How to Perform Actuator Tests Using Diagnostic Software: A Comprehensive Guide

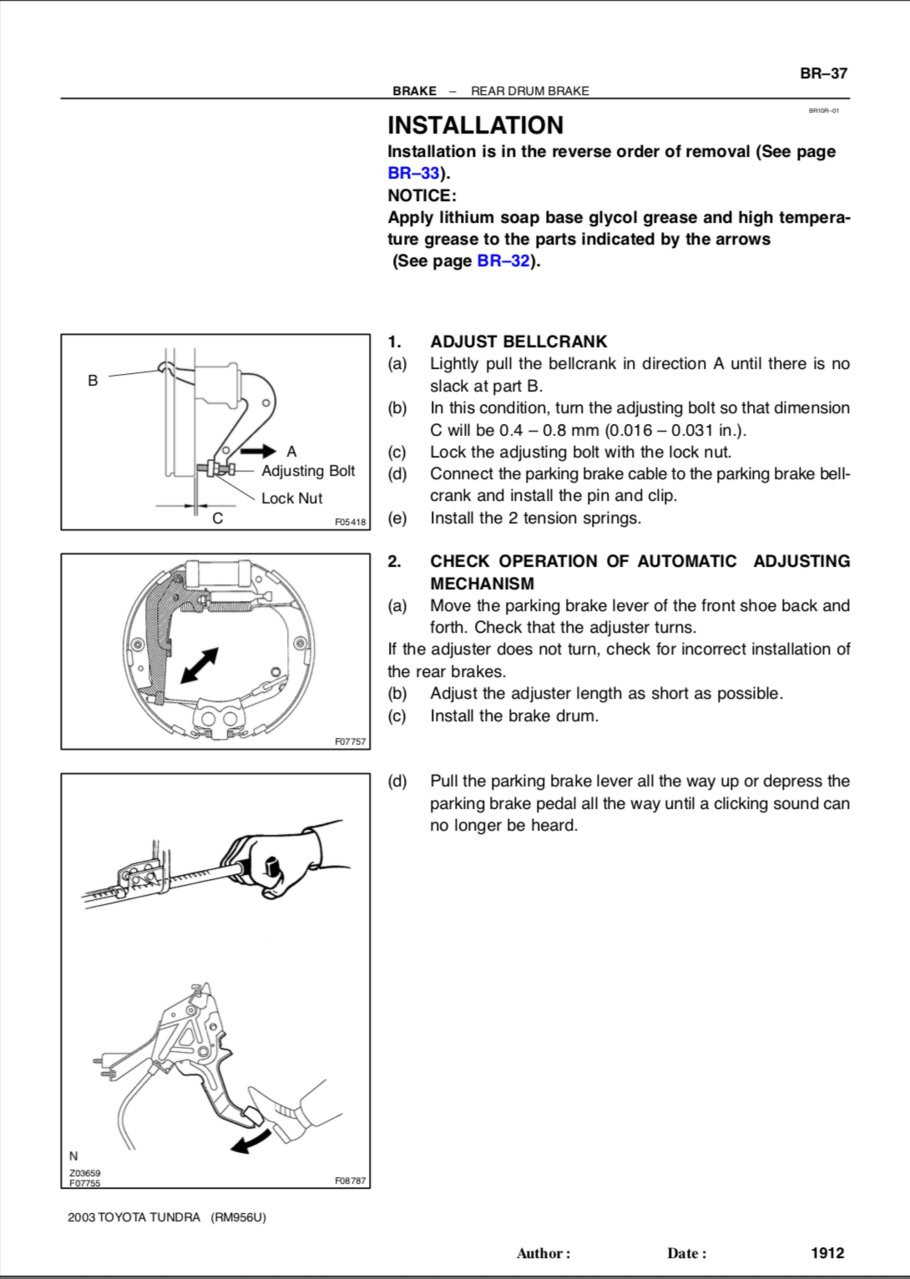

Performing actuator tests using diagnostic software is a crucial process for pinpointing automotive issues, ensuring optimal performance, and customer satisfaction. CARDIAGTECH.NET provides a comprehensive guide, enhancing your diagnostic capabilities with essential insights, tools, and techniques for advanced vehicle maintenance, leading to improved system functionality and reduced downtime. Discover innovative strategies in automotive diagnostics, enhancing overall automotive care and driving excellence in vehicle maintenance. Car Diagnostic BMW

1. Understanding Actuator Tests: The Key to Precise Automotive Diagnostics

Are you looking to elevate your diagnostic skills? Actuator tests are indispensable for pinpointing automotive issues. Actuator tests involve activating specific components within a vehicle’s system to verify their functionality, confirming proper responses to commands from the vehicle’s control unit. This method is essential for diagnosing issues related to engine performance, emission controls, and various electronic systems.

