How to Check the Self-Adjusting Mechanisms of Drum Brake Shoes?

Ensuring optimal performance of your vehicle’s braking system is crucial, and understanding how to check the self-adjusting mechanisms of drum brake shoes is a key part of that. At CARDIAGTECH.NET, we provide the tools and expertise needed to diagnose and maintain these critical components, ensuring your safety and the longevity of your vehicle. Regular inspection and maintenance of drum brake systems will deliver optimal performance and safety, alongside enhancing the durability of your vehicle’s braking system.

1. Understanding Self-Adjusting Drum Brake Systems

Self-adjusting drum brakes automatically maintain the correct distance between the brake shoes and the drum, compensating for wear over time to ensure consistent braking power. These systems use an adjuster lever and star wheel to autonomously maintain that optimal space between the brake shoes and drum, adjusting for any wear over time.

1.1. Components of Self-Adjusting Drum Brakes

The self-adjusting mechanism in drum brakes is a marvel of engineering, but what are the key components that make it all work?

- Adjuster Lever: The adjuster lever’s pivotal role nudges the adjuster gear forward one tooth whenever there’s an expansion of space between the brake drum and shoe during reverse stops.

- Star Wheel: This ensures that any rotation serves only to tighten against the drum. A brake spoon can be used via an access slot specifically designed for such adjustments.

- Wheel Cylinder: A central element essential for optimal performance across all aspects of your vehicle’s braking process.

- Brake Shoes: These components press against the drum to create friction and slow the vehicle. The self-adjusting mechanism ensures they remain at the correct distance from the drum as they wear.

