How to Check the Pistons in Brake Calipers for Sticking and Leaks?

Checking the pistons in brake calipers for sticking and leaks involves a thorough inspection and diagnostic process to ensure optimal braking performance and safety. CARDIAGTECH.NET offers expert guidance and high-quality tools to assist you in this essential maintenance task. Understanding the symptoms, causes, and step-by-step procedures will help you identify and address any issues effectively, ensuring your vehicle’s braking system operates smoothly and reliably. By using the right tools and techniques, you can restore your brake calipers to their optimal condition, reducing the risk of brake failure and enhancing overall vehicle safety.

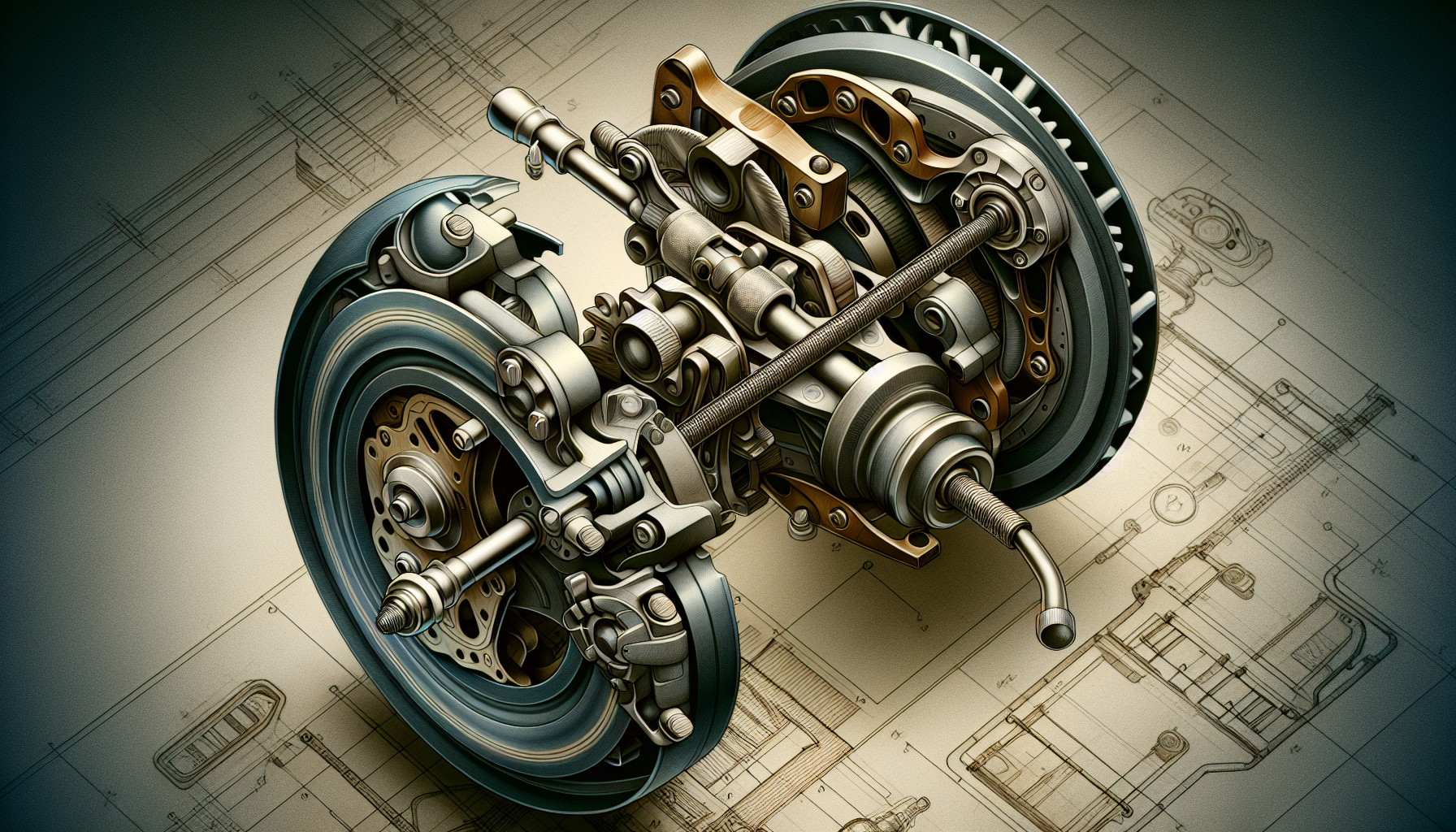

1. Understanding the Brake Caliper and Piston Function

What is the function of the brake caliper and piston in a vehicle’s braking system? The brake caliper houses the brake pads and pistons, playing a crucial role in slowing or stopping the vehicle by applying pressure to the brake rotors. The pistons, typically one or more within the caliper, are responsible for pressing the brake pads against the rotor when hydraulic pressure from the master cylinder is applied. According to a study by the National Highway Traffic Safety Administration (NHTSA), faulty brake calipers and pistons can significantly increase stopping distances, raising the risk of accidents. The effectiveness of the braking system relies on the proper functioning of these components to ensure consistent and reliable performance. CARDIAGTECH.NET offers expert advice and tools to help maintain these critical parts, ensuring your vehicle’s safety.

