**How to Check the Speed Limiter System: A Comprehensive Guide**

Speed Limiter System: Your go-to guide for understanding, checking, and maintaining your vehicle’s speed limiter system. At CARDIAGTECH.NET, we offer advanced tools and diagnostics to help you ensure this safety feature operates flawlessly, enhancing your driving experience and promoting road safety. Discover innovative solutions and diagnostic equipment available at CARDIAGTECH.NET, designed to make vehicle maintenance easier and more effective.

1. What is a Speed Limiter System?

A speed limiter system is a crucial automotive safety feature designed to prevent a vehicle from exceeding a pre-set speed. This system enhances safety by helping drivers maintain control and avoid unintended speeding, especially in areas with strict speed limits.

1.1. How Does a Speed Limiter Work?

The speed limiter uses sensors to monitor the vehicle’s speed, and when the set limit is reached, it restricts the engine’s power. This can be achieved through various methods, such as:

- Fuel Supply Reduction: Limiting the amount of fuel injected into the engine.

- Throttle Valve Control: Restricting the opening of the throttle valve.

- Ignition Timing Adjustment: Retarding the ignition timing to reduce engine output.

Alt: Diagram of a vehicle speed limiter system in an SUV, showing the engine control unit, speed sensors, and ABS module interconnected.

1.2. What Types of Vehicles Have Speed Limiters?

While initially more common in commercial vehicles like trucks and buses, speed limiters are now increasingly found in passenger vehicles. Many European countries have mandated speed limiters in new cars to enhance road safety, and this trend is growing globally.

1.3. Benefits of Using Speed Limiter Systems

- Enhanced Safety: By preventing excessive speeds, the risk of accidents is reduced.

- Improved Fuel Efficiency: Maintaining a steady speed can optimize fuel consumption.

- Reduced Wear and Tear: Preventing high speeds can reduce stress on vehicle components, extending their lifespan.

- Compliance with Speed Limits: Helps drivers adhere to local speed regulations.

- Lower Insurance Costs: Some insurance companies offer discounts for vehicles equipped with speed limiters due to the reduced risk of accidents.

1.4. Limitations of Speed Limiter Systems

- Overreliance: Drivers might become too dependent on the system, reducing their vigilance.

- Emergency Situations: In situations requiring rapid acceleration, the speed limiter could be a hindrance.

- Technical Malfunctions: System failures could lead to unexpected speed limitations or accelerations.

2. Understanding the Components of a Speed Limiter System

To effectively check a speed limiter system, you should be familiar with its main components:

2.1. Speed Sensors

Speed sensors are crucial for monitoring the vehicle’s speed. They are usually located at the wheels or transmission and send data to the ECU.

2.2. Engine Control Unit (ECU)

The ECU is the brain of the system. It processes the data from the speed sensors and controls the engine’s power output to maintain the set speed limit.

2.3. Throttle Actuator

In electronic throttle control systems, the throttle actuator adjusts the throttle valve opening based on the ECU’s commands to regulate engine power.

2.4. Fuel Injectors

Fuel injectors deliver fuel into the engine cylinders. The ECU can control the fuel injectors to limit the amount of fuel, thereby reducing engine power.

2.5. User Interface

The user interface allows the driver to set and adjust the speed limit. This can be a button, a dial, or a menu in the vehicle’s infotainment system.

3. Why Check Your Speed Limiter System?

Regularly checking your speed limiter system is essential for several reasons:

- Ensuring Proper Functionality: Verifies that the system is accurately limiting speed.

- Preventing Unexpected Failures: Detects potential issues before they lead to breakdowns.

- Maintaining Safety: Guarantees that the safety feature is operational when needed.

- Compliance with Regulations: Ensures adherence to legal requirements, especially for commercial vehicles.

- Optimizing Performance: Ensures the system does not negatively affect normal driving conditions.