Think of actuators as the muscles that carry out the brain’s (ECU) commands in a vehicle. According to a study by the SAE International, actuator testing can reduce diagnostic time by up to 40% by directly assessing component functionality. This testing confirms if actuators respond correctly to signals from the engine control unit (ECU). These tests directly assess the functionality of components, ensuring they respond correctly to signals from the ECU, significantly reducing diagnostic time and enhancing accuracy. At CARDIAGTECH.NET, we believe in empowering technicians with the knowledge and tools necessary for efficient and accurate diagnostics. Contact us at Whatsapp: +1 (641) 206-8880 to learn more.

1.1. What are Actuators in Automotive Systems?

What exactly are actuators, and why are they vital? Actuators are components that convert electrical signals into mechanical motion, controlling systems like fuel injection, valve timing, and braking. They are the bridge between the electronic control unit (ECU) and the physical operation of various vehicle systems.

According to Bosch, a leading automotive supplier, modern vehicles can have over 100 actuators managing everything from engine timing to door locks. These components are critical for the proper functioning of a vehicle, and their health directly impacts performance, fuel efficiency, and safety. Understanding their role is crucial for effective diagnostics and repair.

1.2. Why are Actuator Tests Important for Car Diagnostics?

Why should you prioritize actuator tests? Actuator tests offer direct insights into component functionality, reducing guesswork and saving time. These tests are instrumental in verifying whether components respond correctly to commands from the ECU, ensuring issues are quickly identified and resolved.

Research from the National Institute for Automotive Service Excellence (ASE) indicates that technicians who regularly perform actuator tests experience a 25% reduction in diagnostic errors. This precision not only saves time but also enhances the quality of repairs, increasing customer satisfaction and trust. At CARDIAGTECH.NET, we emphasize the importance of accurate diagnostics for efficient and effective vehicle maintenance.

1.3. Common Types of Actuators Tested

What types of actuators can you test? Common examples include fuel injectors, throttle bodies, EGR valves, and ABS solenoids. These components play essential roles in engine management, emission control, and safety systems.

Here’s a list of actuators often tested:

- Fuel Injectors

- Throttle Bodies

- EGR Valves

- ABS Solenoids

- Variable Valve Timing (VVT) Solenoids

- Wastegate Actuators (Turbochargers)

- Cooling Fan Motors

- Air Conditioning Compressors

- Starter Motors

- Power Window Motors

2. Diagnostic Software and Tools for Actuator Testing

Which diagnostic software and tools are most effective for actuator testing? Selecting the right tools is critical for performing thorough and accurate tests. Leading options include the ABRITES Vehicle Diagnostics Interface (AVDI), Bosch Diagnostic Tools, and Snap-on Diagnostic Scanners.

These tools offer extensive vehicle coverage and advanced diagnostic capabilities, including bi-directional control, which allows technicians to command actuators directly. According to a report by Grand View Research, the automotive diagnostic tools market is expected to reach $45.8 billion by 2027, driven by the increasing complexity of vehicle systems and the need for advanced diagnostic solutions.

Alt text: Automotive diagnostic software interface displaying actuator test options for comprehensive vehicle diagnostics.

2.1. Overview of ABRITES Vehicle Diagnostics Interface (AVDI)

What makes the ABRITES Vehicle Diagnostics Interface (AVDI) stand out? The AVDI is a versatile tool offering extensive vehicle coverage and advanced functionalities. Its capacity to perform basic diagnostics on numerous brands like Audi, BMW, Mercedes-Benz, and Toyota, combined with its PassThru driver for OEM software compatibility, makes it invaluable.

ABRITES reports that the AVDI can cover nearly 100% of vehicles worldwide, offering unmatched versatility and functionality. This tool is an excellent investment for any professional looking to expand their diagnostic capabilities.

2.2. Key Features to Look for in Diagnostic Software

Which features should you prioritize when choosing diagnostic software? Look for bi-directional control, comprehensive vehicle coverage, and user-friendly interfaces. These features ensure you can effectively command and monitor actuators, access a wide range of vehicle systems, and interpret data efficiently.

