How to Check the Torque Converter Lock-Up Function: A Comprehensive Guide

Torque converter lock-up function is a critical aspect of your vehicle’s transmission, influencing fuel efficiency and overall performance. CARDIAGTECH.NET offers expert insights and diagnostic tools to help you understand and address lock-up issues effectively, ensuring optimal performance with the right transmission service and diagnostic procedures. Explore solutions for transmission efficiency, torque converter diagnostics, and transmission performance enhancement to elevate your driving experience.

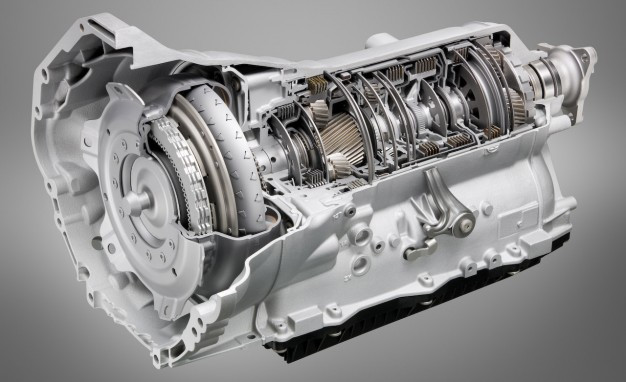

1. What is the Torque Converter Lock-Up Function?

The torque converter lock-up function is a system in automatic transmissions that increases fuel efficiency by mechanically linking the engine to the transmission. According to a 2018 study by the Oak Ridge National Laboratory, torque converter lock-up improves fuel economy by approximately 5-7% by eliminating slippage. This direct connection reduces power loss, lowers heat generation, and boosts overall vehicle efficiency.

1.1 How Does Torque Converter Lock-Up Work?

Torque converter lock-up engages a clutch inside the torque converter that creates a direct, mechanical connection between the engine and transmission. The BorgWarner technical paper from 2020 explained that this process eliminates the fluid coupling inherent in standard torque converter operation, reducing energy loss and improving fuel efficiency.

1.2 Benefits of Torque Converter Lock-Up

The primary benefits of torque converter lock-up include improved fuel economy and reduced heat generation within the transmission. According to the U.S. Department of Energy, reducing heat helps extend the life of transmission components. Further, it enhances overall driving performance by providing a more direct and responsive power transfer.

2. Why is Checking the Torque Converter Lock-Up Function Important?

Checking the torque converter lock-up function is essential to ensure optimal vehicle performance and prevent potential damage to the transmission system. The University of Michigan Transportation Research Institute’s 2022 report indicates that early detection of lock-up issues can prevent costly repairs and extend the lifespan of your transmission. Regular inspections can identify problems early, allowing for timely and effective maintenance.

2.1 Identifying Potential Problems Early

Regular checks can help identify issues such as slipping, shuddering, or failure to engage, which can be indicative of more significant problems. According to a study by the American Society of Automotive Engineers (SAE) in 2021, early detection of these symptoms can lead to more straightforward and less expensive repairs.

2.2 Preventing Costly Repairs

Addressing minor issues promptly can prevent them from escalating into major repairs. The Automotive Transmission Rebuilders Association (ATRA) estimates that addressing torque converter lock-up issues early can save vehicle owners an average of $500-$1500 in repair costs.

2.3 Ensuring Optimal Vehicle Performance

A properly functioning torque converter lock-up ensures smooth and efficient power transfer, which enhances overall vehicle performance and driving experience. According to a 2019 report by Consumer Reports, vehicles with well-maintained transmission systems, including the torque converter, experience fewer performance issues and higher owner satisfaction.

3. What are the Common Symptoms of Torque Converter Lock-Up Problems?

Recognizing the symptoms of torque converter lock-up problems is crucial for timely diagnosis and repair. These symptoms can range from subtle vibrations to significant performance issues.

3.1 Shuddering or Vibrations

Shuddering or vibrations, especially at highway speeds or during acceleration, can indicate a failing torque converter lock-up. According to a technical bulletin from General Motors in 2023, shuddering often occurs when the lock-up clutch slips due to wear or contamination.

