**How to Check Wheel Bearings for Noise and Play? – A Comprehensive Guide**

Are you experiencing unusual noises or vibrations while driving? Wondering if your wheel bearings might be the culprit? At CARDIAGTECH.NET, we understand the importance of a smooth and safe ride. That’s why we’ve created this comprehensive guide to help you diagnose potential wheel bearing issues. Learn how to check for noise and play, understand the symptoms of failing wheel bearings, and discover the best tools and practices for maintaining your vehicle’s performance. Plus, find out how CARDIAGTECH.NET can provide the high-quality tools you need for effective auto repair. Equip yourself with the knowledge and tools for successful wheel bearing diagnosis and maintenance.

1. Understanding Wheel Bearings and Their Importance

What are wheel bearings and why are they crucial for your vehicle’s performance? Wheel bearings are essential components that allow your wheels to rotate smoothly and efficiently. These bearings are designed to reduce friction, support the vehicle’s weight, and ensure stable handling. Proper functioning wheel bearings contribute to a comfortable and safe driving experience. When these bearings fail, they can cause a range of issues, from annoying noises to dangerous driving conditions. According to a study by the National Highway Traffic Safety Administration (NHTSA), faulty wheel bearings can significantly increase the risk of accidents due to compromised vehicle control.

2. Identifying the Symptoms of Failing Wheel Bearings

What are the signs of a bad wheel bearing? Recognizing the symptoms early can prevent more severe damage and costly repairs. Here are some common indicators:

- Unusual Noises: A rumbling, grinding, or whining sound that changes with vehicle speed is a classic sign.

- Vibration: Feeling a vibration in the steering wheel or floorboard can indicate a failing wheel bearing.

- Play in the Wheel: If the wheel feels loose when you try to rock it back and forth, the bearing may be worn.

- Uneven Tire Wear: Premature or uneven tire wear can result from a bad wheel bearing causing misalignment.

- ABS Malfunctions: In some cases, a faulty wheel bearing can trigger the Anti-lock Braking System (ABS) light.

According to automotive experts at the University of Northwestern’s Transportation Center, these symptoms often appear gradually, making regular inspections crucial.

3. How to Check for Wheel Bearing Noise

How can you effectively check for wheel bearing noise? Diagnosing noise issues requires a careful approach. Here’s a step-by-step guide:

- Road Test: Drive the vehicle at varying speeds to identify when the noise is most noticeable. Pay attention to whether the sound changes during turns, which can help pinpoint the affected side.

- Listen Carefully: Try to isolate the noise. Is it a rumble, a grind, or a high-pitched squeal? Note the conditions under which the noise appears.

- Vehicle Speed Sensitivity: Wheel bearing noise typically increases with vehicle speed but remains constant regardless of engine RPM. This helps differentiate it from engine-related sounds.

- Turning Test: Gently swerve the vehicle from side to side. If the noise diminishes or intensifies when turning in a specific direction, it indicates that the bearing on the opposite side may be failing.

- Professional Diagnostic Tools: Consider using tools like automotive stethoscopes, available at CARDIAGTECH.NET, to more accurately pinpoint the source of the noise.

3.1. Using an Automotive Stethoscope for Accurate Diagnosis

How does an automotive stethoscope enhance wheel bearing noise detection? An automotive stethoscope is invaluable for accurately diagnosing wheel bearing noise. By placing the probe on different suspension components while the vehicle is running, you can isolate the source of the sound with greater precision.

- Enhanced Accuracy: Pinpoint noises that are otherwise difficult to detect.

- Ease of Use: Simple to operate, even for novice mechanics.

- Versatility: Useful for diagnosing a variety of mechanical issues beyond wheel bearings.

- Cost-Effective: A relatively inexpensive tool that can save time and money on unnecessary repairs.

According to a study by the American Society of Automotive Engineers (SAE), the use of diagnostic tools like stethoscopes significantly improves the accuracy of identifying mechanical failures.

4. Step-by-Step Guide: Checking for Wheel Bearing Play

How do you check for wheel bearing play, and what tools do you need? Checking for play is essential to assess the bearing’s condition. Here’s how to do it:

- Gather Your Tools:

- Jack

- Jack stands

- Gloves

- Wheel chocks

- Prepare the Vehicle:

- Park the vehicle on a level surface.

