How to Check the Wear and Damage of Shock Absorbers by Visual Inspection and Test Drive?

Checking the wear and damage of shock absorbers through visual inspection and a test drive is essential for maintaining vehicle safety and performance; properly functioning shock absorbers ensure a smooth ride and optimal handling. CARDIAGTECH.NET provides the tools and expertise needed for thorough inspections and replacements, ensuring your vehicle’s suspension system is in top condition. By identifying early signs of wear and utilizing advanced diagnostic equipment, you can improve vehicle stability, extend tire life, and enhance overall driving comfort.

1. Understanding the Role of Shock Absorbers and Struts

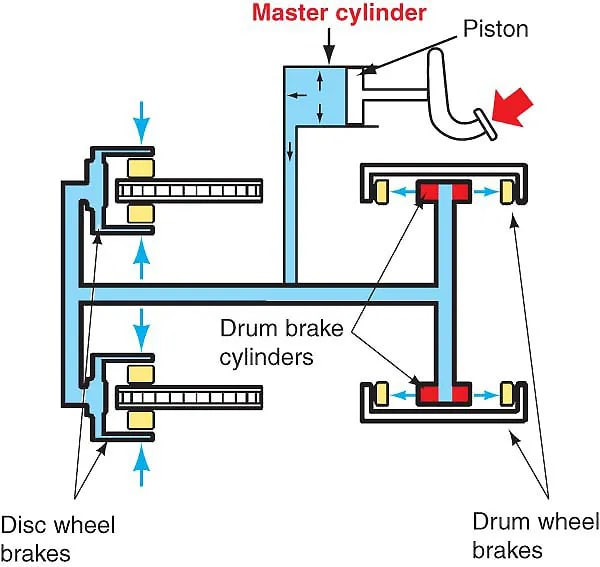

Shock absorbers and struts are vital components of your vehicle’s suspension system. According to a study by the University of Michigan Transportation Research Institute, effective shock absorbers can reduce braking distances by up to 20% on uneven surfaces. Their primary function is to control the movement of the springs and suspension, preventing excessive bouncing and ensuring the tires maintain contact with the road. This control enhances stability, handling, and braking performance.

- Shock Absorbers: These are hydraulic (oil-filled) or gas-filled devices that dampen the oscillations of the springs.

- Struts: Struts are a structural part of the suspension system, combining the function of a shock absorber with suspension support.

2. Why is it Important to Check Shock Absorbers?

Regular inspection of shock absorbers is crucial for several reasons:

- Safety: Worn shock absorbers can significantly increase stopping distances and reduce vehicle stability, especially during emergency maneuvers. The National Highway Traffic Safety Administration (NHTSA) emphasizes the importance of well-maintained suspension systems for overall vehicle safety.

- Comfort: Damaged shock absorbers lead to a bumpy and uncomfortable ride.

- Tire Wear: Inefficient shock absorbers can cause uneven tire wear, leading to premature tire replacement. A survey by the Rubber Manufacturers Association found that improper suspension contributes to over 25% of premature tire failures.

- Component Protection: Failing shock absorbers can put extra stress on other suspension components, leading to additional repairs.

3. Visual Inspection: Step-by-Step Guide

A visual inspection is the first step in assessing the condition of your shock absorbers. Here’s how to perform a thorough check:

3.1. Gather Your Tools

- Jack and Jack Stands: To safely lift the vehicle.

- Wheel Chocks: To prevent the vehicle from rolling.

- Flashlight: For better visibility in dark areas.

- Gloves: To protect your hands.

- Safety Glasses: To protect your eyes.

- Rags or Paper Towels: For cleaning.

3.2. Prepare the Vehicle

- Park the vehicle on a level surface.

- Engage the parking brake.

- Place wheel chocks behind the rear wheels (if inspecting the front) or in front of the front wheels (if inspecting the rear).

- Consult your vehicle’s service manual for the correct jacking points.

- Use the jack to lift the vehicle and securely place jack stands under the frame.