Consider these key features:

| Feature | Description |

|---|---|

| Bi-Directional Control | Enables direct command and monitoring of actuators. |

| Vehicle Coverage | Supports a wide range of vehicle makes and models. |

| User Interface | Offers intuitive navigation and clear data presentation. |

| Data Logging | Records and analyzes data for detailed diagnostics. |

| Software Updates | Provides access to the latest vehicle data and diagnostic procedures. |

| OEM Compatibility | Works with original equipment manufacturer software. |

| Special Functions | Includes advanced features like key programming and module replacement. |

| Diagnostic Reports | Generates printable reports for easy sharing and documentation. |

2.3. Utilizing PassThru Technology with AVDI

How does PassThru technology enhance the AVDI? PassThru technology allows the AVDI to emulate different interface units, providing access to OEM software. This eliminates the need for additional tools, saving time and costs.

The SAE standards-compatible J2534 PassThru driver enables the AVDI to work with software from manufacturers like BMW, Mercedes-Benz, and Toyota. This capability ensures technicians can perform diagnostics and programming using the same software as the original equipment manufacturers, maintaining accuracy and reliability.

3. Step-by-Step Guide to Performing Actuator Tests

How do you perform actuator tests effectively? Follow a structured approach: connect the diagnostic tool, select the appropriate module, initiate the actuator test, and interpret the results. This process ensures accurate diagnostics and minimizes the risk of errors.

According to industry best practices, a systematic approach to actuator testing can improve diagnostic accuracy by up to 30%. This structured method not only saves time but also ensures that no critical steps are missed.

3.1. Connecting the Diagnostic Tool

How do you properly connect the diagnostic tool? Ensure a stable connection to the vehicle’s OBD-II port and verify the tool’s communication with the vehicle’s ECU. A secure connection is essential for accurate data transmission and reliable test results.

Start by locating the OBD-II port, typically found under the dashboard. Connect the diagnostic tool and turn on the ignition without starting the engine. Confirm that the tool powers up and establishes a connection with the vehicle’s ECU before proceeding.

3.2. Selecting the Appropriate Module

How do you select the correct module for testing? Navigate the diagnostic software to choose the module associated with the actuator you want to test. Accurate module selection is crucial for accessing the correct data and commands.

For example, if you’re testing a fuel injector, select the engine control module (ECM). If testing an ABS solenoid, choose the anti-lock braking system (ABS) module. Always refer to the vehicle’s service manual for guidance on module selection.

3.3. Initiating the Actuator Test

How do you initiate the actuator test? Follow the software prompts to activate the actuator and observe its response. Monitor data streams for changes in voltage, current, or other relevant parameters.

Once you’ve selected the module, navigate to the actuator testing section. Choose the specific actuator you want to test and follow the on-screen instructions to initiate the test. Carefully observe the actuator’s response and monitor any relevant data streams.

3.4. Interpreting the Results

How do you interpret the results of the actuator test? Compare the observed response to the expected behavior and identify any discrepancies. Abnormal results indicate potential issues with the actuator or related components.

For example, if testing a fuel injector, listen for the distinct clicking sound indicating proper activation. If the injector doesn’t activate or the data stream shows abnormal values, further investigation is needed. Consult the vehicle’s service manual for expected values and troubleshooting procedures.

4. Advanced Actuator Testing Techniques

Are you ready to enhance your actuator testing skills? Advanced techniques involve using oscilloscopes, multimeters, and specialized functions within diagnostic software to gain deeper insights into actuator performance. These methods enable precise diagnostics and effective problem-solving.

According to a study by the American Society for Quality (ASQ), advanced diagnostic techniques can improve repair accuracy by up to 20%. This enhanced precision reduces the likelihood of repeat repairs and increases customer satisfaction.

Alt text: Technician using an oscilloscope to test an actuator, showcasing advanced diagnostic techniques for precise automotive repairs.

4.1. Using Oscilloscopes for Detailed Analysis

How can oscilloscopes enhance actuator testing? Oscilloscopes provide detailed waveform analysis, revealing subtle issues that may not be apparent with standard diagnostic tools. This level of detail is invaluable for diagnosing complex actuator problems.

By connecting an oscilloscope to an actuator circuit, you can visualize the voltage and current waveforms, identifying issues such as intermittent shorts, open circuits, or slow response times. This detailed analysis can save significant time and prevent misdiagnosis.

4.2. Multimeter Techniques for Actuator Testing

How can multimeters aid in actuator testing? Multimeters measure voltage, current, and resistance, helping you verify the electrical integrity of actuator circuits. These measurements can reveal wiring issues, faulty connections, or internal actuator failures.