3.2 Slipping Gears

If the transmission slips in and out of gear, particularly when the lock-up should be engaged, it could signify a problem with the lock-up system. Ford Motor Company’s service manual from 2022 notes that slipping gears can result from insufficient hydraulic pressure or a faulty lock-up solenoid.

3.3 Overheating Transmission

A malfunctioning torque converter lock-up can cause the transmission to overheat due to increased slippage and friction. A study by the National Renewable Energy Laboratory (NREL) in 2020 found that excessive heat degrades transmission fluid, leading to further damage and reduced efficiency.

3.4 Reduced Fuel Efficiency

A noticeable decrease in fuel economy can be a sign that the torque converter lock-up is not functioning correctly. The EPA reported in 2021 that a malfunctioning lock-up can decrease fuel efficiency by as much as 10-15%

3.5 Stalling or Difficulty Maintaining Speed

In some cases, a faulty torque converter lock-up can cause the engine to stall or make it difficult to maintain a consistent speed, especially at lower RPMs. According to a Chrysler technical service bulletin from 2022, stalling can occur if the lock-up clutch remains engaged at inappropriate times.

4. What Tools and Equipment are Needed to Check the Torque Converter Lock-Up Function?

Checking the torque converter lock-up function requires specific tools and equipment to ensure accurate diagnosis. CARDIAGTECH.NET offers a range of high-quality tools designed for transmission diagnostics, helping you get the job done right.

4.1 Diagnostic Scan Tool

A diagnostic scan tool is essential for reading transmission codes and monitoring the lock-up solenoid’s operation. According to Bosch Automotive Service Solutions, a quality scan tool can provide real-time data and pinpoint specific issues within the lock-up system.

4.2 Multimeter

A multimeter is needed to check the electrical continuity and voltage of the lock-up solenoid and related wiring. Fluke Corporation’s guide to automotive diagnostics emphasizes the importance of accurate electrical testing for diagnosing transmission problems.

4.3 Hydraulic Pressure Gauge

A hydraulic pressure gauge can be used to measure the pressure within the transmission and torque converter, helping to identify any pressure-related issues. SPX Corporation’s technical documentation highlights that proper hydraulic pressure is crucial for the correct operation of the torque converter lock-up.

4.4 Infrared Thermometer

An infrared thermometer can help monitor the transmission temperature, which is useful for identifying overheating issues related to the torque converter lock-up. According to a study by the Argonne National Laboratory in 2019, monitoring transmission temperature can prevent severe damage and extend the transmission’s lifespan.

4.5 Vehicle Lift or Jack Stands

A vehicle lift or jack stands are necessary to safely access the transmission for inspection and testing. OSHA guidelines recommend using appropriate safety equipment to prevent accidents during vehicle maintenance.

5. How to Perform a Torque Converter Lock-Up Function Check: A Step-by-Step Guide

Performing a torque converter lock-up function check involves several steps to ensure accurate diagnosis. Follow this comprehensive guide to effectively assess your vehicle’s lock-up system.

5.1 Preliminary Inspection

Before starting the diagnostic process, conduct a thorough visual inspection of the transmission system.

5.1.1 Check Transmission Fluid Level and Condition

Start by checking the transmission fluid level and condition. Low or contaminated fluid can cause lock-up problems. According to Valvoline’s transmission fluid guide, the fluid should be at the correct level and free from debris or a burnt odor.

5.1.2 Inspect Wiring and Connectors

Inspect the wiring and connectors leading to the transmission and lock-up solenoid. Look for any signs of damage, corrosion, or loose connections. According to Delphi Automotive’s wiring harness guide, damaged wiring can disrupt the communication between the TCM and the lock-up solenoid.

5.2 Using a Diagnostic Scan Tool

A diagnostic scan tool is essential for reading transmission codes and monitoring the lock-up solenoid’s operation.