1.1. The Role of Calipers in the Braking System

What do calipers do in your vehicle’s braking system? Calipers act as clamps that hold the brake pads and use hydraulic pressure to press these pads against the rotors, which are attached to the wheels. The friction between the pads and rotors slows down the vehicle. According to a report by the Society of Automotive Engineers (SAE), caliper design and material directly impact braking efficiency and heat dissipation. High-quality calipers ensure even pressure distribution, reducing the risk of premature wear and improving overall braking performance.

1.2. The Function of Pistons within the Caliper

What is the function of pistons inside the brake caliper? Pistons transfer the hydraulic force from the brake fluid to the brake pads, pushing them against the rotor. The number of pistons in a caliper can vary, with some having single pistons and others multiple pistons for increased braking force. According to research from the University of Michigan Transportation Research Institute (UMTRI), piston size and material affect the braking force and responsiveness. Properly functioning pistons ensure even and effective brake pad engagement, which is critical for safe and reliable braking.

1.3. Materials Used in Caliper and Piston Construction

What materials are commonly used in the manufacturing of brake calipers and pistons? Brake calipers are typically made from cast iron or aluminum, while pistons are often made from steel, aluminum, or phenolic materials. Cast iron calipers are durable and cost-effective but heavier, whereas aluminum calipers are lighter and offer better heat dissipation. Steel pistons are strong and resistant to corrosion, while aluminum pistons are lighter, and phenolic pistons offer good thermal insulation, preventing heat transfer to the brake fluid.

2. Identifying Symptoms of Sticking or Leaking Pistons

How can you recognize the signs of sticking or leaking pistons in your vehicle’s brake calipers? Common symptoms include uneven brake pad wear, pulling to one side during braking, a soft or spongy brake pedal, and visible brake fluid leaks around the caliper. A study by the National Institute for Automotive Service Excellence (ASE) highlights that early detection of these symptoms can prevent more serious and costly brake system failures. Addressing these issues promptly ensures the safety and efficiency of your vehicle’s braking system. CARDIAGTECH.NET provides diagnostic tools and expert guidance to help you identify these problems quickly and accurately.

2.1. Uneven Brake Pad Wear

What causes uneven brake pad wear, and how does it relate to piston issues? Uneven brake pad wear occurs when one brake pad wears down faster than the other on the same axle. This can be a sign of a sticking piston, which applies unequal pressure on the pads. According to a study published in Wear journal, irregular wear patterns can significantly reduce braking efficiency and increase the risk of brake failure.

2.2. Pulling to One Side During Braking

Why does a vehicle pull to one side during braking, and what does it indicate about the brake calipers? Pulling to one side while braking often indicates that the brake caliper on one side is not functioning correctly, causing uneven braking force. This can be due to a sticking piston or a collapsed brake hose. Research from the Vehicle Dynamics International (VDI) suggests that such issues can lead to loss of control, especially in emergency braking situations.

2.3. Soft or Spongy Brake Pedal Feel

What does a soft or spongy brake pedal indicate, and how is it related to the brake caliper system? A soft or spongy brake pedal feel usually indicates air in the brake lines or a leak in the hydraulic system, which can be caused by a leaking piston seal in the brake caliper. A study by the American Automobile Association (AAA) found that a spongy brake pedal reduces braking effectiveness, increasing stopping distances.

2.4. Visible Brake Fluid Leaks

Where should you look for visible brake fluid leaks, and what do they signify? Check around the brake calipers, brake lines, and master cylinder for any signs of brake fluid leakage. Leaks around the caliper often indicate a damaged piston seal, which can compromise braking performance. According to the Brake Manufacturers Council (BMC), brake fluid leaks can lead to a significant loss of braking pressure, posing a severe safety risk.

3. Tools and Materials Needed for Inspection

What tools and materials are essential for inspecting brake calipers for sticking and leaks? You will need a jack and jack stands, a lug wrench, a brake bleeder wrench, a wire brush, brake cleaner, a catch pan, and a flashlight. Additionally, consider having a caliper piston compression tool and a seal pick set. According to the National Automotive Service Task Force (NASTF), using the right tools ensures a thorough and safe inspection process. CARDIAGTECH.NET offers a comprehensive range of high-quality tools to help you perform this task efficiently and effectively.

