How To Check The Wheel Speed Sensors Related To ABS?

Checking wheel speed sensors related to ABS is crucial for maintaining vehicle safety and ensuring optimal braking performance, and CARDIAGTECH.NET can help you diagnose and resolve ABS issues effectively. By identifying faulty sensors early, you can prevent ABS malfunctions and maintain safe driving conditions. Explore how to inspect and test your ABS sensors and learn about the tools and techniques to ensure your anti-lock braking system functions flawlessly, enhancing road safety and driving confidence.

1. What is the Role of Wheel Speed Sensors in the ABS System?

Wheel speed sensors are vital components of the Anti-lock Braking System (ABS), providing real-time data on wheel rotation to the ABS module, as emphasized by the National Highway Traffic Safety Administration (NHTSA). These sensors enable the ABS to prevent wheel lockup during braking, ensuring steering control and minimizing stopping distances. According to a study by the University of Michigan Transportation Research Institute, vehicles equipped with ABS have a 18% lower risk of being involved in accidents. Each sensor monitors the speed of a wheel, and the ABS uses this data to modulate brake pressure to individual wheels. When the ABS detects that a wheel is slowing down too quickly, indicating potential lockup, it reduces brake pressure to that wheel, allowing it to maintain traction. This modulation happens rapidly and continuously, allowing the driver to maintain control of the vehicle during emergency braking situations. Wheel speed sensors enhance overall vehicle safety by optimizing braking performance and preventing skidding, especially on slippery surfaces. Accurate wheel speed data ensures the ABS functions effectively, maintaining vehicle stability and control.

2. What are the Common Symptoms of a Faulty Wheel Speed Sensor?

Common symptoms of a faulty wheel speed sensor include the ABS warning light illuminating on the dashboard, erratic ABS activation during normal driving conditions, reduced braking performance, and potential issues with traction control and stability control systems. According to the AAA, a malfunctioning ABS can increase stopping distances by up to 40% on wet surfaces. For example, if the ABS light is on, and you notice the ABS activating even when you’re not braking hard, it could indicate a faulty sensor providing incorrect data. Similarly, if you experience a loss of traction or stability, especially during wet or slippery conditions, a malfunctioning wheel speed sensor could be to blame. The vehicle’s computer relies on accurate wheel speed data to properly manage these systems. Issues like rough idling or stalling can arise because the engine control unit (ECU) uses wheel speed data for various functions. Addressing these symptoms promptly is crucial to maintaining the safety and performance of your vehicle. Ignoring these signs can lead to decreased braking efficiency and an increased risk of accidents.

3. How Can You Perform a Visual Inspection of the Wheel Speed Sensors?

Performing a visual inspection of the wheel speed sensors involves checking for physical damage, such as frayed or broken wires, corrosion, and debris accumulation. First, safely secure the vehicle using jack stands after lifting it with a jack. Locate the wheel speed sensors behind each wheel hub. Visually inspect the sensor wires for any signs of damage. Look for cuts, abrasions, or exposed wires that could compromise the sensor’s functionality. Check the sensor body for cracks, breaks, or other physical damage that could affect its performance. Clean the sensor area using a brush to remove dirt, brake dust, and other contaminants that might interfere with the sensor’s readings. Ensure that the sensor is properly connected and that the connectors are securely attached. Confirm that the sensor is correctly positioned and aligned with the toothed wheel or magnetic encoder ring. This ring generates the signal that the sensor reads. A thorough visual inspection can often reveal obvious issues that can be easily addressed, saving time and money on more complex diagnostic procedures.