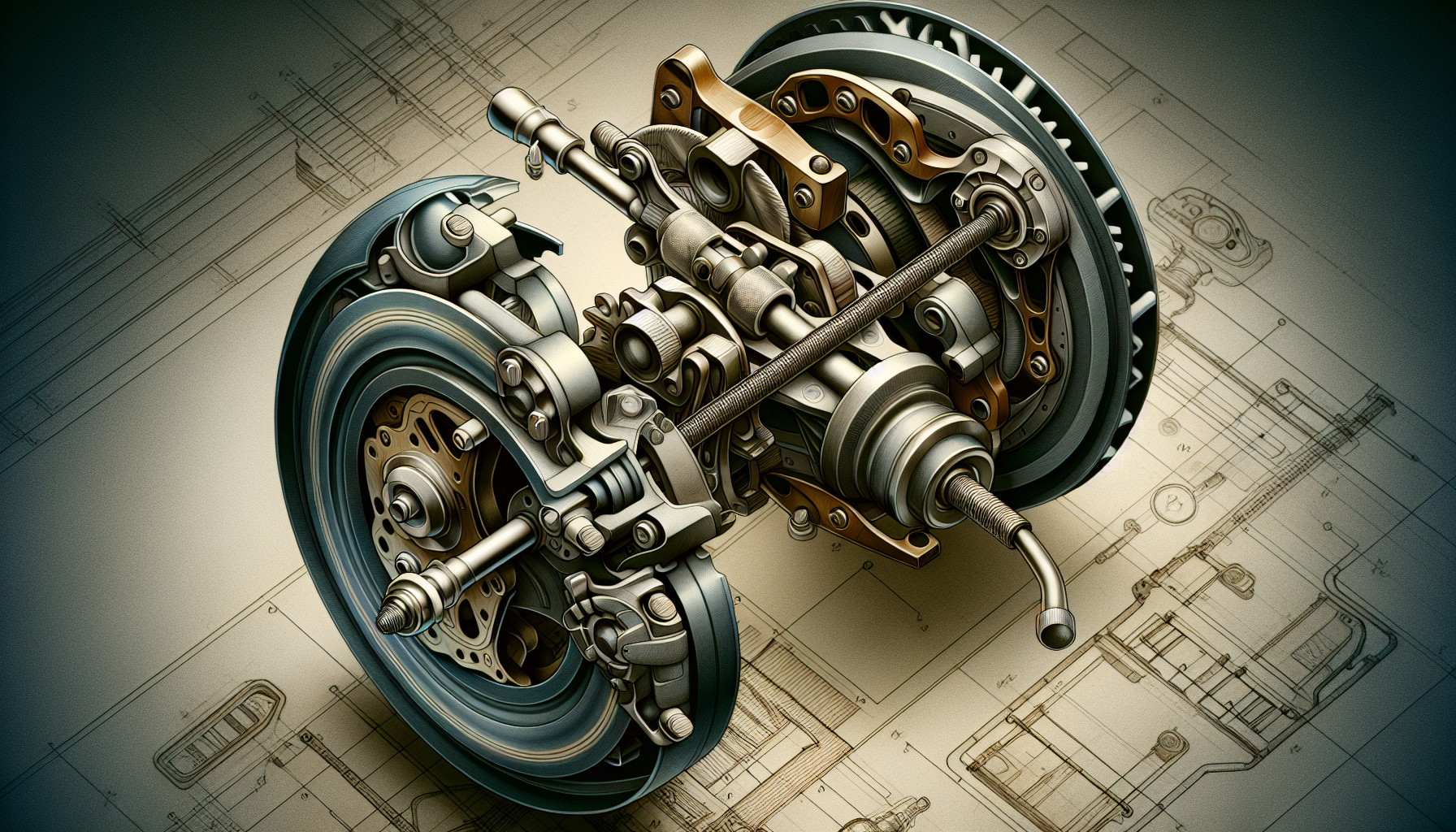

Drum brake components including the star wheel adjuster

Drum brake components including the star wheel adjuster

1.2. Types of Self-Adjusting Drum Brakes

There are variations in self-adjusting drum brake systems are apparent through designs such as duo-servo and leading-trailing shoe configurations.

- Duo-Servo: This design harnesses the friction generated during braking to press the shoes more firmly against the drum, thereby enhancing braking power.

- Leading-Trailing Shoe: This type presents an alternate method within self-adjusting drum brake mechanisms that sets it apart from its duo-servo counterpart.

2. How Self-Adjustment Works

When brake shoe wear causes a noticeable gap, the adjuster lever is activated, nudging the adjuster gear one notch at a time. This incrementally edges the shoes closer to the drum and ensures they remain at an optimal distance for effective braking.

2.1. Detecting and Engaging Slack

Drum brakes utilize a self-adjusting system to identify any slack that may develop. If this happens, indicating the brake shoes are too far from the drum, it triggers an alert for adjustment due to detected slack. During braking application, a linkage mechanism activates. This prompts movement in a lever which interacts with a ratcheted adjuster screw. Through this engagement, automatic adjustments are made as shoes continue to wear down over time—maintaining proper distance between pads and drums is crucial for efficient braking performance.

2.2. Fine-Tuning Brake Shoe Position

The star wheel adjuster is essential for maintaining the appropriate distance between the brake shoes and the drum. When a vehicle reverses and engages forceful braking, this prompts the star wheel adjuster to rotate in a specific direction, which automatically fine-tunes how close each shoe sits relative to their respective drums. After an adjustment has been made, ensuring that there’s correct tension involves spinning the wheel drum forwards.