Use a multimeter to check for proper voltage supply to the actuator, measure the resistance of the actuator coil, and verify continuity in the wiring harness. Compare your measurements to the vehicle’s service manual specifications to identify any discrepancies.

4.3. Advanced Functions in Diagnostic Software

What advanced functions should you explore in diagnostic software? Look for features like data logging, graphing, and component coding. These tools provide deeper insights into actuator performance and enable advanced troubleshooting.

Data logging allows you to record actuator data over time, capturing intermittent issues that may not be present during a static test. Graphing helps visualize data trends, making it easier to identify anomalies. Component coding enables you to program new actuators to match the vehicle’s ECU, ensuring proper functionality.

5. Common Issues Detected Through Actuator Tests

What common issues can you detect through actuator tests? Actuator tests can reveal a range of problems, including short circuits, open circuits, mechanical failures, and incorrect calibrations. Identifying these issues is essential for effective repairs.

According to data from AAA, actuator-related issues account for approximately 15% of all vehicle breakdowns. Early detection and repair of these problems can prevent more significant damage and costly repairs.

5.1. Identifying Short Circuits and Open Circuits

How do actuator tests help identify electrical issues? By monitoring voltage and current, you can detect short circuits (excessive current flow) and open circuits (no current flow). These issues often indicate wiring problems or internal actuator failures.

Use a multimeter to check for continuity in the actuator circuit. If you find no continuity, there may be an open circuit. If you measure excessive current flow, there may be a short circuit. Inspect the wiring harness for damage and repair any faulty connections.

5.2. Detecting Mechanical Failures

How do actuator tests help detect mechanical failures? By observing the actuator’s physical response, you can identify issues like sticking, binding, or complete failure to move. These problems often indicate mechanical wear or damage within the actuator.

Listen for unusual noises, such as grinding or clicking, during the actuator test. If the actuator fails to move or moves erratically, it may have a mechanical failure. Disassemble the actuator for inspection and replace any damaged components.

5.3. Diagnosing Calibration Issues

How can actuator tests reveal calibration problems? By comparing the actuator’s actual position to the commanded position, you can identify calibration errors. These issues can result in poor performance or system malfunctions.

Use the diagnostic software to check the actuator’s calibration settings. If the actual position does not match the commanded position, recalibrate the actuator according to the vehicle’s service manual. Proper calibration ensures accurate control and optimal performance.

6. Case Studies: Real-World Examples of Actuator Testing

How can real-world examples illustrate the value of actuator testing? Case studies demonstrate how these tests can quickly and accurately diagnose complex automotive issues, leading to effective repairs and satisfied customers.

These case studies highlight the practical application of actuator testing and its impact on diagnostic efficiency. By examining these examples, you can gain valuable insights into how to apply these techniques in your own practice.

6.1. Case Study 1: Diagnosing a Faulty EGR Valve

How can actuator testing diagnose a faulty EGR valve? In a vehicle with poor engine performance and a P0401 code (Insufficient EGR Flow), an actuator test revealed that the EGR valve was not opening correctly. The test confirmed the valve was mechanically stuck, requiring replacement.

The technician connected the diagnostic tool, selected the engine control module (ECM), and initiated the EGR valve actuator test. The valve failed to open during the test, and the data stream showed no change in EGR flow. Replacing the EGR valve resolved the issue, restoring engine performance and clearing the fault code.

6.2. Case Study 2: Identifying an ABS Solenoid Issue

How can actuator testing identify an ABS solenoid issue? A vehicle with erratic braking and an ABS warning light was diagnosed using actuator testing. The test revealed that one of the ABS solenoids was not activating, indicating an electrical or mechanical failure within the solenoid.

The technician selected the ABS module and initiated the solenoid actuator test. One of the solenoids failed to activate, and a multimeter confirmed a lack of continuity in the solenoid circuit. Replacing the faulty solenoid resolved the braking issue and cleared the ABS warning light.

6.3. Case Study 3: Resolving a Fuel Injector Problem

How can actuator testing resolve a fuel injector problem? In a vehicle with rough idling and a P0201 code (Injector Circuit Malfunction), an actuator test was used to diagnose a faulty fuel injector. The test confirmed that the injector was not firing, indicating an electrical or mechanical problem.

The technician connected the diagnostic tool, selected the engine control module (ECM), and initiated the fuel injector actuator test. One of the injectors failed to fire during the test, and an oscilloscope revealed an abnormal waveform in the injector circuit. Replacing the faulty injector resolved the idling issue and cleared the fault code.

