How To Diagnose Transmission Problems Based On Symptoms?

Diagnosing transmission problems based on symptoms, such as rough shifting, slipping, and unusual noises, involves a systematic approach to pinpoint the root cause. CARDIAGTECH.NET can equip you with the diagnostic tools needed to accurately assess these issues and provide effective solutions. Addressing these symptoms promptly can prevent further damage and costly repairs. Get ready to enhance your diagnostic capabilities with advanced tools and expert insights.

1. Understanding Transmission Basics

Before diving into diagnosing transmission problems, it’s crucial to understand the basics of how a transmission works. The transmission’s primary job is to transfer power from the engine to the wheels, adjusting the gear ratio to match the driving conditions. According to a study by the University of Michigan’s Transportation Research Institute in 2022, a well-maintained transmission ensures optimal fuel efficiency and vehicle performance. When something goes wrong, it often manifests through noticeable symptoms.

1.1. Types of Transmissions

There are two main types of transmissions: automatic and manual. Each has its own set of common issues.

- Automatic Transmissions: These transmissions automatically shift gears based on the vehicle’s speed and engine load. They use a complex system of hydraulic fluids, valves, and clutches to operate.

- Manual Transmissions: Also known as standard transmissions, these require the driver to manually shift gears using a clutch pedal and gear lever. They are simpler in design but require more driver involvement.

1.2. Key Components

Understanding the key components of a transmission helps in diagnosing problems effectively. Here are some critical parts:

- Torque Converter: In automatic transmissions, the torque converter transfers engine power to the transmission.

- Clutch: In manual transmissions, the clutch disengages the engine from the transmission, allowing for gear changes.

- Gears: Both types of transmissions use gears to provide different speed and torque ratios.

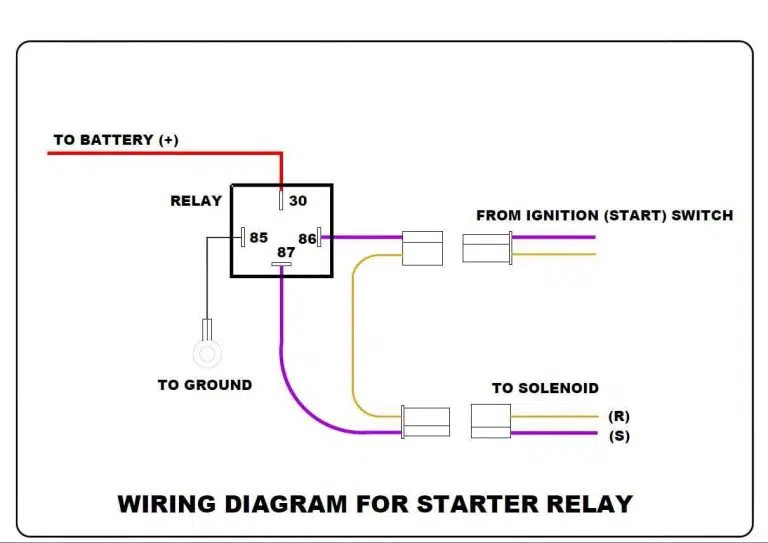

- Solenoids: These electro-hydraulic valves control the flow of fluid in automatic transmissions.

- Transmission Fluid: This fluid lubricates, cools, and provides hydraulic pressure for the transmission’s operation.

2. Identifying Common Transmission Symptoms

Recognizing the symptoms of transmission problems is the first step in diagnosing the issue. Here are some common symptoms:

2.1. Rough Shifting or Jerking

Rough shifting or jerking occurs when the transmission struggles to change gears smoothly. This can feel like a sudden clunk or thud when the vehicle shifts. According to a 2021 study by AAA, rough shifting can lead to increased wear and tear on other vehicle components.

2.1.1. Causes of Rough Shifting

- Low or Poor Condition Transmission Fluid: Lack of adequate lubrication can cause hard shifting.

- Vacuum Troubles: In older vehicles, a faulty vacuum modulator valve can alter the pressure in the transmission, causing rough shifts.