- Engage the parking brake and use wheel chocks behind the rear wheels.

- Loosen the lug nuts on the wheel you’re checking.

- Lift the Vehicle:

- Use the jack to lift the vehicle.

- Place jack stands securely under the vehicle’s frame.

- Ensure the vehicle is stable before proceeding.

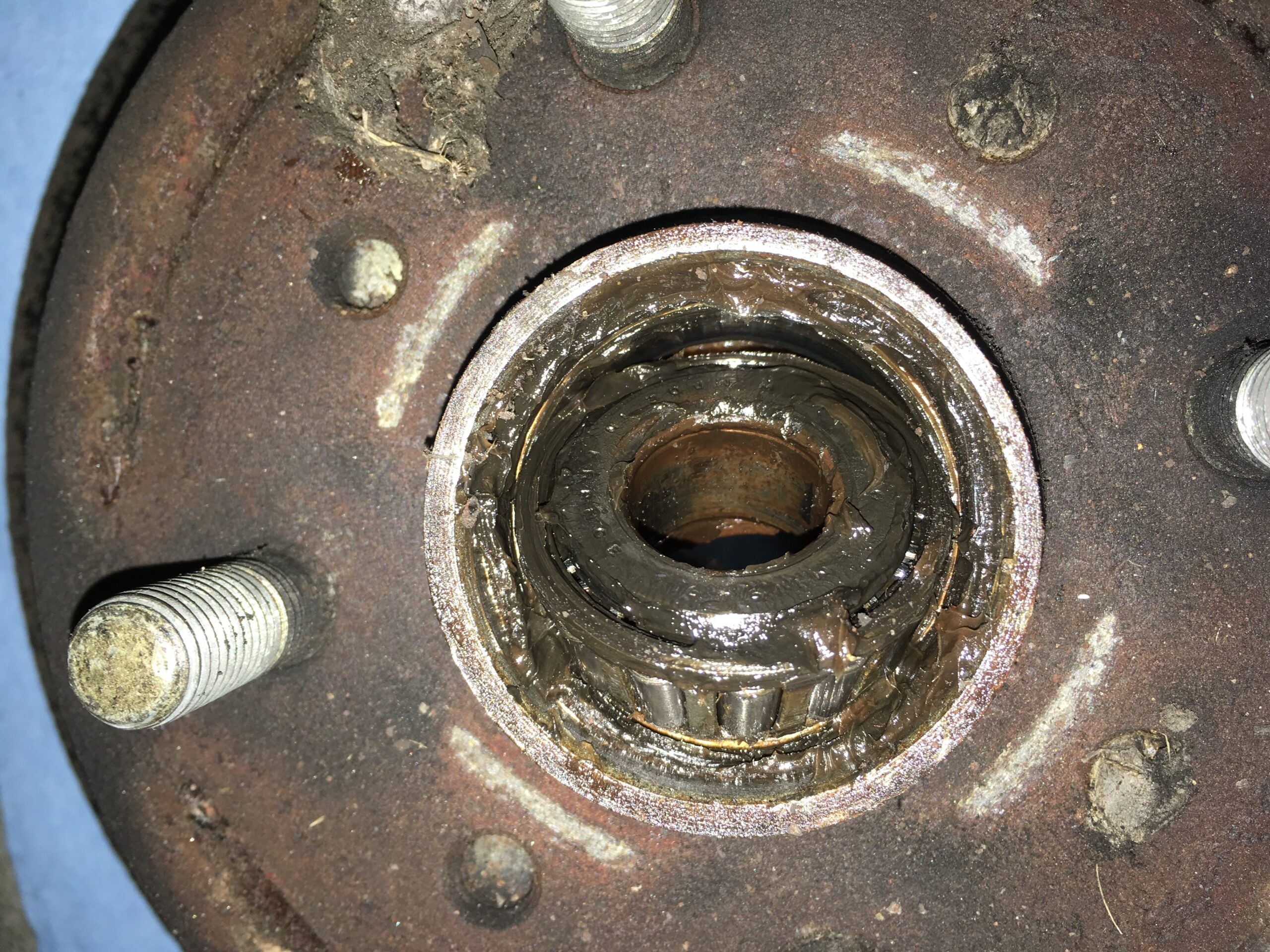

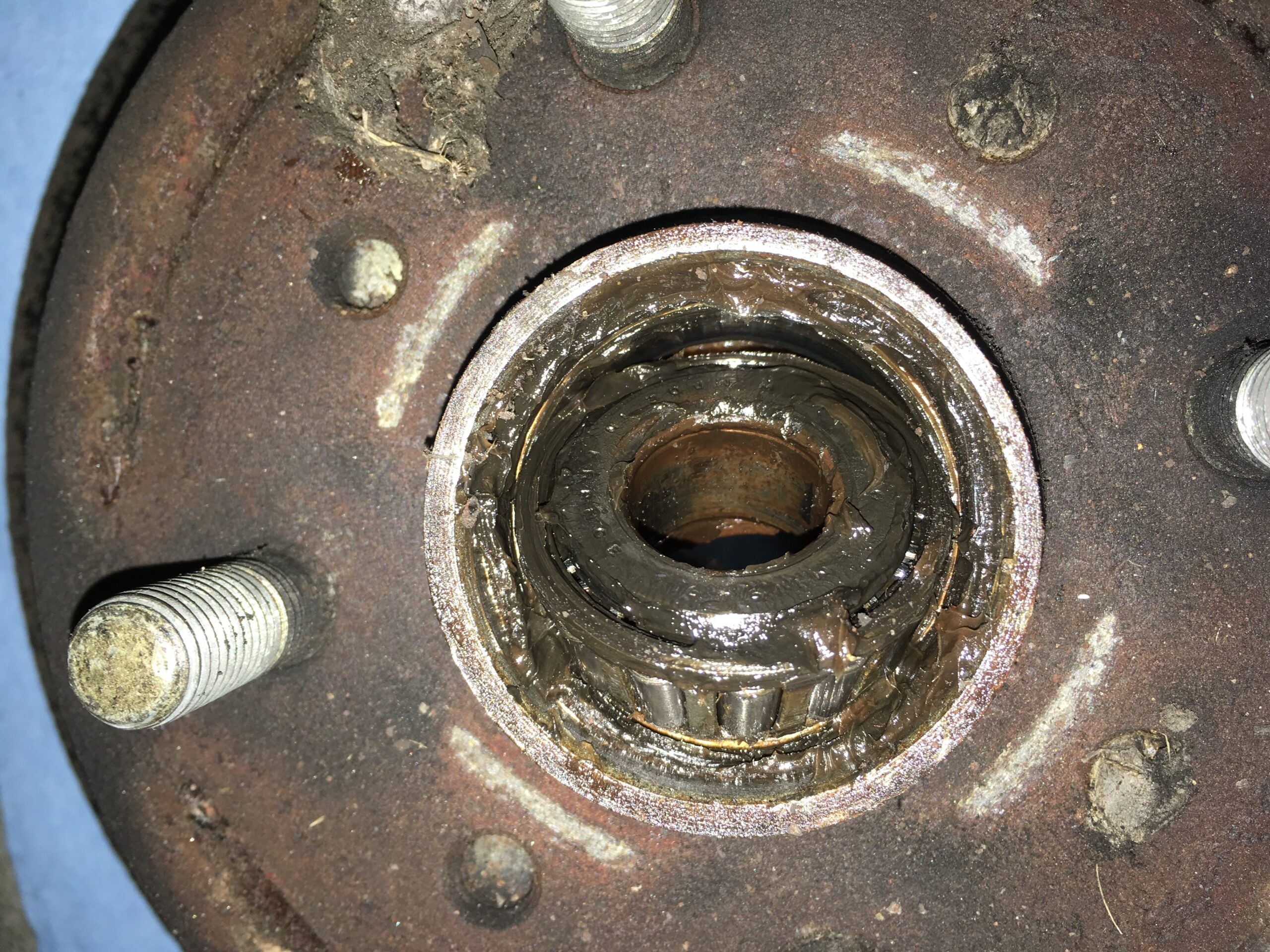

- Check for Play:

- Grip the tire at the 12 o’clock and 6 o’clock positions.

- Try to rock the wheel back and forth.

