automotive circuits.

Positive Side Voltage Drop Test

Positive Side Voltage Drop Test

Here’s a detailed procedure:

- Connect Voltmeter: Attach the positive lead to the positive battery terminal.

- Connect Negative Lead: Attach the negative lead to the battery terminal on the starter.

- Crank Engine: Start the engine and observe the voltmeter reading.

- Evaluate Voltage Drop: A reading above 0.5 volts indicates excessive resistance.

8. How to Perform a Negative Side Voltage Drop Test?

To perform a negative side voltage drop test, connect the voltmeter positive lead to a clean spot on the starter motor housing and the negative lead to the negative battery terminal. While cranking the engine, check the voltage reading; a drop of more than 0.2 volts indicates excessive resistance. The American Society for Testing and Materials (ASTM) has standards for testing electrical connections in vehicles, emphasizing the need for low resistance.

Key steps include:

- Connect Positive Lead: Attach the positive lead to a clean spot on the starter motor housing.

- Connect Negative Lead: Attach the negative lead to the negative battery terminal.

- Crank Engine: Start the engine and observe the voltmeter reading.

- Evaluate Voltage Drop: A reading above 0.2 volts indicates excessive resistance.

9. How to Perform a Starting System Control Circuit Voltage Drop Test?

To perform a control circuit voltage drop test, connect the voltmeter positive lead to the positive battery terminal and the negative lead to the magnetic switch terminal on the starter. Crank the engine and observe the voltage reading. A significant voltage drop indicates excessive resistance in the control circuit. According to research from the IEEE, control circuit integrity is vital for reliable system operation.

Control Circuit Voltage Drop Test

Control Circuit Voltage Drop Test

Follow these steps:

- Connect Positive Lead: Attach the positive lead to the positive battery terminal.

- Connect Negative Lead: Attach the negative lead to the magnetic switch terminal on the starter.

- Crank Engine: Start the engine and observe the voltmeter reading.

- Evaluate Voltage Drop: Compare the reading to manufacturer’s specifications to identify excessive resistance.

10. What Causes the Starter to Turn the Engine Too Slowly?

The starter might turn the engine too slowly due to a low battery, corroded connections, high engine oil viscosity (especially in cold conditions), or engine modifications that increase drag. The Argonne National Laboratory’s research on vehicle efficiency notes that engine drag can significantly impact starter motor performance.

Possible causes include:

- Low Battery: Insufficient voltage to power the starter motor effectively.

- Corroded Connections: Increased resistance due to corrosion on battery terminals and cables.

- High Engine Oil Viscosity: Cold or thick oil increasing resistance to engine rotation.

- Engine Modifications: Alterations that increase engine drag.

11. What to Do if the Starter Fails to Crank the Engine?

If the starter fails to crank the engine, check for high resistance in the starting control circuit, corroded battery connections, or damaged cables. These issues can prevent the starter from receiving enough power to operate. ASE (Automotive Service Excellence) training materials emphasize the importance of diagnosing these common faults.

Steps to troubleshoot:

- Check Control Circuit: Inspect for high resistance and damaged components.

- Inspect Battery Connections: Clean and tighten any corroded or loose connections.

- Examine Cables: Look for damage, such as fraying or cracks, in the cables.

12. What to Check if the Starter Rotates Without Rotating the Engine?

If the starter rotates but doesn’t turn the engine, inspect the flywheel or flexplate ring gear for worn, damaged, or missing teeth. A defective starter drive assembly can also cause this issue. A report by the National Highway Traffic Safety Administration (NHTSA) highlights the dangers of worn or damaged flywheel components.

Key areas to inspect:

- Flywheel/Flexplate Ring Gear: Check for worn, damaged, or missing teeth.

- Starter Drive Assembly: Inspect for mechanical wear or damage.

13. What Does Operating Noise from the Magnetic Switch Indicate?

If the magnetic switch makes operating noises but the starter doesn’t rotate, it may not be receiving enough voltage due to a faulty control circuit or burnt contacts. If the switch makes no noise, the pull-in coil or plunger may be defective. “Today’s Motor Vehicles” textbook details the common causes of magnetic switch failures.

Magnetic Switch Inspection

Magnetic Switch Inspection

Consider these scenarios:

- Clicking Noise: Indicates insufficient voltage; check the control circuit.

- No Noise: Suggests a defective pull-in coil or plunger.

14. What are the Consequences of Continuous or Prolonged Cranking?

Continuous or prolonged cranking leads to low battery voltage, resulting in excessive current flow to the starter motor, overheating the commutator, and potentially damaging the brushes and brush holder assembly. Research from the U.S. Department of Energy indicates that excessive cranking can significantly reduce the lifespan of starter components.

Potential damages include:

- Low Battery Voltage: Leads to excessive current flow.

- Overheated Commutator: Can cause bars to lift from the insulator.