4. What Tools are Needed to Test Wheel Speed Sensors?

To test wheel speed sensors effectively, you will need a multimeter, an oscilloscope (optional but recommended), and an ABS scan tool. A multimeter is essential for measuring resistance, voltage, and continuity, helping you identify electrical issues within the sensor. An oscilloscope provides a visual representation of the sensor’s signal, allowing you to detect irregularities or signal dropouts that a multimeter might miss. An ABS scan tool can read diagnostic trouble codes (DTCs) related to the ABS system, pinpointing specific sensor faults. According to Bosch Automotive, using an ABS scan tool can reduce diagnostic time by up to 50%. For example, a scan tool can differentiate between a general ABS fault and a specific issue with the front-left wheel speed sensor. A digital multimeter with auto-ranging capabilities is ideal for accurate readings. Wiring diagrams for your vehicle are essential to identify the correct pins to test. Wheel chocks and safety glasses are necessary safety equipment. These tools will help you accurately diagnose and address any issues with your wheel speed sensors.

5. How Do You Use a Multimeter to Test a Passive Wheel Speed Sensor?

To test a passive wheel speed sensor using a multimeter, measure the resistance across the sensor terminals and check for an alternating current (AC) voltage signal while the wheel is rotating. First, set the multimeter to measure resistance (Ohms). Disconnect the sensor from its wiring harness to isolate it from the vehicle’s electrical system. Connect the multimeter probes to the sensor terminals. A typical resistance range for a good passive sensor is between 800 to 1200 Ohms, but consult your vehicle’s service manual for the exact specification. Next, set the multimeter to measure AC voltage. Reconnect the sensor to its wiring harness. With the vehicle safely lifted and secured, manually spin the wheel. Observe the multimeter reading; you should see a fluctuating AC voltage signal. The voltage should increase as the wheel speed increases. If the resistance is outside the specified range or if there is no AC voltage signal while spinning the wheel, the sensor is likely faulty and needs replacement. This test confirms the integrity of the sensor coil and its ability to generate a signal.

6. How Do You Use a Multimeter to Test an Active Wheel Speed Sensor?

Testing an active wheel speed sensor with a multimeter involves checking the power supply, ground, and signal output. First, identify the sensor type; active sensors typically have three wires: power, ground, and signal. Set the multimeter to measure DC voltage. With the ignition on, check for a 5V or 12V power supply at the power wire terminal using the vehicle’s ground as a reference. Verify the ground connection by checking for continuity between the ground wire terminal and the vehicle’s chassis. Set the multimeter to measure DC voltage again. Connect the positive probe to the signal wire and the negative probe to the ground. Manually rotate the wheel and observe the multimeter reading. You should see a change in voltage as the wheel rotates, indicating the sensor is producing a signal. If there is no power supply, no ground connection, or no signal output while rotating the wheel, the sensor is likely faulty. Consult your vehicle’s service manual for specific voltage ranges and testing procedures. This test confirms the sensor’s ability to receive power, establish a ground, and generate a signal.

7. What is the Process for Cleaning a Wheel Speed Sensor?

The process for cleaning a wheel speed sensor involves carefully removing any accumulated debris without damaging the sensor. Start by safely lifting the vehicle and removing the wheel to access the sensor. Disconnect the sensor from its wiring harness. Inspect the sensor and the surrounding area for dirt, brake dust, and other contaminants. Use a soft brush or lint-free cloth to gently clean the sensor’s surface. For stubborn deposits, use a specialized electrical contact cleaner, ensuring it is safe for use on electronic components. Spray the cleaner onto the cloth and gently wipe the sensor. Avoid spraying the cleaner directly into the sensor. Clean the toothed wheel or magnetic encoder ring that the sensor reads, as debris here can also affect sensor performance. Ensure that the sensor is completely dry before reconnecting it to the wiring harness and reinstalling the wheel. After cleaning, test the sensor using a multimeter or scan tool to ensure it is functioning correctly. Regular cleaning can help maintain the sensor’s accuracy and prolong its lifespan.