- Feel for any movement or play.

- Assess the Play:

- If you detect any play, it indicates that the wheel bearing is likely worn and needs replacement.

- Also, check for play by gripping the tire at the 3 o’clock and 9 o’clock positions. However, keep in mind that play in these positions might also be due to steering components.

- Repeat: Repeat the process for each wheel to assess all bearings.

Checking wheel bearing play by rocking the tire at 12 and 6 o'clock

Checking wheel bearing play by rocking the tire at 12 and 6 o'clock

4.1. Interpreting the Results: What Does Play Indicate?

What does the presence of play signify in a wheel bearing? Any noticeable play indicates wear and potential failure. Here’s how to interpret the results:

- Minimal Play (Less Than 0.001 Inches): The bearing is likely in good condition.

- Slight Play (0.001 – 0.005 Inches): The bearing is showing signs of wear but may still be functional. Monitor closely.

- Significant Play (More Than 0.005 Inches): The bearing is worn and should be replaced immediately to prevent further damage and safety risks.

According to the SKF Group, a leading bearing manufacturer, regular checks for play can help mechanics predict bearing lifespan and schedule maintenance proactively.

5. Essential Tools for Wheel Bearing Diagnosis and Repair

What tools are essential for wheel bearing diagnosis and repair, and where can you find them? Having the right tools is crucial for accurate diagnosis and effective repair. CARDIAGTECH.NET offers a range of high-quality tools for wheel bearing maintenance:

- Automotive Stethoscope: For pinpointing noise sources.

- Torque Wrench: To ensure proper tightening of lug nuts and bearing components.

- Bearing Puller Kit: For removing and installing bearings without damaging surrounding parts.

- Slide Hammer: For extracting stubborn bearings.

- Hub Grappler Kit: To safely remove hubs from the vehicle.

- Jack and Jack Stands: Essential for lifting and securing the vehicle.

- Wheel Chocks: For safety during vehicle maintenance.

bearing puller tool

bearing puller tool

5.1. CARDIAGTECH.NET: Your Partner in Quality Auto Repair Tools

Why should you choose CARDIAGTECH.NET for your auto repair tool needs? CARDIAGTECH.NET is committed to providing high-quality, reliable tools for automotive professionals and enthusiasts. Here’s why you should partner with us:

- Wide Selection: A comprehensive range of tools for all your auto repair needs.

- Quality Assurance: Products sourced from trusted manufacturers to ensure durability and performance.

- Expert Support: Knowledgeable staff to assist you in selecting the right tools for your specific needs.

- Competitive Pricing: Affordable prices without compromising on quality.

6. Understanding Different Types of Wheel Bearings

What are the different types of wheel bearings, and how do they affect maintenance? Understanding the different types of wheel bearings can help you tailor your maintenance and diagnostic approach. Here are some common types:

- Ball Bearings: Commonly used in lighter vehicles, ball bearings are designed for low to moderate loads and high speeds.

- Tapered Roller Bearings: Ideal for heavier vehicles and applications requiring high load capacity, tapered roller bearings can handle both radial and axial loads.

- Hub Unit Bearings: These pre-assembled units simplify installation and are commonly found in modern vehicles.

- Sealed Bearings: Designed to keep contaminants out and lubrication in, sealed bearings offer extended service life and reduced maintenance.

According to a technical report by the Timken Company, the choice of wheel bearing type significantly impacts vehicle performance and maintenance requirements.

7. Step-by-Step: Wheel Bearing Replacement

How do you replace a wheel bearing, and what precautions should you take? Replacing a wheel bearing is a complex task that requires precision and care. Here’s a general guide. Always refer to your vehicle’s specific repair manual for detailed instructions and safety precautions:

- Preparation:

- Gather all necessary tools, including a bearing puller kit, torque wrench, and safety glasses.

- Park the vehicle on a level surface, engage the parking brake, and use wheel chocks.

- Loosen the lug nuts on the wheel you’re working on.

- Lift and Secure the Vehicle:

- Use a jack to lift the vehicle and place jack stands securely under the frame.

- Ensure the vehicle is stable before proceeding.

- Remove the Wheel and Brake Components:

- Remove the wheel.

- Carefully disassemble the brake components, including the caliper and rotor.