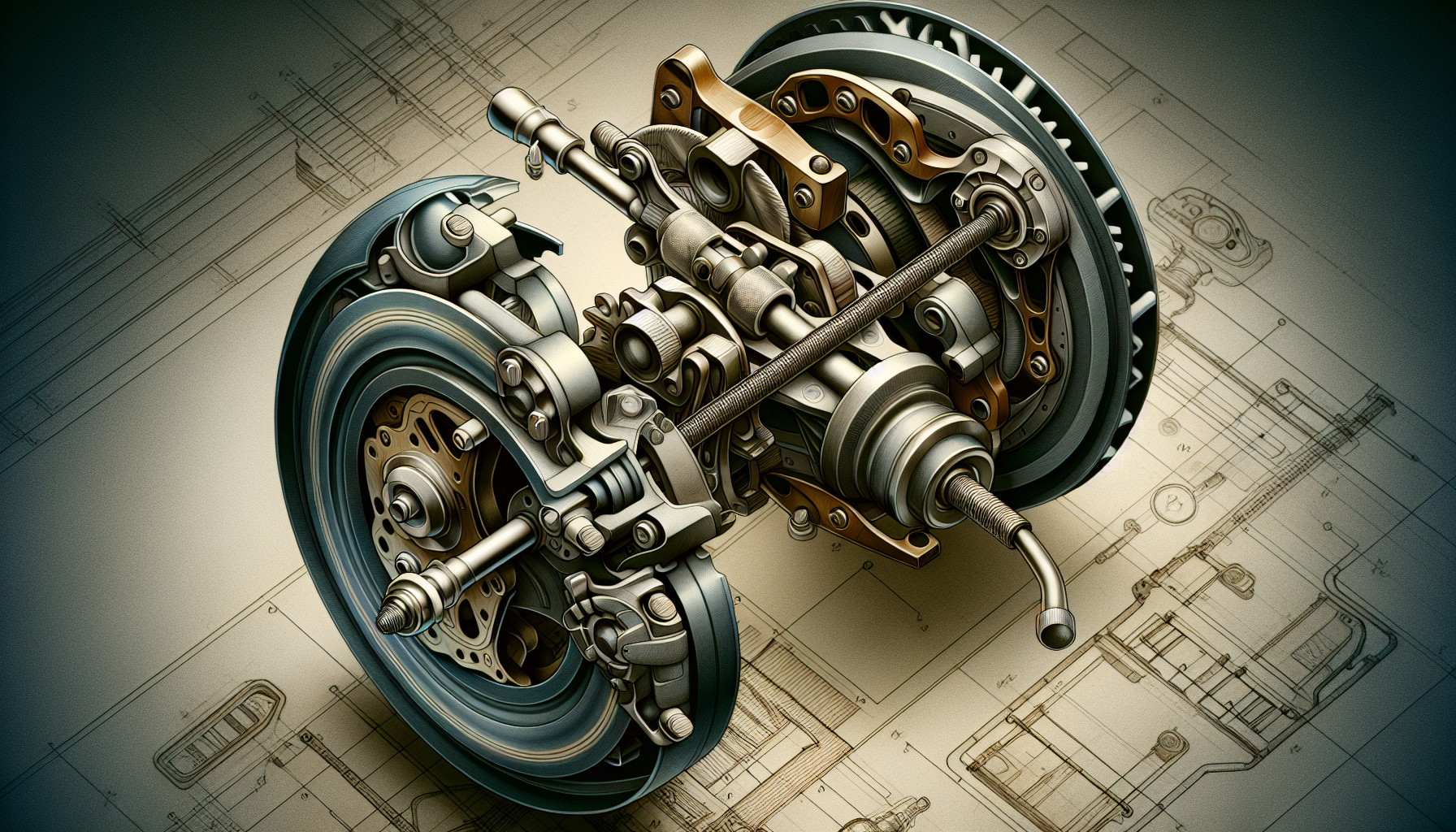

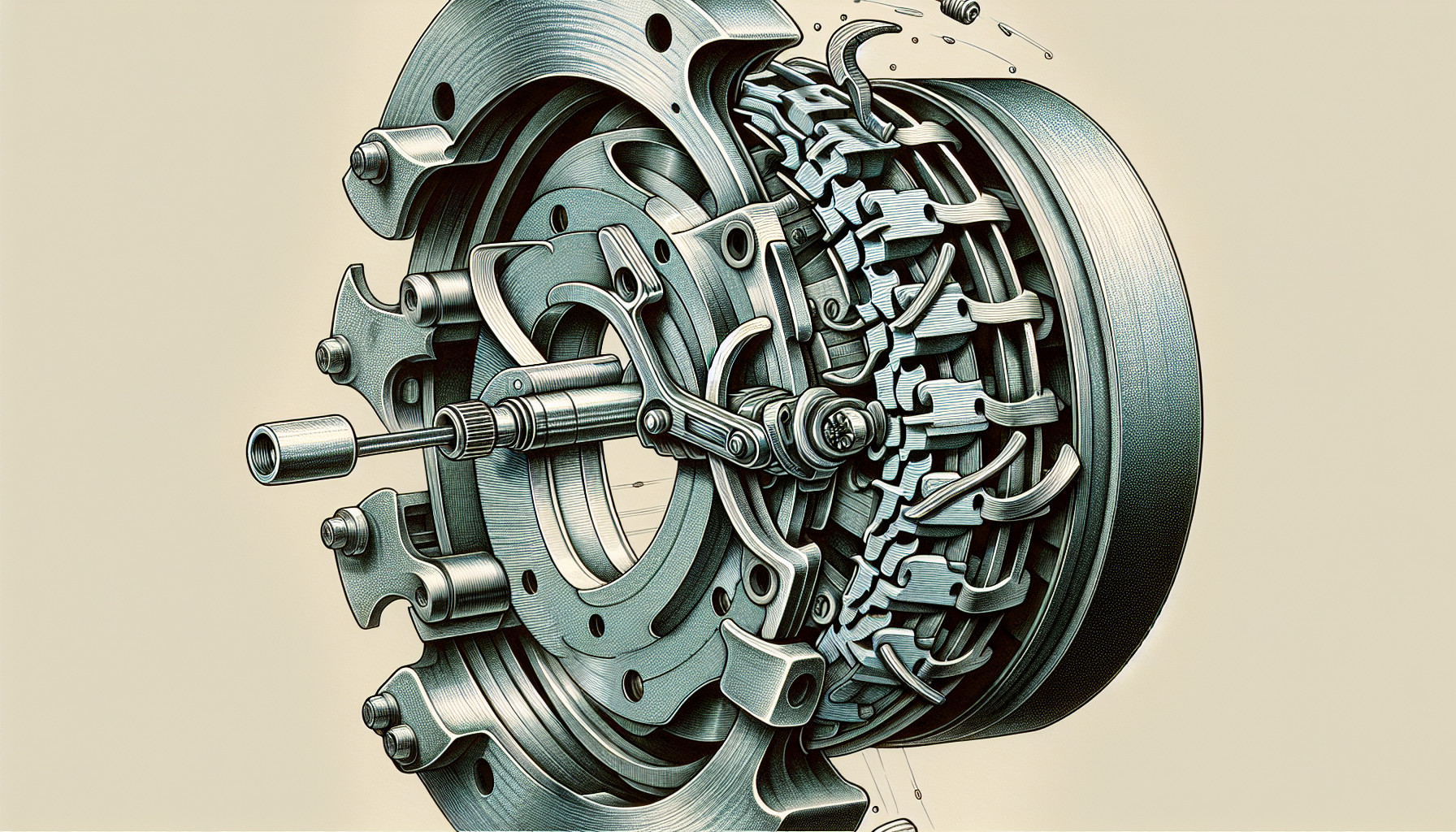

Diagram of a star wheel adjuster for drum brakes

Diagram of a star wheel adjuster for drum brakes

Here’s how the star wheel adjuster functions:

| Step | Description |

|---|---|

| 1 | It features a threaded configuration. |

| 2 | Rotating it causes it to unwind a bit, extending its length. |

| 3 | This movement repositions the brake shoes ensuring they make proper contact with the drum, maintaining optimal performance. |

3. Why Initial Manual Adjustment is Crucial

Even though self-adjusting drum brakes are designed to regulate themselves, a crucial step in ensuring their peak performance is the initial manual adjustment. Failing to execute precise initial manual adjusting can cause complications such as wear and accumulation of rust and dirt that might impair the brake’s ability for automatic self-regulation over time.

3.1. Setting the Stage for Self-Adjustment

The initial manual adjustment of self-adjusting drum brakes is an essential step to prime them for autonomous fine-tuning. This process positions the brake shoes accurately, laying the groundwork so that the self-adjusting feature can maintain proper tension and alignment moving forward. Beyond this preliminary setup, occasional manual adjustments may be needed to guarantee that automatic calibrations remain effective throughout regular use of the drum brakes.

4. Recognizing and Addressing Self-Adjustment Problems

Self-adjusting drum brakes, similar to other mechanical systems, are susceptible to wear and tear which can impede their capacity for self adjustment. The enclosed design of these brake systems may lead to issues such as corrosion or accumulated heat that hinders the correct adjustment of the brake shoes.

4.1. Identifying Signs of Wear and Malfunction

To maintain the functionality of your drum brakes, it is essential to identify any signs of deterioration or malfunction.

- A brake pedal that feels low or spongy.

- The vehicle swerving to one side while braking.

- Noise emissions such as scraping or grinding during brake engagement.