- Faulty Sensors: Malfunctioning sensors can send incorrect data to the transmission, leading to rough shifting.

2.2. Slipping Transmission

Slipping occurs when the transmission shifts erratically or fails to maintain the correct gear. This can result in a sudden increase in RPMs without a corresponding increase in speed. A 2023 report by the National Institute for Automotive Service Excellence (ASE) indicates that transmission slipping often points to internal damage or fluid issues.

Slipping transmission causes

Slipping transmission causes

2.2.1. Causes of Slipping

- Low or Burnt Transmission Fluid: Insufficient or degraded fluid can cause slipping.

- Faulty Clutch: Worn or damaged clutches can prevent proper gear engagement.

- Worn Out Gears or Transmission Bands: These components can wear down over time, leading to slipping.

- Torque Converter Issues: Problems with the torque converter can disrupt the flow of power, causing slipping.

- Failed Solenoid: A malfunctioning solenoid can disrupt fluid flow, leading to slipping.

2.3. Delayed Engagement

Delayed engagement refers to a noticeable pause when shifting from Park to Drive or Reverse. This delay can range from a few seconds to a minute. A study published in the SAE International Journal of Fuels and Lubricants in 2022 emphasizes that delayed engagement is a critical warning sign that requires immediate attention.

2.3.1. Causes of Delayed Engagement

- Low Transmission Fluid: Inadequate fluid levels can cause delays in gear engagement.

- Poor Fluid Maintenance: Old or contaminated fluid can hinder the transmission’s performance.

- Failed Transmission Solenoids: These can cause delays in fluid flow, leading to delayed engagement.

2.4. Unusual Noises

Unusual noises, such as whining, clunking, or humming, can indicate various transmission problems. These noises often change with the vehicle’s speed or gear. Research from the University of California, Berkeley’s Mechanical Engineering Department in 2023 suggests that identifying the type and timing of the noise can greatly assist in pinpointing the problem.

2.4.1. Types of Noises and Their Causes

- Whining: Often indicates low fluid or a worn-out pump.

- Clunking: Can suggest worn gears or damaged U-joints.

- Humming: May point to a failing torque converter or worn bearings.

2.5. Leaking Transmission Fluid

Transmission fluid leaks are a common sign of trouble. The fluid is typically red or brown and has a distinct odor. Leaks can lead to low fluid levels, causing a range of transmission problems. According to a 2021 report by the Car Care Council, addressing leaks promptly can prevent more extensive damage.

2.5.1. Common Leak Locations

- Seals and Gaskets: These can dry out and crack over time, leading to leaks.

- Transmission Pan: Damage to the pan can cause leaks.

- Hoses and Lines: Cracks or loose connections can result in fluid loss.

2.6. Check Engine Light

The check engine light can illuminate for a variety of reasons, including transmission problems. Diagnostic trouble codes (DTCs) stored in the vehicle’s computer can provide valuable information about the issue. A 2022 study by the National Highway Traffic Safety Administration (NHTSA) highlights the importance of using a reliable OBD-II scanner to retrieve these codes.

3. Step-by-Step Diagnostic Process

Diagnosing transmission problems involves a systematic approach to identify the root cause. Here’s a step-by-step process:

3.1. Preliminary Inspection

Begin with a visual inspection of the transmission and surrounding area. Check for any obvious signs of damage or leaks.

3.1.1. Checking Transmission Fluid Level and Condition

- Locate the Dipstick: Usually marked and accessible under the hood.

- Remove and Inspect: Wipe the dipstick clean, reinsert it, and remove it again to check the fluid level.

- Evaluate Fluid Condition: The fluid should be bright red and clear. Dark, burnt-smelling fluid indicates a problem.

3.2. Using an OBD-II Scanner

An OBD-II scanner can retrieve diagnostic trouble codes (DTCs) that provide clues about the transmission issue.

3.2.1. Common Transmission-Related DTCs

- P0700: Transmission Control System Malfunction

- P0715: Input/Turbine Speed Sensor Circuit Malfunction

- P0740: Torque Converter Clutch Circuit Malfunction

- P0750: Shift Solenoid A Malfunction

3.3. Test Driving the Vehicle

A test drive can help you experience the symptoms firsthand and gather more information about the problem.