3.1. Essential Hand Tools

What are the must-have hand tools for brake caliper inspection? Essential hand tools include a lug wrench for removing wheels, a brake bleeder wrench for opening and closing bleeder screws, a wire brush for cleaning caliper surfaces, and a set of wrenches and sockets for disconnecting brake lines. According to a survey by Professional Tool & Equipment News (PTEN), having the right hand tools improves efficiency and accuracy in brake service.

3.2. Cleaning and Safety Supplies

What cleaning and safety supplies are necessary for brake caliper inspection? Necessary cleaning and safety supplies include brake cleaner for removing grease and debris, a catch pan for collecting brake fluid, safety glasses to protect your eyes, and gloves to protect your hands from chemicals. The Occupational Safety and Health Administration (OSHA) recommends using appropriate personal protective equipment (PPE) when working with brake systems.

3.3. Diagnostic Tools for Identifying Leaks

What diagnostic tools can help identify brake fluid leaks during inspection? Diagnostic tools such as a flashlight for visual inspection, a brake pressure tester for measuring hydraulic pressure, and a leak detection dye can help identify hard-to-find leaks. A study by the Automotive Aftermarket Suppliers Association (AASA) indicates that using diagnostic tools improves the accuracy and efficiency of brake system inspections.

3.4. Caliper Piston Compression Tool

Why is a caliper piston compression tool important for brake maintenance? A caliper piston compression tool is essential for retracting the piston back into the caliper bore, allowing for easy installation of new brake pads. This tool prevents damage to the piston and caliper seals. According to Motor Age magazine, using a piston compression tool ensures proper piston retraction and extends the life of the caliper assembly.

4. Step-by-Step Guide: Checking Pistons for Sticking

How do you systematically check brake caliper pistons for signs of sticking? Begin by safely lifting the vehicle and removing the wheel. Inspect the caliper for any visible damage or corrosion. Remove the brake pads and use a caliper piston compression tool to gently push the piston back into the caliper. If the piston is difficult to move or doesn’t retract smoothly, it is likely sticking. A technical bulletin from Bosch recommends lubricating the piston with brake fluid and attempting retraction again. If the problem persists, further disassembly and cleaning may be required. Remember to consult CARDIAGTECH.NET for detailed guides and the necessary tools.

4.1. Preparing the Vehicle for Inspection

What steps should you take to prepare your vehicle for brake caliper inspection? First, park the vehicle on a level surface, engage the parking brake, and loosen the lug nuts on the wheel you will be inspecting. Use a jack to lift the vehicle and securely place it on jack stands. According to the National Safety Council (NSC), proper vehicle support is critical to prevent accidents during maintenance.

4.2. Visual Inspection of the Caliper

What should you look for during a visual inspection of the brake caliper? Examine the caliper for signs of damage, corrosion, or brake fluid leaks. Check the condition of the brake hoses and connections. According to a guide by the ASE, visual inspection can reveal many common brake system problems.

4.3. Removing Brake Pads for Piston Access

How do you safely remove brake pads to access the piston for inspection? Remove the caliper mounting bolts and carefully slide the caliper away from the rotor. Take out the old brake pads, noting their wear pattern. A technical article in Underhood Service magazine recommends cleaning the caliper mounting hardware before reinstallation.

4.4. Testing Piston Movement

What is the best way to test the movement of the brake caliper piston? Use a caliper piston compression tool to gently push the piston back into the caliper bore. Observe how smoothly the piston retracts. If it requires excessive force or doesn’t move at all, it indicates a sticking piston. According to a report by the TUV Rheinland Group, smooth piston movement is essential for effective braking.

5. Step-by-Step Guide: Checking Pistons for Leaks

How can you check brake caliper pistons for leaks to ensure the brake system’s integrity? Clean the caliper thoroughly with brake cleaner and dry it with a clean cloth. Have someone slowly depress the brake pedal while you observe the piston area for any signs of brake fluid leakage. According to the Hydraulic Institute, even small leaks can compromise the braking system’s performance. If leaks are detected, the caliper seals likely need replacement. CARDIAGTECH.NET offers seal kits and expert advice to help you with this repair.

5.1. Cleaning the Caliper for Leak Detection

Why is cleaning the brake caliper important for leak detection? Cleaning the caliper with brake cleaner removes dirt, grease, and old brake fluid, making it easier to spot fresh leaks. According to a guide by CRC Industries, a clean surface improves the accuracy of leak detection.

