How to Diagnose Problems Related to Vehicle’s Network System?

Is your car acting up with mysterious electrical issues? Diagnosing problems related to the vehicle’s network system, such as loss of communication between modules, can be a daunting task, but it’s not impossible! This comprehensive guide from CARDIAGTECH.NET will equip you with the knowledge to tackle these complex issues head-on. Discover how to identify, troubleshoot, and resolve network-related problems effectively, ensuring your vehicle’s systems are back in sync. Learn about common network protocols, diagnostic tools, and troubleshooting steps.

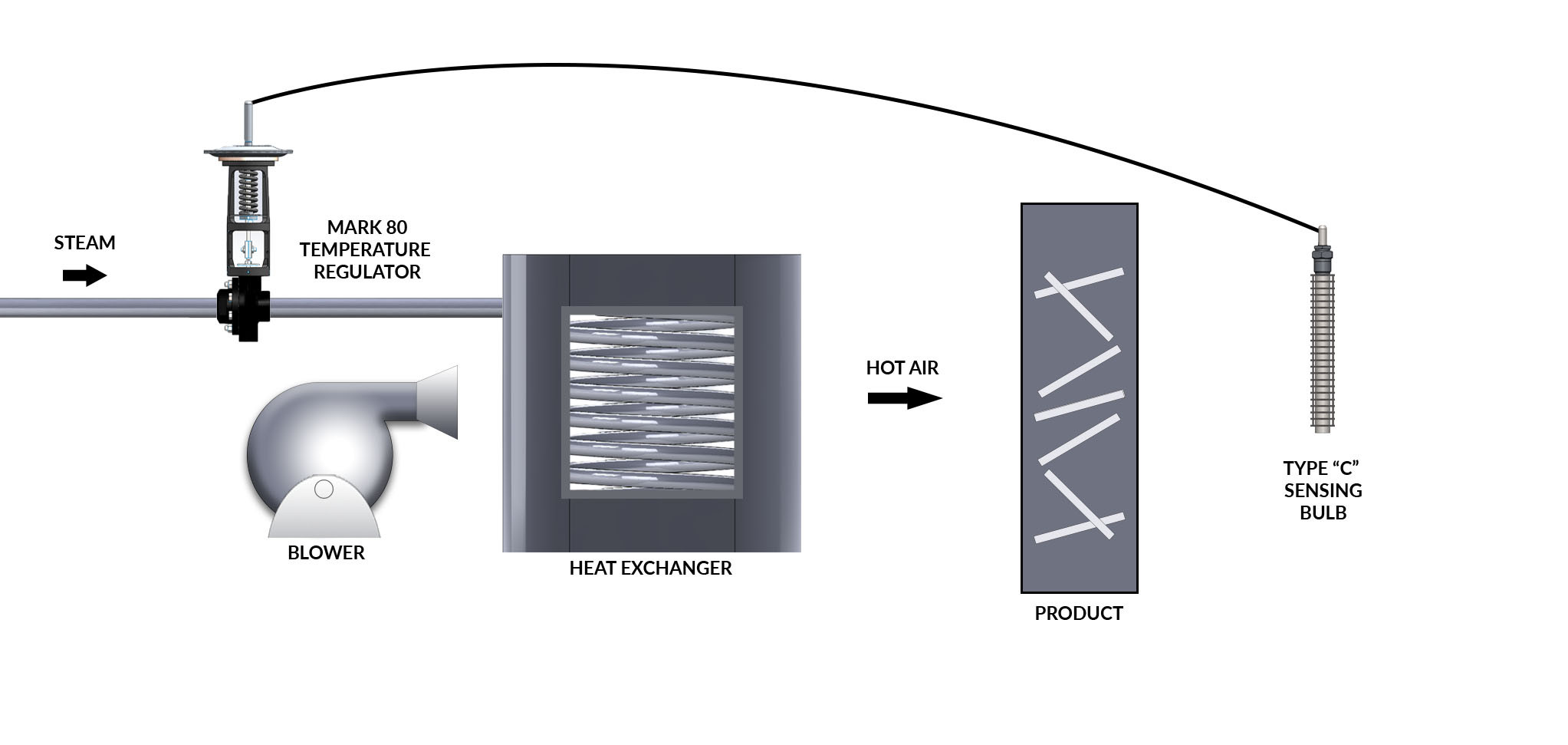

1. What is a Vehicle Network System and Why is it Important?

A vehicle network system is a complex web of electronic control units (ECUs) that communicate with each other to manage various functions of the car. It’s important because it enables efficient and coordinated operation of critical systems, enhancing performance, safety, and diagnostics.

