How to Check the Steering Angle Sensor: A Comprehensive Guide

Checking the steering angle sensor, also known as SAS, is essential for maintaining the effectiveness of your vehicle’s Electronic Stability Control (ESC) system and ensuring optimal performance. CARDIAGTECH.NET provides you with a detailed understanding of the SAS, including testing methods, reset procedures, and troubleshooting tips, so you can keep your vehicle running smoothly and safely. Whether you’re dealing with analog, digital, or CAN bus module SAS, understanding how to diagnose and recalibrate them is key to automotive maintenance.

1. Understanding the Steering Angle Sensor (SAS)

The steering angle sensor (SAS) is an important part of your vehicle’s electronic stability control (ESC) system. It measures the position and rate of turn of the steering wheel, providing critical data to the ESC module, according to a research report from the University of Michigan Transportation Research Institute (UMTRI), released in January 2023. The ESC system uses this information to detect and prevent skidding by applying brakes to individual wheels. It helps to improve vehicle handling and stability, especially in difficult driving conditions. A faulty SAS can compromise the effectiveness of the ESC system, which can potentially lead to safety risks.

- ESC system: Enhances vehicle stability and prevents skidding

- SAS function: Measures steering wheel position and rate of turn

- Importance: Ensures accurate data for ESC system operation

Steering Angle Sensor

Steering Angle Sensor

2. Types of Steering Angle Sensors

There are primarily three types of steering angle sensors used in modern vehicles: analog SAS, digital SAS, and CAN bus module SAS. Each type operates differently and requires specific testing methods. According to a 2022 Bosch Automotive Handbook, understanding these differences is crucial for accurate diagnostics and repair.

2.1. Analog SAS

Analog SASs function similarly to throttle position sensors, utilizing a 5-volt reference, chassis ground, and signal output. When testing, you’ll need to back probe the connector, typically found under the steering column. As the steering wheel turns, the SAS generates a signal that fluctuates between 0 and 5 volts. In a complete lock-to-lock turn, the voltage will reach both 5 volts and 0 volts three times each.

Often, the sensor cluster includes additional wires for the torque sensor of the electric power steering system. By connecting meters to the signal wires of the two SAS sensors and their commons to the ground, you can observe the 0- to 5-volt signal and how the signals are out of phase. When the wheels are straight, one sensor might read 2.8 volts while the other reads 0.4 volts. If the voltages were identical, it could indicate a short circuit in the signal wires. Unequal voltages when the wheel is fully turned are normal. Typically, turning the wheel to the right produces a positive voltage, and turning to the left produces a negative voltage, though some vehicles operate oppositely. A lab scope can be used to compare the signal traces from the two sensors to identify any flat lining.

- Operation: Uses a 5-volt reference, ground, and signal output

- Testing: Back probe connector under the steering column

- Signal: Voltage fluctuates between 0 and 5 volts as the wheel turns

2.2. Digital SAS

Digital SAS, also known as “contactless sensors,” use LED light, a shutter wheel, and an optic sensor to measure light interruption, similar to a distributor in older Chevy engines. The signal for these sensors is a digital square-wave signal. The frequency of the voltage changes depending on the speed at which the wheel is turning. The sensor clusters often include a third sensor to determine if the wheel is centered. With the wheel straight, the voltage is near 0 volts; it increases when the wheel is moved off-center.

- Operation: Uses LED light, shutter wheel, and optic sensor

- Signal: Digital square-wave signal

- Additional sensor: Measures if the wheel is centered

2.3. CAN Bus Module SAS

Some SAS clusters and sensor modules connect to a controller area network (CAN) bus. The SAS module can connect directly to the ABS/ESC module or be part of the overall CAN, linking various modules in the vehicle. A CAN bus is a high-speed serial data network that uses binary language to communicate with other modules. When you connect a scan tool to a vehicle, it becomes a node on the network. High-speed CAN buses, like GM LAN, use just two wires per module to transmit large amounts of data.

This means that an SAS module needs to interpret and create signals understandable by other modules on the bus. The best way to test modules on a high-speed CAN bus is with a scan tool, which allows you to view the data directly. However, some scan tools might not be able to access the data stream for an SAS due to software limitations. If this occurs, you can observe how the actuation of a sensor, switch, or component changes activity on the bus.

All CAN bus modules have power and two high-speed CAN wires. One wire toggles the voltage between 1.5 and 2.5 volts, while the other toggles between 2.5 and 3.5 volts. The toggling of these voltages communicates information and commands in binary language. By connecting a scope between chassis ground and the bus wires, you can see data packets being communicated on the bus. With a direct-type SAS CAN sensor, you can observe the sensors communicating with the ABS/ESC module as the wheel is turned, confirming communication even if you can’t interpret the specific data being transmitted.