4. Preliminary Checks Before Diagnostic Testing

Before diving into diagnostic testing, perform these preliminary checks:

4.1. Visual Inspection

Inspect all visible components for damage or wear. Check the wiring, connectors, and sensors for any signs of corrosion, loose connections, or physical damage.

4.2. Checking the User Interface

Verify that the user interface is functioning correctly. Ensure that the buttons, dials, or touch screen controls are responsive and that the set speed is accurately displayed.

4.3. Reviewing the Vehicle’s Manual

Consult the vehicle’s manual for specific information on the speed limiter system. The manual can provide details on the system’s operation, troubleshooting tips, and recommended maintenance procedures.

4.4. Road Test

Conduct a road test to observe the system in action. Set the speed limiter to a specific speed and monitor the vehicle’s behavior. Note any unusual behavior, such as:

- Failure to maintain the set speed.

- Jerky or erratic acceleration.

- Unusual engine noises.

- Warning lights on the dashboard.

5. Essential Tools for Checking the Speed Limiter System

To accurately diagnose and repair issues with a speed limiter system, you’ll need specific tools. CARDIAGTECH.NET offers a range of high-quality diagnostic tools designed to meet the needs of both professional technicians and DIY enthusiasts.

5.1. OBD-II Scanner

An OBD-II scanner is an indispensable tool for reading diagnostic trouble codes (DTCs) stored in the ECU. These codes can provide valuable insights into the nature and location of faults within the speed limiter system. CARDIAGTECH.NET offers advanced OBD-II scanners with features like live data streaming, freeze frame data, and bidirectional control.

5.2. Multimeter

A multimeter is essential for testing the electrical components of the speed limiter system. You can use it to check voltage, current, and resistance in circuits, sensors, and actuators. Look for multimeters with high accuracy and safety features at CARDIAGTECH.NET.

5.3. Oscilloscope

An oscilloscope is used to visualize electrical signals over time. This tool is particularly useful for diagnosing intermittent faults and analyzing the performance of sensors and actuators. CARDIAGTECH.NET offers a range of oscilloscopes suitable for automotive diagnostics.

5.4. Diagnostic Software

Diagnostic software provides advanced capabilities for analyzing and troubleshooting complex systems like speed limiters. This software can access detailed system information, perform component tests, and reprogram ECUs. CARDIAGTECH.NET offers a variety of diagnostic software solutions compatible with different vehicle makes and models.

5.5. Hand Tools

A set of basic hand tools, including screwdrivers, pliers, wrenches, and sockets, is necessary for accessing and disconnecting components. Invest in high-quality tools from CARDIAGTECH.NET to ensure durability and reliability.

6. Step-by-Step Guide to Checking the Speed Limiter System

Follow these steps to thoroughly check your vehicle’s speed limiter system:

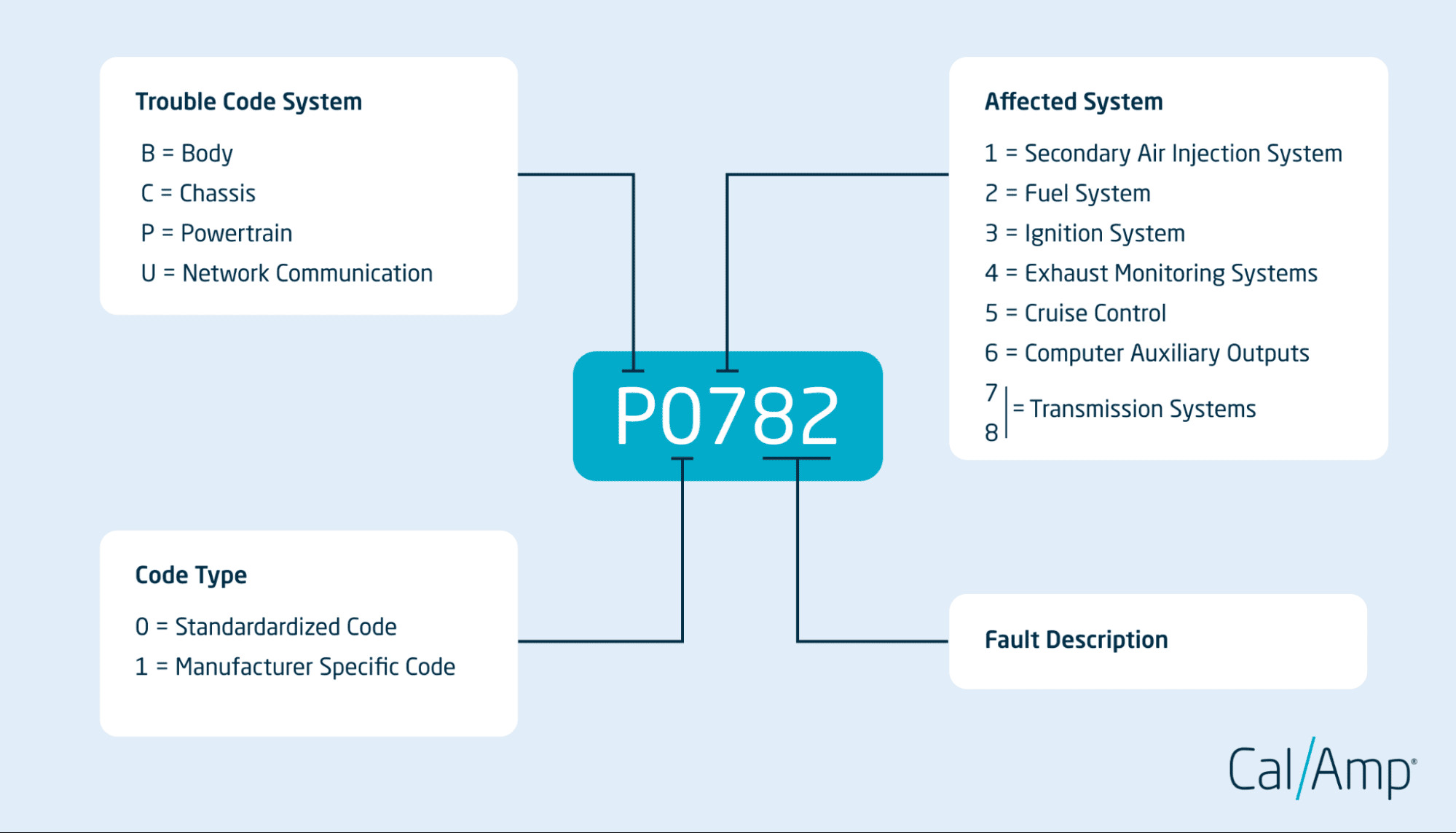

6.1. Reading Diagnostic Trouble Codes (DTCs)

- Connect the OBD-II Scanner: Plug the OBD-II scanner into the diagnostic port, usually located under the dashboard.

- Turn on the Ignition: Turn the ignition key to the “on” position without starting the engine.

- Read the DTCs: Follow the scanner’s instructions to read any stored DTCs. Note down the codes and their descriptions.

- Interpret the Codes: Consult the vehicle’s service manual or a reliable online database to interpret the meaning of the DTCs. This will help you identify the specific components or circuits that are causing the problem.

6.2. Testing Speed Sensors

- Locate the Speed Sensors: Identify the location of the speed sensors, usually at the wheels or transmission.

- Check for Voltage: Use a multimeter to check the voltage at the sensor connector. Refer to the vehicle’s service manual for the correct voltage specifications.

- Check for Signal Output: Use an oscilloscope to check the signal output from the sensor while the wheel is rotating. The signal should be a clean waveform with the correct frequency and amplitude.

- Test Sensor Resistance: Disconnect the sensor and use a multimeter to measure the resistance across the sensor terminals. Compare the reading to the specifications in the service manual.