8. How Do You Use an ABS Scan Tool to Diagnose Wheel Speed Sensor Issues?

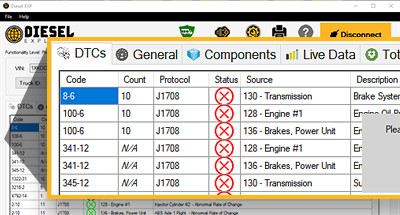

Using an ABS scan tool to diagnose wheel speed sensor issues involves connecting the tool to the vehicle’s diagnostic port, reading any stored trouble codes, and interpreting the data to pinpoint the faulty sensor. First, locate the diagnostic port, typically found under the dashboard on the driver’s side. Connect the ABS scan tool to the port and turn on the vehicle’s ignition. Navigate the scan tool menu to select the ABS system. Read any stored diagnostic trouble codes (DTCs). Codes such as C0031, C0034, C0037, and C0040 indicate issues with specific wheel speed sensors (front left, front right, rear left, and rear right, respectively). Clear the codes and perform a test drive to see if the codes reappear. Use the scan tool to monitor live data from each wheel speed sensor while driving. Compare the readings from each sensor to identify any discrepancies or dropouts. If a particular sensor shows inconsistent or absent readings, it is likely faulty. The scan tool can also perform ABS system tests, such as activating the ABS pump and solenoids, to further diagnose issues. Properly interpreting the data from the scan tool allows for accurate diagnosis and targeted repairs.

9. What are the Potential Causes of Wheel Speed Sensor Failure?

Potential causes of wheel speed sensor failure include physical damage, contamination, electrical issues, and wear and tear. Physical damage can occur from road debris, impacts, or improper installation. Contamination from dirt, brake dust, and moisture can interfere with the sensor’s ability to accurately read wheel speed. Electrical issues such as frayed wires, corroded connectors, and short circuits can disrupt the sensor’s signal. Over time, normal wear and tear can cause the sensor to degrade, leading to inaccurate readings or complete failure. Exposure to extreme temperatures and harsh environmental conditions can also accelerate sensor degradation. Rodents chewing on the sensor wires is another common cause of electrical failure. Regular inspection and maintenance can help identify and address these potential issues before they lead to sensor failure. According to a study by the Society of Automotive Engineers (SAE), proper maintenance can extend the lifespan of wheel speed sensors by up to 30%.

10. How Can You Replace a Faulty Wheel Speed Sensor?

Replacing a faulty wheel speed sensor involves removing the old sensor, installing the new sensor, and verifying its functionality. First, safely lift the vehicle and remove the wheel to access the sensor. Disconnect the faulty sensor from its wiring harness. Remove any retaining bolts or clips that secure the sensor to the wheel hub or knuckle. Carefully remove the sensor from its mounting location. If the sensor is stuck, use a penetrating oil to loosen it, avoiding excessive force that could damage the surrounding components. Install the new sensor in the same orientation as the old one. Secure it with the retaining bolts or clips, tightening them to the manufacturer’s specified torque. Reconnect the sensor to the wiring harness. Reinstall the wheel and lower the vehicle. Use an ABS scan tool to clear any stored diagnostic trouble codes (DTCs). Perform a test drive to ensure the new sensor is functioning correctly and the ABS system is operating as expected. Monitor the ABS system with the scan tool during the test drive to confirm that the wheel speed readings are accurate and consistent. Replacing a faulty wheel speed sensor restores proper ABS functionality and ensures vehicle safety.

11. What Safety Precautions Should You Take When Working on ABS Systems?

When working on ABS systems, several safety precautions should be followed to prevent injury and ensure accurate repairs. Always disconnect the vehicle’s battery before starting any electrical work to prevent accidental shorts or electrical shocks. Wear safety glasses to protect your eyes from debris and chemicals. Use jack stands to safely support the vehicle when lifting it, never relying solely on a jack. Avoid using excessive force when removing or installing ABS components, as they can be delicate and easily damaged. Follow the manufacturer’s instructions and torque specifications when tightening bolts and fasteners. Be aware that the ABS system may retain pressure even after the vehicle is turned off, so release any residual pressure before disconnecting hydraulic lines. Work in a well-ventilated area when using cleaning solvents or brake fluids. Properly dispose of used brake fluid and cleaning materials according to local regulations. If you are not comfortable working on ABS systems, seek assistance from a qualified technician. According to the National Safety Council, following proper safety procedures can significantly reduce the risk of injury when working on automotive systems.