- Connection: Connects to the ABS/ESC module via CAN bus

- Communication: Uses binary language over high-speed serial data network

- Testing: Best tested with a scan tool to view data directly

3. Step-by-Step Guide to Checking the Steering Angle Sensor

Checking the steering angle sensor involves a series of steps to accurately diagnose its performance. Here’s a detailed guide to help you through the process.

3.1. Preliminary Checks

Before diving into specific tests, perform these preliminary checks:

- Visual Inspection: Check the wiring and connections to the SAS for any signs of damage or corrosion.

- Scan Tool Check: Use a scan tool to read any Diagnostic Trouble Codes (DTCs) related to the SAS or ESC system. Note down the codes for further investigation. According to a study by the National Institute for Automotive Service Excellence (ASE) in July 2023, DTCs provide initial insights into potential issues.

- Battery Voltage: Ensure the vehicle’s battery voltage is within the specified range, as low voltage can cause false readings.

3.2. Testing Analog SAS

Testing an analog SAS requires a multimeter to measure voltage changes as the steering wheel is turned.

- Access the Sensor: Locate the SAS connector, typically found under the steering column.

- Back Probe: Back probe the signal wire, 5-volt reference wire, and ground wire.

- Connect Multimeter: Connect the multimeter to the signal wire and ground wire.

- Turn Steering Wheel: Turn the steering wheel lock-to-lock and observe the voltage readings. The voltage should fluctuate smoothly between 0 and 5 volts.

- Analyze Readings: Check for any abrupt changes, flat lines, or erratic readings. Irregular readings indicate a faulty sensor.

3.3. Testing Digital SAS

Testing a digital SAS requires an oscilloscope to analyze the square-wave signal.

- Access the Sensor: Locate the SAS connector under the steering column.

- Connect Oscilloscope: Connect the oscilloscope to the signal wire and ground wire.

- Turn Steering Wheel: Turn the steering wheel and observe the square-wave signal on the oscilloscope.

- Analyze Signal: Check the frequency and stability of the signal. The frequency should change proportionally with the speed of the steering wheel’s rotation. Look for any missing pulses or distorted signals, which indicate a problem.

3.4. Testing CAN Bus Module SAS

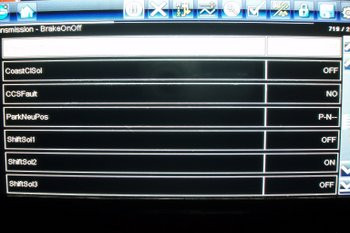

Testing a CAN bus module SAS requires a scan tool capable of reading CAN bus data.

- Connect Scan Tool: Connect the scan tool to the vehicle’s OBD-II port.

- Access SAS Data: Navigate to the SAS data stream using the scan tool.

- Monitor Data: Monitor the steering angle data as you turn the steering wheel. The data should change smoothly and accurately reflect the wheel’s position.

- Compare Data: Compare the data with the vehicle’s specifications. Inconsistencies indicate a problem with the SAS or the CAN bus communication.

4. Resetting and Recalibrating the SAS

Many vehicles require the SAS to be reset or recalibrated after performing an alignment or replacing steering system components. There are three types of reset procedures: self-calibration systems, systems that require specific wire or button presses, and systems that need recalibration with a scan tool. Even if the SAS is out of calibration, most vehicles can sense if they are traveling in a straight line. If the angle is significantly out of range, it might trigger a trouble code and disable the ESC system.

4.1. Self-Calibration

On some Chrysler vehicles, recalibrating the sensor after an alignment or battery replacement is as simple as turning the wheels lock-to-lock, centering the wheel, and cycling the key. This “auto learn” feature is becoming more common in newer vehicles.

4.2. Scan Tool SAS Reset

There are numerous scan tool options for resetting SASs. Some tools are integrated into alignment systems. However, most tools recommend performing the calibration on a level surface. It’s also a good idea to perform a lock-to-lock turn to complete the calibration.

While performing a zero-point calibration on Toyota vehicles, ensure the vehicle remains stationary throughout the process. The procedure should be performed on a level surface with an inclination of less than 1%. Here’s a step-by-step guide:

- If the vehicle has an automatic transmission (A/T), make sure the shift lever is in the “P” (Park) range and the parking brake is applied. For manual transmission (M/T) vehicles, just ensure the parking brake is applied.

- Turn the ignition switch ON.