- Disconnect any ABS sensors or other electrical connections.

- Access the Wheel Bearing:

- Depending on your vehicle’s design, you may need to remove the hub assembly to access the wheel bearing.

- Use a bearing puller kit to separate the hub from the bearing.

- Remove the Old Bearing:

- Use a bearing press or slide hammer to remove the old bearing from the hub or housing.

- Be careful not to damage the surrounding components.

- Install the New Bearing:

- Clean the hub and housing thoroughly.

- Use a bearing press to carefully install the new bearing.

- Ensure the bearing is seated correctly and aligned properly.

- Reassemble Components:

- Reinstall the hub assembly.

- Reattach the brake components, ensuring everything is properly aligned and secured.

- Reconnect any ABS sensors or electrical connections.

- Torque Specifications:

- Use a torque wrench to tighten all bolts and nuts to the manufacturer’s specified torque settings.

- Reinstall the Wheel:

- Reinstall the wheel and tighten the lug nuts in a star pattern.

- Lower the vehicle and remove the jack stands.

- Torque the lug nuts to the correct specification.

- Test Drive:

- Take the vehicle for a test drive to ensure the new bearing is functioning correctly and there are no unusual noises or vibrations.

7.1. Important Safety Precautions During Wheel Bearing Replacement

What safety measures should you take when replacing wheel bearings? Safety should always be a top priority. Here are some crucial precautions:

- Wear Safety Glasses: Protect your eyes from debris and fluids.

- Use Gloves: Protect your hands from sharp edges and chemicals.

- Secure the Vehicle: Always use jack stands to support the vehicle.

- Follow Torque Specifications: Use a torque wrench to ensure proper tightening.

- Disconnect Electrical Components: Prevent damage to electrical systems by disconnecting sensors and wiring.

8. Preventing Wheel Bearing Failure: Maintenance Tips

How can you extend the life of your wheel bearings through proactive maintenance? Regular maintenance can significantly extend the lifespan of your wheel bearings. Here are some tips:

- Regular Inspections: Periodically check for noise and play.

- Proper Lubrication: Ensure bearings are adequately lubricated.

- Avoid Overloading: Do not exceed your vehicle’s load capacity.

- Use Quality Parts: Replace worn bearings with high-quality replacements from trusted suppliers like CARDIAGTECH.NET.

- Proper Installation: Ensure correct installation and torque specifications.

According to a study by the Maintenance Technology Magazine, proactive maintenance programs can reduce wheel bearing failures by up to 50%.

9. Diagnosing Common Wheel Bearing Problems

What are the common problems associated with wheel bearings, and how can you diagnose them? Understanding the root causes of wheel bearing issues can help you diagnose and address them effectively. Here are some common problems:

- Contamination: Dirt, water, and other contaminants can damage bearings.

- Lack of Lubrication: Insufficient lubrication leads to increased friction and wear.

- Overloading: Exceeding the vehicle’s load capacity can stress the bearings.

- Improper Installation: Incorrect installation can cause premature failure.

- Normal Wear and Tear: Over time, bearings naturally wear down due to use.

9.1. Troubleshooting Guide for Wheel Bearing Issues

How can you systematically troubleshoot wheel bearing problems? Use this troubleshooting guide to diagnose common issues:

| Symptom | Possible Cause | Diagnostic Steps | Solution |

|---|---|---|---|

| Rumbling Noise | Worn or damaged bearing | Road test, listen for noise changes, check for play | Replace the bearing |

| Grinding Noise | Contamination or severe damage | Inspect the bearing for contamination, check for play | Replace the bearing, clean surrounding components |

| Vibration | Imbalance or bearing damage | Check for uneven tire wear, check for play | Replace the bearing, balance tires |

| Uneven Tire Wear | Misalignment due to worn bearing | Check for play, inspect suspension components | Replace the bearing, align the wheels |

| ABS Malfunction | Bearing affecting ABS sensor | Check ABS sensor connection, inspect the bearing | Replace the bearing, repair or replace the ABS sensor |

| Steering Wheel Play | Worn bearing or steering component | Check for play, inspect steering linkage | Replace the bearing, repair or replace the steering component |

| Wheel Feels Loose | Excessive bearing play | Check for play at 12 and 6 o’clock positions | Replace the bearing |

10. Advanced Diagnostic Techniques for Wheel Bearings

What advanced techniques can you use for diagnosing wheel bearings? For complex cases, consider these advanced diagnostic methods:

- Vibration Analysis: Use vibration analysis equipment to identify specific bearing frequencies and pinpoint faults.