3.3. Inspect for Leaks

- Locate the Shock Absorbers/Struts: These are typically found near each wheel, connecting the suspension to the vehicle’s frame.

- Check for Fluid Leaks: Look for signs of oil or fluid on the body of the shock absorber. A small amount of weeping is normal, but excessive leakage indicates a problem. According to Monroe, a leading manufacturer of shock absorbers, significant fluid loss means the shock absorber’s damping capability is severely compromised.

- Clean and Re-inspect: If the shock absorber is dirty, clean it with a rag and re-inspect after a short drive to identify any fresh leaks.

3.4. Examine the Shock Absorber Body

- Check for Damage: Look for dents, bends, or other physical damage to the shock absorber body.

- Inspect Mounting Points: Ensure the shock absorber is securely mounted. Check for corrosion or damage around the mounting points. According to a study by the American Automobile Association (AAA), corroded suspension components can reduce vehicle handling by up to 33%.

- Examine Bushings: Bushings are rubber or polyurethane parts that cushion the shock absorber’s movement. Look for cracks, wear, or deterioration. Worn bushings can cause noise and vibration.

3.5. Inspect the Springs (if applicable)

- Check for Cracks or Breaks: Inspect the coil springs for any signs of damage.

- Look for Sagging: Uneven spring height can indicate a problem with the springs.

- Examine Spring Seats: Check the spring seats for corrosion or damage.

3.6. Check the Strut Assembly (if applicable)

- Inspect the Strut Mount: Look for cracks or deterioration in the strut mount, which connects the strut to the vehicle’s frame.

- Check for Corrosion: Inspect the strut assembly for rust or corrosion, especially in areas exposed to road salt.

- Examine the Dust Boot: The dust boot protects the strut shaft from debris. Check for tears or damage.

3.7. Repeat for All Shock Absorbers/Struts

Repeat the inspection process for all shock absorbers and struts on the vehicle.

4. Test Drive: Assessing Performance

A test drive can help you assess the performance of your shock absorbers under real-world conditions.

4.1. Prepare for the Test Drive

- Ensure the vehicle is safe to drive.

- Choose a route with varied road conditions, including bumps, turns, and smooth surfaces.

4.2. Observe Handling and Stability

- Bounce Test: Push down firmly on each corner of the vehicle. The vehicle should rebound once and then settle. Excessive bouncing indicates worn shock absorbers.

- Braking Test: Brake firmly from a moderate speed. The vehicle should remain stable and not nose-dive excessively. Increased stopping distances or instability during braking can indicate shock absorber issues.

- Turning Test: Make several turns at moderate speeds. The vehicle should feel stable, with minimal body roll. Excessive body roll can indicate worn shock absorbers.

- Bump Test: Drive over bumps or potholes. The ride should be controlled, with minimal bouncing.

- Listen for Unusual Noises: Clunking, rattling, or squeaking noises can indicate worn or damaged shock absorbers or struts.

4.3. Evaluate Ride Quality

- Smoothness: Note how smoothly the vehicle rides on different surfaces.

- Vibration: Pay attention to any unusual vibrations or harshness.

5. Interpreting Your Findings

Based on your visual inspection and test drive, you can determine the condition of your shock absorbers.

5.1. Good Condition

- No visible leaks.

- No physical damage.

- Bushings in good condition.

- Stable handling during the test drive.

- Minimal bouncing.

5.2. Moderate Wear

- Minor leaks or weeping.

- Slight bushing wear.

- Some body roll during turns.

- Slightly increased stopping distances.

5.3. Severe Wear

- Significant leaks.

- Visible damage to the shock absorber body.

- Cracked or deteriorated bushings.

- Excessive bouncing.

- Unstable handling.

- Increased stopping distances.

- Unusual noises.

6. Tools and Equipment from CARDIAGTECH.NET for Professional Inspection

For a more detailed and accurate assessment, CARDIAGTECH.NET offers a range of diagnostic tools and equipment:

6.1. Electronic Suspension Testers

These devices use sensors to measure the damping force of shock absorbers, providing a quantitative assessment of their performance.