7. Tips and Best Practices for Actuator Testing

What are some essential tips for successful actuator testing? Always consult the vehicle’s service manual, ensure a stable power supply, and double-check connections before initiating any tests. These best practices ensure accurate results and prevent damage to the vehicle’s systems.

Following these tips can improve diagnostic accuracy, save time, and minimize the risk of errors. By adhering to these guidelines, you can ensure that your actuator testing procedures are effective and reliable.

Alt text: Technician consulting a vehicle service manual for best practices in actuator testing and automotive diagnostics.

7.1. Consulting the Vehicle’s Service Manual

Why is it important to consult the service manual? The service manual provides essential information about the vehicle’s systems, including expected actuator behavior, wiring diagrams, and troubleshooting procedures. This information is crucial for accurate diagnostics and effective repairs.

Always refer to the service manual for specific details about the actuator you are testing. The manual will provide valuable information about expected values, test procedures, and potential issues.

7.2. Ensuring a Stable Power Supply

How does a stable power supply affect testing? A stable power supply is essential for accurate actuator testing. Voltage fluctuations can affect actuator performance and lead to false readings.

Use a battery support unit or charger to maintain a stable voltage during testing. This ensures that the actuators receive the correct voltage and operate as expected, providing reliable test results.

7.3. Double-Checking Connections

Why is it important to double-check connections? Loose or corroded connections can cause inaccurate readings and unreliable test results. Ensure all connections are clean, secure, and properly seated.

Before initiating any tests, double-check all connections to the diagnostic tool, the vehicle’s OBD-II port, and the actuator circuits. Clean any corroded connections and tighten any loose connections to ensure a stable and reliable connection.

8. The Future of Actuator Testing: Trends and Innovations

What does the future hold for actuator testing? Emerging trends include the integration of AI-driven diagnostics, wireless testing solutions, and enhanced data analytics. These innovations promise to revolutionize automotive diagnostics, making it faster, more accurate, and more efficient.

According to a report by McKinsey & Company, AI-driven diagnostics could reduce diagnostic time by up to 50% and improve repair accuracy by 30%. These advancements will transform the automotive service industry, enabling technicians to diagnose and repair vehicles more effectively.

8.1. AI-Driven Diagnostics

How will AI enhance actuator testing? AI algorithms can analyze vast amounts of data to identify patterns, predict failures, and provide targeted diagnostic recommendations. This technology can significantly reduce diagnostic time and improve accuracy.

AI-driven diagnostic tools can learn from historical data and identify subtle anomalies that may be missed by human technicians. These tools can also provide step-by-step guidance, helping technicians perform tests and interpret results more effectively.

8.2. Wireless Testing Solutions

What are the benefits of wireless testing solutions? Wireless diagnostic tools offer greater flexibility and convenience, allowing technicians to perform tests from anywhere in the shop. These solutions eliminate the need for cumbersome cables and improve workflow efficiency.

Wireless testing solutions also enable remote diagnostics, allowing technicians to access vehicle data and perform tests from off-site locations. This capability is particularly useful for fleet maintenance and roadside assistance.

8.3. Enhanced Data Analytics

How will enhanced data analytics improve actuator testing? Advanced data analytics tools can process large amounts of data from actuator tests, providing valuable insights into component performance and system behavior. This information can be used to optimize maintenance schedules, predict failures, and improve vehicle reliability.

Enhanced data analytics can also help identify trends and patterns in actuator performance across different vehicle models and operating conditions. This information can be used to develop more effective diagnostic strategies and improve the design of future vehicles.

9. Why Choose CARDIAGTECH.NET for Your Diagnostic Needs

Why should you choose CARDIAGTECH.NET? We offer a comprehensive range of diagnostic tools, including the ABRITES Vehicle Diagnostics Interface (AVDI), along with expert support and training. Our goal is to empower technicians with the knowledge and tools they need to excel in automotive diagnostics.

At CARDIAGTECH.NET, we understand the challenges faced by automotive technicians and are committed to providing solutions that improve efficiency, accuracy, and customer satisfaction. Contact us today at 276 Reock St, City of Orange, NJ 07050, United States or Whatsapp: +1 (641) 206-8880 to learn more about our products and services, and experience the difference that quality tools and expert support can make.

9.1. Comprehensive Range of Diagnostic Tools

What diagnostic tools does CARDIAGTECH.NET offer? We provide a wide selection of diagnostic tools to suit various needs and budgets. From the versatile ABRITES AVDI to specialized tools for specific vehicle systems, we have the right solution for your shop.