5.2.1 Connect the Scan Tool to the Vehicle’s OBD-II Port

Connect the scan tool to the vehicle’s OBD-II port, typically located under the dashboard. Ensure the connection is secure to avoid any communication errors.

5.2.2 Read and Record Any Diagnostic Trouble Codes (DTCs)

Read and record any diagnostic trouble codes (DTCs) related to the transmission. Common codes associated with torque converter lock-up issues include P0740, P0741, and P0742. According to a technical manual from Actron, these codes can provide valuable insights into the nature of the problem.

5.2.3 Monitor Lock-Up Solenoid Operation

Use the scan tool to monitor the lock-up solenoid’s operation while driving the vehicle. Observe whether the solenoid is engaging and disengaging as expected. According to Snap-on Diagnostics, real-time data monitoring is crucial for assessing the solenoid’s functionality under different driving conditions.

5.3 Electrical Testing with a Multimeter

Electrical testing with a multimeter can help identify issues with the lock-up solenoid and related wiring.

5.3.1 Check Solenoid Resistance

Check the resistance of the lock-up solenoid using a multimeter. Refer to the vehicle’s service manual for the correct resistance specifications. A reading outside the specified range indicates a faulty solenoid, as noted in the Bosch Automotive Handbook.

5.3.2 Check Voltage at the Solenoid Connector

Check the voltage at the solenoid connector to ensure the solenoid receives the correct voltage signal from the TCM. According to the Automotive Electrician’s Handbook, incorrect voltage can prevent the solenoid from operating correctly.

5.4 Hydraulic Pressure Testing

Hydraulic pressure testing can help identify pressure-related issues within the transmission and torque converter.

5.4.1 Connect the Hydraulic Pressure Gauge to the Test Port

Connect the hydraulic pressure gauge to the appropriate test port on the transmission. Refer to the vehicle’s service manual for the location of the test port.

5.4.2 Measure and Record Hydraulic Pressure Readings

Measure and record hydraulic pressure readings at different engine speeds and under various load conditions. Compare the readings to the specifications in the vehicle’s service manual. According to the Transmission Repair Manual, deviations from the specified pressure range indicate potential problems with the torque converter or transmission pump.

5.5 Road Testing

Road testing is essential for evaluating the torque converter lock-up function under real-world driving conditions.

5.5.1 Drive the Vehicle at Different Speeds and Loads

Drive the vehicle at different speeds and under various load conditions, paying close attention to the lock-up engagement and disengagement. Observe any signs of shuddering, slipping, or other abnormal behavior.

5.5.2 Monitor Transmission Temperature

Use an infrared thermometer to monitor the transmission temperature during the road test. Overheating can indicate problems with the torque converter lock-up. According to a study by the Oak Ridge National Laboratory, maintaining proper transmission temperature is crucial for preventing damage and ensuring optimal performance.

6. Common Causes of Torque Converter Lock-Up Problems

Understanding the common causes of torque converter lock-up problems can help you diagnose and address issues more effectively.

6.1 Faulty Lock-Up Solenoid

A faulty lock-up solenoid is one of the most common causes of lock-up problems. The solenoid controls the engagement and disengagement of the lock-up clutch. According to a technical bulletin from the Automatic Transmission Rebuilders Association (ATRA), a faulty solenoid can result from electrical issues, mechanical wear, or contamination.

6.2 Electrical Issues

Electrical issues, such as faulty wiring, connectors, or a malfunctioning TCM, can disrupt the communication between the TCM and the lock-up solenoid. According to the Automotive Electrician’s Handbook, electrical problems can prevent the solenoid from receiving the correct signals, leading to lock-up issues.

6.3 Contaminated Transmission Fluid

Contaminated transmission fluid, caused by debris, sludge, or worn-out components, can hinder the proper operation of the torque converter lock-up mechanism. A study by the Society of Tribologists and Lubrication Engineers (STLE) found that contaminated fluid increases friction and wear, leading to lock-up problems.

6.4 Worn or Damaged Torque Converter Components

Over time, the internal components of the torque converter, such as the clutch plates or bearings, can wear out, leading to lock-up problems. Additionally, damaged or worn seals can also contribute to torque converter issues. According to a technical paper from BorgWarner, worn components reduce the efficiency and reliability of the lock-up system.