12. How Do You Diagnose Intermittent ABS Issues Related to Wheel Speed Sensors?

Diagnosing intermittent ABS issues related to wheel speed sensors can be challenging but involves careful observation and systematic testing. Start by using an ABS scan tool to check for any stored diagnostic trouble codes (DTCs). Intermittent issues may not always trigger a permanent code, so check for any historical or pending codes as well. Monitor live data from the wheel speed sensors while driving, paying close attention to any unusual readings or dropouts. Record the data to review later if the issue does not occur during the initial test drive. Inspect the sensor wiring and connectors for any signs of damage, corrosion, or loose connections. Perform a wiggle test by gently moving the wiring harness while monitoring the sensor readings to see if the issue can be replicated. Check the wheel bearings for excessive play, as this can affect the sensor’s ability to accurately read wheel speed. If the issue persists, consider using an oscilloscope to capture the sensor signal and identify any intermittent signal disruptions. Consulting with experienced technicians or automotive forums can also provide valuable insights and troubleshooting tips.

13. What Role Do Wheel Bearings Play in Wheel Speed Sensor Functionality?

Wheel bearings play a crucial role in wheel speed sensor functionality by ensuring proper alignment and stability of the wheel hub, which directly affects the sensor’s ability to accurately read wheel speed. Worn or damaged wheel bearings can cause excessive play or wobble in the wheel hub, leading to inconsistent sensor readings. This misalignment can create a larger gap between the sensor and the toothed wheel or magnetic encoder ring, reducing the signal strength and accuracy. In severe cases, a failing wheel bearing can damage the wheel speed sensor itself, requiring replacement of both components. According to Timken, a leading manufacturer of bearings, maintaining proper wheel bearing preload and lubrication is essential for optimal ABS performance. Regularly inspecting and replacing worn wheel bearings can prevent ABS issues related to inaccurate wheel speed readings. Ensuring the wheel hub is stable and properly aligned allows the wheel speed sensor to function as intended, providing reliable data to the ABS system.

14. How Can You Prevent Wheel Speed Sensor Problems?

Preventing wheel speed sensor problems involves regular maintenance and careful attention to the vehicle’s braking system. Regularly inspect the wheel speed sensors and their wiring for any signs of damage, corrosion, or wear. Clean the sensors and surrounding areas to remove dirt, brake dust, and other contaminants that can interfere with their performance. Ensure that the sensor wiring is properly secured and protected from abrasion or damage. When performing brake repairs, handle the wheel speed sensors with care to avoid damaging them. Replace worn wheel bearings promptly to prevent excessive play in the wheel hub, which can affect sensor accuracy. Use high-quality brake pads and rotors to minimize brake dust accumulation. Avoid driving through deep water or mud, which can introduce contaminants into the sensor area. Follow the manufacturer’s recommended maintenance schedule for the ABS system. According to a study by J.D. Power, vehicles with well-maintained braking systems have fewer ABS-related issues.

15. What are the Differences Between OEM and Aftermarket Wheel Speed Sensors?

The differences between OEM (Original Equipment Manufacturer) and aftermarket wheel speed sensors lie in their quality, reliability, and compatibility. OEM sensors are manufactured by the vehicle’s original manufacturer or a supplier approved by the manufacturer, ensuring they meet specific performance and quality standards. Aftermarket sensors are produced by third-party companies and may vary in quality and performance. OEM sensors are typically more expensive but offer guaranteed compatibility and reliability. Aftermarket sensors may be more affordable but can sometimes have fitment issues or shorter lifespans. According to Consumer Reports, OEM parts generally outperform aftermarket parts in terms of durability and performance. However, some aftermarket brands offer high-quality sensors that meet or exceed OEM specifications. When choosing between OEM and aftermarket sensors, consider the vehicle’s age, value, and intended use. Research different brands and read customer reviews to make an informed decision.