5.2. Applying Brake Pressure to Check for Leaks

How do you apply brake pressure to check for leaks around the piston? With the caliper installed and the brake pads removed, have an assistant slowly depress the brake pedal. Observe the area around the piston and seals for any signs of brake fluid leakage. The Federal Motor Carrier Safety Administration (FMCSA) emphasizes the importance of checking for brake leaks during routine inspections.

5.3. Identifying the Source of Leaks

Where are common leak points on a brake caliper, and how can you identify them? Common leak points include the piston seal, the bleeder screw, and the brake hose connection. Use a flashlight to closely inspect these areas for any signs of wetness or dripping brake fluid. According to a report by the National Transportation Safety Board (NTSB), identifying and repairing leaks promptly is critical for preventing brake failures.

5.4. Confirming Leakage with Paper Test

What is the paper test, and how does it help confirm brake fluid leaks? Hold a piece of clean, dry paper near the suspect area while brake pressure is applied. If brake fluid is leaking, it will leave a wet spot on the paper. This method helps confirm small leaks that may be difficult to see otherwise. According to a publication by the Society of Automotive Technicians (SAT), the paper test is a simple and effective way to detect brake fluid leaks.

6. Common Causes of Sticking Pistons

What are the primary causes of brake caliper pistons sticking, affecting braking performance? Common causes include corrosion, buildup of dirt and debris, and damaged or worn piston seals. Brake fluid contamination can also contribute to these issues. According to a study by the University of Waterloo, regular brake maintenance, including fluid flushes and caliper cleaning, can prevent these problems. CARDIAGTECH.NET offers maintenance products and expert advice to help you keep your brake system in optimal condition.

6.1. Corrosion and Rust

How does corrosion and rust contribute to brake piston sticking? Corrosion and rust can form on the piston and caliper bore, causing the piston to bind and stick. This is more common in vehicles operated in areas with high humidity or road salt use. A study published in Corrosion Science journal found that protective coatings on brake components can significantly reduce corrosion.

6.2. Build-up of Dirt and Debris

Why does the accumulation of dirt and debris lead to piston problems? Dirt and debris can accumulate around the piston seal, causing it to degrade and allowing contaminants to enter the caliper bore. This can lead to piston sticking and uneven brake pad wear. According to a report by the Automotive Maintenance and Repair Association (AMRA), regular cleaning of brake components is essential for preventing these issues.

6.3. Damaged or Worn Piston Seals

How do damaged or worn piston seals cause sticking and leaks? Piston seals prevent brake fluid from leaking and keep contaminants out of the caliper bore. When these seals become damaged or worn, they can cause the piston to stick and allow brake fluid to leak. According to a study by the Rubber Manufacturers Association (RMA), using high-quality seals can extend the life of the brake caliper.

6.4. Brake Fluid Contamination

How does contaminated brake fluid affect the brake caliper system? Contaminated brake fluid can introduce moisture and debris into the brake system, leading to corrosion and damage to the caliper and piston. According to a report by the National Brake Safety Association (NBSA), regular brake fluid flushes are crucial for maintaining brake system health.

7. Common Causes of Leaking Pistons

What are the common causes of brake caliper pistons leaking, leading to loss of brake pressure? The primary causes of leaks are damaged or deteriorated piston seals, corrosion on the piston or caliper bore, and physical damage to the caliper housing. A technical report by the SAE indicates that the quality of the seals and the cleanliness of the brake fluid are critical factors in preventing leaks. CARDIAGTECH.NET provides high-quality replacement parts and expert advice to address these issues effectively.

7.1. Deteriorated Piston Seals

What causes piston seals to deteriorate, and what are the consequences? Piston seals can deteriorate due to age, exposure to contaminants, and heat. Deteriorated seals lose their elasticity and can no longer effectively seal the piston, leading to brake fluid leaks. According to a study by the Polymer Engineering journal, using seals made from high-quality materials can improve their resistance to degradation.

7.2. Corrosion on Piston or Caliper Bore

How does corrosion on the piston or caliper bore lead to leaks? Corrosion on the piston or caliper bore can create rough surfaces that damage the piston seal, leading to leaks. Corrosion can also weaken the caliper housing, making it more prone to cracking. According to a report by the American Society for Metals (ASM), corrosion-resistant coatings can protect brake components from environmental damage.

7.3. Physical Damage to the Caliper Housing

What types of physical damage can cause brake caliper leaks? Physical damage to the caliper housing, such as cracks or dents, can compromise its integrity and lead to brake fluid leaks. This type of damage can be caused by impacts, improper handling, or corrosion. According to a study by the Insurance Institute for Highway Safety (IIHS), maintaining proper vehicle maintenance can prevent many types of physical damage.