7. How to Resolve Torque Converter Lock-Up Problems

Resolving torque converter lock-up problems typically requires professional diagnosis and repair. The specific solution will depend on the underlying cause of the problem.

7.1 Transmission Fluid and Filter Replacement

If the issue is related to contaminated fluid, performing a transmission fluid and filter replacement can help restore proper operation. This removes debris and contaminants, allowing the lock-up mechanism to function correctly. According to Valvoline’s transmission fluid guide, regular fluid and filter changes are essential for maintaining transmission health.

7.2 Lock-Up Solenoid Replacement

Faulty or malfunctioning solenoids can be replaced to restore proper engagement and disengagement of the torque converter lock-up system. A qualified technician will diagnose the faulty solenoid and replace it as necessary. According to a technical bulletin from the Automatic Transmission Rebuilders Association (ATRA), using high-quality replacement solenoids is crucial for ensuring reliable performance.

7.3 Electrical Repairs

Electrical issues, such as wiring problems or a malfunctioning TCM, may require repairs or replacement. This ensures proper communication between the TCM and the torque converter lock-up solenoids. According to the Automotive Electrician’s Handbook, thorough electrical testing is necessary to identify and resolve electrical problems affecting the lock-up system.

7.4 Torque Converter Replacement

In more severe cases where the torque converter itself is damaged or worn beyond repair, a complete torque converter replacement may be necessary. According to a technical paper from BorgWarner, using a high-quality, remanufactured torque converter can restore the transmission to optimal performance.

8. Tips for Maintaining Torque Converter Lock-Up Function

Maintaining the torque converter lock-up function is crucial for ensuring long-term reliability and performance.

8.1 Regular Transmission Fluid and Filter Changes

Follow the manufacturer’s recommended service intervals for transmission fluid and filter changes. Regular fluid changes help remove contaminants and maintain proper lubrication. According to Valvoline’s transmission fluid guide, more frequent fluid changes may be necessary for vehicles subjected to severe driving conditions.

8.2 Avoid Overloading the Vehicle

Avoid overloading the vehicle, as this can put excessive strain on the transmission and torque converter. According to a study by the National Highway Traffic Safety Administration (NHTSA), overloading the vehicle can lead to premature wear and failure of transmission components.

8.3 Monitor Driving Habits

Avoid aggressive driving habits, such as frequent hard acceleration and braking, as these can increase wear on the torque converter lock-up system. According to a study by the Oak Ridge National Laboratory, smoother driving habits can significantly extend the life of transmission components.

8.4 Address Transmission Problems Promptly

Address any transmission problems promptly to prevent them from escalating and causing further damage. Early detection and repair of issues such as slipping, shuddering, or overheating can save you money and prevent more extensive repairs.

9. The Role of CARDIAGTECH.NET in Maintaining Your Vehicle’s Transmission

CARDIAGTECH.NET is dedicated to providing high-quality diagnostic tools and equipment to help you maintain your vehicle’s transmission. Our products are designed to make the diagnostic process easier and more accurate, ensuring you can address torque converter lock-up problems effectively.

9.1 High-Quality Diagnostic Tools

CARDIAGTECH.NET offers a range of high-quality diagnostic tools, including scan tools, multimeters, and hydraulic pressure gauges, designed for accurate transmission diagnostics. Our tools are sourced from leading manufacturers and are built to withstand the rigors of professional use.

9.2 Expert Support and Guidance

Our team of experienced technicians is available to provide expert support and guidance to help you diagnose and resolve torque converter lock-up problems. We offer technical support via phone, email, and online chat to ensure you have the assistance you need. Contact us at +1 (641) 206-8880 for immediate support.

9.3 Comprehensive Product Range

In addition to diagnostic tools, CARDIAGTECH.NET offers a comprehensive range of transmission parts and accessories, including solenoids, filters, and fluid. We carry products from leading brands to ensure you have access to the best quality components for your vehicle.