16. How Does a Lifted Suspension Affect Wheel Speed Sensors?

A lifted suspension can affect wheel speed sensors by altering their position and potentially stretching or damaging the wiring. When a vehicle is lifted, the suspension components are extended, which can put strain on the wheel speed sensor wiring. This can lead to frayed wires, loose connections, or even broken wires. The increased ride height can also expose the sensors to more road debris and environmental contaminants. Additionally, lifting the vehicle can change the angle of the sensor relative to the toothed wheel or magnetic encoder ring, affecting its accuracy. According to a study by the Specialty Equipment Market Association (SEMA), proper installation and maintenance are crucial when modifying a vehicle’s suspension. To mitigate these issues, use longer wheel speed sensor wiring extensions designed for lifted vehicles. Ensure that the wiring is properly routed and secured to prevent abrasion or damage. Regularly inspect the sensors and wiring for any signs of wear or damage.

17. Can a Faulty Wheel Speed Sensor Affect Transmission Performance?

Yes, a faulty wheel speed sensor can affect transmission performance in modern vehicles. The vehicle’s computer uses wheel speed data to manage various functions, including gear shifting, torque converter lockup, and electronic stability control. If a wheel speed sensor is providing inaccurate or inconsistent data, the transmission may experience erratic shifting, delayed engagement, or even go into limp mode. The transmission control module (TCM) relies on accurate wheel speed information to determine the appropriate gear and shift timing. A faulty sensor can disrupt this process, leading to poor transmission performance. According to a technical bulletin from Ford Motor Company, inaccurate wheel speed data can cause the transmission to shift harshly or fail to shift at all. Addressing wheel speed sensor issues promptly is essential for maintaining optimal transmission performance and preventing further damage.

18. How Do You Test Wheel Speed Sensors with an Oscilloscope?

Testing wheel speed sensors with an oscilloscope provides a more detailed analysis of the sensor’s signal than a multimeter can offer. First, connect the oscilloscope to the wheel speed sensor wiring harness. Use back probes to access the signal without damaging the wires. Set the oscilloscope to the appropriate voltage and time scale. A typical voltage range is 0-5V, and a time scale of 10-20 milliseconds per division. With the vehicle safely lifted and secured, manually spin the wheel. Observe the oscilloscope display. A functioning sensor should produce a clean, sinusoidal waveform. Look for any irregularities in the waveform, such as flat spots, dropouts, or excessive noise. Compare the waveform from each sensor to identify any discrepancies. An oscilloscope can detect subtle issues that a multimeter might miss, such as intermittent signal disruptions or weak signals. According to Fluke Corporation, using an oscilloscope can improve diagnostic accuracy by up to 40%. Save the waveforms for future reference and comparison.

19. What is the Cost of Replacing a Wheel Speed Sensor?

The cost of replacing a wheel speed sensor can vary depending on the vehicle’s make and model, the type of sensor, and whether you choose OEM or aftermarket parts. Generally, the cost of a wheel speed sensor ranges from $50 to $200. Labor costs can range from $50 to $150 per sensor, depending on the location and complexity of the repair. On average, the total cost to replace a wheel speed sensor is between $100 and $350. OEM sensors are typically more expensive than aftermarket sensors. Some vehicles may require more time and effort to access the sensor, increasing labor costs. Getting quotes from multiple repair shops can help you find the best price. Performing the replacement yourself can save on labor costs, but it requires the necessary tools and experience. According to RepairPal, the average cost to replace a wheel speed sensor on a Honda Civic is between $120 and $250.

20. Where Can You Find Reliable Wheel Speed Sensors and Diagnostic Tools?

You can find reliable wheel speed sensors and diagnostic tools at CARDIAGTECH.NET. We offer a wide range of high-quality automotive diagnostic tools and equipment, including ABS scan tools, multimeters, and oscilloscopes, ensuring you have the right tools for the job. Our wheel speed sensors are sourced from trusted manufacturers and are designed to meet or exceed OEM specifications, providing reliable performance and durability. At CARDIAGTECH.NET, we are committed to providing top-notch products and exceptional customer service, ensuring you have a seamless experience from purchase to installation.