- Thermal Imaging: Use thermal imaging to detect overheating bearings, indicating excessive friction.

- Lubricant Analysis: Analyze the lubricant for contaminants and wear particles, providing insights into bearing condition.

According to a study by the Vibration Institute, advanced diagnostic techniques can significantly improve the accuracy of predictive maintenance for wheel bearings.

11. The Importance of Using Quality Replacement Parts

Why is it crucial to use high-quality replacement parts when servicing wheel bearings? Using quality replacement parts ensures longevity, reliability, and safety. Here’s why it matters:

- Durability: High-quality bearings are made from superior materials, offering extended service life.

- Performance: Quality bearings provide smoother and more efficient operation.

- Safety: Reliable bearings ensure stable handling and prevent potential accidents.

- Warranty: Trusted brands often offer warranties, providing peace of mind.

CARDIAGTECH.NET partners with reputable manufacturers to offer high-quality replacement parts for your auto repair needs.

12. Case Studies: Real-World Examples of Wheel Bearing Diagnosis and Repair

Can you provide real-world examples of wheel bearing diagnosis and repair? Examining case studies can provide valuable insights into diagnosing and resolving wheel bearing issues.

- Case Study 1: A vehicle exhibited a rumbling noise that increased with speed. Using an automotive stethoscope from CARDIAGTECH.NET, the technician pinpointed the noise to the right front wheel bearing. Upon inspection, significant play was detected, confirming the diagnosis. The bearing was replaced, resolving the noise issue.

- Case Study 2: A vehicle experienced vibration and uneven tire wear. The technician checked for play and found excessive movement in the left rear wheel bearing. After replacing the bearing and aligning the wheels, the vibration and tire wear issues were resolved.

13. Common Mistakes to Avoid When Working with Wheel Bearings

What are some common mistakes to avoid when working with wheel bearings? Avoiding these common mistakes can save time and prevent damage:

- Ignoring Early Symptoms: Addressing issues early prevents more severe damage.

- Improper Installation: Following the correct installation procedures is crucial.

- Using Incorrect Tools: Using the right tools ensures precision and prevents damage.

- Neglecting Torque Specifications: Tightening bolts to the correct torque is essential.

- Failing to Inspect Surrounding Components: Check for wear or damage to related parts.

14. How to Choose the Right Wheel Bearing for Your Vehicle

What factors should you consider when choosing a wheel bearing for your vehicle? Selecting the right wheel bearing is critical for performance and safety. Consider these factors:

- Vehicle Make and Model: Ensure the bearing is compatible with your vehicle.

- Load Capacity: Choose a bearing that meets or exceeds your vehicle’s load requirements.

- Bearing Type: Select the appropriate bearing type for your vehicle’s application.

- Quality and Brand: Opt for reputable brands known for quality and reliability.

CARDIAGTECH.NET offers a wide selection of wheel bearings to meet the needs of various vehicles and applications.

15. Integrating Wheel Bearing Maintenance into Your Regular Vehicle Checkup

How can you incorporate wheel bearing checks into your routine vehicle maintenance? Regular checkups are essential for maintaining vehicle health. Here’s how to include wheel bearing maintenance:

- Visual Inspection: Check for signs of wear or damage during tire rotations.

- Noise Check: Listen for unusual noises while driving.

- Play Check: Periodically check for play in the wheels.

- Lubrication Check: Ensure proper lubrication during servicing.

By integrating these checks into your routine, you can identify and address potential issues before they escalate.

16. The Future of Wheel Bearing Technology and Maintenance

What innovations are on the horizon for wheel bearing technology and maintenance? The future of wheel bearing technology is focused on improving performance, extending service life, and enhancing diagnostic capabilities. Here are some emerging trends:

- Smart Bearings: Integrating sensors to monitor bearing condition in real-time.

- Advanced Materials: Using new materials to improve durability and reduce friction.