8. Step-by-Step Guide: Cleaning and Lubricating Pistons

How do you properly clean and lubricate brake caliper pistons to ensure smooth operation? Begin by disassembling the caliper and carefully removing the piston. Clean the piston and caliper bore with brake cleaner and a soft brush. Inspect the piston and bore for any signs of damage or corrosion. Lubricate the piston and seals with fresh brake fluid before reassembling the caliper. According to a guide by Permatex, proper cleaning and lubrication are essential for preventing sticking and leaks. CARDIAGTECH.NET offers high-quality brake cleaners and lubricants to assist you in this process.

8.1. Disassembling the Caliper

What steps should you take to disassemble the brake caliper safely? First, disconnect the brake line from the caliper. Remove the caliper mounting bolts and carefully slide the caliper off the rotor. Remove the brake pads and any retaining hardware. Use a specialized tool to carefully extract the piston from the caliper bore. According to a service manual by Haynes, following proper disassembly procedures prevents damage to the caliper components.

8.2. Cleaning the Piston and Caliper Bore

What is the best method for cleaning the piston and caliper bore? Use brake cleaner and a soft brush to remove dirt, grease, and corrosion from the piston and caliper bore. Avoid using harsh abrasives that could damage the surfaces. According to a guide by 3M, using the right cleaning products ensures a thorough and safe cleaning process.

8.3. Inspecting for Damage or Corrosion

What should you look for when inspecting the piston and caliper bore? Check the piston and caliper bore for signs of scoring, pitting, or corrosion. Replace any components that are damaged or excessively worn. According to a report by the Vehicle Safety Research Centre (VSRC), identifying and replacing damaged components is critical for maintaining brake system performance.

8.4. Lubricating and Reassembling the Caliper

What type of lubricant should you use when reassembling the brake caliper? Lubricate the piston and seals with fresh brake fluid before reassembling the caliper. This ensures smooth piston movement and prevents damage to the seals. According to a guide by ACDelco, using the correct lubricant is essential for proper brake system operation.

9. Replacing Piston Seals and Boots

When should you replace the piston seals and boots in a brake caliper, and what does the process involve? Replace the piston seals and boots if they are damaged, worn, or leaking. The process involves disassembling the caliper, removing the old seals and boots, cleaning the caliper components, installing new seals and boots, and reassembling the caliper. According to a technical bulletin from Federal-Mogul, replacing seals and boots as part of routine maintenance can extend the life of the caliper. CARDIAGTECH.NET offers high-quality seal and boot kits to help you with this repair.

9.1. Selecting the Right Seal and Boot Kit

How do you choose the correct seal and boot kit for your brake caliper? Ensure the seal and boot kit is compatible with your vehicle’s make, model, and year. Check the part number and compare it to the original components to ensure a proper fit. According to a guide by Napa Auto Parts, using the correct parts ensures proper brake system operation and safety.

9.2. Removing Old Seals and Boots

What is the best method for removing old seals and boots from the caliper? Use a seal pick or small screwdriver to carefully remove the old seals and boots from the caliper. Be careful not to damage the caliper bore or piston during the removal process. According to a service tip by Snap-on Tools, using specialized tools can simplify the removal process and prevent damage.

9.3. Installing New Seals and Boots

What steps should you follow when installing new seals and boots? Lubricate the new seals and boots with fresh brake fluid before installation. Carefully press the seals and boots into their respective grooves, ensuring they are properly seated. According to a guide by Dorman Products, proper installation is critical for preventing leaks and ensuring brake system performance.

9.4. Verifying Proper Seal Installation

How do you verify that the new seals and boots are installed correctly? After installation, inspect the seals and boots to ensure they are properly seated and not twisted or damaged. Apply brake pressure to the caliper and check for any signs of leaks. According to a report by the European Union Road Federation (ERF), proper installation of brake components is essential for road safety.

10. When to Consider Replacing the Entire Caliper

In what situations is it more practical to replace the entire brake caliper rather than repairing it? Consider replacing the entire caliper if the caliper bore is severely corroded or damaged, if the caliper housing is cracked, or if the bleeder screw is broken off inside the caliper. A report by the Motor Equipment & Tool Institute (METI) suggests that replacing the entire caliper can be more cost-effective in the long run if significant damage is present. CARDIAGTECH.NET offers a wide selection of high-quality brake calipers to meet your needs.

10.1. Severe Corrosion or Damage

When is corrosion or damage severe enough to warrant caliper replacement? If the caliper bore is heavily corroded or if there are deep scratches or pitting, it may be impossible to restore the caliper to proper working condition. Similarly, cracks or fractures in the caliper housing require replacement. According to a study by the National Association of Corrosion Engineers (NACE), severe corrosion can compromise the structural integrity of brake components.