For personalized assistance and expert advice, contact us via:

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

Let CARDIAGTECH.NET be your trusted partner in automotive diagnostics and repair. We will help you select the best tools and parts to keep your vehicle running smoothly and safely.

Why Choose CARDIAGTECH.NET for Your Automotive Diagnostic Needs?

Extensive Product Range

At CARDIAGTECH.NET, we understand the diverse needs of automotive technicians and DIY enthusiasts. Our extensive product range includes:

- ABS Scan Tools: Diagnose and troubleshoot ABS issues with precision.

- Multimeters: Essential for testing electrical components and circuits.

- Oscilloscopes: Capture and analyze sensor signals for in-depth diagnostics.

- Wheel Speed Sensors: High-quality sensors for accurate and reliable performance.

We offer products from leading brands, ensuring you have access to the best tools and equipment available.

Expert Support and Guidance

Choosing the right diagnostic tools and parts can be overwhelming. Our team of experienced professionals is here to help. We offer:

- Expert Advice: Get personalized recommendations based on your specific needs and budget.

- Technical Support: Receive assistance with product setup, troubleshooting, and usage.

- Training Resources: Access valuable resources to enhance your diagnostic skills.

We are committed to providing exceptional customer service and support, ensuring you have a seamless experience with CARDIAGTECH.NET.

Commitment to Quality and Reliability

At CARDIAGTECH.NET, we prioritize quality and reliability. All our products are rigorously tested to ensure they meet the highest standards. We stand behind our products and offer warranties to provide peace of mind.

- High-Quality Products: Sourced from trusted manufacturers and tested for performance.

- Competitive Prices: Offering the best value for your investment.

- Customer Satisfaction: Committed to exceeding your expectations with every purchase.

The Growing Demand for Automotive Diagnostic Tools

The automotive industry is rapidly evolving, with vehicles becoming increasingly complex. As technology advances, the demand for sophisticated diagnostic tools and equipment is growing. According to a report by Global Market Insights, the automotive diagnostic tools market is expected to reach $45 billion by 2027.

Factors Driving This Growth

- Increasing Vehicle Complexity: Modern vehicles are equipped with advanced electronic systems that require specialized diagnostic tools.

- Stringent Emission Standards: Compliance with emission standards necessitates accurate diagnostics and maintenance.

- Growing Demand for Vehicle Maintenance: As the average age of vehicles on the road increases, so does the need for diagnostic and repair services.

Why This Matters to You

Whether you are a professional technician or a DIY enthusiast, having the right diagnostic tools is essential for keeping your vehicle running smoothly and safely. Investing in high-quality tools can save you time and money in the long run by enabling you to accurately diagnose and address issues before they escalate.

Addressing the Challenges Faced by Automotive Technicians

We recognize the challenges faced by automotive technicians in today’s fast-paced environment. Our goal is to provide solutions that help you overcome these challenges and improve your efficiency and productivity.

Common Challenges

- Keeping Up with Technology: Staying current with the latest automotive technologies and diagnostic techniques.

- Diagnosing Complex Issues: Troubleshooting intricate electronic systems and identifying the root cause of problems.

- Time Constraints: Balancing the need for thorough diagnostics with the pressure to complete repairs quickly.

How CARDIAGTECH.NET Can Help

- Comprehensive Product Selection: We offer a wide range of diagnostic tools and equipment to meet your specific needs.

- Expert Support: Our team of experienced professionals can provide guidance and assistance with product selection and usage.

- Training Resources: We offer access to valuable training materials to help you enhance your diagnostic skills and stay up-to-date with the latest technologies.

The Importance of Staying Informed About Automotive Technology

The automotive industry is constantly evolving, with new technologies and innovations emerging regularly. Staying informed about these advancements is crucial for automotive technicians and DIY enthusiasts alike.

Key Trends in Automotive Technology

- Electric Vehicles (EVs): The growing popularity of EVs is driving the need for specialized diagnostic tools and expertise.

