How to Check the Operation of the Windshield Wiper Motor?

Windshield wiper motor operation check involves diagnosing the functionality of your car’s wiper system to ensure clear visibility. CARDIAGTECH.NET provides an in-depth guide to help you examine your wiper motor efficiently. By understanding the testing procedures, you can quickly resolve wiper issues and maintain a safe driving environment with automotive diagnostic tools, windshield wiper diagnosis, and automotive repair.

1. Understanding the Windshield Wiper System

The windshield wiper system is a crucial safety component of any vehicle, ensuring clear visibility during inclement weather. According to a study by the National Highway Traffic Safety Administration (NHTSA), visibility impairments due to weather conditions contribute to over 500,000 crashes annually. Therefore, maintaining a functional windshield wiper system is paramount.

1.1. Key Components of the Windshield Wiper System

The windshield wiper system consists of several key components:

- Wiper Motor: Provides the power to move the wiper blades across the windshield.

- Wiper Blades: Rubber blades that physically clear water, snow, and debris from the windshield.

- Wiper Arms: Metal arms that hold the wiper blades and apply pressure to the windshield.

- Wiper Linkage: A series of mechanical linkages that translate the motor’s rotational motion into the oscillating movement of the wiper arms.

- Wiper Switch: Located inside the vehicle, allowing the driver to control the wiper speed and operation.

- Washer Fluid Reservoir and Pump: Stores and sprays washer fluid onto the windshield to aid in cleaning.

1.2. Types of Wiper Motors

There are mainly two types of wiper motors:

- Single-Speed Wiper Motors: Operate at one fixed speed.

- Two-Speed Wiper Motors: Offer two speed settings for varying weather conditions.

According to a report by the AAA Foundation for Traffic Safety, using the appropriate wiper speed can significantly improve visibility, reducing accident risks by up to 20%.

1.3. The Importance of Proper Wiper Function

Properly functioning windshield wipers are essential for maintaining clear visibility and ensuring driver safety. Malfunctioning wipers can severely impair visibility, increasing the risk of accidents, especially in adverse weather conditions. Regular maintenance and timely repairs are critical for keeping the wiper system in optimal condition.

2. Identifying Common Wiper Motor Problems

Recognizing the signs of a failing wiper motor is the first step in troubleshooting wiper issues. Several common problems can affect the performance of the wiper motor.

2.1. Common Symptoms of a Failing Wiper Motor

- Wipers Not Working: The most obvious sign of a failing wiper motor is when the wipers fail to operate at all.

- Intermittent Operation: The wipers work sporadically, stopping and starting without a consistent pattern.

- Slow or Jerky Movement: The wipers move slower than usual or exhibit jerky, uneven motion.

- Wipers Stop in the Middle of the Windshield: The wipers fail to return to their park position and stop abruptly in the middle of the windshield.

- Unusual Noises: Grinding, whining, or other unusual noises coming from the wiper motor area.

2.2. Potential Causes of Wiper Motor Failure

Several factors can contribute to wiper motor failure:

- Electrical Issues: Problems with the wiring, fuses, or switches can prevent the motor from receiving power.

- Mechanical Wear: Over time, the motor’s internal components can wear out, leading to decreased performance or failure.

- Corrosion: Exposure to moisture and road salt can cause corrosion, affecting the motor’s electrical connections and mechanical parts.

- Overload: Attempting to use the wipers to clear heavy snow or ice can overload the motor, causing it to fail.

- Linkage Problems: Issues with the wiper linkage can put excessive strain on the motor, leading to premature failure.

2.3. Diagnosing Electrical vs. Mechanical Issues

Distinguishing between electrical and mechanical issues is crucial for effective troubleshooting.

- Electrical Issues: Often manifest as intermittent operation or complete failure, with no unusual noises. Electrical problems can be diagnosed using a multimeter to check for voltage and continuity in the wiring and switches.

- Mechanical Issues: Typically involve slow or jerky movement, unusual noises, or the wipers stopping in the middle of the windshield. Mechanical problems often require a visual inspection of the motor and linkage for signs of wear, corrosion, or damage.

3. Tools and Materials Needed for Testing

Before you begin testing the wiper motor, gather the necessary tools and materials. Having the right equipment on hand will make the process smoother and more efficient.

3.1. Essential Tools for Wiper Motor Testing

- Multimeter: Used to measure voltage, current, and resistance in the electrical circuits.

- Jumper Wires: Used to bypass switches and connect the motor directly to a power source.

- Socket Set: Needed to remove and install the wiper motor.

- Screwdrivers: Both flathead and Phillips screwdrivers may be required.

- Pliers: Useful for gripping and manipulating wires and connectors.