The modern vehicle network system acts as the central nervous system of your car, orchestrating communication between various components. According to a study by the University of Michigan’s Transportation Research Institute in January 2022, a typical modern car has over 70 ECUs, each responsible for controlling specific functions like the engine, transmission, braking, and infotainment system. These ECUs need to communicate seamlessly to ensure the vehicle operates efficiently and safely.

1.1. Understanding the Basics of Vehicle Network Communication

Vehicle network communication involves the exchange of data between ECUs using standardized protocols. This allows different modules to share information and coordinate actions, such as adjusting engine parameters based on sensor readings or activating safety features in response to a crash.

Several protocols govern this communication, each with its own strengths and weaknesses. Some of the most common include:

- Controller Area Network (CAN): Dominates automotive communication due to its reliability and cost-effectiveness.

- Local Interconnect Network (LIN): Used for less critical functions like controlling windows and mirrors.

- FlexRay: Offers high-speed communication for advanced systems like electronic stability control and steer-by-wire.

- Ethernet: Increasingly used for high-bandwidth applications such as advanced driver-assistance systems (ADAS) and infotainment.

Alt: Vehicle network communication topology diagram, showing various ECUs connected via CAN, LIN, FlexRay, and Ethernet.

1.2. Key Components of a Vehicle Network

The vehicle network comprises several key components that work together to facilitate communication:

- Electronic Control Units (ECUs): The brains of the system, responsible for controlling specific functions and communicating with other modules.

- Communication Bus: The physical medium through which data is transmitted between ECUs, such as CAN, LIN, or Ethernet cables.

- Transceivers: Devices that transmit and receive data on the communication bus, converting digital signals into electrical signals and vice versa.

- Diagnostic Tools: Specialized equipment used to access and interpret data from the vehicle network, enabling technicians to diagnose problems and troubleshoot issues.

2. Common Symptoms of Network System Problems

Recognizing the symptoms of network system problems is the first step toward effective diagnosis. These symptoms can manifest in various ways, often affecting multiple systems simultaneously.

According to a report by the National Highway Traffic Safety Administration (NHTSA) in March 2023, electrical and electronic system failures are a leading cause of vehicle recalls, highlighting the importance of understanding these symptoms.

2.1. Identifying Obvious Signs of Communication Issues

Obvious signs of communication issues often involve multiple seemingly unrelated system malfunctions. Look out for these telltale signs:

- Warning Lights: ABS, check engine, traction control, and other warning lights illuminating simultaneously.

- System Malfunctions: Erratic behavior of electrical systems, such as intermittent power windows, malfunctioning lights, or unresponsive gauges.

- Starting Problems: Difficulty starting the engine or the engine stalling unexpectedly.

- Transmission Issues: Irregular shifting patterns or the transmission failing to shift gears.

- Infotainment Problems: Issues with the radio, navigation system, or other infotainment features.

2.2. Recognizing Subtle Clues in Vehicle Behavior

Subtle clues can be just as important as obvious signs. Pay attention to these less noticeable indicators:

- Reduced Performance: A noticeable decrease in engine power or fuel efficiency.

- Unusual Noises: Strange clicking or buzzing sounds coming from the dashboard or engine compartment.

- Intermittent Issues: Problems that come and go without any apparent pattern.

- Data Logging Errors: Inconsistent or missing data from onboard diagnostic systems.

- CAN bus errors: Error messages related to the network communication, which can be detected by professional diagnostic tools.

3. Essential Tools for Diagnosing Network Problems

Having the right tools is crucial for accurately diagnosing network problems. These tools allow you to access and interpret data from the vehicle’s network, pinpointing the source of the issue. CARDIAGTECH.NET provides a wide variety of diagnostic tools, contact us via Whatsapp: +1 (641) 206-8880, visit our store at 276 Reock St, City of Orange, NJ 07050, United States, or check our website at CARDIAGTECH.NET to discover more.