- Excessive movement in the parking brake lever or pedal before it engages.

According to a study by the National Highway Traffic Safety Administration (NHTSA), brake-related issues are a significant factor in vehicle accidents, emphasizing the importance of regular inspections and maintenance.

4.2. Maintaining Optimal Function

To ensure that your self-adjusting drum brakes operate at peak performance, it is essential to perform routine maintenance. Accumulated brake dust from semi-metallic pads can interfere with the functioning of the drum brake’s self-adjusting mechanism which may result in problems with adjusting. Consistent inspection for corrosion and prompt replacement of defective parts within the drum brakes are crucial steps in preserving their self-adjustment capability.

5. The Importance of Regular Maintenance

Even though drum brakes are designed to adjust themselves, it’s important to inspect them consistently. Driving conditions and accumulation of materials, along with typical wear and tear, can interfere with the performance of self-adjusting drum brakes. Thus, routinely examining and maintaining your vehicle’s self-adjusting drum brake system is crucial. Such maintenance not only keeps the braking system functioning at its best, but also prolongs the durability of the drum brakes, securing their status as a dependable element in your vehicle’s overall safety mechanisms.

5.1. Why Regular Brake Checks Are Necessary

Routine brake inspections are crucial to identify wear and ensure safety, even when self-adjusting mechanisms are present in drum brakes. Regular inspections can detect early signs of problems in brakes, allowing for timely repairs and avoiding more extensive and costly damage. Checking your brakes daily to ensure they maintain correct push rod travel, which should be less than one inch when manually pulled, is a recommended practice.

5.2. Extending the Life of Drum Brake Systems

Maintaining drum brakes through consistent inspection for wear on the brake shoes and verifying that the adjuster mechanism is unobstructed is crucial to maintaining their effectiveness and extending their life. Cleaning drum brakes every 60,000 miles to clear away collected brake dust not only maintains cleanliness, but also safeguards against any potential interference with the self-adjusting feature of the brakes due to this buildup.

6. Step-by-Step Guide to Manually Adjusting Drum Brakes

For car enthusiasts who take pleasure in performing their own maintenance, the process of adjusting drum brakes can provide a sense of accomplishment. This procedure involves raising the vehicle’s rear axle with a jack and taking off the wheels—much like when you change a tire—to make way for adjustment access to the wheel drum.

6.1. Essential Tools for Manual Adjustment

To carry out the manual adjustment of drum brakes, certain specialized tools are necessary. The brake spoon is an essential instrument for this job. It looks similar to a bent-shaft flat-head screwdriver and provides entry to the star wheel via the backing plate of the brake drum.

Other critical implements needed for adjusting drum brakes include a lug wrench plus a jack paired with jack stands. For secure execution of these adjustments on drum brakes, employing safety gear like chocks and perhaps even using a flashlight can be crucial.