3.3.1. Identifying Symptoms During the Test Drive

- Note Shifting Patterns: Pay attention to how the transmission shifts between gears.

- Listen for Noises: Identify any unusual sounds that occur during operation.

- Check for Slipping: Observe if the engine RPMs increase without a corresponding increase in speed.

3.4. Manual Transmission Specific Checks

For manual transmissions, additional checks are necessary to diagnose problems.

3.4.1. Clutch Inspection

- Check Clutch Pedal Travel: Ensure the pedal moves smoothly and returns properly.

- Inspect Clutch Linkage: Look for any signs of damage or wear in the linkage.

- Test Clutch Engagement: Check for proper engagement and disengagement of the clutch.

3.4.2. Gearbox Inspection

- Check for Gear Grinding: Listen for grinding noises when shifting gears.

- Inspect Shift Linkage: Look for any play or looseness in the shift linkage.

- Evaluate Gear Selection: Ensure all gears can be selected smoothly.

3.5. Automatic Transmission Specific Checks

Automatic transmissions require different diagnostic steps due to their complexity.

3.5.1. Solenoid Testing

- Use a Multimeter: Check the resistance of the solenoids to ensure they are within the specified range.

- Listen for Clicking: Use a stethoscope to listen for the solenoids clicking when activated.

- Check Wiring: Inspect the wiring and connectors for any damage or corrosion.

3.5.2. Pressure Testing

- Connect a Pressure Gauge: Attach a pressure gauge to the transmission test port.

- Record Pressure Readings: Monitor the pressure readings at different engine speeds and gear positions.

- Compare to Specifications: Compare the readings to the manufacturer’s specifications to identify any issues.

4. Advanced Diagnostic Techniques

For complex transmission problems, advanced diagnostic techniques may be necessary.

4.1. Using a Scan Tool for Live Data

A scan tool can provide live data from the transmission control module (TCM), allowing you to monitor various parameters in real-time.

4.1.1. Monitoring Key Parameters

- Transmission Fluid Temperature: Monitor the temperature to ensure it is within the normal range.

- Input and Output Speeds: Check the speeds to identify any discrepancies.

- Solenoid Activation: Verify that the solenoids are activating correctly.

4.2. Performing a Stall Test

A stall test can help diagnose torque converter problems in automatic transmissions.

4.2.1. Steps for Performing a Stall Test

- Ensure Safety: Perform the test in a safe area with no obstructions.

- Apply Parking Brake: Engage the parking brake firmly.

- Start the Engine: Start the engine and allow it to reach operating temperature.

- Shift to Drive: Shift the transmission into Drive.

- Depress Accelerator: Fully depress the accelerator pedal.

- Note RPMs: Observe the engine RPMs.

- Compare to Specifications: Compare the RPMs to the manufacturer’s specifications.

4.3. Conducting a Hydraulic Pressure Test

A hydraulic pressure test can help identify internal leaks or valve body problems in automatic transmissions.

4.3.1. Interpreting Pressure Test Results

- Low Pressure: Indicates a leak or a faulty pump.

- High Pressure: Suggests a blocked passage or a stuck valve.

- Fluctuating Pressure: May point to a failing pressure regulator.

5. Common Transmission Problems and Solutions

Understanding common transmission problems and their solutions can help you address issues efficiently.

5.1. Low Transmission Fluid

Low transmission fluid is a common problem that can cause a range of symptoms.

5.1.1. Symptoms of Low Fluid

- Slipping

- Rough Shifting

- Delayed Engagement

5.1.2. Solutions

- Check for Leaks: Identify and repair any leaks in the transmission system.

- Add Fluid: Add the appropriate type of transmission fluid to the correct level.

5.2. Contaminated Transmission Fluid

Contaminated fluid can cause internal damage and lead to various transmission problems.

5.2.1. Signs of Contaminated Fluid

- Dark or Burnt-Smelling Fluid

- Sludge or Debris in the Fluid

5.2.2. Solutions

- Flush the Transmission: Remove the old fluid and replace it with new fluid.