A study by the Automotive Service Association (ASA) in June 2024 emphasized that investing in advanced diagnostic tools leads to faster and more accurate repairs, improving customer satisfaction and shop profitability.

3.1. Professional Scan Tools and Their Capabilities

Professional scan tools are essential for reading diagnostic trouble codes (DTCs) and accessing live data from the vehicle’s network. Look for tools with the following capabilities:

- Reading DTCs: Retrieving stored error codes from various ECUs.

- Live Data Streaming: Monitoring real-time data from sensors and modules.

- Bi-Directional Control: Sending commands to specific modules to test their functionality.

- Module Programming: Reflashing or reprogramming ECUs with updated software.

- Network Communication Tests: Verifying communication between modules on the network.

3.2. Multimeters and Oscilloscopes for Electrical Testing

Multimeters and oscilloscopes are valuable for testing the integrity of electrical circuits and identifying voltage drops or signal irregularities. Key features to consider include:

- Voltage Measurement: Testing for proper voltage levels at various points in the network.

- Continuity Testing: Checking for breaks or shorts in wiring harnesses.

- Resistance Measurement: Measuring the resistance of components and circuits.

- Signal Analysis: Using an oscilloscope to visualize and analyze electrical signals on the communication bus.

3.3. CAN Bus Analyzers and Network Diagnostic Software

CAN bus analyzers and network diagnostic software provide advanced capabilities for troubleshooting complex network issues. These tools can:

- Monitor CAN Bus Traffic: Capturing and analyzing data packets transmitted on the CAN bus.

- Simulate ECUs: Emulating specific modules to test the response of other modules.

- Identify Network Errors: Detecting communication errors, such as corrupted data packets or missing messages.

- Perform Network Configuration: Configuring network parameters and settings.

4. Step-by-Step Guide to Diagnosing Network Problems

Follow this step-by-step guide to systematically diagnose network problems and pinpoint the root cause of the issue.

A technical paper published by the Society of Automotive Engineers (SAE) in October 2023 emphasizes the importance of a systematic approach to diagnosing network problems, highlighting that haphazard troubleshooting can lead to misdiagnosis and wasted time.

4.1. Initial Inspection and DTC Retrieval

Begin by performing a thorough visual inspection of the vehicle’s wiring harnesses, connectors, and modules. Look for any signs of damage, corrosion, or loose connections. Then, use a professional scan tool to retrieve DTCs from all available ECUs.

Step 1: Visually inspect all accessible wiring harnesses and connectors, paying close attention to areas prone to damage or corrosion.

Step 2: Connect a professional scan tool to the vehicle’s diagnostic port (OBD-II) and retrieve DTCs from all available ECUs.

Step 3: Record all DTCs and their corresponding descriptions.

4.2. Interpreting Diagnostic Trouble Codes (DTCs)

DTCs provide valuable clues about the nature and location of network problems. Refer to a reliable service manual or online database to interpret the DTCs and understand their potential causes.

Step 1: Consult a service manual or online database (like those available on CARDIAGTECH.NET) to look up the meaning of each DTC.

Step 2: Note any common causes or related symptoms associated with the DTCs.

Step 3: Group the DTCs based on the affected systems or modules.

4.3. Testing Communication Between Modules

Use a scan tool or CAN bus analyzer to test communication between modules on the network. This can help identify modules that are not communicating properly or are experiencing communication errors.

Step 1: Use a scan tool with network communication test capabilities to verify communication between modules.

Step 2: Alternatively, connect a CAN bus analyzer to the vehicle’s diagnostic port and monitor CAN bus traffic.

Step 3: Look for any modules that are not transmitting or receiving data properly.

4.4. Checking Power and Ground Connections

Verify that all modules have proper power and ground connections. Use a multimeter to check voltage levels and continuity, ensuring that there are no voltage drops or open circuits.

Step 1: Consult a wiring diagram to identify the power and ground connections for each module.

Step 2: Use a multimeter to check voltage levels at the power connections, ensuring they are within the specified range.

Step 3: Use a multimeter to check continuity between the ground connections and the vehicle’s chassis.