6.3. Checking the Engine Control Unit (ECU)

- Check ECU Power Supply: Verify that the ECU is receiving power and ground. Use a multimeter to check the voltage at the ECU power and ground pins.

- Check ECU Communication: Use an OBD-II scanner to verify that the ECU is communicating with other modules in the vehicle.

- Perform ECU Reset: In some cases, resetting the ECU can resolve minor issues. Follow the scanner’s instructions to perform an ECU reset.

6.4. Verifying Throttle Actuator Functionality

- Check Actuator Voltage: Use a multimeter to check the voltage at the throttle actuator connector. Refer to the vehicle’s service manual for the correct voltage specifications.

- Perform Actuator Test: Use a diagnostic scanner to perform an actuator test. This test will command the actuator to move through its range of motion, allowing you to observe its performance.

- Check Actuator Position Sensor: Use a multimeter to check the position sensor signal. The signal should change smoothly as the actuator moves.

6.5. Inspecting Fuel Injectors

- Check Injector Resistance: Disconnect the fuel injectors and use a multimeter to measure the resistance across the injector terminals. Compare the reading to the specifications in the service manual.

- Check Injector Voltage: Use a multimeter to check the voltage at the injector connector while the engine is running. The voltage should be pulsing as the injectors are firing.

- Listen to Injector Operation: Use a stethoscope or a long screwdriver to listen to the injectors while the engine is running. You should hear a distinct clicking sound as the injectors are firing.

7. Common Issues and Troubleshooting Tips

7.1. Speed Limiter Not Engaging

- Possible Causes: Faulty speed sensors, ECU issues, wiring problems, user interface malfunctions.

- Troubleshooting Steps:

- Check speed sensor signals with an oscilloscope.

- Verify ECU power and ground connections.

- Inspect wiring and connectors for damage.

- Test the user interface controls.

7.2. Speed Limiter Engaging Erratically

- Possible Causes: Intermittent sensor faults, ECU glitches, throttle actuator issues.

- Troubleshooting Steps:

- Use an oscilloscope to monitor sensor signals for dropouts or noise.

- Perform an ECU reset.

- Check the throttle actuator position sensor.

7.3. Incorrect Speed Limiter Setting

- Possible Causes: User error, software bugs, ECU programming issues.

- Troubleshooting Steps:

- Review the user interface settings.

- Update the ECU software.

- Reprogram the ECU if necessary.

7.4. Warning Lights On the Dashboard

- Possible Causes: Various system faults, including sensor failures, ECU problems, and wiring issues.

- Troubleshooting Steps:

- Read DTCs with an OBD-II scanner.

- Interpret the codes to identify the specific fault.

- Follow the troubleshooting steps for the identified fault.

8. Advanced Diagnostic Techniques

For complex issues, consider these advanced diagnostic techniques:

8.1. Data Logging

Use an OBD-II scanner or diagnostic software to log data from the speed limiter system while driving. This can help you identify intermittent faults and analyze system performance under various conditions.

8.2. Component Isolation

Disconnect individual components to isolate faults. For example, disconnect a speed sensor to see if the problem goes away.

8.3. Wiring Harness Testing

Use a multimeter to test the continuity and resistance of the wiring harness. This can help you identify shorts, opens, and high-resistance connections.

8.4. ECU Reprogramming

In some cases, reprogramming the ECU can resolve software bugs or compatibility issues. However, ECU reprogramming should only be performed by trained professionals with the proper equipment.

9. Maintenance Tips for Speed Limiter Systems

9.1. Regular Inspections

Conduct regular visual inspections of the system components, including wiring, connectors, and sensors.

9.2. Cleaning Sensors

Clean speed sensors regularly to remove dirt and debris that can interfere with their performance.

9.3. Software Updates

Keep the ECU software up to date to ensure compatibility and optimal performance.

9.4. Professional Service

Have the