- Test Light: An alternative to a multimeter, used to check for power in the circuits.

3.2. Safety Equipment

- Safety Glasses: To protect your eyes from debris.

- Gloves: To protect your hands from dirt, grease, and electrical shock.

3.3. Additional Materials

- Wiring Diagram: A wiring diagram specific to your vehicle can be invaluable for identifying the correct wires and terminals.

- Pen and Paper: To record your test results and observations.

- Cleaning Supplies: To clean any corroded connections.

4. Step-by-Step Guide to Checking Wiper Motor Operation

Testing the wiper motor involves a series of steps to diagnose the problem accurately. Follow this comprehensive guide to check the wiper motor effectively.

4.1. Preliminary Checks

Before diving into detailed testing, perform these preliminary checks:

- Check the Fuse: Locate the fuse for the windshield wipers in the fuse box (refer to your vehicle’s manual for the exact location). Inspect the fuse for any signs of damage or a blown filament. Replace the fuse if necessary.

- Inspect the Wiper Blades: Ensure the wiper blades are in good condition and not torn or worn. Replace them if needed, as damaged blades can put extra strain on the motor.

- Check the Wiper Linkage: Examine the wiper linkage for any signs of damage, binding, or excessive play. Ensure all connections are secure.

- Verify Ground Connections: Check that the wiper motor is properly grounded. Clean any corroded ground connections.

4.2. Testing the Wiper Motor In-Vehicle

If the preliminary checks don’t reveal the issue, proceed with testing the wiper motor while it’s still installed in the vehicle.

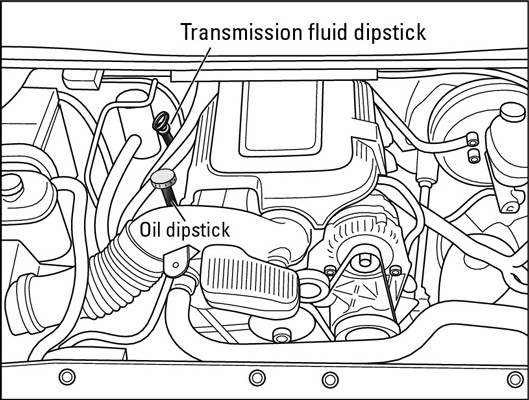

- Access the Wiper Motor: Locate the wiper motor, typically found under the hood near the base of the windshield. You may need to remove a plastic cover to access it.

- Disconnect the Electrical Connector: Disconnect the electrical connector from the wiper motor.

- Test for Power: Use a multimeter to check for power at the electrical connector. With the ignition switch on and the wiper switch activated, you should see voltage at the power terminal. If there’s no power, trace the wiring back to the fuse box and switch, looking for any breaks or shorts.

- Test the Ground Connection: Use the multimeter to check the ground connection at the motor. There should be continuity between the motor housing and a known good ground point on the vehicle’s chassis.

- Bypass the Wiper Switch: Use a jumper wire to bypass the wiper switch. Connect the jumper wire directly from the power source to the motor terminal. If the motor runs, the problem is likely with the wiper switch.

4.3. Testing the Wiper Motor Out-of-Vehicle

If the in-vehicle tests don’t pinpoint the problem, you may need to remove the wiper motor for further testing.

- Remove the Wiper Motor: Disconnect the wiper linkage from the motor. Remove any mounting bolts or screws holding the motor in place. Carefully remove the motor from the vehicle.

- Bench Test the Motor:

- Ground the Motor Housing: Use a jumper wire to connect the motor housing to a known good ground.

- Connect Power: Connect a jumper wire from a 12V power source directly to the power terminal on the motor.

- Test High and Low Speeds: If it’s a two-speed motor, use jumper wires to test both high and low-speed settings. Refer to the wiring diagram for the correct terminal connections.

- Observe Motor Operation: Observe the motor’s operation. It should run smoothly and consistently at the appropriate speed.

4.4. Interpreting Test Results

- No Power: If there’s no power at the motor, the problem could be a blown fuse, a faulty switch, or a break in the wiring.

- Motor Doesn’t Run: If the motor doesn’t run when directly connected to a power source, the motor itself is likely faulty and needs to be replaced.

- Intermittent Operation: Intermittent operation can be caused by loose connections, corroded terminals, or internal motor problems.

- Slow or Jerky Movement: Slow or jerky movement often indicates mechanical wear or binding in the motor or linkage.

5. Wiper Motor Troubleshooting Tips

Effective troubleshooting requires a systematic approach. Here are some tips to help you diagnose and resolve wiper motor issues.

5.1. Common Mistakes to Avoid

- Skipping Preliminary Checks: Always start with the basic checks, such as the fuse and wiper blades, before moving on to more complex testing.