- Predictive Maintenance: Leveraging data analytics to predict bearing failures and optimize maintenance schedules.

These advancements promise to make wheel bearing maintenance more efficient and effective.

17. Maximizing the Life of Your Wheel Bearings

What are the key strategies for maximizing the lifespan of your wheel bearings? By following these best practices, you can extend the life of your wheel bearings and ensure a safe and smooth ride:

- Regular Inspections: Check for noise and play.

- Proper Lubrication: Use high-quality lubricants.

- Avoid Overloading: Stay within the vehicle’s load capacity.

- Use Quality Parts: Replace worn bearings with trusted brands.

- Follow Torque Specifications: Ensure correct installation and tightening.

18. How Wheel Alignment Affects Wheel Bearings

How does wheel alignment impact the health and longevity of wheel bearings? Proper wheel alignment is crucial for the health of your wheel bearings. Misalignment can cause uneven load distribution, leading to premature wear and failure. Ensure your vehicle’s wheels are aligned according to manufacturer specifications to maximize bearing life.

19. The Role of Suspension in Wheel Bearing Wear

How does the suspension system contribute to wheel bearing wear? The suspension system plays a vital role in protecting wheel bearings from excessive stress. Worn or damaged suspension components can transmit impacts directly to the bearings, accelerating wear. Regularly inspect and maintain your suspension to ensure optimal bearing performance.

20. Wheel Bearing FAQs

20.1. What causes wheel bearings to fail?

Wheel bearings typically fail due to contamination, lack of lubrication, overloading, improper installation, and normal wear and tear. Regular maintenance and proper care can extend their lifespan.

20.2. How often should wheel bearings be replaced?

Wheel bearings typically last between 75,000 and 150,000 miles. However, this can vary depending on driving conditions and maintenance practices. Regular inspections can help determine when replacement is necessary.

20.3. Can I drive with a bad wheel bearing?

Driving with a bad wheel bearing is not recommended. It can compromise vehicle safety and lead to further damage. Replace worn bearings as soon as possible.

20.4. How much does it cost to replace a wheel bearing?

The cost to replace a wheel bearing can vary depending on the vehicle make and model, as well as labor rates. On average, expect to pay between $150 and $800 per wheel.

20.5. What tools do I need to replace a wheel bearing?

Essential tools include a jack, jack stands, torque wrench, bearing puller kit, slide hammer, and hub grappler kit. CARDIAGTECH.NET offers a wide range of high-quality tools for wheel bearing maintenance.

20.6. Are front and rear wheel bearings the same?

Front and rear wheel bearings can differ depending on the vehicle’s design. Ensure you select the correct bearing type for each location.

20.7. How do I know if my ABS sensor is related to a wheel bearing issue?

If your ABS light comes on and you also notice symptoms of a bad wheel bearing, the two may be related. Inspect the ABS sensor and bearing for damage.

20.8. Can I replace a wheel bearing myself?

Replacing a wheel bearing is a complex task that requires specialized tools and knowledge. If you are not experienced, it is best to have a professional mechanic perform the replacement.

20.9. How important is it to torque wheel bearing components correctly?

Proper torque is critical for ensuring wheel bearing components are securely fastened and function correctly. Always follow the manufacturer’s torque specifications.

20.10. What are the benefits of using sealed wheel bearings?

Sealed wheel bearings offer extended service life and reduced maintenance by keeping contaminants out and lubrication in. They are a reliable choice for modern vehicles.

21. Conclusion: Ensuring a Smooth and Safe Ride with Proper Wheel Bearing Maintenance

Maintaining your vehicle’s wheel bearings is essential for a smooth, safe, and efficient driving experience. Regular inspections, timely replacements, and the use of high-quality tools and parts from CARDIAGTECH.NET can help you avoid costly repairs and potential accidents. Equip yourself with the knowledge and tools you need to keep your vehicle running smoothly.

Are you ready to take the next step in ensuring your vehicle’s optimal performance? Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States, or call us on Whatsapp at +1 (641) 206-8880. Visit our website at CARDIAGTECH.NET to explore our wide range of auto repair tools and get expert advice on maintaining your vehicle. Let us help you keep your ride smooth and safe.