- Brake Spoon

- Lug Wrench

- Jack and Jack Stands

- Safety Chocks

- Flashlight

6.2. Step-by-Step Adjustment Process

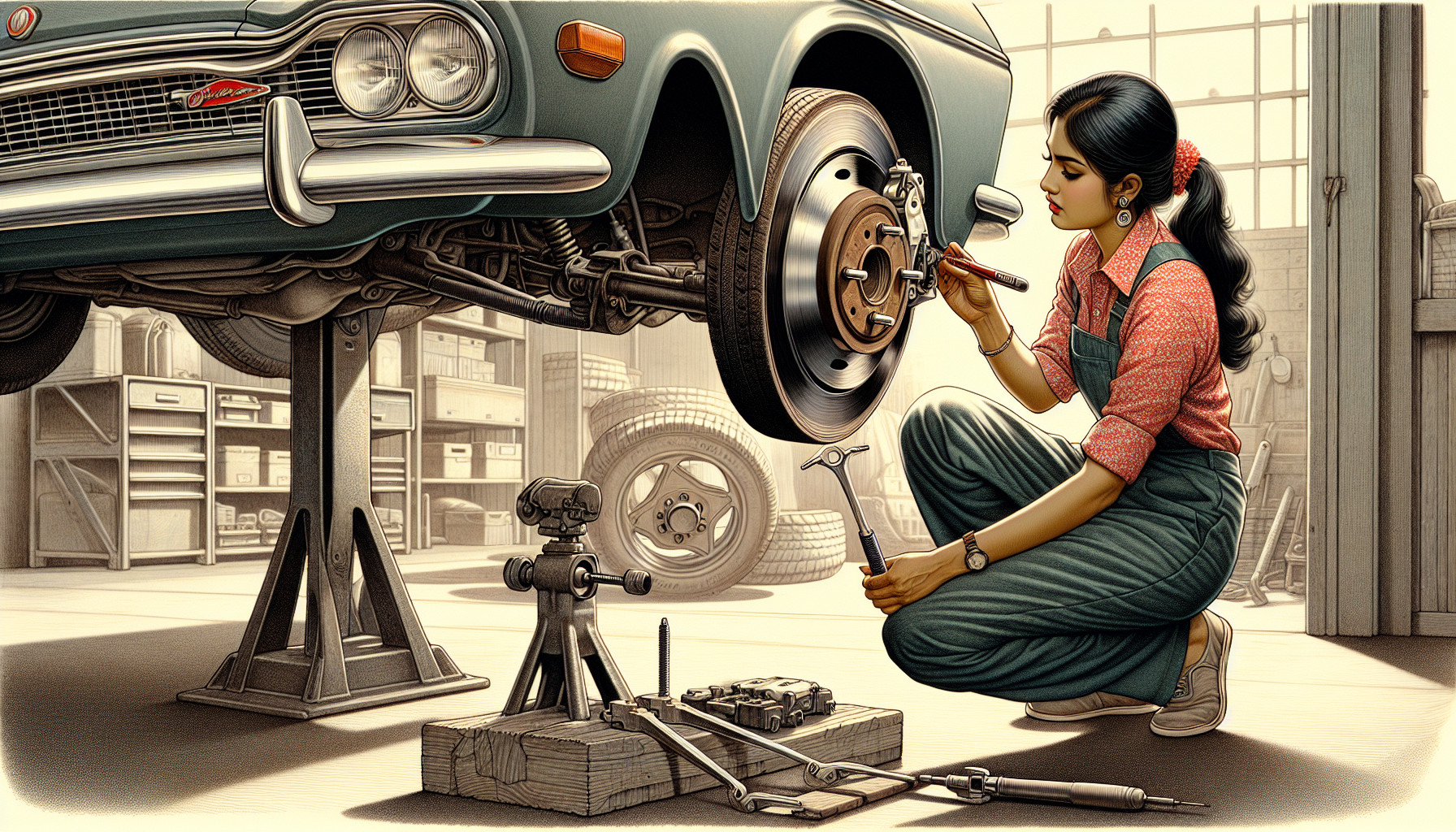

Image depicting the manual adjustment process for drum brakes

Image depicting the manual adjustment process for drum brakes

Follow these steps to manually adjust your drum brakes:

| Step | Description |

|---|---|

| 1 | Preparation: Safely lift the vehicle and remove the wheel to access the drum brake. Place the detached rear tire flat on its side beneath the central part of your vehicle’s undercarriage to prevent any potential fall from jack stands during maintenance. |

| 2 | Locate the Star Wheel: Find the star wheel adjuster through the access hole on the backing plate. |

| 3 | Adjust the Star Wheel: Insert the brake spoon and rotate the star wheel. Rotating in one direction will tighten the connection between the shoes, while the opposite will loosen them. |

| 4 | Optimal Adjustment: Aim for a close proximity of shoes to drum without generating any drag, which is critical for effective braking performance. If there is excess tightness in brakes, employing a screwdriver becomes necessary. This tool pushes against the lever associated with the adjuster thereby freeing up the star wheel enabling its movement towards loosening side concerning brake shoes. |

| 5 | Test and Reassemble: Spin the drum by hand to check for minor resistance. Reassemble the wheel and lower the vehicle. |

7. CARDIAGTECH.NET: Your Partner in Brake Maintenance

At CARDIAGTECH.NET, we understand the critical role that well-maintained brakes play in your safety and the longevity of your vehicle. That’s why we offer a wide range of high-quality tools and equipment designed to help you diagnose and maintain your drum brake systems effectively.