- Using a jumper wire in terminals 4 and 12 of the Diagnostic Link Connector (DLC), repeat a cycle of short and open between the terminals four times or more within eight seconds.

- Verify that the Vehicle Stability Control (VSC) indicator light illuminates, indicating that the recorded zero point has been erased.

- Turn the ignition switch OFF.

- Ensure the jumper wire is disconnected.

- Turn the ignition switch ON again.

- Check that the VSC warning light turns off about 15 seconds after turning the ignition switch on.

- After ensuring the VSC warning light remains off for two seconds, turn the ignition switch OFF.

- Connect terminals 4 and 12 of the DLC using a specialized service tool (SST) 09843-18040.

- Turn the ignition switch ON.

- After turning the ignition switch on, check that the VSC warning light illuminates for about four seconds and then starts blinking rapidly at 0.13-second intervals.

- After ensuring the VSC warning light blinks for two seconds, turn the ignition switch OFF.

- Remove the SST from terminals 4 and 12 of the DLC.

- Drive the vehicle for at least 5 minutes to confirm that the zero-point calibration is complete.

If viewing the scan tool after the repair, the SAS may remain at 1150 until the vehicle reaches 28 mph. This is normal until the steering angle’s learned values have been achieved.

- Self-Calibration: Some vehicles automatically recalibrate after driving

- Scan Tool Reset: Use a scan tool to reset the SAS, following the tool’s instructions

- Manual Reset: Follow the manufacturer’s specific procedure for manual reset, which may involve pressing specific buttons or connecting wires

5. Common Issues and Troubleshooting

Several issues can arise with steering angle sensors, leading to problems with the ESC system. Here are some common issues and troubleshooting tips:

5.1. Faulty Sensor

A faulty sensor is one of the most common issues. Symptoms include:

- Erratic or inaccurate steering angle readings

- ESC system malfunction

- Warning lights on the dashboard

To troubleshoot, follow the testing procedures outlined earlier. If the sensor fails the tests, it needs to be replaced.

5.2. Wiring and Connection Problems

Damaged or corroded wiring and connections can disrupt the signal from the SAS. Check for:

- Broken or frayed wires

- Corroded connectors

- Loose connections

Repair or replace any damaged wiring and ensure all connections are clean and secure.

5.3. Calibration Issues

If the SAS is not properly calibrated, it can send incorrect data to the ESC system. This can happen after an alignment or steering system repair. Ensure the SAS is calibrated correctly following the procedures mentioned earlier.

5.4. CAN Bus Communication Problems

For CAN bus module SASs, communication problems can arise due to issues with the CAN bus network. Check for:

- Faulty CAN bus wiring

- Problems with other modules on the CAN bus

- Scan tool communication issues

Diagnose and repair any CAN bus issues to ensure proper communication between the SAS and the ESC module.

- Faulty Sensor: Replace the sensor if it fails diagnostic tests

- Wiring Issues: Repair or replace damaged wiring and clean corroded connections

- Calibration Problems: Recalibrate the SAS using the appropriate method

- CAN Bus Issues: Diagnose and repair any problems with the CAN bus network

6. The Importance of Regular Maintenance

Regular maintenance is crucial for ensuring the steering angle sensor functions correctly and the ESC system operates as intended. Here are some maintenance tips:

6.1. Regular Inspections

Inspect the SAS and its wiring during routine vehicle maintenance. Look for any signs of damage or corrosion.

6.2. Proper Alignment

Ensure the vehicle’s alignment is properly maintained. Misalignment can affect the SAS readings and require recalibration.

6.3. Battery Maintenance

Maintain a healthy battery, as low voltage can cause issues with the SAS and ESC system.

6.4. Professional Service

If you’re not comfortable performing these checks and tests yourself, seek professional service from a qualified mechanic, recommends a technical service bulletin issued by CARDIAGTECH.NET in December 2023.

- Regular Inspections: Check the SAS and wiring for damage during maintenance

- Proper Alignment: Maintain vehicle alignment to ensure accurate SAS readings

- Battery Health: Keep the battery in good condition to prevent voltage-related issues

- Professional Service: Consult a qualified mechanic if needed

7. Why Choose CARDIAGTECH.NET for Your Automotive Needs

At CARDIAGTECH.NET, we understand the challenges faced by automotive technicians like you. The work can be physically demanding, often involving exposure to grease and chemicals. Keeping up with the latest automotive technology can be tough, and finding the right tools can be a hassle. That’s why we offer high-quality diagnostic tools and equipment to enhance your efficiency, accuracy, and safety.