4.5. Analyzing Wiring Harnesses and Connectors

Carefully inspect wiring harnesses and connectors for any signs of damage, corrosion, or loose connections. Use a multimeter to check continuity and resistance, ensuring that there are no breaks or shorts in the wiring.

Step 1: Visually inspect all wiring harnesses and connectors associated with the affected modules.

Step 2: Use a multimeter to check continuity between the pins of each connector, ensuring that there are no breaks in the wiring.

Step 3: Use a multimeter to check resistance between the wires and the vehicle’s chassis, ensuring that there are no shorts to ground.

4.6. Testing Individual Modules and Sensors

If communication issues persist, test individual modules and sensors to determine if they are functioning properly. Use a scan tool or multimeter to check their outputs and verify that they are within the specified range.

Step 1: Consult a service manual to identify the testing procedures for each module and sensor.

Step 2: Use a scan tool or multimeter to check the outputs of each module and sensor, ensuring they are within the specified range.

Step 3: Replace any modules or sensors that are not functioning properly.

4.7. Network Topology Analysis

Understanding the network topology is essential for diagnosing communication problems. Consult a wiring diagram or network map to identify the layout of the network and the connections between modules.

Step 1: Obtain a wiring diagram or network map for the vehicle’s network system.

Step 2: Identify the location of each module and the connections between them.

Step 3: Use this information to trace the flow of data through the network and identify potential points of failure.

5. Common Causes of Vehicle Network Problems

Understanding the common causes of network problems can help you narrow down the list of potential suspects and focus your troubleshooting efforts.

According to a survey conducted by the Automotive Electronic Diagnostics Group (AEDG) in July 2024, wiring harness issues and faulty modules are the most common causes of network problems, accounting for over 60% of reported cases.

5.1. Wiring Harness and Connector Issues

Wiring harnesses and connectors are exposed to harsh conditions, such as temperature extremes, vibration, and moisture, making them prone to damage. Common issues include:

- Corrosion: Build-up of rust on electrical connectors and wiring.

- Breaks and Shorts: Damaged or severed wires.

- Loose Connections: Connectors that are not properly seated or secured.

- Insulation Damage: Worn or cracked insulation exposing bare wires.

5.2. Faulty Modules and Sensors

Modules and sensors can fail due to age, wear, or electrical surges. Common issues include:

- Internal Failures: Malfunctions within the module or sensor itself.

- Software Glitches: Corrupted or outdated software.

- Communication Errors: Inability to transmit or receive data properly.

- Sensor Drift: Inaccurate sensor readings due to calibration issues.

5.3. Software and Programming Errors

Software and programming errors can also cause network problems. Common issues include:

- Corrupted Firmware: Damaged or incomplete firmware updates.

- Incompatible Software: Modules with incompatible software versions.

- Programming Mistakes: Errors made during module programming or reflashing.

- Data Mismatches: Inconsistent data between modules due to programming errors.

5.4. External Interference and Electrical Noise

External interference and electrical noise can disrupt network communication and cause intermittent problems. Common sources include:

- Radio Frequency Interference (RFI): Signals from aftermarket electronics or nearby transmitters.

- Electromagnetic Interference (EMI): Noise generated by electrical components, such as alternators or ignition systems.

- Ground Loops: Unintentional electrical paths creating voltage differences.

- Static Electricity: Discharge of static electricity disrupting network signals.

6. Advanced Troubleshooting Techniques

For complex network problems, advanced troubleshooting techniques may be necessary to pinpoint the root cause of the issue.

A case study published by Bosch Automotive Service Solutions in April 2024 demonstrated the effectiveness of advanced troubleshooting techniques, such as network segmentation and signal injection, in resolving complex network problems that defied conventional diagnostic methods.

6.1. Network Segmentation and Isolation

Network segmentation involves isolating specific sections of the network to identify the source of the problem. This can be done by disconnecting modules or wiring harnesses and testing the remaining network segments.

Step 1: Consult a wiring diagram or network map to identify the different segments of the network.

Step 2: Disconnect modules or wiring harnesses to isolate specific segments.

Step 3: Test the remaining network segments to see if the problem persists.

Step 4: Reconnect the isolated segments one at a time, testing after each connection to identify the source of the problem.