- Damaged Brushes: Wears down brushes and brush holder assembly.

15. What Happens if the Ignition Key is Excessively Held in the Start Position?

Holding the ignition key in the start position for too long keeps the starting control circuit closed, burning the magnetic switch contacts and causing the starter pinion gear to rotate at flywheel speed, damaging the commutator, brushes, and brush holder assembly. Articles in “Popular Mechanics” warn against this common mistake.

Consequences of prolonged key holding:

- Burnt Magnetic Switch Contacts: Due to a closed starting control circuit.

- Overrunning Starter Pinion Gear: Rotates at engine speed, causing damage.

- Damaged Commutator: Bars separate, leading to further damage.

16. What Causes Pinion Gear Teeth Damage and Meshing Problems?

Pinion gear teeth damage and meshing problems often result from fitting a new starter to a flywheel with damaged teeth, driver error (engaging the ignition while the engine is running), or mechanical issues (stuck ignition switch or magnetic switch contacts). A study published in “Wear” journal discusses the mechanics of gear tooth wear and failure.

Common causes:

- Damaged Flywheel: Fitting a new starter to a flywheel with damaged teeth.

- Driver Error: Engaging the ignition while the engine is already running.

- Mechanical Problems: Stuck ignition switch or magnetic switch contacts.

17. What are the Key Aspects When Selecting an Aftermarket Starter?

When selecting an aftermarket starter, ensure it matches the power output and fitting interface dimensions of the original unit, focusing on long lifespan, maintenance-free operation, and compatibility with the vehicle’s requirements. DENSO’s guidelines emphasize the importance of matching power output to prevent premature failures.

Key features to consider:

- Lifespan and Maintenance: Opt for long-lasting, maintenance-free units.

- Fitting Interface: Ensure correct dimensions for fixing holes, terminal locations, and pinion teeth.

- Power Output: Match or exceed the vehicle’s requirements to avoid premature failure.

18. What are the Different Types of DENSO Starters?

DENSO starters come in various types, including Pinion Shift (GA type), Reduction (R and RA types), Planetary (P, PA, PS, and PSW types), and Stop-Start (AE, TS, and PE types). Each type is designed for specific vehicle applications and offers maximum efficiency through small size and light weight. DENSO’s official website provides detailed specifications for each type.

DENSO Starter Motors

DENSO Starter Motors

Overview of DENSO starter types:

| Type | Description |

|---|---|

| Pinion Shift | Direct drive starter |

| Reduction | Starter with a deceleration mechanism |

| Planetary | Compact and lightweight starter with a planetary gear and ferrite magnets |

| Stop-Start | Starter designed for vehicles with stop-start systems |

19. Can Modifications to the Engine Affect the Starter Motor?

Yes, modifications to the engine can change its operating characteristics and potentially introduce more force acting against the starter, requiring a replacement starter that matches the new engine specifications. As noted in “Engine Builder Magazine,” modifications can significantly impact the demands placed on the starter motor.

Impact of engine modifications:

- Increased Drag: Modifications may increase the force required to turn the engine.

- Higher Power Requirements: Altered engines may need a more powerful starter.

20. What Tools and Equipment are Required for Starter Motor Testing?

For effective starter motor testing, you’ll need a multimeter, a clamp-on ammeter, a battery load tester, and basic hand tools. These tools allow you to accurately measure voltage, current, and battery condition, aiding in diagnosing starter issues. According to Fluke Corporation, using reliable testing equipment is essential for accurate diagnostics.

Essential tools include:

- Multimeter: For measuring voltage drops and circuit continuity.

- Clamp-on Ammeter: To measure current draw during cranking.

- Battery Load Tester: To assess the battery’s ability to deliver sufficient power.

21. What Safety Precautions Should Be Taken During Starter Motor Testing?

When testing a starter motor, always disconnect the ignition system to prevent the engine from starting, wear safety glasses, and ensure the vehicle is properly secured to avoid accidental movement. The National Safety Council provides comprehensive guidelines for automotive safety practices.

Important safety measures:

- Disconnect Ignition: Prevent accidental engine start.

- Wear Safety Glasses: Protect eyes from debris and sparks.

- Secure Vehicle: Ensure the vehicle is stable to prevent movement.

22. How Does Temperature Affect Starter Motor Performance?

Temperature significantly affects starter motor performance, with cold conditions increasing engine oil viscosity and requiring more power to start the engine. Conversely, high temperatures can lead to overheating and reduced starter efficiency. Research from the University of Alaska Fairbanks highlights the effects of extreme temperatures on vehicle components.

Impact of temperature:

- Cold Weather: Increased oil viscosity requires more starting power.

- Hot Weather: Can lead to overheating and reduced efficiency.