- Replace Filter: Install a new transmission filter to remove contaminants.

5.3. Faulty Solenoids

Faulty solenoids can disrupt fluid flow and cause shifting problems in automatic transmissions.

5.3.1. Symptoms of Faulty Solenoids

- Erratic Shifting

- Failure to Shift

- Check Engine Light

5.3.2. Solutions

- Test Solenoids: Use a multimeter to check the resistance of the solenoids.

- Replace Faulty Solenoids: Replace any solenoids that are not functioning correctly.

5.4. Worn Clutches or Bands

Worn clutches or bands can cause slipping and shifting problems in both automatic and manual transmissions.

5.4.1. Symptoms of Worn Clutches or Bands

- Slipping

- Failure to Engage

- Burning Smell

5.4.2. Solutions

- Replace Clutches or Bands: Replace the worn components with new ones.

- Inspect Related Parts: Check for any damage to related parts and replace as necessary.

5.5. Torque Converter Problems

Torque converter problems can cause slipping, stalling, and other performance issues in automatic transmissions.

5.5.1. Symptoms of Torque Converter Problems

- Slipping

- Stalling

- Poor Acceleration

5.5.2. Solutions

- Test Torque Converter: Perform a stall test to evaluate the torque converter’s performance.

- Replace Torque Converter: Replace the torque converter if it is not functioning correctly.

6. Preventive Maintenance Tips

Preventive maintenance can help extend the life of your transmission and avoid costly repairs.

6.1. Regular Fluid Checks and Changes

Regularly checking and changing the transmission fluid is one of the most important maintenance tasks.

6.1.1. Recommended Fluid Change Intervals

- Normal Driving Conditions: Every 30,000 to 60,000 miles.

- Severe Driving Conditions: Every 15,000 to 30,000 miles.

6.2. Inspecting for Leaks

Regularly inspect the transmission for any signs of leaks.

6.2.1. How to Check for Leaks

- Look for Fluid: Check for fluid spots under the vehicle.

- Inspect Seals and Gaskets: Look for any signs of leaks around seals and gaskets.

- Check Hoses and Lines: Inspect the hoses and lines for any cracks or damage.

6.3. Avoiding Harsh Driving Habits

Avoiding harsh driving habits can help reduce wear and tear on the transmission.

6.3.1. Tips for Avoiding Harsh Driving

- Smooth Acceleration: Avoid sudden acceleration.

- Gentle Braking: Avoid hard braking.

- Proper Towing: Follow the manufacturer’s recommendations for towing.

7. Tools and Equipment for Transmission Diagnostics

Having the right tools and equipment is essential for effective transmission diagnostics. CARDIAGTECH.NET offers a range of high-quality tools to assist with your diagnostic needs.

7.1. Essential Diagnostic Tools

- OBD-II Scanner: For retrieving diagnostic trouble codes.

- Multimeter: For testing electrical components.

- Pressure Gauge: For measuring hydraulic pressure.

- Stethoscope: For listening to internal noises.

- Fluid Dipstick: For checking fluid level and condition.

7.2. Advanced Diagnostic Equipment

- Scan Tool with Live Data: For monitoring real-time parameters.

- Hydraulic Test Kit: For performing hydraulic pressure tests.

- Transmission Fluid Tester: For evaluating fluid condition.

8. Case Studies

Examining real-world case studies can provide valuable insights into diagnosing transmission problems.

8.1. Case Study 1: Rough Shifting in a 2015 Toyota Camry

- Symptoms: The vehicle experienced rough shifting between gears.

- Diagnostic Steps:

- Checked transmission fluid level and condition.

- Retrieved DTCs using an OBD-II scanner.

- Performed a test drive to observe shifting patterns.

- Findings: The transmission fluid was low and contaminated. DTC P0700 indicated a transmission control system malfunction.

- Solution: Flushed the transmission, replaced the filter, and added new fluid. The rough shifting issue was resolved.

8.2. Case Study 2: Slipping Transmission in a 2012 Honda Accord

- Symptoms: The vehicle experienced slipping during acceleration.