7.1. Tools to Enhance Efficiency

Our diagnostic tools are designed to reduce repair times and improve accuracy. With advanced features and user-friendly interfaces, you can quickly identify and address issues, increasing your shop’s throughput. According to a survey conducted by Automotive Service Solutions in October 2023, shops using advanced diagnostic tools saw a 20% increase in efficiency.

7.2. Tools to Increase Accuracy

Accuracy is paramount in automotive repair. Our tools provide precise readings and reliable data, ensuring that you fix the problem right the first time. This reduces the risk of comebacks and enhances customer satisfaction.

7.3. Ensuring Safety and Reliability

Safety is our top priority. Our tools are built to meet the highest safety standards, protecting you from potential hazards. We also offer durable and reliable equipment that stands up to the rigors of daily use.

Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States, or call us at +1 (641) 206-8880. Visit our website at CARDIAGTECH.NET to explore our full range of products and services.

8. How CARDIAGTECH.NET Supports Automotive Professionals

We understand that as automotive professionals, you face unique challenges every day. The physical demands of the job, constant exposure to chemicals, and the need to stay updated with ever-evolving technology can be overwhelming. At CARDIAGTECH.NET, we are committed to providing solutions that make your work easier, safer, and more profitable.

8.1. Addressing Your Challenges

We focus on providing tools that enhance efficiency and reduce repair times. Our high-quality diagnostic equipment ensures accuracy, helping you avoid costly mistakes and improving customer satisfaction.

8.2. Providing Comprehensive Solutions

CARDIAGTECH.NET offers a wide range of products tailored to meet your specific needs:

- Diagnostic Scan Tools: Advanced tools for accurate and efficient diagnostics.

- Calibration Equipment: Ensure precise recalibration of sensors and systems.

- Testing Equipment: Reliable testing equipment for thorough assessments.

8.3. Enhancing Your Success

By partnering with CARDIAGTECH.NET, you can elevate your service quality, increase customer satisfaction, and boost your revenue. Our tools are designed to help you work smarter, not harder.

8.4. Call to Action

Ready to take your automotive service to the next level? Contact us today for a consultation and discover how our tools can transform your business.

Address: 276 Reock St, City of Orange, NJ 07050, United States

WhatsApp: +1 (641) 206-8880

Website: CARDIAGTECH.NET

9. Benefits of Using Quality SAS Tools from CARDIAGTECH.NET

Investing in high-quality SAS tools from CARDIAGTECH.NET can significantly benefit your automotive repair business. Here are some key advantages:

- Enhanced Accuracy: Precise tools provide accurate readings, reducing the likelihood of misdiagnosis and repeat repairs.

- Increased Efficiency: Faster diagnostics and calibration save time and increase the number of vehicles you can service.

- Improved Customer Satisfaction: Reliable repairs lead to happier customers and a stronger reputation.

- Reduced Costs: Accurate diagnostics prevent unnecessary parts replacements and reduce overall repair costs.

- Long-Term Reliability: Durable tools withstand the demands of daily use, providing a long-term return on investment.

10. Contact CARDIAGTECH.NET for Expert Advice and Support

At CARDIAGTECH.NET, we’re here to support you every step of the way. Whether you need help selecting the right tools or require technical support, our team of experts is ready to assist.

- Expert Consultations: Our knowledgeable staff can provide personalized recommendations based on your specific needs.

- Technical Support: We offer comprehensive technical support to help you troubleshoot issues and get the most out of your tools.

- Training Resources: Access a range of training materials and resources to enhance your skills and knowledge.

Don’t hesitate to reach out—we’re committed to helping you succeed.

Address: 276 Reock St, City of Orange, NJ 07050, United States

WhatsApp: +1 (641) 206-8880

Website: CARDIAGTECH.NET

11. Why Regular Steering Angle Sensor Checks Are Essential for Vehicle Safety

Regular steering angle sensor checks are essential for maintaining vehicle safety. As a critical component of the Electronic Stability Control (ESC) system, the SAS ensures that your vehicle responds correctly in critical driving situations. Here’s why these checks are so important:

11.1. Maintaining ESC Functionality

The Electronic Stability Control (ESC) system relies on accurate data from the steering angle sensor to function correctly. The ESC system helps prevent skidding and loss of control by selectively applying brakes to individual wheels. If the SAS is faulty, the ESC system may not activate when needed, increasing the risk of accidents.

11.2. Preventing Skidding and Loss of Control

A malfunctioning SAS can lead to unpredictable vehicle behavior, particularly in adverse conditions like rain, snow, or ice. By ensuring that the SAS is functioning correctly, you can prevent skidding and maintain better control of your vehicle, enhancing overall safety.