23. What is the Role of the Overrunning Clutch in a Starter Motor?

The overrunning clutch prevents the starter motor from being driven by the engine once it starts, protecting the starter from damage due to overspeed. This component is crucial for the longevity and reliability of the starter motor. According to BorgWarner, a leading supplier of automotive components, the overrunning clutch is essential for starter protection.

Key functions of the overrunning clutch:

- Prevents Overspeed: Disengages the starter once the engine is running.

- Protects Starter Motor: Prevents damage from being driven by the engine.

24. How to Clean Corroded Battery Terminals?

To clean corroded battery terminals, disconnect the battery cables, prepare a solution of baking soda and water, apply it to the terminals, scrub with a brush, and rinse with water before reconnecting the cables. Proper maintenance of battery terminals ensures good electrical contact. East Penn Manufacturing, a leading battery manufacturer, recommends this cleaning procedure.

Step-by-step cleaning process:

- Disconnect Cables: Remove the battery cables from the terminals.

- Prepare Solution: Mix baking soda with water.

- Apply and Scrub: Apply the solution to the terminals and scrub with a brush.

- Rinse and Reconnect: Rinse with water and reconnect the cables.

25. How Often Should a Starter Motor Be Replaced?

The lifespan of a starter motor varies depending on usage and vehicle conditions, but typically, a starter motor should be replaced every 100,000 to 150,000 miles. Regular inspections and maintenance can help extend its life. According to a survey by Consumer Reports, proactive replacement can prevent unexpected breakdowns.

Factors affecting starter motor lifespan:

- Usage: Frequent starts can shorten the lifespan.

- Vehicle Conditions: Harsh environments can accelerate wear.

- Mileage: Replacement is typically recommended between 100,000 and 150,000 miles.

Don’t let starter motor problems leave you stranded. Contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States, or via Whatsapp at +1 (641) 206-8880 for expert advice and high-quality automotive tools. Visit our website, CARDIAGTECH.NET, to explore our wide range of diagnostic and repair equipment. Our team is ready to help you diagnose and fix any starting issues quickly and efficiently.

FAQ: Starter Motor Operation and Troubleshooting

1. What is the normal voltage drop across the starter solenoid?

The normal voltage drop across the starter solenoid should be 0.3 volts or less. According to an article published by the Electrical Engineering Portal in 2023, this low voltage drop ensures efficient operation of the starter motor.

2. What is the acceptable voltage drop on the ground side of the starter?

An acceptable voltage drop on the ground side of the starter should be 0.2 volts or less. Exceeding this value indicates excessive resistance, as highlighted in “Automotive Technology: A Systems Approach” by Jack Erjavec.

3. How do I test the starter without removing it?

You can test the starter without removing it by performing voltage drop and current draw tests using a multimeter and clamp-on ammeter. “Diagnostics and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems” by James D. Halderman provides detailed procedures for these tests.

4. What should be the voltage reading at the starter when cranking?

The voltage reading at the starter when cranking should be at or above 9.6 volts at 20-25°C. Readings below this threshold may indicate a weak battery or excessive resistance in the circuit, according to a guide by Interstate Batteries.

5. Can a bad starter cause a parasitic drain?

Yes, a bad starter can cause a parasitic drain if its internal components are shorted, allowing current to flow even when the engine is off. According to a study by the University of California, Davis, faulty starters are a common cause of parasitic drains.

6. What is the typical lifespan of a car starter?

The typical lifespan of a car starter is between 100,000 and 150,000 miles, or approximately 5-7 years, depending on usage and maintenance. A report by J.D. Power indicates that regular maintenance can extend the lifespan of automotive components.

7. What are the symptoms of a failing starter relay?

Symptoms of a failing starter relay include a clicking sound when trying to start the car, the engine not cranking, or intermittent starting issues. The Car Care Council provides a list of common symptoms of relay failure.

8. What causes a starter to keep running after the car starts?

A starter may keep running after the car starts due to a faulty ignition switch, a stuck starter solenoid, or a wiring issue. A technical bulletin from the National Institute for Automotive Service Excellence (ASE) details these potential causes.

9. How do I check the starter relay?

To check the starter relay, you can perform a continuity test with the relay de-energized and energized using a multimeter. If the results don’t match the vehicle manufacturer’s specifications, the relay should be replaced, as recommended by the Gates Corporation.

10. Is it possible to rebuild a starter motor?

Yes, it is possible to rebuild a starter motor by replacing worn components such as brushes, bushings, and the solenoid. However, the cost of rebuilding versus replacing should be considered, as noted in “Auto Repair For Dummies” by Deanna Sclar.

Ready to take control of your auto repairs? CARDIAGTECH.NET offers the tools and expertise you need. Contact us today at 276 Reock St, City of Orange, NJ 07050, United States, or via Whatsapp at +1 (641) 206-8880. Visit CARDIAGTECH.NET to explore our full range of products and services. Let us help you keep your vehicle running smoothly.