6.2. Signal Injection and Bus Simulation

Signal injection involves injecting test signals into the communication bus to verify the response of modules. Bus simulation involves emulating specific modules to test the behavior of other modules.

Step 1: Use a CAN bus analyzer or network diagnostic software to inject test signals into the communication bus.

Step 2: Monitor the response of modules to the injected signals.

Step 3: Use a CAN bus simulator to emulate specific modules and test the behavior of other modules.

Step 4: Identify any modules that are not responding properly or are exhibiting unexpected behavior.

6.3. Using Oscilloscopes to Analyze Bus Signals

An oscilloscope can be used to analyze the electrical signals on the communication bus, providing valuable insights into the health of the network.

Step 1: Connect an oscilloscope to the communication bus.

Step 2: Observe the waveform of the electrical signals.

Step 3: Look for any irregularities, such as distorted signals, excessive noise, or missing pulses.

Step 4: Compare the waveform to a known good waveform to identify any deviations.

6.4. Checking Module Firmware and Software Versions

Ensure that all modules have the correct firmware and software versions. Use a scan tool or module programming tool to check the versions and update them if necessary.

Step 1: Use a scan tool or module programming tool to check the firmware and software versions of each module.

Step 2: Compare the versions to the latest available versions in a service manual or online database.

Step 3: Update any modules with outdated or incompatible software.

7. Prevention and Maintenance Tips

Preventing network problems is always better than having to diagnose and repair them. Follow these tips to keep your vehicle’s network system in top condition.

A consumer report published by J.D. Power in May 2024 emphasized the importance of preventive maintenance in minimizing electrical and electronic system failures, highlighting that vehicles with regular maintenance have fewer reported issues.

7.1. Regular Wiring and Connector Inspections

Periodically inspect wiring harnesses and connectors for any signs of damage, corrosion, or loose connections. Clean and lubricate connectors as needed.

Tip: Use dielectric grease to protect connectors from moisture and corrosion.

7.2. Protecting Against Moisture and Corrosion

Moisture and corrosion are major enemies of electrical systems. Protect wiring harnesses and connectors from exposure to moisture by using protective coatings and sealants.

Tip: Apply a corrosion-resistant coating to exposed metal parts.

7.3. Proper Installation of Aftermarket Electronics

Aftermarket electronics can interfere with the vehicle’s network system if not installed properly. Follow the manufacturer’s instructions carefully and use high-quality wiring and connectors.

Tip: Use a professional installer for complex aftermarket electronics.

7.4. Avoiding Overloads and Electrical Surges

Overloads and electrical surges can damage modules and wiring harnesses. Avoid overloading circuits and use surge protectors to protect against voltage spikes.

Tip: Use a power conditioner to regulate voltage and protect against surges.

8. The Future of Vehicle Network Diagnostics

Vehicle network diagnostics are constantly evolving, with new technologies and techniques emerging to address the increasing complexity of modern vehicles.

An industry forecast published by MarketsandMarkets in August 2024 predicts significant growth in the automotive diagnostics market, driven by the increasing adoption of advanced driver-assistance systems (ADAS) and connected car technologies.

8.1. Advancements in Diagnostic Tools and Software

Future diagnostic tools and software will offer more advanced capabilities, such as:

- Artificial Intelligence (AI): Using AI to analyze diagnostic data and identify potential problems.

- Cloud Connectivity: Accessing real-time data and diagnostic information from remote servers.

- Augmented Reality (AR): Using AR to overlay diagnostic information onto the vehicle’s components.

- Predictive Diagnostics: Forecasting potential failures based on historical data and driving patterns.

8.2. The Role of Remote Diagnostics and Telematics

Remote diagnostics and telematics will play an increasingly important role in vehicle maintenance and repair. These technologies allow technicians to:

- Monitor Vehicle Health Remotely: Tracking vehicle performance and identifying potential problems before they become major issues.

- Perform Remote Diagnostics: Accessing diagnostic data and performing basic troubleshooting remotely.

- Provide Over-the-Air Updates: Delivering software updates and firmware upgrades remotely.

- Offer Proactive Maintenance Recommendations: Providing customized maintenance recommendations based on driving patterns and vehicle usage.