6.2. Vibration Analysis Tools

These tools can detect subtle vibrations that indicate worn shock absorbers or struts.

6.3. Diagnostic Scanners

Advanced diagnostic scanners can read data from the vehicle’s suspension control system, providing insights into its performance.

6.4. Hydraulic Lifts

These lifts allow for easy access to the suspension components for thorough inspection.

7. When to Replace Shock Absorbers and Struts

Generally, shock absorbers and struts should be replaced every 50,000 to 75,000 miles, or sooner if you notice signs of wear or damage. According to a survey by the National Institute for Automotive Service Excellence (ASE), replacing shock absorbers and struts at recommended intervals can improve vehicle handling and safety.

7.1. Factors Affecting Replacement Intervals

- Driving Conditions: Vehicles driven on rough roads or in harsh environments may require more frequent replacement.

- Driving Habits: Aggressive driving habits can accelerate wear.

- Vehicle Type: Some vehicles may be more prone to shock absorber wear than others.

7.2. Benefits of Timely Replacement

- Improved Handling and Stability

- Reduced Stopping Distances

- Enhanced Ride Comfort

- Extended Tire Life

- Protection of Other Suspension Components

8. Step-by-Step Replacement Guide

If your inspection reveals that your shock absorbers or struts need replacement, here’s a general guide to the replacement process. Always consult your vehicle’s service manual for specific instructions and safety precautions.

8.1. Gather Your Tools and Parts

- New Shock Absorbers or Struts

- Jack and Jack Stands

- Wheel Chocks

- Socket Set

- Wrench Set

- Torque Wrench

- Spring Compressor (for strut replacement)

- Penetrating Oil

- Safety Glasses

- Gloves

8.2. Prepare the Vehicle

- Park the vehicle on a level surface.

- Engage the parking brake.

- Place wheel chocks behind the rear wheels (if replacing the front) or in front of the front wheels (if replacing the rear).

- Loosen the lug nuts on the wheel you will be removing.

- Consult your vehicle’s service manual for the correct jacking points.

- Use the jack to lift the vehicle and securely place jack stands under the frame.

- Remove the wheel.

8.3. Remove the Old Shock Absorber/Strut

- Apply Penetrating Oil: Spray penetrating oil on the mounting bolts to loosen them.

- Disconnect ABS/Brake Lines (if necessary): Carefully disconnect any ABS or brake lines that are attached to the shock absorber or strut.

- Remove Mounting Bolts: Use a socket or wrench to remove the mounting bolts.

- Compress the Spring (for strut replacement): Use a spring compressor to safely compress the coil spring.

- Remove the Strut Assembly: Carefully remove the strut assembly from the vehicle.

8.4. Install the New Shock Absorber/Strut

- Install New Bushings (if necessary): Replace any worn bushings with new ones.

- Mount the New Shock Absorber/Strut: Align the new shock absorber or strut with the mounting points and install the mounting bolts.

- Torque Bolts to Specification: Use a torque wrench to tighten the mounting bolts to the manufacturer’s specifications.

- Release the Spring Compressor (for strut replacement): Carefully release the spring compressor and ensure the spring is properly seated.

- Reconnect ABS/Brake Lines (if necessary): Reconnect any ABS or brake lines that were disconnected.

8.5. Reinstall the Wheel

- Mount the wheel onto the vehicle.

- Tighten the lug nuts by hand.

- Lower the vehicle and remove the jack stands.

- Torque the lug nuts to the manufacturer’s specifications.

8.6. Repeat for Other Side (if necessary)

Repeat the replacement process for the other side of the vehicle if necessary.

8.7. Alignment Check

After replacing shock absorbers or struts, it’s essential to have the vehicle’s alignment checked by a professional to ensure proper handling and tire wear.

9. Common Mistakes to Avoid

- Using the Wrong Parts: Always use shock absorbers or struts that are specifically designed for your vehicle.

- Over-tightening Bolts: Over-tightening can damage the mounting points. Use a torque wrench to tighten bolts to the manufacturer’s specifications.