- Advanced Driver-Assistance Systems (ADAS): ADAS features such as adaptive cruise control, lane departure warning, and automatic emergency braking require precise calibration and maintenance.

- Connected Car Technologies: Vehicles are becoming increasingly connected, enabling remote diagnostics and over-the-air software updates.

How CARDIAGTECH.NET Helps You Stay Ahead

- Latest Products: We continuously update our product selection to include the latest diagnostic tools and equipment for emerging technologies.

- Informative Resources: Our website features articles, videos, and other resources to help you stay informed about automotive technology trends.

- Partnerships with Industry Experts: We collaborate with leading experts in the automotive industry to provide valuable insights and training opportunities.

Enhance Your Diagnostic Capabilities with CARDIAGTECH.NET

Whether you are a professional technician or a DIY enthusiast, CARDIAGTECH.NET is your trusted partner for automotive diagnostic tools and equipment. With our extensive product range, expert support, and commitment to quality, we are here to help you enhance your diagnostic capabilities and keep your vehicle running smoothly and safely.

Take the Next Step

- Browse Our Products: Explore our wide selection of diagnostic tools and equipment.

- Contact Us: Get personalized assistance and expert advice from our team.

- Join Our Community: Stay informed about the latest automotive technology trends and diagnostic techniques.

FAQ: Wheel Speed Sensors and ABS

1. What happens if a wheel speed sensor fails?

If a wheel speed sensor fails, the ABS system may not function properly, leading to reduced braking performance and potential loss of control during emergency braking situations. The ABS warning light will typically illuminate on the dashboard.

2. Can I drive with a faulty wheel speed sensor?

While it is possible to drive with a faulty wheel speed sensor, it is not recommended. The ABS system may be disabled, and other related systems such as traction control and stability control may also be affected. Driving with a faulty sensor can increase the risk of accidents.

3. How often should wheel speed sensors be replaced?

Wheel speed sensors do not have a specific replacement interval. They should be replaced when they fail or show signs of degradation. Regular inspection can help identify potential issues early on.

4. Can a dirty wheel speed sensor cause problems?

Yes, a dirty wheel speed sensor can cause inaccurate readings and lead to ABS malfunctions. Cleaning the sensor can often resolve the issue.

5. Are all wheel speed sensors the same?

No, wheel speed sensors can be either passive or active, and they may vary in design and specifications depending on the vehicle’s make and model. It is important to use the correct sensor for your vehicle.

6. Can I replace a wheel speed sensor myself?

Replacing a wheel speed sensor is a relatively straightforward task that can be done by experienced DIYers. However, it requires the proper tools and knowledge of automotive repair procedures. If you are not comfortable performing the replacement yourself, it is best to seek assistance from a qualified technician.

7. How do I know if my wheel speed sensor is bad?

Common symptoms of a bad wheel speed sensor include the ABS warning light illuminating, erratic ABS activation, reduced braking performance, and issues with traction control and stability control systems.

8. Can a wheel alignment affect wheel speed sensors?

While a wheel alignment does not directly affect the wheel speed sensors, it can indirectly impact their performance. Misalignment can cause uneven tire wear, which can affect wheel speed readings.

9. What is the difference between a passive and active wheel speed sensor?

Passive wheel speed sensors generate their own signal using a coil and magnet, while active wheel speed sensors require an external power supply to generate a signal. Active sensors are generally more accurate and reliable.

10. Where are wheel speed sensors located?

Wheel speed sensors are typically located near each wheel hub, mounted on the wheel knuckle or hub assembly. They are positioned to read the speed of a toothed wheel or magnetic encoder ring that rotates with the wheel.

By understanding these aspects of wheel speed sensors, you can ensure your vehicle’s ABS system remains in optimal condition. Remember to consult CARDIAGTECH.NET for all your diagnostic and repair needs, ensuring safety and performance on the road.

Take action now and contact CARDIAGTECH.NET at +1 (641) 206-8880 or visit our website to learn more about our products and services. Let us help you keep your vehicle running smoothly and safely. Our address is 276 Reock St, City of Orange, NJ 07050, United States.