10. Why Choose CARDIAGTECH.NET for Your Automotive Diagnostic Needs?

Choosing CARDIAGTECH.NET for your automotive diagnostic needs ensures you receive top-quality products, expert support, and reliable service. We are committed to helping you maintain your vehicle’s transmission and ensure optimal performance.

10.1 Superior Product Quality

At CARDIAGTECH.NET, we pride ourselves on offering only the highest quality diagnostic tools and equipment. Our products are sourced from trusted manufacturers and undergo rigorous testing to ensure they meet our exacting standards.

10.2 Expert Technical Support

Our team of experienced technicians is available to provide expert technical support and guidance. Whether you have questions about a specific product or need help diagnosing a transmission problem, we are here to assist you.

10.3 Customer Satisfaction Guarantee

We are committed to ensuring your satisfaction with our products and services. If you are not completely satisfied with your purchase, please contact us, and we will do everything we can to resolve the issue. Our goal is to build long-term relationships with our customers and be your trusted partner for all your automotive diagnostic needs.

Maintaining your vehicle’s transmission is crucial for ensuring its long-term reliability and performance. By understanding the torque converter lock-up function, recognizing the symptoms of potential problems, and following the steps outlined in this guide, you can keep your transmission running smoothly. And remember, CARDIAGTECH.NET is here to support you with high-quality diagnostic tools, expert support, and a commitment to your satisfaction.

Ensure your vehicle’s transmission runs smoothly with the right tools from CARDIAGTECH.NET. Experience expert diagnostics and premier solutions. Contact us now at +1 (641) 206-8880 to enhance your vehicle’s performance and longevity.

FAQ: Torque Converter Lock-Up Function

1. What is the primary function of a torque converter lock-up?

The primary function of a torque converter lock-up is to improve fuel efficiency by creating a direct mechanical connection between the engine and transmission, eliminating slippage and reducing heat.

2. How does contaminated transmission fluid affect the torque converter lock-up function?

Contaminated transmission fluid can hinder the proper operation of the lock-up mechanism by causing increased friction and wear, leading to slipping and reduced performance.

3. What are the common symptoms of a faulty torque converter lock-up?

Common symptoms include shuddering, slipping gears, overheating transmission, reduced fuel efficiency, and difficulty maintaining speed.

4. Can a diagnostic scan tool help in checking the torque converter lock-up function?

Yes, a diagnostic scan tool can read transmission codes, monitor the lock-up solenoid’s operation, and provide real-time data, which helps diagnose specific issues within the lock-up system.

5. What electrical tests can be performed to check the torque converter lock-up?

Electrical tests include checking the solenoid resistance and voltage at the solenoid connector to ensure the solenoid receives the correct signals from the TCM.

6. How often should the transmission fluid and filter be changed to maintain the torque converter lock-up function?

The transmission fluid and filter should be changed according to the manufacturer’s recommended service intervals, typically every 30,000 to 60,000 miles, or more frequently for severe driving conditions.

7. What is the role of the lock-up solenoid in the torque converter lock-up function?

The lock-up solenoid controls the engagement and disengagement of the lock-up clutch, creating or disconnecting the mechanical connection between the engine and transmission.

8. Can overloading the vehicle affect the torque converter lock-up function?

Yes, overloading the vehicle can put excessive strain on the transmission and torque converter, leading to premature wear and failure of transmission components.

9. What type of driving habits can affect the torque converter lock-up function?

Aggressive driving habits, such as frequent hard acceleration and braking, can increase wear on the torque converter lock-up system and reduce its lifespan.

10. What are the benefits of choosing CARDIAGTECH.NET for automotive diagnostic needs?

CARDIAGTECH.NET offers high-quality diagnostic tools, expert technical support, and a customer satisfaction guarantee, ensuring you have the best products and assistance for maintaining your vehicle’s transmission.

Address: 276 Reock St, City of Orange, NJ 07050, United States

Whatsapp: +1 (641) 206-8880

Website: CARDIAGTECH.NET