10.2. Broken Bleeder Screw

Why does a broken bleeder screw often necessitate caliper replacement? If the bleeder screw is broken off inside the caliper and cannot be removed, it can be difficult to properly bleed the brakes. This can compromise braking performance and make caliper replacement the most practical solution. According to a guide by Craftsman Tools, attempting to drill out a broken bleeder screw can damage the caliper.

10.3. Cost vs. Repair

How do you determine whether it is more cost-effective to repair or replace a brake caliper? Compare the cost of replacement parts (seals, boots, pistons) and your time to the cost of a new or remanufactured caliper. If the repair cost approaches or exceeds the replacement cost, it may be more economical to replace the entire caliper. According to a report by Consumer Reports, considering both the initial cost and long-term reliability is essential when making repair decisions.

11. Bleeding the Brakes After Caliper Service

Why is bleeding the brakes necessary after servicing the brake calipers, and what is the correct procedure? Bleeding the brakes removes air from the brake lines, ensuring a firm brake pedal and proper braking performance. The correct procedure involves opening the bleeder screw while an assistant depresses the brake pedal, then closing the screw before the pedal is released. Repeat until no air bubbles are present. According to a guide by Prestone, proper bleeding is essential for safe and effective braking. CARDIAGTECH.NET offers brake bleeding kits and expert advice to help you with this task.

11.1. Why Bleeding is Necessary

Why is it important to bleed the brakes after working on the calipers? When you open the brake system to service the calipers, air can enter the brake lines. Air in the brake lines compresses under pressure, leading to a spongy brake pedal and reduced braking effectiveness. According to a report by the National Brake Safety Association (NBSA), bleeding the brakes removes this air, restoring proper braking performance.

11.2. Manual Bleeding Procedure

What are the steps involved in the manual brake bleeding procedure? Attach a clear hose to the bleeder screw and submerge the other end in a container of brake fluid. Have an assistant slowly depress the brake pedal while you open the bleeder screw. Close the screw before the pedal is released. Repeat until no air bubbles are visible in the hose. According to a guide by Popular Mechanics, using the correct bleeding sequence is important for thorough air removal.

11.3. Pressure Bleeding Method

What is the pressure bleeding method, and what are its advantages? The pressure bleeding method uses a pressurized device to force brake fluid through the system, pushing out air bubbles. This method is often faster and more efficient than manual bleeding. According to a study by the Automotive Research Association of India (ARAI), pressure bleeding can improve the consistency and effectiveness of brake bleeding.

11.4. Sequence for Bleeding Brakes

What is the correct sequence for bleeding brakes on a vehicle? Typically, you should start with the wheel farthest from the master cylinder and work your way closer. The sequence is usually right rear, left rear, right front, and left front. However, consult your vehicle’s service manual for the specific sequence. According to a guide by Midas, following the correct sequence ensures that all air is removed from the brake system.

12. Brake Fluid Recommendations and Maintenance

What type of brake fluid should you use, and what maintenance practices are essential for brake fluid? Use the brake fluid type specified in your vehicle’s owner’s manual, typically DOT 3, DOT 4, or DOT 5.1. Regularly check the brake fluid level and condition, and flush the brake fluid every two to three years to remove contaminants and moisture. According to a guide by Valvoline, using the correct brake fluid and maintaining it properly is crucial for brake system performance and safety. CARDIAGTECH.NET offers a range of high-quality brake fluids and maintenance products.

12.1. Types of Brake Fluid

What are the different types of brake fluid available? The most common types of brake fluid are DOT 3, DOT 4, and DOT 5.1. DOT 3 and DOT 4 are glycol-based fluids, while DOT 5 is silicone-based. DOT 5.1 is also glycol-based but has a higher boiling point than DOT 3 and DOT 4. According to a guide by Castrol, using the correct type of brake fluid is essential for compatibility and performance.

12.2. Importance of Regular Fluid Checks

Why is it important to regularly check the brake fluid level and condition? Checking the brake fluid level ensures that there is sufficient fluid in the system for proper braking. Checking the fluid condition can reveal contamination or moisture, which can compromise braking performance. According to a report by the Swedish National Road and Transport Research Institute (VTI), regular fluid checks can help prevent brake system failures.

12.3. Recommended Brake Fluid Flush Intervals

How often should you flush the brake fluid in your vehicle? Most manufacturers recommend flushing the brake fluid every two to three years or every 24,000 to 36,000 miles. However, consult your vehicle’s owner’s manual for the specific recommendation. According to a guide by Pennzoil, regular brake fluid flushes can extend the life of the brake system.