7.1. Why Choose CARDIAGTECH.NET?

- Expertise: Our team of experienced professionals can provide the guidance and support you need to tackle any brake maintenance task.

- Quality Tools: We offer a curated selection of top-of-the-line tools, including brake spoons, lug wrenches, jacks, and more, to ensure you have everything you need to get the job done right.

- Comprehensive Support: From diagnostic equipment to replacement parts, we’ve got you covered with a full range of products and services.

7.2. Benefits of Using Our Tools

Investing in high-quality tools from CARDIAGTECH.NET can lead to:

- Increased Efficiency: Our tools are designed to make brake maintenance tasks faster and easier, saving you time and effort.

- Improved Accuracy: Precise and reliable tools help ensure that your adjustments are accurate and effective.

- Enhanced Safety: By using the right tools for the job, you can reduce the risk of accidents and injuries.

- Cost Savings: Proper maintenance can extend the life of your brake system, saving you money on costly repairs in the long run.

7.3. Contact Us Today

Don’t wait until your brakes start showing signs of wear or malfunction. Contact CARDIAGTECH.NET today to learn more about our products and services, and how we can help you keep your drum brake systems in top condition.

Address: 276 Reock St, City of Orange, NJ 07050, United States

WhatsApp: +1 (641) 206-8880

Website: CARDIAGTECH.NET

8. Conclusion

Understanding how to check the self-adjusting mechanisms of drum brake shoes is essential for vehicle maintenance. This understanding helps maintain reliable braking efficacy despite deterioration. Grasping how they operate, identifying indications of degradation and faults, along with performing routine upkeep, is crucial for their peak performance. Opting to trust experts or taking a DIY stance on managing your vehicle’s brake system can both improve your driving enjoyment and bolster road safety.

9. Frequently Asked Questions (FAQ)

- Should you adjust self-adjusting brakes?

Yes, despite the implication of their name, self-adjusting brakes do necessitate an initial adjustment to secure optimal brake function and performance. - What is the role of the adjuster lever in self-adjusting drum brakes?

The adjuster lever prompts a one-tooth advancement of the adjuster gear when there is an expansion in the space between the drum and shoe, notably during stops made in reverse, ensuring that drum brakes are correctly adjusted. - What are the signs that drum brakes need adjusting?

Clear indications that an adjustment is required for your drum brakes are when you experience a spongy sensation or a decrease in height when pressing the brake pedal, your vehicle veering to one side while applying the brakes, hear scraping or grinding sounds, or encounter too much movement in either the parking brake lever or pedal before it engages. - How often should I check my drum brakes?

It’s important to inspect your drum brakes on a daily basis to confirm that the push rod travel is within safe limits, ideally not exceeding one inch when pulled by hand. Routine checks and upkeep are crucial to guarantee the secure functioning of self-adjusting drum brakes. - Can I manually adjust my drum brakes at home?

Yes, with the appropriate tools and understanding, you have the capability to manually adjust your drum brakes yourself. If there is any uncertainty in your ability to do so, it’s advisable to seek assistance from a professional for this task involving drum brakes adjustment. - What tools do I need to manually adjust drum brakes?

You’ll need a brake spoon, lug wrench, jack, jack stands, safety chocks, and a flashlight. - What is the purpose of the star wheel adjuster?

The star wheel adjuster is essential for maintaining the appropriate distance between the brake shoes and the drum, facilitating adjustments to make them more or less snug as necessary. - How does brake dust affect self-adjusting drum brakes?

Accumulated brake dust from semi-metallic pads can interfere with the functioning of the drum brake’s self-adjusting mechanism, which may result in problems with adjusting. - What is the importance of initial manual adjustment?

The initial manual adjustment is crucial to prime the self-adjusting mechanism for autonomous fine-tuning, positioning the brake shoes accurately and laying the groundwork for proper tension and alignment moving forward. - How can CARDIAGTECH.NET help with my brake maintenance needs?

CARDIAGTECH.NET offers a wide range of high-quality tools and equipment, along with expert guidance and support, to help you diagnose and maintain your drum brake systems effectively, ensuring your safety and the longevity of your vehicle.

Don’t hesitate to reach out to CARDIAGTECH.NET for all your automotive tool and equipment needs. We’re here to help you keep your vehicle running smoothly and safely.