- Ignoring Wiring Diagrams: Refer to the wiring diagram to ensure you’re connecting the jumper wires to the correct terminals.

- Neglecting Ground Connections: A poor ground connection can cause a variety of problems, so make sure the motor is properly grounded.

- Forgetting Safety Precautions: Always wear safety glasses and gloves when working with electrical components.

5.2. Diagnosing Intermittent Wiper Problems

Intermittent wiper problems can be particularly challenging to diagnose. Here are some tips:

- Check for Loose Connections: Inspect all wiring connections for looseness or corrosion.

- Test the Wiper Switch: The wiper switch may be faulty, causing intermittent operation. Use a multimeter to test the switch for continuity in different positions.

- Examine the Motor Internally: If the problem persists, the motor may have internal issues, such as worn brushes or a faulty armature.

5.3. Addressing Wiper Motor Noise Issues

Unusual noises from the wiper motor area can indicate mechanical problems.

- Identify the Source of the Noise: Determine whether the noise is coming from the motor itself or the wiper linkage.

- Check for Binding: Inspect the linkage for any signs of binding or obstruction.

- Lubricate Moving Parts: Lubricate the moving parts of the linkage to reduce friction and noise.

- Inspect the Motor Gearbox: If the noise is coming from the motor, the gearbox may need to be inspected for worn or damaged gears.

6. Maintaining Your Windshield Wiper System

Preventive maintenance is key to keeping your windshield wiper system in optimal condition.

6.1. Regular Maintenance Tasks

- Check Wiper Blades Regularly: Inspect the wiper blades for wear and tear every few months. Replace them as needed, typically every 6-12 months.

- Clean Wiper Blades: Clean the wiper blades regularly with a damp cloth to remove dirt and debris.

- Check Washer Fluid Level: Keep the washer fluid reservoir filled with a quality washer fluid.

- Inspect Wiper Linkage: Periodically inspect the wiper linkage for any signs of damage or excessive play.

- Lubricate Moving Parts: Lubricate the moving parts of the wiper linkage to ensure smooth operation.

6.2. Extending the Life of Your Wiper Motor

- Avoid Overloading the Motor: Don’t use the wipers to clear heavy snow or ice.

- Use the Correct Wiper Speed: Use the appropriate wiper speed for the weather conditions.

- Park Wipers Properly: In freezing weather, lift the wipers off the windshield to prevent them from sticking.

- Protect from Corrosion: Protect the motor and linkage from corrosion by applying a corrosion-resistant coating.

6.3. Choosing the Right Replacement Parts

When replacing wiper motor components, choose high-quality parts that are compatible with your vehicle.

- OEM vs. Aftermarket Parts: OEM (Original Equipment Manufacturer) parts are made by the same manufacturer as the original parts, ensuring a perfect fit and reliable performance. Aftermarket parts can be less expensive but may not offer the same level of quality.

- Check Compatibility: Ensure that the replacement parts are compatible with your vehicle’s make, model, and year.

- Read Reviews: Read online reviews to get feedback from other customers about the quality and performance of the replacement parts.

7. Advanced Testing Techniques

For more in-depth diagnostics, consider these advanced testing techniques.

7.1. Using an Oscilloscope for Advanced Diagnostics

An oscilloscope can provide valuable insights into the electrical signals within the wiper motor circuit.

- Capture Waveforms: Use an oscilloscope to capture the waveforms of the voltage and current signals in the wiper motor circuit.

- Analyze Signal Patterns: Analyze the signal patterns to identify any abnormalities, such as voltage drops, spikes, or signal distortion.

- Diagnose Complex Issues: An oscilloscope can help diagnose complex issues that may not be apparent with a multimeter alone.

7.2. Testing the Park Switch

The park switch is responsible for returning the wipers to their park position when they are turned off.

- Locate the Park Switch: The park switch is typically located inside the wiper motor housing.

- Test for Continuity: Use a multimeter to test the park switch for continuity. The switch should be closed when the wipers are in the park position and open when they are not.

- Clean or Replace the Switch: If the park switch is not functioning properly, it may need to be cleaned or replaced.

7.3. Checking the Wiper Control Module

Some vehicles use a wiper control module to manage the operation of the windshield wipers.

- Locate the Control Module: Refer to your vehicle’s service manual to locate the wiper control module.

- Check for Power and Ground: Use a multimeter to check that the control module is receiving power and ground.

- Test Input and Output Signals: Use a multimeter or oscilloscope to test the input and output signals of the control module.

- Replace the Module: If the control module is faulty, it may need to be replaced.

8. Safety Precautions When Working with Electrical Systems

Working with electrical systems can be dangerous if proper safety precautions are not followed.