12.4. Signs of Contaminated Brake Fluid

What are the signs of contaminated brake fluid, and how does it affect the braking system? Signs of contaminated brake fluid include a dark or murky appearance, sediment in the fluid, and a spongy brake pedal. Contaminated brake fluid can cause corrosion, reduce braking effectiveness, and damage brake components. According to a report by the Japan Automobile Research Institute (JARI), contaminated brake fluid can significantly reduce braking performance.

13. Safety Precautions During Brake Service

What safety precautions should you take when working on brake systems to prevent injury? Always wear safety glasses and gloves to protect your eyes and hands. Work in a well-ventilated area and avoid breathing brake dust. Use jack stands to support the vehicle securely. Properly dispose of used brake fluid and cleaning materials. According to OSHA, following safety guidelines is essential for preventing accidents during brake service. CARDIAGTECH.NET emphasizes safety and provides resources to help you work safely.

13.1. Personal Protective Equipment (PPE)

What personal protective equipment (PPE) is necessary when working on brakes? Wear safety glasses to protect your eyes from brake dust and fluid splashes. Wear gloves to protect your hands from chemicals and sharp edges. Consider wearing a dust mask to avoid inhaling brake dust. According to the National Institute for Occupational Safety and Health (NIOSH), using PPE can significantly reduce the risk of injury and illness during brake service.

13.2. Proper Vehicle Support

Why is it important to use jack stands when working on brakes? Jack stands provide a stable and secure platform for supporting the vehicle while you work underneath. Never rely solely on a jack to support the vehicle. According to the National Safety Council (NSC), using jack stands is critical for preventing accidents during vehicle maintenance.

13.3. Handling Brake Fluid Safely

What precautions should you take when handling brake fluid? Brake fluid can damage painted surfaces and irritate the skin. Avoid spilling brake fluid on your vehicle and wear gloves to protect your hands. Properly dispose of used brake fluid according to local regulations. According to a safety data sheet (SDS) by Dow Chemical, proper handling and disposal of brake fluid are essential for environmental protection.

13.4. Disposing of Waste Materials

How should you properly dispose of used brake pads, fluid, and cleaning materials? Dispose of used brake pads and fluid according to local regulations. Many auto parts stores will accept used brake fluid for recycling. Dispose of cleaning materials in a sealed container to prevent environmental contamination. According to the Environmental Protection Agency (EPA), proper disposal of waste materials is essential for protecting the environment.

14. The Importance of Regular Brake Maintenance

Why is regular brake maintenance essential for vehicle safety and performance? Regular brake maintenance, including inspections, cleaning, lubrication, and fluid flushes, can prevent brake problems and ensure reliable braking performance. According to a study by the National Highway Traffic Safety Administration (NHTSA), properly maintained brakes can significantly reduce the risk of accidents. CARDIAGTECH.NET promotes regular brake maintenance and offers the products and expertise you need to keep your brakes in top condition.

14.1. Preventing Costly Repairs

How does regular maintenance help prevent more expensive brake repairs in the future? Regular maintenance can identify and address minor brake problems before they escalate into major issues. This can save you money on costly repairs and replacements. According to a report by the Automotive Aftermarket Industry Association (AAIA), preventive maintenance is a cost-effective way to extend the life of your vehicle.

14.2. Ensuring Safe Driving Conditions

How does proper brake maintenance contribute to safer driving conditions? Properly maintained brakes ensure that your vehicle can stop quickly and safely in all driving conditions. This can help you avoid accidents and protect yourself and others on the road. According to a report by the Insurance Institute for Highway Safety (IIHS), well-maintained vehicles are less likely to be involved in crashes.

14.3. Extending Brake System Life

What steps can you take to extend the life of your brake system? Regular maintenance, using high-quality replacement parts, and following recommended service intervals can extend the life of your brake system. This can save you money on replacements and ensure reliable braking performance. According to a study by the Vehicle Maintenance Reporting Standards (VMRS) Council, proper maintenance practices can significantly extend the life of vehicle components.

14.4. Maintaining Vehicle Value

How does proper brake maintenance affect the resale value of your vehicle? A well-maintained brake system is a sign that the vehicle has been properly cared for, which can increase its resale value. Potential buyers are more likely to pay a premium for a vehicle with a documented maintenance history. According to a report by Kelley Blue Book, maintenance history is an important factor in determining vehicle value.

15. Finding Quality Brake Service and Parts

Where can you find reliable brake service and high-quality brake parts? Look for certified mechanics and reputable auto parts stores in your area. Check online reviews and ask for recommendations from friends and family. CARDIAGTECH.NET offers a wide selection of high-quality brake parts and provides access to expert advice and resources.