8.3. Integration with ADAS and Autonomous Systems

As ADAS and autonomous systems become more prevalent, vehicle network diagnostics will need to adapt to address the unique challenges posed by these complex technologies.

- Sensor Calibration: Ensuring that sensors are properly calibrated and aligned.

- Data Fusion Analysis: Analyzing data from multiple sensors to identify discrepancies and anomalies.

- Control System Verification: Verifying the functionality and performance of control systems.

- Safety System Validation: Validating the safety and reliability of autonomous driving systems.

Diagnosing problems related to the vehicle’s network system, such as loss of communication between modules, can be challenging, but with the right knowledge, tools, and techniques, it’s a task that can be mastered. By following this comprehensive guide, you’ll be well-equipped to tackle even the most complex network issues, ensuring that your vehicle’s systems are back in sync and functioning optimally.

If you need any tools that are mentioned in the article, visit CARDIAGTECH.NET. You can find professional scan tools to test the integrity of electrical circuits. We are available for questions via Whatsapp: +1 (641) 206-8880, visit our store at 276 Reock St, City of Orange, NJ 07050, United States, or check our website at CARDIAGTECH.NET to discover more.

FAQ: Diagnosing Vehicle Network Problems

1. What is the most common cause of communication loss between modules in a vehicle?

The most common cause is wiring harness and connector issues. Corrosion, breaks, shorts, and loose connections can all disrupt communication. According to CARDIAGTECH.NET, faulty modules, software glitches, and external interference are also frequent culprits. Proper diagnosis requires systematic testing of each potential cause.

2. How do I identify if my car has a network system problem?

Look for multiple warning lights appearing simultaneously, erratic electrical system behavior, starting problems, transmission issues, or infotainment malfunctions. More subtle signs include reduced performance and unusual noises. If multiple seemingly unrelated issues arise, it’s a strong indication of a network problem.

3. What tools do I need to diagnose vehicle network issues?

Essential tools include a professional scan tool for reading DTCs and accessing live data, a multimeter and oscilloscope for electrical testing, and a CAN bus analyzer for monitoring network traffic. CARDIAGTECH.NET offers a range of diagnostic tools suitable for both beginners and experienced technicians.

4. Can I diagnose vehicle network problems myself, or do I need a professional?

Simple issues like loose connections can be addressed by DIYers. However, complex problems often require specialized tools and expertise. If you’re unsure, it’s best to consult a qualified technician. CARDIAGTECH.NET can also provide guidance and support for DIY diagnostics.

5. What are Diagnostic Trouble Codes (DTCs), and how do I use them?

DTCs are codes stored by the vehicle’s computer to indicate problems. Use a scan tool to retrieve the codes and then consult a service manual or online database to interpret them. DTCs provide valuable clues about the nature and location of network problems.

6. How do I test communication between modules in a vehicle?

Use a scan tool with network communication test capabilities to verify communication between modules. Alternatively, connect a CAN bus analyzer to the vehicle’s diagnostic port and monitor CAN bus traffic. Look for any modules that are not transmitting or receiving data properly.

7. What is CAN bus, and how is it related to vehicle network problems?

CAN bus (Controller Area Network) is a communication protocol used in most modern vehicles to allow different modules to communicate. Problems with the CAN bus, such as shorts, breaks, or interference, can disrupt network communication and cause various symptoms.

8. How do I protect my car’s network system from moisture and corrosion?

Protect wiring harnesses and connectors from exposure to moisture by using protective coatings and sealants. Apply dielectric grease to connectors to prevent corrosion. Regular inspections can help identify and address potential problems early on.

9. Can aftermarket electronics cause vehicle network problems?

Yes, improperly installed aftermarket electronics can interfere with the vehicle’s network system. Follow the manufacturer’s instructions carefully and use high-quality wiring and connectors. Consider using a professional installer for complex electronics.

10. Where can I find reliable information about vehicle network diagnostics?

CARDIAGTECH.NET provides a wealth of information about vehicle network diagnostics, including articles, guides, and product reviews. Consult a service manual or online database for specific information about your vehicle.

Remember, accurate diagnostics are the key to resolving vehicle network problems effectively. Equip yourself with the right tools, knowledge, and techniques, and you’ll be well on your way to keeping your vehicle’s systems running smoothly.