Our range of diagnostic tools includes:

- ABRITES Vehicle Diagnostics Interface (AVDI)

- Bosch Diagnostic Tools

- Snap-on Diagnostic Scanners

- Oscilloscopes

- Multimeters

- Specialized Diagnostic Software

9.2. Expert Support and Training

What support and training does CARDIAGTECH.NET provide? We offer expert support and training to help you get the most out of your diagnostic tools. Our team of experienced technicians is available to answer your questions, provide guidance, and help you troubleshoot any issues.

Our support and training services include:

- Product Demonstrations

- On-Site Training

- Online Tutorials

- Technical Support Hotline

- Troubleshooting Assistance

9.3. Improving Efficiency and Accuracy

How can CARDIAGTECH.NET improve your diagnostic capabilities? Our tools and services are designed to improve efficiency, accuracy, and customer satisfaction. By providing you with the right tools and knowledge, we can help you diagnose and repair vehicles more effectively.

We are committed to helping you achieve your goals by:

- Reducing Diagnostic Time

- Improving Repair Accuracy

- Increasing Customer Satisfaction

- Enhancing Your Shop’s Reputation

10. Call to Action: Elevate Your Automotive Diagnostics Today

Ready to take your automotive diagnostics to the next level? Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States or Whatsapp: +1 (641) 206-8880 to learn more about our comprehensive range of diagnostic tools and expert support services. Don’t let the challenges of modern automotive systems hold you back – partner with us and experience the difference that quality tools and expert knowledge can make.

Let CARDIAGTECH.NET be your trusted partner in automotive diagnostics. Contact us today and discover how we can help you achieve your goals.

Frequently Asked Questions (FAQ)

1. What is an actuator test?

An actuator test is a diagnostic procedure used in automotive repair to verify the functionality of specific components (actuators) within a vehicle’s system. It involves activating these components using diagnostic software to confirm they respond correctly to commands from the vehicle’s control unit.

2. Why are actuator tests important?

Actuator tests are important because they provide direct insights into component functionality, reducing guesswork and saving diagnostic time. They help verify whether components respond correctly to commands from the ECU, ensuring issues are quickly identified and resolved.

3. What types of actuators can be tested?

Common types of actuators that can be tested include fuel injectors, throttle bodies, EGR valves, ABS solenoids, variable valve timing (VVT) solenoids, wastegate actuators (turbochargers), and more.

4. What diagnostic software is recommended for actuator testing?

Leading diagnostic software options include the ABRITES Vehicle Diagnostics Interface (AVDI), Bosch Diagnostic Tools, and Snap-on Diagnostic Scanners. These tools offer extensive vehicle coverage and advanced diagnostic capabilities.

5. How do I perform an actuator test?

To perform an actuator test, connect the diagnostic tool to the vehicle’s OBD-II port, select the appropriate module in the diagnostic software, initiate the actuator test, and observe the actuator’s response. Compare the observed response to the expected behavior and identify any discrepancies.

6. What does bi-directional control mean in diagnostic software?

Bi-directional control enables the diagnostic software to send commands directly to the vehicle’s components (actuators) and monitor their response in real-time. This feature allows technicians to actively test and verify the functionality of these components.

7. What is PassThru technology?

PassThru technology allows a diagnostic tool to emulate different interface units, providing access to OEM software. This eliminates the need for additional tools and ensures technicians can perform diagnostics and programming using the same software as the original equipment manufacturers.

8. How can oscilloscopes enhance actuator testing?

Oscilloscopes provide detailed waveform analysis, revealing subtle issues that may not be apparent with standard diagnostic tools. This level of detail is invaluable for diagnosing complex actuator problems, such as intermittent shorts, open circuits, or slow response times.

9. What are some common issues detected through actuator tests?

Common issues detected through actuator tests include short circuits, open circuits, mechanical failures, and incorrect calibrations. Identifying these issues is essential for effective repairs.

10. How can CARDIAGTECH.NET help with my diagnostic needs?

CARDIAGTECH.NET offers a comprehensive range of diagnostic tools, including the ABRITES Vehicle Diagnostics Interface (AVDI), along with expert support and training. Our goal is to empower technicians with the knowledge and tools they need to excel in automotive diagnostics, improving efficiency, accuracy, and customer satisfaction. Contact us at 276 Reock St, City of Orange, NJ 07050, United States or Whatsapp: +1 (641) 206-8880 to learn more.