- Diagnostic Steps:

- Checked transmission fluid level and condition.

- Retrieved DTCs using an OBD-II scanner.

- Performed a stall test.

- Findings: The transmission fluid was at the correct level but smelled burnt. DTC P0740 indicated a torque converter clutch circuit malfunction. The stall test revealed abnormal RPM readings.

- Solution: Replaced the torque converter and flushed the transmission. The slipping issue was resolved.

9. The Role of CARDIAGTECH.NET in Transmission Diagnostics

CARDIAGTECH.NET provides a comprehensive suite of tools and resources to help diagnose and address transmission problems effectively.

9.1. High-Quality Diagnostic Tools

CARDIAGTECH.NET offers a wide range of high-quality diagnostic tools, including OBD-II scanners, multimeters, pressure gauges, and more. These tools are designed to provide accurate and reliable results, helping you pinpoint the root cause of transmission problems quickly and efficiently.

9.2. Expert Support and Training

CARDIAGTECH.NET provides expert support and training to help you get the most out of your diagnostic tools. Our team of experienced technicians can provide guidance on using the tools, interpreting diagnostic data, and implementing effective solutions.

9.3. Comprehensive Resources

CARDIAGTECH.NET offers a comprehensive library of resources, including diagnostic guides, technical articles, and video tutorials. These resources can help you expand your knowledge of transmission systems and improve your diagnostic skills.

10. Conclusion: Mastering Transmission Diagnostics

Diagnosing transmission problems based on symptoms requires a combination of knowledge, skill, and the right tools. By understanding the basics of transmission systems, recognizing common symptoms, and following a systematic diagnostic process, you can effectively identify and address transmission issues.

Remember, regular maintenance and prompt attention to symptoms can help extend the life of your transmission and avoid costly repairs. With the right tools and resources from CARDIAGTECH.NET, you can master transmission diagnostics and keep your vehicle running smoothly.

Don’t let transmission troubles slow you down. Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States, or call us at +1 (641) 206-8880 for expert advice and top-quality diagnostic tools. Visit our website at CARDIAGTECH.NET and experience the difference that professional equipment and support can make. Let us help you keep your transmission in top condition and your vehicle on the road!

FAQ: Diagnosing Transmission Problems

1. What are the most common symptoms of transmission problems?

The most common symptoms include rough shifting, slipping, delayed engagement, unusual noises, leaking fluid, and the check engine light illuminating.

2. How can I check my transmission fluid?

Locate the dipstick, remove it, wipe it clean, reinsert it, and remove it again to check the fluid level and condition. The fluid should be bright red and clear.

3. What does it mean if my transmission fluid is dark or smells burnt?

Dark or burnt-smelling fluid indicates that the fluid is contaminated or overheated, which can cause internal damage.

4. What is an OBD-II scanner and how can it help with transmission diagnostics?

An OBD-II scanner retrieves diagnostic trouble codes (DTCs) from the vehicle’s computer, providing clues about the transmission issue.

5. What is transmission slipping and what causes it?

Slipping occurs when the transmission shifts erratically or fails to maintain the correct gear. It can be caused by low or burnt fluid, faulty clutches, worn gears, or torque converter issues.

6. What is delayed engagement and what causes it?

Delayed engagement is a noticeable pause when shifting from Park to Drive or Reverse, often caused by low fluid, poor fluid maintenance, or failed solenoids.

7. What are some common tools needed for transmission diagnostics?

Essential tools include an OBD-II scanner, multimeter, pressure gauge, stethoscope, and fluid dipstick.

8. How often should I change my transmission fluid?

For normal driving conditions, change the fluid every 30,000 to 60,000 miles. For severe conditions, change it every 15,000 to 30,000 miles.

9. What is a stall test and how is it performed?

A stall test diagnoses torque converter problems by engaging the parking brake, shifting to Drive, fully depressing the accelerator, and comparing the engine RPMs to the manufacturer’s specifications.

10. How can CARDIAGTECH.NET help with transmission diagnostics?

CARDIAGTECH.NET offers high-quality diagnostic tools, expert support, and comprehensive resources to help diagnose and address transmission problems effectively.