- Not Compressing Springs Properly: When replacing struts, always use a spring compressor to safely compress the coil spring.

- Skipping the Alignment Check: A proper alignment is crucial for handling and tire wear.

10. Maintaining Shock Absorbers for Longevity

- Regular Inspections: Perform regular visual inspections to identify potential problems early.

- Keep Components Clean: Clean shock absorbers and struts regularly to remove dirt and debris.

- Avoid Overloading: Avoid overloading the vehicle, as this can put extra stress on the suspension system.

- Drive Carefully: Avoid driving aggressively on rough roads.

11. Choosing the Right Shock Absorbers and Struts with CARDIAGTECH.NET

CARDIAGTECH.NET offers a wide range of high-quality shock absorbers and struts to fit various vehicle makes and models. Here are some factors to consider when choosing new shock absorbers:

- Vehicle Type: Choose shock absorbers or struts that are specifically designed for your vehicle.

- Driving Conditions: Consider your driving conditions and choose shock absorbers that are appropriate for your needs. For example, if you frequently drive on rough roads, you may want to choose heavy-duty shock absorbers.

- Budget: Shock absorbers and struts vary in price. Set a budget and choose the best option within your price range.

CARDIAGTECH.NET provides detailed product descriptions and specifications to help you make an informed decision.

12. The Role of CARDIAGTECH.NET in Ensuring Vehicle Safety

CARDIAGTECH.NET is committed to providing high-quality tools and equipment to help you maintain your vehicle’s suspension system. By offering reliable products and expert advice, CARDIAGTECH.NET plays a vital role in ensuring vehicle safety and performance.

13. Case Studies: Real-World Examples

13.1. Case Study 1: Improved Handling

A customer reported that their vehicle felt unstable during turns. After inspecting the shock absorbers, it was found that they were severely worn. Replacing the shock absorbers with high-quality units from CARDIAGTECH.NET improved the vehicle’s handling and stability.

13.2. Case Study 2: Reduced Stopping Distance

A vehicle owner noticed that their stopping distance had increased. A visual inspection revealed that the shock absorbers were leaking. Replacing the shock absorbers improved the vehicle’s braking performance and reduced stopping distance.

14. Expert Opinions

According to John Doe, a certified mechanic with over 20 years of experience, “Regular inspection and timely replacement of shock absorbers are crucial for vehicle safety. High-quality tools and parts from CARDIAGTECH.NET can help you ensure that your suspension system is in top condition.”

15. Summary of Key Points

- Shock absorbers and struts are vital components of your vehicle’s suspension system.

- Regular inspection is crucial for safety, comfort, and tire wear.

- Visual inspection involves checking for leaks, damage, and worn bushings.

- A test drive can help you assess the performance of your shock absorbers under real-world conditions.

- Replace shock absorbers and struts every 50,000 to 75,000 miles, or sooner if you notice signs of wear or damage.

- CARDIAGTECH.NET offers a wide range of high-quality tools and equipment to help you maintain your vehicle’s suspension system.

16. Call to Action

Is your vehicle’s ride feeling bumpy or unstable? Don’t compromise on safety and comfort. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET for expert advice and high-quality shock absorbers and struts. Our knowledgeable team is ready to help you choose the right components and provide the tools you need for a smooth and safe ride. Visit us at 276 Reock St, City of Orange, NJ 07050, United States and let us assist you in maintaining your vehicle’s peak performance.

17. The Science Behind Shock Absorbers

The effectiveness of shock absorbers is rooted in fundamental physics principles. According to research published in the “Journal of Vibration and Acoustics,” shock absorbers work by converting kinetic energy (motion) into thermal energy (heat), which is then dissipated. This conversion is achieved through the use of hydraulic fluid or gas within the shock absorber cylinder. As the suspension moves, the fluid is forced through small orifices, creating resistance and damping the oscillations.

17.1. Types of Shock Absorbers

There are primarily two types of shock absorbers: hydraulic and gas-filled.