8.1. Disconnecting the Battery

- Disconnect the Negative Terminal: Always disconnect the negative terminal of the battery before working on any electrical components.

- Prevent Accidental Reconnection: Take steps to prevent accidental reconnection of the battery while you are working.

8.2. Using Proper Protective Gear

- Wear Safety Glasses: Always wear safety glasses to protect your eyes from debris.

- Wear Gloves: Wear gloves to protect your hands from electrical shock and contaminants.

8.3. Avoiding Water and Moisture

- Work in a Dry Environment: Always work in a dry environment to avoid the risk of electrical shock.

- Protect Electrical Components from Moisture: Protect electrical components from water and moisture.

8.4. Handling Electrical Components Carefully

- Avoid Damaging Wires and Connectors: Handle wires and connectors carefully to avoid damage.

- Use the Right Tools: Use the right tools for the job to avoid damaging electrical components.

9. When to Seek Professional Help

While many wiper motor problems can be resolved with DIY testing and repair, some situations require professional help.

9.1. Complex Electrical Issues

If you encounter complex electrical issues that you are not comfortable diagnosing or repairing, it’s best to seek professional help.

9.2. Internal Motor Problems

If the wiper motor has internal problems, such as worn brushes or a faulty armature, it may be more cost-effective to replace the motor than to attempt to repair it.

9.3. Safety Concerns

If you have any safety concerns about working with electrical systems, it’s always best to seek professional help.

10. Purchasing Quality Automotive Tools from CARDIAGTECH.NET

For reliable automotive tools and diagnostic equipment, turn to CARDIAGTECH.NET. Our extensive selection includes everything you need to test and repair your windshield wiper system effectively.

10.1. Why Choose CARDIAGTECH.NET?

- Wide Selection: We offer a wide range of automotive tools and diagnostic equipment to meet your needs.

- High-Quality Products: Our products are sourced from trusted manufacturers, ensuring quality and reliability.

- Competitive Prices: We offer competitive prices to help you save money on your automotive repairs.

- Expert Support: Our team of experts can provide you with the support and guidance you need to choose the right tools for your job.

10.2. Featured Products for Wiper Motor Testing

- Multimeters: Our multimeters are accurate, reliable, and easy to use, making them perfect for testing electrical circuits.

- Jumper Wire Kits: Our jumper wire kits provide you with a variety of wire lengths and connector types to meet your testing needs.

- Socket Sets: Our socket sets include a comprehensive selection of sockets and ratchets to help you remove and install wiper motors and other components.

10.3. Contact Us for Expert Advice

Need help choosing the right tools for your wiper motor testing? Contact CARDIAGTECH.NET today.

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

FAQ Section

1. How do I know if my windshield wiper motor is bad?

If your wipers are not working, move slowly, or stop in the middle of the windshield, it may indicate a bad windshield wiper motor.

2. Can a blown fuse affect the windshield wiper motor?

Yes, a blown fuse can prevent the wiper motor from receiving power, causing it to fail.

3. How do I test a windshield wiper motor with a multimeter?

Use a multimeter to check for voltage at the motor’s power terminal with the wiper switch on. Also, check the ground connection for continuity.

4. What tools do I need to test a windshield wiper motor?

You will need a multimeter, jumper wires, socket set, screwdrivers, and pliers.

5. Is it safe to test a windshield wiper motor myself?

Yes, but always disconnect the battery, wear safety glasses and gloves, and work in a dry environment.

6. How often should I replace my windshield wiper blades?

Replace your windshield wiper blades every 6-12 months or as needed if they show signs of wear.

7. What causes a windshield wiper motor to fail?

Common causes include electrical issues, mechanical wear, corrosion, overload, and linkage problems.

8. Can I repair a windshield wiper motor, or should I replace it?

For complex internal problems, it may be more cost-effective to replace the motor.

9. How do I find the right replacement windshield wiper motor for my car?

Check your vehicle’s make, model, and year to ensure compatibility. Consult your vehicle’s service manual or a trusted auto parts retailer.

10. Where can I buy high-quality automotive tools for testing and repairing windshield wiper motors?

You can purchase high-quality automotive tools at CARDIAGTECH.NET, including multimeters, jumper wire kits, and socket sets.

By following this comprehensive guide, you can effectively check the operation of your windshield wiper motor, troubleshoot common issues, and maintain a clear and safe driving environment. If you need high-quality automotive tools or expert advice, contact CARDIAGTECH.NET today. Our team is ready to assist you with all your automotive diagnostic and repair needs. Contact us at 276 Reock St, City of Orange, NJ 07050, United States, WhatsApp: +1 (641) 206-8880, or visit our website at CARDIAGTECH.NET.