15.1. Certified Mechanics

How do you identify a qualified and certified mechanic for brake service? Look for mechanics who are certified by the National Institute for Automotive Service Excellence (ASE). ASE certification indicates that the mechanic has met specific training and experience requirements and has passed rigorous exams. According to the ASE website, using a certified mechanic ensures that your vehicle is serviced by a knowledgeable and skilled professional.

15.2. Reputable Auto Parts Stores

What factors should you consider when choosing an auto parts store for brake components? Choose an auto parts store that offers high-quality parts from reputable brands, provides knowledgeable customer service, and has a good return policy. Check online reviews and ask for recommendations from other vehicle owners. According to a survey by Consumer Reports, customer satisfaction is an important indicator of the quality of an auto parts store.

15.3. Online Resources and Reviews

How can online resources and reviews help you find quality brake service and parts? Online resources such as Yelp, Google Reviews, and Angie’s List can provide valuable information about the reputation and quality of local mechanics and auto parts stores. Read reviews from other customers to get an idea of their experiences. According to a study by BrightLocal, online reviews have a significant impact on consumer purchasing decisions.

15.4. Warranty and Return Policies

Why are warranty and return policies important when purchasing brake components? A warranty provides protection against defects in materials and workmanship. A good return policy allows you to return parts that do not fit or meet your expectations. According to a guide by the Better Business Bureau (BBB), understanding the warranty and return policies is essential for protecting your investment.

By following these steps and guidelines, you can effectively check the pistons in your brake calipers for sticking and leaks, ensuring your vehicle’s braking system operates safely and reliably. CARDIAGTECH.NET is your trusted partner for all your automotive diagnostic and repair needs.

Don’t let sticking or leaking brake calipers compromise your safety! At CARDIAGTECH.NET, we understand the challenges you face in keeping your customers’ vehicles running smoothly. From the physical demands of the job to the constant need to update your skills, we know you need reliable tools and expert support. That’s why we offer a wide range of high-quality brake service tools and equipment designed to increase your efficiency, accuracy, and profitability. Contact us today at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET to discover how we can help you overcome these challenges and elevate your service. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let CARDIAGTECH.NET be your partner in success.

FAQ: Brake Caliper Pistons

1. How do I know if my brake caliper piston is sticking?

If your brake caliper piston is sticking, you may notice symptoms such as uneven brake pad wear, pulling to one side during braking, a soft or spongy brake pedal, or the brakes staying engaged after releasing the pedal. According to a study by the National Highway Traffic Safety Administration (NHTSA), sticking brake caliper pistons can significantly impair braking performance.

2. What causes a brake caliper piston to stick?

A brake caliper piston can stick due to corrosion, buildup of dirt and debris, damaged or worn piston seals, or contaminated brake fluid. According to a report by the Automotive Maintenance and Repair Association (AMRA), regular maintenance and cleaning can prevent these issues.

3. Can I fix a sticking brake caliper piston myself?

Yes, you can often fix a sticking brake caliper piston yourself by disassembling the caliper, cleaning the piston and caliper bore, inspecting for damage, and lubricating the components before reassembly. However, if you are not comfortable with this type of repair, it is best to take your vehicle to a qualified mechanic. CARDIAGTECH.NET provides tools and guides to assist with this task.

4. What tools do I need to check a brake caliper piston?

To check a brake caliper piston, you will need a jack and jack stands, a lug wrench, a brake bleeder wrench, a wire brush, brake cleaner, a catch pan, a flashlight, and a caliper piston compression tool. According to a survey by Professional Tool & Equipment News (PTEN), having the right tools improves efficiency and accuracy in brake service.

5. How do I clean a brake caliper piston?

To clean a brake caliper piston, use brake cleaner and a soft brush to remove dirt, grease, and corrosion from the piston and caliper bore. Avoid using harsh abrasives that could damage the surfaces. According to a guide by 3M, using the right cleaning products ensures a thorough and safe cleaning process.

6. What type of lubricant should I use on a brake caliper piston?

You should use fresh brake fluid to lubricate a brake caliper piston. This ensures smooth piston movement and prevents damage to the seals. According to a guide by ACDelco, using the correct lubricant is essential for proper brake system operation.

7. How often should I replace brake caliper seals?

You should replace brake caliper seals whenever they are damaged, worn, or leaking. As a general rule, it is also a good idea to replace the seals whenever you replace the brake pads. According to a technical bulletin from Federal-Mogul, replacing seals and boots as part of routine maintenance can extend the life of the caliper.

8. When should I replace the entire brake caliper?

Consider replacing the entire brake caliper if the caliper bore is severely corroded or damaged, if the caliper housing is cracked, or if the bleeder screw is broken off inside the caliper. A report by the Motor Equipment & Tool Institute (METI) suggests that replacing the entire caliper can be more cost-effective in the