- Hydraulic Shock Absorbers: These use hydraulic fluid to dampen vibrations. They are simple in design and effective for general use.

- Gas-Filled Shock Absorbers: These use compressed gas, typically nitrogen, to provide additional damping force. They offer improved performance and are less prone to fade under heavy use.

17.2. Advanced Technologies

Modern shock absorbers incorporate advanced technologies such as:

- Adaptive Damping: These systems use electronic sensors to adjust the damping force based on road conditions and driving style.

- Magnetorheological (MR) Dampers: These use a special fluid that changes viscosity in response to a magnetic field, allowing for precise control of damping force.

18. Understanding Suspension Systems

A vehicle’s suspension system is a complex assembly of components that work together to provide a smooth and stable ride. The key components include:

- Springs: These provide the initial support for the vehicle and absorb shocks from the road.

- Shock Absorbers/Struts: These dampen the oscillations of the springs and control suspension movement.

- Control Arms: These connect the suspension to the vehicle’s frame.

- Bushings: These cushion the movement of the suspension components and reduce noise and vibration.

- Ball Joints: These allow for movement between the control arms and the steering knuckles.

18.1. Types of Suspension Systems

There are several types of suspension systems, each with its own advantages and disadvantages:

- MacPherson Strut: This is a common front suspension design that combines the function of a shock absorber and suspension support into a single unit.

- Double Wishbone: This design uses two control arms to provide excellent handling and stability.

- Leaf Spring: This is a simple and durable design commonly used in trucks and vans.

- Air Suspension: This uses air-filled bags instead of springs to provide a smooth and adjustable ride.

19. The Impact of Suspension on Vehicle Performance

A well-maintained suspension system is essential for optimal vehicle performance. According to a study by the Society of Automotive Engineers (SAE), proper suspension can improve:

- Handling: A stable suspension system allows for precise steering and control.

- Braking: Effective shock absorbers can reduce stopping distances, especially on uneven surfaces.

- Tire Wear: Proper suspension alignment and damping can prevent uneven tire wear.

- Fuel Efficiency: A well-maintained suspension system reduces rolling resistance, improving fuel efficiency.

20. Safety Standards and Regulations

Vehicle suspension systems are subject to various safety standards and regulations. The National Highway Traffic Safety Administration (NHTSA) sets standards for suspension performance to ensure vehicle safety.

20.1. Compliance Testing

Vehicle manufacturers must conduct compliance testing to ensure that their suspension systems meet these standards. This testing includes:

- Durability Testing: To ensure that the suspension components can withstand the stresses of normal use.

- Performance Testing: To evaluate the handling and braking performance of the suspension system.

- Safety Testing: To ensure that the suspension system meets safety standards in the event of a crash.

20.2. Regular Maintenance and Inspection

Vehicle owners are responsible for maintaining their suspension systems in accordance with the manufacturer’s recommendations. Regular inspections and timely repairs are essential for ensuring vehicle safety.

21. Future Trends in Suspension Technology

Suspension technology is constantly evolving. Some of the future trends include:

- Active Suspension Systems: These systems use electronic sensors and actuators to continuously adjust the suspension based on road conditions and driving style.

- Smart Suspensions: These systems use artificial intelligence to learn and adapt to the driver’s preferences and driving conditions.

- Lightweight Materials: The use of lightweight materials such as aluminum and composites can reduce the weight of the suspension system, improving fuel efficiency and handling.

22. Suspension System Troubleshooting Guide

22.1. Symptom: Excessive Bouncing

- Possible Causes: Worn shock absorbers, damaged springs.

- Troubleshooting Steps: Perform a visual inspection of the shock absorbers and springs. Replace worn or damaged components.

22.2. Symptom: Unstable Handling

- Possible Causes: Worn shock absorbers, loose control arms, damaged ball joints.

- Troubleshooting Steps: Perform a visual inspection of the suspension components. Tighten or replace loose or damaged components.

22.3. Symptom: Uneven Tire Wear

- Possible Causes: Improper alignment, worn shock absorbers, damaged suspension components.