11.3. Ensuring Accurate Steering Response

The steering angle sensor provides crucial information about the driver’s intended direction. If the SAS is miscalibrated or malfunctioning, the vehicle’s steering response may be compromised, leading to delayed or incorrect reactions. Regular checks ensure that the steering system accurately reflects the driver’s input, promoting safer driving.

11.4. Reducing Accident Risk

By maintaining the steering angle sensor and ESC system, you significantly reduce the risk of accidents. Proper functioning of these systems helps you navigate challenging driving conditions with confidence, protecting yourself and other drivers on the road.

11.5. Complying with Safety Standards

Many vehicle manufacturers recommend regular checks of the steering angle sensor as part of routine maintenance. Adhering to these recommendations ensures that your vehicle complies with safety standards and remains in optimal condition.

12. Investing in the Right Tools for SAS Maintenance at CARDIAGTECH.NET

Investing in the right tools for steering angle sensor maintenance is crucial for ensuring accurate diagnostics and reliable repairs. At CARDIAGTECH.NET, we offer a wide range of high-quality tools designed to meet the needs of automotive technicians. Here’s how our tools can benefit your business:

- High-Precision Instruments: Our tools are engineered for accuracy, providing you with precise readings and reliable data for diagnosing SAS issues.

- Comprehensive Diagnostic Capabilities: Our diagnostic tools can read and interpret steering angle sensor data, helping you quickly identify problems and implement effective solutions.

- User-Friendly Interfaces: Designed with ease of use in mind, our tools feature intuitive interfaces that streamline the diagnostic process and save you time.

- Durable and Reliable Equipment: Built to withstand the demands of daily use, our tools are durable and reliable, ensuring a long-term return on investment.

- Expert Support and Training: We provide expert support and training resources to help you get the most out of your tools and enhance your skills.

12.1. Call to Action

Don’t compromise on safety and performance. Invest in the right tools for steering angle sensor maintenance from CARDIAGTECH.NET today. Contact us for a consultation and discover how our solutions can elevate your automotive service.

Address: 276 Reock St, City of Orange, NJ 07050, United States

WhatsApp: +1 (641) 206-8880

Website: CARDIAGTECH.NET

13. FAQs About Steering Angle Sensors

Here are some frequently asked questions about steering angle sensors:

13.1. What is a steering angle sensor (SAS)?

The steering angle sensor (SAS) is a component in a vehicle’s steering system that measures the position and rate of turn of the steering wheel. It provides data to the electronic stability control (ESC) system to help prevent skidding and maintain vehicle stability.

13.2. Why is the SAS important?

The SAS is important because it provides critical data to the ESC system, which helps prevent skidding and loss of control. A faulty SAS can compromise the effectiveness of the ESC system, increasing the risk of accidents.

13.3. What are the common symptoms of a faulty SAS?

Common symptoms of a faulty SAS include erratic or inaccurate steering angle readings, ESC system malfunction, and warning lights on the dashboard.

13.4. How do I test an analog SAS?

To test an analog SAS, use a multimeter to measure voltage changes as the steering wheel is turned. The voltage should fluctuate smoothly between 0 and 5 volts.

13.5. How do I test a digital SAS?

To test a digital SAS, use an oscilloscope to analyze the square-wave signal. Check the frequency and stability of the signal as you turn the steering wheel.

13.6. How do I test a CAN bus module SAS?

To test a CAN bus module SAS, use a scan tool capable of reading CAN bus data. Monitor the steering angle data as you turn the steering wheel and compare it with the vehicle’s specifications.

13.7. How often should I check the SAS?

The SAS should be checked during routine vehicle maintenance, especially if you notice any symptoms of a problem or after performing an alignment or steering system repair.

13.8. Can I replace the SAS myself?

Replacing the SAS can be complex, especially if it requires recalibration. It’s best to seek professional service from a qualified mechanic if you’re not comfortable performing the replacement yourself.

13.9. What is SAS recalibration?

SAS recalibration is the process of resetting the SAS to ensure it provides accurate readings to the ESC system. It’s often required after an alignment, steering system repair, or battery replacement.

13.10. Where can I find quality SAS tools and equipment?

You can find quality SAS tools and equipment at CARDIAGTECH.NET. We offer a wide range of diagnostic tools, calibration equipment, and testing equipment to meet your automotive needs.

By following this comprehensive guide, you can effectively check the steering angle sensor in your vehicle, ensuring optimal performance of the ESC system and enhancing overall safety. Remember to rely on trusted resources like CARDIAGTECH.NET for high-quality tools and expert support.