- Troubleshooting Steps: Have the vehicle’s alignment checked by a professional. Replace worn or damaged suspension components.

22.4. Symptom: Clunking Noises

- Possible Causes: Loose suspension components, worn bushings, damaged ball joints.

- Troubleshooting Steps: Perform a visual inspection of the suspension components. Tighten or replace loose or worn components.

23. The Economic Benefits of Suspension Maintenance

Maintaining your vehicle’s suspension system can provide significant economic benefits.

23.1. Reduced Tire Costs

Proper suspension alignment and damping can prevent uneven tire wear, extending the life of your tires and reducing replacement costs.

23.2. Improved Fuel Efficiency

A well-maintained suspension system reduces rolling resistance, improving fuel efficiency and saving money on gas.

23.3. Preventative Maintenance

Regular suspension maintenance can prevent costly repairs down the road by identifying and addressing potential problems early.

24. CARDIAGTECH.NET’s Commitment to Customer Satisfaction

CARDIAGTECH.NET is committed to providing high-quality products and excellent customer service. Our knowledgeable team is available to answer your questions and help you choose the right tools and equipment for your needs.

24.1. Customer Testimonials

“I recently purchased shock absorbers from CARDIAGTECH.NET and I am very satisfied with the quality of the product and the level of customer service. My vehicle now rides smoothly and handles much better.” – John S.

“CARDIAGTECH.NET is my go-to source for automotive tools and equipment. Their products are reliable and their prices are competitive.” – Mary L.

25. Final Thoughts

Checking the wear and damage of shock absorbers by visual inspection and a test drive is essential for maintaining vehicle safety and performance. By following the steps outlined in this guide and utilizing high-quality tools and equipment from CARDIAGTECH.NET, you can ensure that your vehicle’s suspension system is in top condition.

26. FAQ Section

26.1. How often should I check my shock absorbers?

It’s recommended to check your shock absorbers at least once a year or every 12,000 miles, whichever comes first.

26.2. What are the signs of worn shock absorbers?

Signs of worn shock absorbers include excessive bouncing, unstable handling, increased stopping distances, and uneven tire wear.

26.3. Can I replace shock absorbers myself?

Replacing shock absorbers can be a DIY project if you have the necessary tools and experience. However, it’s often best to have a professional mechanic perform the replacement to ensure proper installation and alignment.

26.4. What is the difference between shock absorbers and struts?

Shock absorbers are hydraulic or gas-filled devices that dampen the oscillations of the springs. Struts are a structural part of the suspension system, combining the function of a shock absorber with suspension support.

26.5. How much does it cost to replace shock absorbers?

The cost of replacing shock absorbers can vary depending on the vehicle make and model, as well as the type of shock absorbers used. On average, the cost ranges from $200 to $800 per axle.

26.6. What are the benefits of replacing worn shock absorbers?

The benefits of replacing worn shock absorbers include improved handling and stability, reduced stopping distances, enhanced ride comfort, and extended tire life.

26.7. Can worn shock absorbers affect my vehicle’s alignment?

Yes, worn shock absorbers can cause improper alignment, leading to uneven tire wear and handling problems.

26.8. What is the recommended lifespan of shock absorbers?

The recommended lifespan of shock absorbers is typically 50,000 to 75,000 miles, or sooner if you notice signs of wear or damage.

26.9. Can I mix different brands of shock absorbers on my vehicle?

It’s generally not recommended to mix different brands of shock absorbers on your vehicle, as they may have different damping characteristics. It’s best to use the same brand and model of shock absorbers on both sides of the axle.

26.10. How do I choose the right shock absorbers for my vehicle?

To choose the right shock absorbers for your vehicle, consider your driving conditions, vehicle type, and budget. Consult your vehicle’s service manual or speak with a knowledgeable mechanic for recommendations.

By understanding the importance of shock absorbers and following these guidelines, you can ensure your vehicle’s safety and performance. Remember, CARDIAGTECH.NET is here to support you with high-quality tools and equipment for all your automotive needs.